Have you ever noticed how a worn lathe handwheel can make your work feel tougher? It’s amazing how small things can impact your projects. A lathe handwheel that doesn’t work well can slow you down and ruin your momentum. What if I told you that regrinding your handwheel could make a huge difference?

Many people don’t think about this simple fix. They often assume it’s too hard or that they need to buy a new one. But regrinding your lathe handwheel is easier than you think! This simple process can save you time and money. Plus, it can extend the life of your tool.

In this article, we will share some valuable tips on lathe handwheel regrinding. Whether you are a beginner or an expert, these tips can help you get the best results. Are you ready to learn how to improve your lathe experience? Let’s dive in!

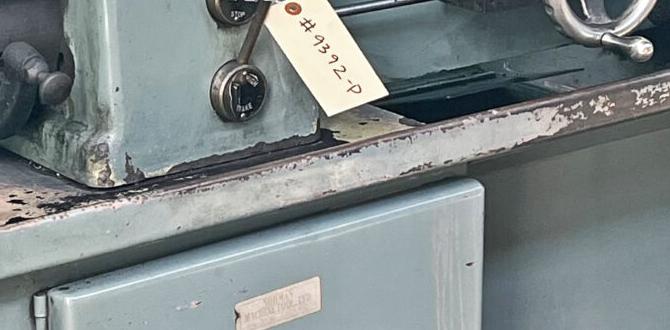

Essential Lathe Handwheel Regrinding Tips For Precision When It Comes To Maintaining The Performance And Accuracy Of Your Lathe, Regrinding The Handwheel Is An Often-Overlooked Yet Crucial Task. A Well-Reground Handwheel Can Enhance The Overall Functionality Of Your Lathe, Ensuring Smoother Operations And Improved Precision. In This Article, We Will Delve Into The Essential Tips For Lathe Handwheel Regrinding That Every Machinist Should Keep In Mind. Understanding Lathe Handwheel Functionality The Lathe Handwheel Serves As A Vital Component, Providing The Means To Control The Movement Of The Cutting Tool. An Accurately Functioning Handwheel Allows For Precise Adjustments, Making It Essential For Achieving The Desired Results In Your Machining Projects. Over Time, Wear And Tear Can Affect Its Efficacy, Necessitating Regrinding. Tools You Will Need Before Starting The Regrinding Process, Ensure You Have The Following Tools At Hand: 1. **Lathe Tool Bits**: For Performing The Actual Regrinding. 2. **Measuring Instruments**: Such As Calipers And Micrometers For Precision Measurement. 3. **Conical Tools**: Useful In Achieving The Required Angles During The Regrinding Process. 4. **Bench Grinder**: For Reshaping And Smoothing The Edges. Step-By-Step Regrinding Process 1. **Assessment**: Begin By Assessing The Condition Of The Lathe Handwheel. Look For Any Signs Of Wear, Chips, Or Irregularities That Need Addressing. 2. **Setup**: Secure The Handwheel In A Stable Position. This Will Ensure Safety And Precision During The Grinding Process. 3. **Angle Adjustment**: Adjust Your Tools To The Correct Angles Required For Regrinding. This Is Vital For Maintaining The Handwheel’S Effective Functioning. 4. **Begin Grinding**: Start With A Coarse Grit To Remove Any Significant Imperfections. Gradually Transition To Finer Grits To Smooth Out The Surface. 5. **Measure Regularly**: Consistently Measure The Handwheel Dimensions Throughout The Process To Avoid Over-Grinding, Which Could Lead To Functional Issues. 6. **Final Polish**: Once The Desired Shape And Dimensions Are Achieved, Give The Handwheel A Final Polish To Ensure A Smooth Finish. Tips For Successful Regrinding – **Consistency Is Key**: Maintain A Consistent Hand Pressure While Grinding To Avoid Uneven Surfaces. – **Cool Down**: Regularly Pause To Allow The Handwheel To Cool Down, As Excessive Heat May Lead To Warping Or Damage. – **Use Appropriate Grit**: Start With A More Abrasive Grit Before Moving To Finer Ones; This Will Help In Achieving The Best Results. Conclusion Regrinding Your Lathe Handwheel Is An Essential Maintenance Task That Can Significantly Improve The Performance And Lifespan Of Your Lathe. By Following These Lathe Handwheel Regrinding Tips, You Can Ensure Precision And Efficiency In Your Machining Operations. Always Prioritize Safety And Accuracy To Achieve The Best Results For Your Projects.

Lathe Handwheel Regrinding Tips

Regrinding a lathe handwheel can improve its performance and lifespan. Start by cleaning the handwheel to remove grit and debris. Choose the right abrasive material for the job. Did you know that a diamond wheel can offer a smoother finish compared to regular ones? Don’t forget to check for any cracks before you begin. Proper adjustments can make your lathe operate more smoothly and accurately. Give your handwheel some care and watch your projects flourish!Understanding Lathe Handwheel Functionality

Explanation of the handwheel’s role in lathe operation.. Importance of maintaining the handwheel for precision work..The handwheel in a lathe is like a steering wheel for a car. It controls the movement of the tool, helping you shape materials accurately. Without it, you’d be lost in a sea of shavings! Maintaining the handwheel is crucial, as a smooth operation ensures precision work. Remember, a well-kept handwheel can help you avoid unexpected surprises, like a tool that goes rogue. So, give it some love and keep it in top condition!

| Tip | Importance |

|---|---|

| Regular Cleaning | Keeps movement smooth |

| Check for Damage | Avoids mishaps |

| Lubrication | Enhances precision |

Common Issues with Lathe Handwheels

Identification of typical problems affecting handwheel performance.. Impacts of wear and tear on lathe operations..Handwheels can encounter a few hiccups during use. Common problems include wobbling, stiffness, or grinding noises. These issues often stem from wear and tear over time. A worn handwheel can make even the best lathe feel like a stubborn mule. If the wheel isn’t moving smoothly, it can lead to sloppy cuts and frustrating mistakes. Here’s a quick table to spot these pesky problems:

| Issue | Possible Impact |

|---|---|

| Wobbling | Uneven cuts |

| Stiffness | Increased effort |

| Grinding noises | Potential damage |

Addressing these issues early can save you time and headaches. And hey, nobody wants a handwheel that acts like it’s auditioning for a horror movie!

Step-by-Step Regrinding Process

Detailed instructions on how to prepare the handwheel for regrinding.. Techniques for effective grinding and achieving a smooth finish..First, gather your tools. You need a lathe, safety goggles, and the handwheel. Check the handwheel for any chips or damage. Clean it up so it shines like a new penny. Next, attach it securely to the lathe. Applying gentle pressure while grinding helps achieve a smooth finish. Remember: too much pressure can create uneven spots. For a helpful reference, see the table below:

| Step | Action |

|---|---|

| 1 | Gather tools and safety gear. |

| 2 | Inspect and clean the handwheel. |

| 3 | Secure it to the lathe. |

| 4 | Begin grinding with gentle pressure. |

Don’t forget to check your progress often! A smooth handwheel is a happy handwheel, and that’s no joke!

Post-Regrinding Adjustments and Checks

Necessary adjustments to ensure proper alignment after regrinding.. Tips for testing the handwheel functionality postregrinding..After regrinding, it’s important to check that everything lines up right. This ensures your lathe handwheel works well again. Start by adjusting the handwheel’s position. Make small changes and test the fit. You want a smooth movement.

Here are tips for testing the handwheel:

- Turn it slowly to check for any sticking points.

- Listen carefully for any strange sounds while turning.

- Ensure no wobbling occurs during use.

These steps will help keep your lathe running smoothly.

How do I know if my handwheel is working properly?

To check if your handwheel is working, you should look for smooth movement and no unusual noises. It’s important that it doesn’t wobble while spinning.

Maintenance Tips for Longevity

Best practices for regularly maintaining handwheels to extend life.. Signs to watch for that indicate the need for regrinding or replacement..Taking care of handwheels can help them last longer. Regular checks are key to keeping everything in good shape. Look out for these signs:

- Worn edges that feel rough or jagged.

- Difficulty turning the handwheel smoothly.

- Loose fittings that cause wobbling.

If you see these signs, it might be time for regrinding or replacement. A little maintenance can save you time and money!

What are the best practices for maintaining handwheels?

To keep handwheels in top shape:

- Clean them regularly to remove dust and debris.

- Lubricate moving parts so they work smoothly.

- Inspect for damage at least once a month.

Frequently Asked Questions

Common queries related to lathe handwheel regrinding.. Expert answers to assist users in their regrinding efforts..Many users have questions about lathe handwheel regrinding. Here are some answers that can help you out.

| Question | Answer |

|---|---|

| How often should I regrind my handwheel? | Every few months is a good rule, especially if you see wear and tear. |

| Can I do this myself? | Yes! With the right tools, it’s a fun DIY project! |

| What tools do I need? | A good lathe, grit wheel, and some elbow grease! |

Regrinding is like giving your handwheel a spa day. Keep it happy and it will serve you well!

Conclusion

In conclusion, regrinding your lathe handwheel can improve its performance. Always check for errors and use the right tools. Take your time for better results. Clean the wheel after grinding to keep it in good shape. If you want to learn more, check out guides or videos online. Start practicing these tips, and you’ll see great improvements!FAQs

What Materials Are Best Suited For Lathe Handwheel Regrinding To Ensure Durability And Precision?For lathe handwheel regrinding, we should use hard materials like steel or cast iron. These materials are strong and last a long time. They can handle a lot of use without breaking. Using the right materials helps keep everything working smoothly and accurately.

How Can You Assess Whether A Lathe Handwheel Needs To Be Reground Or Replaced?To check if a lathe handwheel needs regrinding or replacing, you should look for signs of wear. Feel for any rough spots or bumps on the wheel. If it shakes or wobbles when you turn it, that’s not good. You can also measure how deep any grooves or damage are. If it’s too deep, you should replace it.

What Are The Safety Precautions To Consider When Regrinding A Lathe Handwheel?When regrinding a lathe handwheel, wear protective goggles to shield your eyes. Use gloves to keep your hands safe. Make sure the lathe is turned off and unplugged before you start. Keep your hair tied back and loose clothing away from moving parts. Always follow instructions carefully to avoid accidents.

What Common Techniques Or Tools Can Be Used For Achieving A Smooth Finish During The Regrinding Process?To get a smooth finish when regrinding, you can use a few simple tools. First, use sandpaper to smooth out rough spots. You can also use grinding wheels to make surfaces even. For the best results, try polishing compounds, which add shine. Lastly, take your time and go slowly for a better finish!

How Can The Proper Alignment Of The Lathe Affect The Handwheel Regrinding Process?When the lathe is properly aligned, it helps the handwheel turn smoothly. If it’s out of line, the handwheel can wobble or grind unevenly. This means we might not get a nice, flat surface when we regrind it. A straight lathe leads to better results, making our job easier and more accurate. This way, we can make the handwheel work well again!