Have you ever wondered how a lathe works? It’s a powerful tool that shapes metal and wood. But just like any machine, it can wear out over time. One of the key parts that can show wear is the gib. Yes, that’s right—the lathe gibs can wear down and affect how your machine operates.

What are these gibs? They’re the parts that help keep everything tight and aligned. When they start to wear, you might notice some signs. These signs can tell you whether your lathe needs some attention. For example, have you noticed any unusual vibrations or inconsistency in your work? These might be signs of gib wear.

It’s surprising how easy it is to miss these signs. Regular checks can save you time and money. After all, a small issue can become a big problem if ignored. So, let’s dive into the signs of lathe gibs wear and learn how to spot them before they become serious!

Lathe Gibs Wear Signs: Identifying Crucial Indicators

Lathe Gibs Wear Signs

Recognizing wear signs on lathe gibs is important for smooth machine operation. Look for play in the carriage or uneven cuts in material. These issues may arise when gibs are loose or worn out. A simple test involves moving the carriage; if it shifts too easily, gibs may need adjustment. Regular checks can prevent costly repairs. Did you know that small signs of wear may lead to bigger problems if ignored? Keeping an eye on these details ensures accurate machining!What are Lathe Gibs?

Definition and function of lathe gibs in machining.. Importance of gibs in maintaining tool stability and precision..In the world of machining, lathe gibs play a critical role. They are special parts that help hold the sliding pieces of a lathe together. Think of them as glue for moving pieces, ensuring everything stays put while you work. Without gibs, tools might become wobbly like a jelly on a plate! This stability is key for making precise cuts. If the gibs wear out, it can lead to messy work, so keeping them in check is essential.

| Function | Importance |

|---|---|

| Hold moving parts | Ensure tool stability |

| Guide smooth movement | Maintain precision |

Common Signs of Gibs Wear

Detailed examination of physical indicators of wear on gibs.. Impact of wear on the performance of the lathe..Gibs wear happens over time, and it can cause some trouble for your lathe. Watch for **looseness**; if the gibs feel wobbly or don’t hold objects tight, that’s a red flag. Another sign is **uneven cuts**. If your lathe suddenly starts to act like it’s tired, that’s not just fatigue—it might be gibs wear. Keep an eye out for **vibrations** during operation; it’s not a dance party, just a cry for help!

| Wear Sign | What It Means |

|---|---|

| Looseness | Gibs aren’t gripping well |

| Uneven Cuts | Performance is slipping |

| Vibrations | Your lathe is unhappy |

These signs can lead to poor performance, making your tools crankier than a cat in a bathtub! Regular checks can help keep everything spinning smoothly.

Causes of Gibs Wear

Common factors contributing to gib wear, including material fatigue and improper maintenance.. Influence of environmental conditions on gib longevity..Gibs can wear out for many reasons. One big factor is material fatigue. As machines work hard, parts can get tired—kind of like you after gym class! Improper maintenance is another culprit. If gibs aren’t regularly checked, they may wear down faster than a favorite pair of sneakers. Environmental conditions also play a role. Dust and moisture can sneak in and speed things up. Here’s a quick look at the common causes:

| Cause | Description |

|---|---|

| Material Fatigue | Parts wear out from heavy use. |

| Improper Maintenance | Skipping checks makes wear happen faster. |

| Environmental Conditions | Dust and moisture speed up wear. |

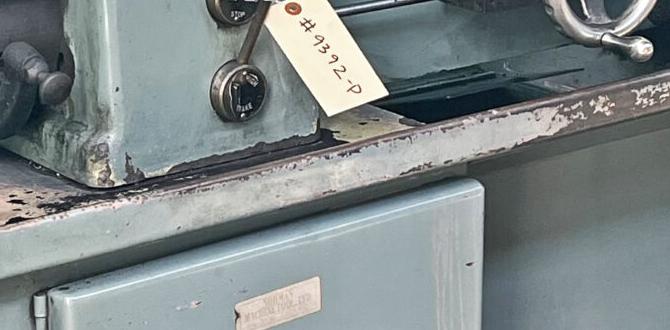

How to Identify Wear Signs

Techniques for visually inspecting lathe gibs for wear.. Tools and methods for measuring gib wear accurately..Looking for wear signs on lathe gibs? Start by using your eyes! Check for uneven surfaces or any shiny spots where parts meet. These shiny areas can reveal wear from frequent use. To be precise, grab a dial indicator—it’s a handy tool that measures small distances accurately. If you don’t have one, feel free to use a feeler gauge, which is basically like a doctor checking if you need a check-up. Regular check-ups keep your lathe happy and running smoothly!

| Wear Indicator | Inspection Method |

|---|---|

| Shiny Spots | Visual Inspection |

| Uneven Edges | Feel with Fingertips |

| Excess Slop | Dial Indicator Measurement |

Preventive Measures to Reduce Gib Wear

Maintenance practices to extend the life of lathe gibs.. Recommended lubrication techniques and intervals..Keeping your lathe gibs in tip-top shape doesn’t have to be boring! Regular maintenance is key. Clean them often to prevent grime buildup. Use a suitable lubricant that fits the task—grease is great for general use, while oil works wonders for lighter loads. Stick to a routine, like oiling them every month, to keep things running smoothly. Not sure how much to apply? The table below can help!

| Lubrication Type | Recommended Interval | Notes |

|---|---|---|

| Grease | Every 1-2 months | Use for heavy loads |

| Oil | Every month | A great option for lighter tasks |

Think of it like giving your lathe a spa day! Who wouldn’t want that?

Repairing and Replacing Gibs

Guidelines for repairing worn gibs vs. when to replace them.. Stepbystep process for replacing gib assemblies safely..Worn gibs can cause serious machine problems. You may choose to repair or replace them. If the damage is minor, repairing is an option. Look for scratches, deep wear, or loose parts. If these signs are clear, it’s best to replace them. Here’s how:

- Turn off the machine and unplug it.

- Carefully remove old gibs.

- Clean the area and check for other issues.

- Install new gibs and secure them tightly.

- Test the machine to ensure everything works smoothly.

This process helps keep your lathe running well. Always follow safety steps!

How do I know when to replace gibs?

Check for worn or damaged surfaces. If they have noticeable scratches or wear, it’s time to replace them. You want your equipment to run safely.

Impact of Gib Wear on Machining Operations

Analysis of how gib wear affects machining accuracy and surface finish.. Case studies illustrating the consequences of neglecting gib maintenance..Gib wear can really mess with your machining game! When those little gibs wear down, they cause inaccuracies in cuts and ruin the surface finish. Imagine trying to slice a cake but the knife keeps wobbling—messy, right? Studies show that neglecting gib maintenance can lead to lost production. There’s a famous case of a factory that faced a 20% drop in quality due to worn gibs. Don’t let that happen to you!

| Consequence of Gib Wear | Impact on Machining |

|---|---|

| Poor Accuracy | Increased scrap rates, frustrated workers |

| Bad Surface Finish | More time spent on finishing work |

| Increased Downtime | Loss of production, lower profits |

Remember, keeping an eye on your gibs is crucial. Regular checks can save you a lot of headaches!

Best Practices for Machining with Worn Gibs

Tips to mitigate the effects of gibs wear on machining processes.. Adjustments to operational techniques that can accommodate minor wear..To manage work with worn gibs, make small changes to your technique. This helps keep your machine running well. Here are some tips:

- Check and tighten gibs regularly.

- Use lighter cuts to reduce stress.

- Apply lubricant to minimize friction.

- Adjust speeds to prevent damage.

- Monitor parts for any unusual noises.

By following these simple steps, you can help your machining processes work better even with wear.

How to deal with worn gibs in machining?

Making minor adjustments and keeping a close eye on machine conditions will help. Always ensure your equipment gets the care it needs!

Conclusion

In summary, checking for wear signs in lathe gibs is crucial for smooth operation. Look for gaps, rough surfaces, and unusual sounds. These signs can affect your machine’s performance. If you see these issues, consider adjusting or replacing the gibs. For more tips, explore guides on lathe maintenance. Stay informed, and keep your lathe running well!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Gibs Wear Signs:Sure! Here are five simple questions about lathe gibs wear signs: 1. What are lathe gibs? Lathe gibs are parts that help keep the machine steady. They hold things in place. 2. How can we tell if gibs are worn? Worn gibs can cause the machine to shake. You might see loose parts or hear strange noises. 3. What should you do if you find worn gibs? If you find worn gibs, you should report it. It’s important to fix them so the lathe works well. 4. Can worn gibs make it hard to cut materials? Yes, worn gibs can make cutting harder. The machine may not stay still, affecting the cuts. 5. How often should we check the gibs? You should check the gibs regularly. This helps keep the lathe running smoothly and safely.

Sure! Please provide the question you would like me to answer.

What Are The Common Visual Indicators Of Wear On Lathe Gibs That Operators Should Look For?You should look for scratches or grooves on the lathe gibs. These can show that they are worn down. Also, check for uneven surfaces; they should be smooth. If you see rust or dirt buildup, that’s a sign they need cleaning. Lastly, check if the gibs move freely; they shouldn’t feel stuck or stiff.

How Can The Performance Of A Lathe Be Affected By Worn Gibs, And What Symptoms Might Be Observed?Worn gibs can make the lathe move less smoothly. You might notice that the machine shakes or makes weird noises. When you try to cut, the tool may dig in too much or not enough. This can create uneven shapes or rough surfaces on your work. Fixing or replacing gibs helps the lathe work better again.

What Maintenance Practices Can Be Implemented To Minimize Wear On Lathe Gibs And Extend Their Lifespan?To keep lathe gibs in good shape, we should clean them often to remove dirt and chips. Use a light oil or grease to keep them moving smoothly. Check for any loose screws and tighten them if needed. Lastly, avoid forcing the machine to work too hard; this helps prevent damage.

How Do You Accurately Measure The Wear On Lathe Gibs To Determine If They Need Adjustment Or Replacement?To measure the wear on lathe gibs, you can use a feeler gauge. This tool helps you check gaps between the gibs and the carriage. Place it in the gap and see if it fits. If it fits too easily or there are big gaps, you might need to adjust or replace the gibs. Regular checks will help keep your lathe working well.

What Is The Difference Between Regular Gib Adjustment And Repairing Or Replacing Worn Gibs In A Lathe?Regular gib adjustment means you make small changes to keep things tight and smooth. It’s like tightening the screws on your toys. Repairing or replacing worn gibs is when parts are really damaged, and you need new ones. This is more work and helps the machine work better. We do regular adjustments often, but we only replace parts when they are too worn out.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Gibs Wear Signs:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five simple questions about lathe gibs wear signs: 1. What are lathe gibs? Lathe gibs are parts that help keep the machine steady. They hold things in place. 2. How can we tell if gibs are worn? Worn gibs can cause the machine to shake. You might see loose parts or hear strange noises. 3. What should you do if you find worn gibs? If you find worn gibs, you should report it. It’s important to fix them so the lathe works well. 4. Can worn gibs make it hard to cut materials? Yes, worn gibs can make cutting harder. The machine may not stay still, affecting the cuts. 5. How often should we check the gibs? You should check the gibs regularly. This helps keep the lathe running smoothly and safely.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Common Visual Indicators Of Wear On Lathe Gibs That Operators Should Look For?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should look for scratches or grooves on the lathe gibs. These can show that they are worn down. Also, check for uneven surfaces; they should be smooth. If you see rust or dirt buildup, that’s a sign they need cleaning. Lastly, check if the gibs move freely; they shouldn’t feel stuck or stiff.”}},{“@type”: “Question”,”name”: “How Can The Performance Of A Lathe Be Affected By Worn Gibs, And What Symptoms Might Be Observed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Worn gibs can make the lathe move less smoothly. You might notice that the machine shakes or makes weird noises. When you try to cut, the tool may dig in too much or not enough. This can create uneven shapes or rough surfaces on your work. Fixing or replacing gibs helps the lathe work better again.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Can Be Implemented To Minimize Wear On Lathe Gibs And Extend Their Lifespan?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep lathe gibs in good shape, we should clean them often to remove dirt and chips. Use a light oil or grease to keep them moving smoothly. Check for any loose screws and tighten them if needed. Lastly, avoid forcing the machine to work too hard; this helps prevent damage.”}},{“@type”: “Question”,”name”: “How Do You Accurately Measure The Wear On Lathe Gibs To Determine If They Need Adjustment Or Replacement?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To measure the wear on lathe gibs, you can use a feeler gauge. This tool helps you check gaps between the gibs and the carriage. Place it in the gap and see if it fits. If it fits too easily or there are big gaps, you might need to adjust or replace the gibs. Regular checks will help keep your lathe working well.”}},{“@type”: “Question”,”name”: “What Is The Difference Between Regular Gib Adjustment And Repairing Or Replacing Worn Gibs In A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Regular gib adjustment means you make small changes to keep things tight and smooth. It’s like tightening the screws on your toys. Repairing or replacing worn gibs is when parts are really damaged, and you need new ones. This is more work and helps the machine work better. We do regular adjustments often, but we only replace parts when they are too worn out.”}}]}