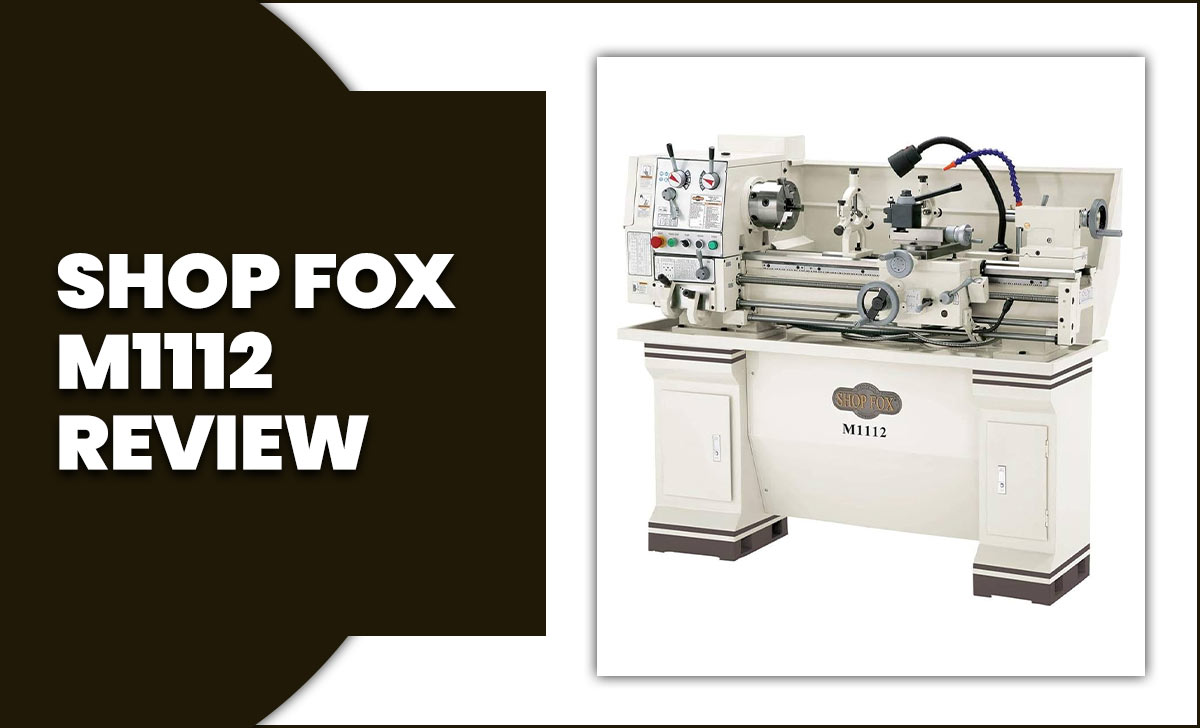

Have you ever tried to make something cool with a metal lathe? If you have, you know that a lathe is a powerful tool. It helps shape metal into smooth and precise parts. But did you know that the lathe headstock plays a big role in how well it works? That’s right! The headstock is where the motor and spindle are located. If the bearings are not good, your metal lathe may not run smoothly.

Many metal lathe accessories can help improve your lathe’s performance. They can make carving metal easier and more fun. For example, a good bearing can reduce vibrations that make it hard to get a nice finish. Imagine trying to build a model and it keeps wobbling! That can be frustrating.

Here’s a fun fact: A well-maintained lathe can last for decades! With the proper accessories, you can keep it running like new. So, let’s dive deeper into the world of lathe headstock bearings and discover how you can boost your metal lathe experience!

Lathe Headstock Bearing: Essential Metal Lathe Accessories

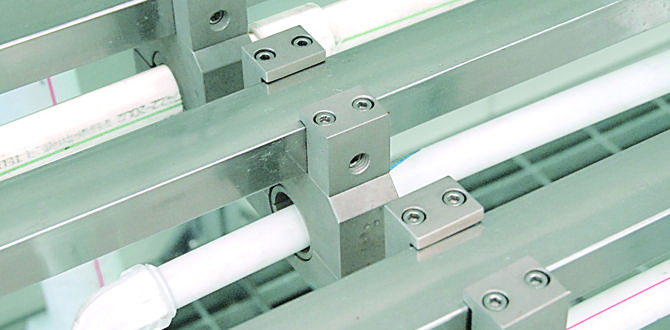

Lathe Headstock Bearing Metal Lathe Accessories

Understanding lathe headstock bearings is vital for smooth operation. These parts support the spindle, affecting how well the metal lathe performs. By using the right accessories, you enhance precision and longevity. Curious about upgrading your lathe? Choosing high-quality bearings can make all the difference. Imagine creating flawless pieces effortlessly! Small changes in setup or accessories can lead to big improvements in your projects. Invest wisely to enjoy smooth, accurate results every time.What is a Lathe Headstock Bearing?

Definition and function of headstock bearings in a lathe.. Types of bearings and their roles in lathe performance..A lathe headstock bearing helps support the spinning part of the lathe. It makes sure everything moves smoothly and stays stable while you work. There are different types of bearings used in lathes. Each type has a special job to help the lathe work better. This is important for creating strong and precise items.

- Ball Bearings: These have small balls inside. They reduce friction and help with smooth movement.

- Roller Bearings: These use cylinder shapes to support heavy loads. They are great for big tasks.

- Sleeve Bearings: These are simple and usually low-cost. They work well for lighter tasks.

What does a lathe headstock bearing do?

It supports the spinning parts and ensures stability. This helps the lathe run smoothly, making your projects easier and more accurate.

Importance of Quality Headstock Bearings

How headstock bearing quality impacts machining precision.. The effect of worn or damaged bearings on lathe operation..Quality headstock bearings are vital for smooth machining. If the bearings are good, the lathe operates well. This means more accurate cuts and better finishes. However, worn or damaged bearings can cause problems. They lead to vibrations and inaccuracies, which ruin projects.

- Precision: Good bearings keep everything aligned.

- Life Span: Worn bearings reduce the lathe’s life.

- Efficiency: Smooth bearings save time and energy.

How do bearings affect lathe performance?

Good bearings ensure precision and reduce wear on the lathe. Worn bearings cause mistakes, making it important to check them regularly. Keeping bearings in great shape means better projects every time.Signs Your Lathe Headstock Bearing Needs Replacement

Key indicators of bearing wear or failure.. How to assess bearing condition during maintenance..Notice strange noises? You might need a new bearing. Other signs include vibrations or a rough feel while turning. Check your lathe during maintenance for these clues:

- Look for visible damage on the bearing.

- Listen for grinding sounds while it runs.

- Pay attention to unusual heat.

These symptoms mean it’s time to think about a replacement. An old bearing can slow you down and cause other issues, so stay alert!

How do I know if my lathe headstock bearing is failing?

Check for noise, vibration, or heat. These are signs of a problem. Regular checks help catch issues early.

Choosing the Right Bearing for Your Metal Lathe

Factors to consider when selecting headstock bearings.. Compatibility with different lathe models and styles..Choosing the best bearing for your lathe headstock is important. Start by checking if it fits your lathe model. Here are some key points to think about:

- **Size Compatibility:** Make sure the bearing matches the size of your lathe.

- **Weight Capacity:** Choose a bearing that can handle the weight of your work.

- **Material Quality:** Look for durable materials that resist wear.

Considering these factors will help you find the right bearings for smooth operation.

What should I look for in lathe headstock bearings?

Pay attention to size, weight capacity, and material. This ensures your lathe performs well and lasts longer.

Installing Lathe Headstock Bearings: A Step-by-Step Guide

Essential tools and materials needed for installation.. Detailed procedures to ensure proper bearing installation..Before diving into the installation, gather your tools and materials. You will need:

- Wrenches

- Screwdrivers

- New bearings

- Grease or oil

- Ruler or caliper

To install the bearings, follow these steps:

- First, remove the old bearings carefully.

- Clean the area to remove dust and debris.

- Place the new bearings in the correct position.

- Tighten everything securely.

- Test the lathe to ensure it works smoothly.

What tools do I need to install headstock bearings?

Essential tools include wrenches, screwdrivers, and new bearings.

How can I ensure proper installation?

Always clean the area, check positions, and tighten all parts correctly.

Maintenance Tips for Longevity of Headstock Bearings

Recommended maintenance practices to extend bearing life.. Common mistakes to avoid during maintenance..Headstock bearings are vital for smooth lathe operation. To keep them working well, follow these maintenance tips:

- Check for proper lubrication regularly.

- Clean the bearings to remove dirt and debris.

- Inspect for wear or damage.

- Store the lathe in a dry place.

Avoid these common mistakes:

- Skipping cleaning before lubrication.

- Using the wrong type of oil.

- Neglecting regular inspections.

Taking care of your bearings helps them last longer. Happy lathing!

How can I extend the life of my lathe’s headstock bearings?

To extend your lathe’s headstock bearing life, ensure proper lubrication and regular cleaning. Also, avoid contamination with dust and debris. Regular checks help catch issues early.

Upgrading Your Lathe: When to Consider New Bearings

Situations where upgrading bearings enhances lathe performance.. Benefits of investing in highquality bearings..Sometimes, your lathe may need a boost. If you notice vibrations, noise, or uneven cuts, it might be time for new bearings. Upgrading lathe headstock bearings can make a big difference in performance.

High-quality bearings improve speed and precision. They last longer, too. Investing in these will help you work better and with less hassle.

- Increased accuracy

- Less friction

- Longer machine life

Why should you upgrade your lathe bearings?

Upgrading your lathe bearings can lead to smoother operations and better results.

Where to Buy Quality Lathe Headstock Bearings

Recommended suppliers and brands for lathe accessories.. Factors to consider for purchasing bearings online vs. instore..Finding the right lathe headstock bearings is like hunting for treasure. Start with reputable suppliers like Amazon, McMaster-Carr, or MSC Industrial Supply. They sell quality parts and have good customer reviews. When buying online, check if the bearings fit your lathe. In-store shopping lets you ask questions and see the item, but sometimes it costs more. So, weigh the factors before you dive in!

| Supplier | Online or In-Store | Pros | Cons |

|---|---|---|---|

| Amazon | Online | Wide selection | Shipping wait time |

| McMaster-Carr | Online | Quality brands | Limited physical stores |

| Local Hardware Stores | In-Store | See items first | Higher prices |

Conclusion

In summary, lathe headstock bearings are vital for smooth metal lathe operation. They reduce friction and support the spindle well. Using quality accessories improves performance. We hope you explore more about choosing the right bearings and accessories for your lathe. With the right tools, you can achieve better projects. Happy machining, and keep learning!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing And Metal Lathe Accessories:Sure! The headstock on a lathe helps hold and turn the metal. The bearing supports the spinning parts so they move smoothly. If you want to make cool shapes from metal, you can use different lathe accessories. Accessories can help you cut, shape, and polish the metal better. They make your work easier and more fun!

Sure! Please provide the question you would like me to answer.

What Types Of Bearings Are Commonly Used In Lathe Headstocks, And How Do They Affect The Performance Of The Lathe?Lathe headstocks usually use ball bearings and roller bearings. Ball bearings help things spin smoothly and easily. Roller bearings can carry more weight and help with heavy jobs. Good bearings let the lathe work faster and last longer. If the bearings are not good, the lathe might not work well.

How Can I Determine If The Headstock Bearing On My Metal Lathe Needs Replacement Or Maintenance?To check if the headstock bearing on your metal lathe needs help, listen for strange noises. You should also feel for any rough spots when you spin the spindle. If it wobbles or doesn’t spin smoothly, it might need fixing. Finally, look for any signs of damage or wear. If you notice these problems, it’s time for maintenance or replacement.

What Accessories Can Enhance The Functionality Of A Metal Lathe In Conjunction With The Headstock Bearing System?You can use a three-jaw chuck to hold round pieces tightly. A steady rest helps keep long parts straight while you work on them. A tailstock can add support for drilling holes. Tool holders let you change tools easily. Together, these accessories make your metal lathe work better and help you make cool projects!

What Are The Common Signs Of Wear Or Damage In Lathe Headstock Bearings, And How Can They Be Addressed?Common signs of wear or damage in lathe headstock bearings include noise, rough movement, and loose parts. If you hear strange sounds or feel bumps when the lathe runs, something may be wrong. You can fix this by checking the bearings and adding oil if they are dry. If they are very worn, you might need to replace them. Always ask an adult for help if you aren’t sure what to do!

How Do Different Types Of Headstock Bearings (E.G., Ball Bearings Vs. Tapered Roller Bearings) Impact The Precision And Speed Of A Metal Lathe?Ball bearings are small, round balls that help things move smoothly. They are great for speed and keep the metal lathe running fast. Tapered roller bearings look like cones and can handle heavier loads better. They help with precision, making sure everything stays in place. So, ball bearings are better for speed, while tapered roller bearings are better for accuracy.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing And Metal Lathe Accessories:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! The headstock on a lathe helps hold and turn the metal. The bearing supports the spinning parts so they move smoothly. If you want to make cool shapes from metal, you can use different lathe accessories. Accessories can help you cut, shape, and polish the metal better. They make your work easier and more fun!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Types Of Bearings Are Commonly Used In Lathe Headstocks, And How Do They Affect The Performance Of The Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe headstocks usually use ball bearings and roller bearings. Ball bearings help things spin smoothly and easily. Roller bearings can carry more weight and help with heavy jobs. Good bearings let the lathe work faster and last longer. If the bearings are not good, the lathe might not work well.”}},{“@type”: “Question”,”name”: “How Can I Determine If The Headstock Bearing On My Metal Lathe Needs Replacement Or Maintenance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if the headstock bearing on your metal lathe needs help, listen for strange noises. You should also feel for any rough spots when you spin the spindle. If it wobbles or doesn’t spin smoothly, it might need fixing. Finally, look for any signs of damage or wear. If you notice these problems, it’s time for maintenance or replacement.”}},{“@type”: “Question”,”name”: “What Accessories Can Enhance The Functionality Of A Metal Lathe In Conjunction With The Headstock Bearing System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use a three-jaw chuck to hold round pieces tightly. A steady rest helps keep long parts straight while you work on them. A tailstock can add support for drilling holes. Tool holders let you change tools easily. Together, these accessories make your metal lathe work better and help you make cool projects!”}},{“@type”: “Question”,”name”: “What Are The Common Signs Of Wear Or Damage In Lathe Headstock Bearings, And How Can They Be Addressed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common signs of wear or damage in lathe headstock bearings include noise, rough movement, and loose parts. If you hear strange sounds or feel bumps when the lathe runs, something may be wrong. You can fix this by checking the bearings and adding oil if they are dry. If they are very worn, you might need to replace them. Always ask an adult for help if you aren’t sure what to do!”}},{“@type”: “Question”,”name”: “How Do Different Types Of Headstock Bearings (E.G., Ball Bearings Vs. Tapered Roller Bearings) Impact The Precision And Speed Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Ball bearings are small, round balls that help things move smoothly. They are great for speed and keep the metal lathe running fast. Tapered roller bearings look like cones and can handle heavier loads better. They help with precision, making sure everything stays in place. So, ball bearings are better for speed, while tapered roller bearings are better for accuracy.”}}]}