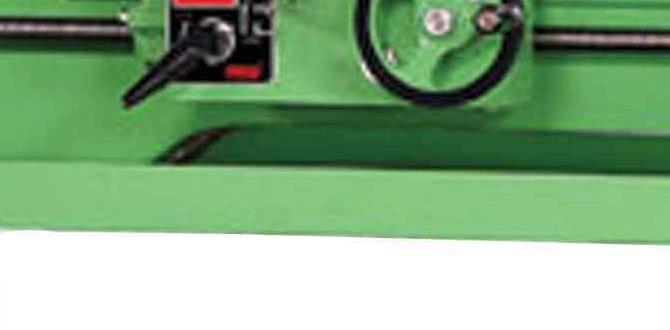

Have you ever watched a lathe at work? It’s amazing how a simple piece of metal transforms into something beautiful. But did you know the lathe headstock is a key part of this process? It helps the machine spin the workpiece smoothly. Without it, all those creative projects might just fall apart!

Now, imagine if the lathe’s headstock didn’t have the proper bearing. The machine would shake and wobble, making it hard to create anything. Bearings help reduce friction, allowing the lathe to run freely. They wear out over time, which is why keeping them in good shape is so important.

And what about the belt? The lathe belt connects the motor to the headstock. If it’s loose or damaged, the whole machine struggles. A tight, well-maintained belt means your projects will come out just right.

In this article, we will dive deeper into the importance of the lathe headstock bearing and the lathe belt. Together, they play a vital role in how your metal lathe functions. Let’s explore how you can keep these parts in top shape for your next big project!

Lathe Headstock Bearing: Optimizing Your Metal Lathe Belt

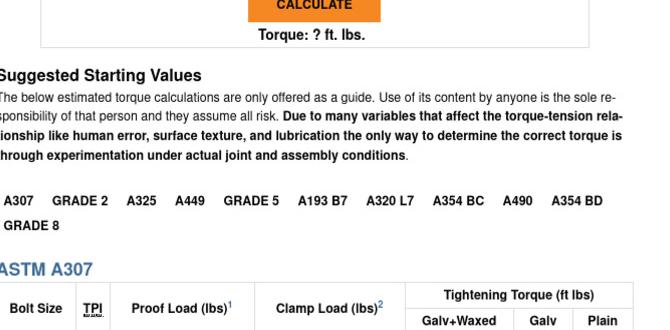

Lathe Headstock Bearing Metal Lathe Belt

Lathe headstock bearings play a crucial role in the smooth operation of metal lathes. They support the spindle and help reduce friction. A well-maintained bearing ensures your lathe runs efficiently and provides high precision. Choosing the right lathe belt is also important, as it connects the motor to the spindle. Did you know regular checks of these components can prolong your lathe’s lifespan? Keeping everything in top shape makes for better projects and less downtime!What is a Lathe Headstock?

Definition and functions of a headstock in metal lathes. Importance of headstock components in lathe operation.A lathe headstock is an important part of a metal lathe. It holds the spindle and drives the machine. The headstock controls speed and direction. This allows the lathe to shape materials effectively. Key components in the headstock include gears, bearings, and motors. Each part plays a vital role in operation, ensuring smooth performance.

- Spindle: Holds and rotates the workpiece.

- Gears: Adjusts speed and torque.

- Bearings: Support and stabilize the spindle.

- Motor: Powers the headstock.

Why is the lathe headstock important?

The lathe headstock ensures precision and efficiency in machining operations. Without it, the lathe would be unable to function properly, leading to poor results.

Components of Lathe Headstock Bearings

Different types of bearings used in headstocks (ball, roller, sleeve). Role of bearings in reducing friction and enhancing performance.Lathe headstock bearings are like the quiet heroes of a metal lathe. They come in three flavors: ball bearings, roller bearings, and sleeve bearings. Each type plays a unique role. Ball bearings minimize friction, making your lathe smoother than a buttered slide. Roller bearings can handle heavy loads without breaking a sweat. Sleeve bearings are simple yet effective, keeping everything in check. Together, they boost performance and keep your lathe running clean and fast!

| Type of Bearing | Function |

|---|---|

| Ball Bearings | Reduce friction for smooth operation. |

| Roller Bearings | Support heavy loads with ease. |

| Sleeve Bearings | Keep parts aligned and reduce wear. |

Common Issues with Lathe Headstock Bearings

Signs of wear and failure in headstock bearings. Maintenance tips to prolong the lifespan of bearings.Lathe headstock bearings can show signs of wear like strange noises or vibrations. These are red flags, just like a dog barking at a pizza delivery guy! If you notice these signs, it might be time to check your bearings. To keep them lasting longer, remember to clean them regularly, check for lubrication, and avoid over-tightening. Think of it as giving your lathe a nice oil massage. A happy lathe makes for happy projects!

| Signs of Wear | Maintenance Tips |

|---|---|

| Unusual noises | Regular cleaning |

| Vibration issues | Check lubrication |

| Difficulty in operation | Avoid over-tightening |

Choosing the Right Metal Lathe Belt

Types of belts used in metal lathes (Vbelt, flat belt, toothed belt). Factors to consider when selecting a belt for optimal performance.Metal lathes use different types of belts. The main types are V-belts, flat belts, and toothed belts. Each has its own strengths. V-belts are good for high power. Flat belts work well for smooth operations. Toothed belts provide precise movement.

When choosing a belt, consider these factors:

- Drive system type

- Load capacity

- Speed requirements

- Durability and lifespan

A good belt impacts your lathe’s performance.

What type of belt is best for metal lathes?

V-belts are popular for high power, while toothed belts are great for precision tasks.

Installation and Maintenance of Lathe Belts

Stepbystep guide to installing lathe belts correctly. Best practices for maintaining and adjusting lathe belts.Installing lathe belts isn’t rocket science! First, make sure the machine is off. Loosen the old belt and carefully remove it. Place the new belt over the pulleys, ensuring it sits snugly. Tighten it just right, not like a python squeeze! Regular checks are important too. Keep an eye out for wear and tear. Adjust tension if it feels loose. Trust me, a happy belt means a happy lathe.

| Best Practices | Description |

|---|---|

| Regular Inspection | Check the belt for cracks and fraying. |

| Proper Tension | Make sure the belt isn’t too tight or loose. |

| Cleanliness | Keep the area around the belt clean and oil-free. |

Upgrading and Replacing Bearings and Belts

When to consider upgrades or replacements for better efficiency. Recommendations for highquality bearings and belts on the market.Upgrading or replacing bearings and belts can make your metal lathe run smoother. Look for signs like unusual noise or vibration. These indicate that it’s time for a change. High-quality parts can greatly improve efficiency. Some top brands include Timken, SKF, and Bosch. Investing in better gear will help your projects turn out great.

When should you upgrade your bearings and belts?

Replace them if you notice noises or see signs of wear.Recommendations for high-quality options:

- Timken: Known for durability

- SKF: Offers long-lasting products

- Bosch: Trusted for performance

Impacts of Bearings and Belts on Lathe Performance

How bearings and belts contribute to precision machining. Case studies showcasing improvements after upgrading components.Bearings and belts play a big role in how well a lathe works. High-quality bearings boost precision machining, allowing for smooth and accurate cuts. This can lead to better products and less waste. For example, a factory that upgraded their lathe bearings saw a 30% increase in production speed. Another shop found that new belts reduced wear and tear, improving their lathe’s lifespan.

- Improved Precision: Quality components mean tighter tolerances.

- Increased Speed: Better belts and bearings enhance rotation rates.

- Longer Lifespan: Upgrades can cut down on repairs.

How do bearings and belts affect machining quality?

Bearings and belts directly impact the accuracy and longevity of machining projects. Using upgraded parts means better performance and fewer mistakes in production.

Conclusion

In summary, the lathe headstock bearing supports the spindle for smooth operation. The belt transfers power, making the lathe work efficiently. Understanding these parts helps you maintain your metal lathe better. We encourage you to read more about lathe maintenance or try hands-on practice. This way, you’ll improve your skills and enjoy using your lathe even more!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing, Metal Lathe, And Belt:Sure! The headstock is the part of the lathe that holds the spinning tools. It helps keep everything steady while we work. The bearings inside the headstock help the tool spin smoothly. The belt connects the motor to the lathe, making the machine run. Together, these parts make our metal lathe work well.

Sure! Please provide the question you want me to answer.

What Materials Are Commonly Used For Lathe Headstock Bearings, And How Do They Affect Performance And Durability?Lathe headstock bearings are often made from metal or plastic. Metals, like steel, are strong and last a long time. Plastic can be quieter but might wear out faster. The choice of material helps the lathe run smoothly and last longer.

How Can The Alignment Of The Lathe Headstock Bearings Impact The Accuracy And Finish Of Machined Parts?When the bearings in a lathe headstock are aligned correctly, the machine works better. This means that the tool can cut the metal or wood smoothly. If the bearings are not straight, the tool can wobble. This wobbling can cause parts to be uneven and rough. So, proper alignment helps make nice and accurate pieces!

What Factors Should Be Considered When Selecting A Belt For A Metal Lathe To Ensure Optimal Power Transmission And Longevity?When choosing a belt for a metal lathe, think about the size and strength of the belt. It should fit well and be strong enough to handle heavy work. We also want to check the material; some last longer than others. Lastly, consider how much noise the belt makes and whether it runs smoothly. This helps your lathe work better and last longer.

How Often Should Lathe Headstock Bearings Be Inspected And Maintained To Prevent Wear And Ensure Smooth Operation?You should check the lathe headstock bearings every month. If you use the lathe a lot, it’s good to look at them more often. Clean and oil them when needed to keep them working well. This helps prevent wear and keeps everything running smoothly. Always make sure to follow the instructions in your lathe’s manual.

What Are The Signs That A Lathe’S Headstock Bearings May Be Failing, And What Steps Can Be Taken To Address These Issues?If the lathe makes strange noises or feels rough when you turn it, the headstock bearings might be failing. You might also see more vibrations than usual. To fix this, you should first check the bearings for damage. If they look bad, you can replace them or get help from a technician to repair them. Always remember to turn off the lathe before you check anything!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing, Metal Lathe, And Belt:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! The headstock is the part of the lathe that holds the spinning tools. It helps keep everything steady while we work. The bearings inside the headstock help the tool spin smoothly. The belt connects the motor to the lathe, making the machine run. Together, these parts make our metal lathe work well.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used For Lathe Headstock Bearings, And How Do They Affect Performance And Durability?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe headstock bearings are often made from metal or plastic. Metals, like steel, are strong and last a long time. Plastic can be quieter but might wear out faster. The choice of material helps the lathe run smoothly and last longer.”}},{“@type”: “Question”,”name”: “How Can The Alignment Of The Lathe Headstock Bearings Impact The Accuracy And Finish Of Machined Parts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When the bearings in a lathe headstock are aligned correctly, the machine works better. This means that the tool can cut the metal or wood smoothly. If the bearings are not straight, the tool can wobble. This wobbling can cause parts to be uneven and rough. So, proper alignment helps make nice and accurate pieces!”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting A Belt For A Metal Lathe To Ensure Optimal Power Transmission And Longevity?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a belt for a metal lathe, think about the size and strength of the belt. It should fit well and be strong enough to handle heavy work. We also want to check the material; some last longer than others. Lastly, consider how much noise the belt makes and whether it runs smoothly. This helps your lathe work better and last longer.”}},{“@type”: “Question”,”name”: “How Often Should Lathe Headstock Bearings Be Inspected And Maintained To Prevent Wear And Ensure Smooth Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the lathe headstock bearings every month. If you use the lathe a lot, it’s good to look at them more often. Clean and oil them when needed to keep them working well. This helps prevent wear and keeps everything running smoothly. Always make sure to follow the instructions in your lathe’s manual.”}},{“@type”: “Question”,”name”: “What Are The Signs That A Lathe’S Headstock Bearings May Be Failing, And What Steps Can Be Taken To Address These Issues?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the lathe makes strange noises or feels rough when you turn it, the headstock bearings might be failing. You might also see more vibrations than usual. To fix this, you should first check the bearings for damage. If they look bad, you can replace them or get help from a technician to repair them. Always remember to turn off the lathe before you check anything!”}}]}