Have you ever wondered how to keep your lathe running smoothly? A lathe gearbox oil flush procedure can make a big difference. Just like changing the oil in a car, this process helps remove old oil and dirt. It can even extend the life of your lathe!

Imagine you have a favorite toy that starts making funny noises. You’d want to fix it, right? Your lathe deserves that same care. When you don’t clean out the old oil, it can cause problems. So, why not learn this simple yet important process?

Here’s a fun fact: Regular oil flushes can improve your lathe’s performance. Many users see results right away. Your machinery can run easier and last longer. This article will guide you through the lathe gearbox oil flush procedure step by step. Let’s dive in and discover how to keep your lathe happy!

Lathe Gearbox Oil Flush Procedure: A Step-By-Step Guide

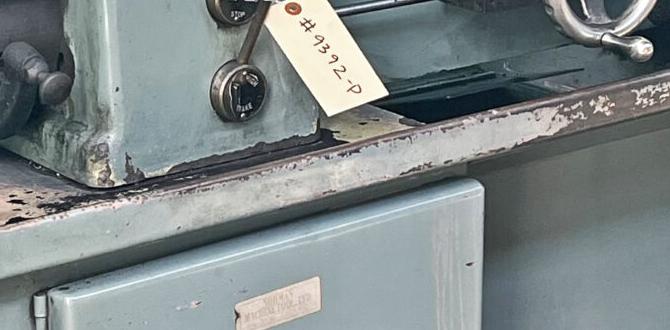

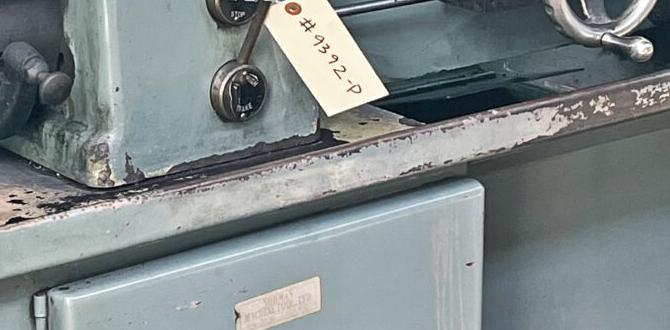

Lathe Gearbox Oil Flush Procedure

Cleaning your lathe’s gearbox with an oil flush is vital for smooth operation. First, drain the old oil completely. Have a container ready to catch the used oil. Then, introduce a flushing oil to clear out dirt and debris. Run the lathe for a few minutes to ensure a thorough clean. Finally, drain the flushing oil and refill with fresh, high-quality gearbox oil. Regular maintenance can extend your lathe’s lifespan significantly. Why not make this part of your routine?Understanding the Importance of Oil Flushing

Explanation of oil flushing benefits for lathe gearboxes. Impact on machine longevity and performance.Flushing oil from lathe gearboxes has many benefits. It helps remove dirt, old oil, and debris. This clean oil improves how the machine runs, making it smoother and more efficient. Regular oil flushing can also help the machine last longer. A well-maintained machine can save money on repairs. Better maintenance means fewer breakdowns. Here are some key benefits:

- Increased Longevity: Clean oil protects parts from wear.

- Better Performance: Fresh oil makes machines run faster.

- Cost Savings: Fewer repairs lead to lower costs.

Why is oil flushing important for lathe gearboxes?

Oil flushing is important because it keeps the machine clean and running well. It prevents problems and helps the machine last longer.

Preparation for the Oil Flush Procedure

Required tools and materials. Safety precautions and best practices.To start the oil flush, gather the right tools and materials. You will need:

- Oil flush kit

- Protective gloves

- Safety goggles

- Rags

- Container for old oil

Safety should always come first. Wear protective gloves and goggles to shield yourself from oil. Work in a well-ventilated area. Keep tools organized to avoid accidents. Remember, a safe workspace means a smooth process.

What should I consider before starting the oil flush?

Make sure to read the machine’s manual first. It gives important info on how to do the procedure safely.

Step-by-Step Lathe Gearbox Oil Flush Procedure

Detailed instructions for draining old oil. Flushing process including cleaning agents or solvents.Begin the oil flush by carefully draining the old oil from the gearbox. Make sure to have a container handy—no one wants a messy floor! Next, use a suitable cleaning agent, like a degreaser or solvent. Pour it into the gearbox and let it sit for a while. This step is like giving your lathe a spa day! Afterward, drain the cleaning agent out completely. Rinse and repeat if necessary. Here’s a simple table to help you remember the steps:

| Step | Action |

|---|---|

| 1 | Drain old oil |

| 2 | Pour in cleaning agent |

| 3 | Let it sit |

| 4 | Drain cleaning agent |

| 5 | Repeat if necessary |

Following these steps will help keep your lathe running smoothly. Remember, a clean lathe is a happy lathe!

Post-Flush Maintenance and Inspection

Importance of visual inspection after oil flush. Recommended followup maintenance actions.After flushing the lathe gearbox oil, checking for issues is vital. A visual inspection can reveal leaks, dirt, or damage. This ensures the machine runs smoothly and safely. Always look closely and take notes on what you see.

Recommended follow-up maintenance actions include:

- Replace any worn parts.

- Clean filters and vents.

- Check oil levels regularly.

- Test the controls for proper function.

These steps help keep the lathe in great shape and extend its life.

Why is visual inspection important?

Visual inspection helps catch problems early before they cause bigger issues.

Additional Maintenance Tips:

- Document findings for future reference.

- Schedule regular check-ups.

Troubleshooting Common Issues During Oil Flush

Identification of potential problems and solutions. Tips for resolving issues without damaging the lathe.Troubleshooting issues during an oil flush can be a bit like finding a sock in a dryer—frustrating! First, look for signs of leaks. If oil is everywhere, that’s a red flag. Check all seals and connections to fix the problem quickly. Next, listen for strange noises, like a cat having a bad day. These noises could mean something isn’t working right. Finally, always follow the manual to avoid mishaps. Just remember, a little patience can save you a lot of headaches!

| Common Issues | Potential Solutions |

|---|---|

| Oil Leaks | Inspect seals and tighten connections |

| Unusual Noises | Check for loose parts or low oil levels |

| Poor Flow | Clean filters and ensure proper pump function |

Frequency of Oil Flushing for Optimal Performance

Recommended intervals for oil flush based on usage. Signs indicating the need for an oil flush sooner than usual.Oil flushing keeps your lathe gearbox happy and humming. It’s like giving it a nice bath! Generally, it’s best to flush the oil every 6 to 12 months. However, if you use your machine heavily, consider flushing more often. Watch for signs like strange noises or oil that looks like a muddy puddle. These indicate it’s time for a flush sooner rather than later, like when your favorite snack runs out!

| Usage Level | Recommended Flush Interval |

|---|---|

| Light Use | 12 months |

| Moderate Use | 9 months |

| Heavy Use | 6 months |

Conclusion

In conclusion, flushing your lathe gearbox oil is vital for smooth operation. It removes dirt and old oil, helping your machine last longer. Make sure to follow each step carefully. Always use the right oil afterward. We encourage you to check your manufacturer’s guidelines and consider doing this regularly. Taking care of your tools keeps them working well for you!FAQs

What Are The Signs That Indicate It’S Time To Flush The Oil In A Lathe Gearbox?You should flush the oil in a lathe gearbox if you notice a change in color. If the oil looks dark or dirty, it’s time to clean it out. Also, if you hear strange noises while using the lathe, the oil might be old and ineffective. Finally, if you find metal shavings in the oil, it’s a sign you need to replace it.

What Type Of Oil Is Recommended For Lathe Gearbox Lubrication After The Flush Procedure?After flushing the lathe gearbox, you should use a high-quality gear oil. Look for oil that meets the gear manufacturer’s recommendation. It’s usually an oil labeled as 68 or 100 weight. This oil keeps the gears running smoothly and prevents wear. Always check your machine’s manual for specific suggestions!

What Specific Steps Should Be Followed In The Lathe Gearbox Oil Flush Procedure?To flush the lathe gearbox oil, first, turn off and unplug the machine for safety. Next, find the drain plug and open it to let old oil out. After that, add a special cleaning oil to rinse out dirt. Run the machine for a few minutes so the cleaning oil can work. Finally, drain the cleaning oil and refill with fresh gear oil.

How Do You Properly Dispose Of The Old Oil And Contaminants After Flushing The Lathe Gearbox?To dispose of old oil and stuff safely, first, let it cool down. Then, put the used oil in a sealed container. You can take it to a recycling center that accepts oil. Never pour it down the drain or in the trash. It can harm the environment.

Are There Any Specific Safety Precautions To Take Before Performing An Oil Flush On A Lathe Gearbox?Yes, there are safety precautions to take. First, turn off the lathe and unplug it so it can’t start. Then, wear safety glasses to protect your eyes from any oil splashes. Always use gloves to keep your hands safe and clean. Make sure the area is well-ventilated so you can breathe easily.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Signs That Indicate It’S Time To Flush The Oil In A Lathe Gearbox? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should flush the oil in a lathe gearbox if you notice a change in color. If the oil looks dark or dirty, it’s time to clean it out. Also, if you hear strange noises while using the lathe, the oil might be old and ineffective. Finally, if you find metal shavings in the oil, it’s a sign you need to replace it.”}},{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Lathe Gearbox Lubrication After The Flush Procedure? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “After flushing the lathe gearbox, you should use a high-quality gear oil. Look for oil that meets the gear manufacturer’s recommendation. It’s usually an oil labeled as 68 or 100 weight. This oil keeps the gears running smoothly and prevents wear. Always check your machine’s manual for specific suggestions!”}},{“@type”: “Question”,”name”: “What Specific Steps Should Be Followed In The Lathe Gearbox Oil Flush Procedure? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To flush the lathe gearbox oil, first, turn off and unplug the machine for safety. Next, find the drain plug and open it to let old oil out. After that, add a special cleaning oil to rinse out dirt. Run the machine for a few minutes so the cleaning oil can work. Finally, drain the cleaning oil and refill with fresh gear oil.”}},{“@type”: “Question”,”name”: “How Do You Properly Dispose Of The Old Oil And Contaminants After Flushing The Lathe Gearbox? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To dispose of old oil and stuff safely, first, let it cool down. Then, put the used oil in a sealed container. You can take it to a recycling center that accepts oil. Never pour it down the drain or in the trash. It can harm the environment.”}},{“@type”: “Question”,”name”: “Are There Any Specific Safety Precautions To Take Before Performing An Oil Flush On A Lathe Gearbox? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are safety precautions to take. First, turn off the lathe and unplug it so it can’t start. Then, wear safety glasses to protect your eyes from any oil splashes. Always use gloves to keep your hands safe and clean. Make sure the area is well-ventilated so you can breathe easily.”}}]}