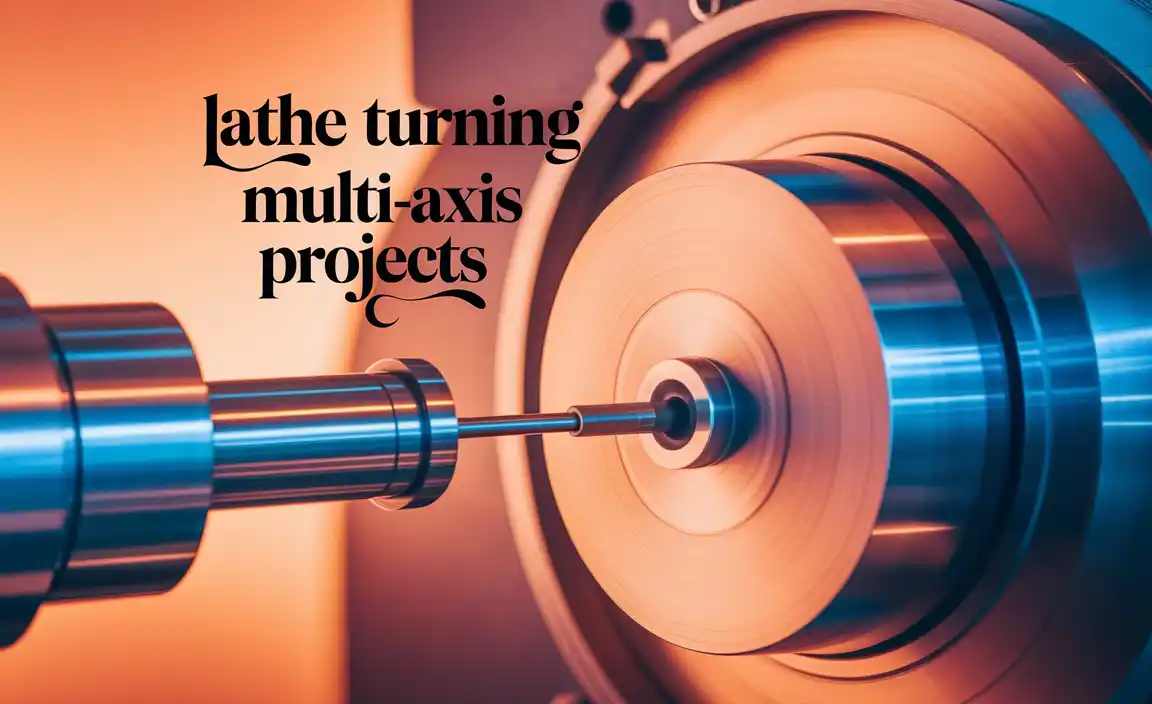

Have you ever wondered how metal parts are made? It all starts with machines like the lathe. The lathe is a fantastic tool, and one of its most important parts is the headstock. This is where the lathe’s power comes from. But what makes a great lathe headstock? The answer lies in the bearing design.

Imagine working on a metal lathe and feeling the smooth operation of the machine. The secret is often in the details of CAD design. This technology helps create precise and reliable headstock bearings. With the right design, you can achieve better results in your projects.

Did you know that the right lathe headstock bearing can make a huge difference? It can improve the machine’s lifespan and accuracy. This article explores how to design the best bearings for your metal lathe using CAD. Get ready to dive into the world of lathe design!

Lathe Headstock Bearing: Metal Lathe Cad Design Explained

Lathe Headstock Bearing Metal Lathe CAD Design

Lathe headstock bearings are crucial for smooth operation in metal lathes. Readers discover how CAD design enhances precision in crafting these bearings. Understanding different materials helps improve durability and performance. Have you ever wondered how these machines create perfect shapes? Skilled designers use CAD to visualize and test their ideas before making them. This innovative approach not only saves time but also boosts creativity in metalworking projects. Embrace technology to refine your lathe designs!Understanding Lathe Headstock Bearings

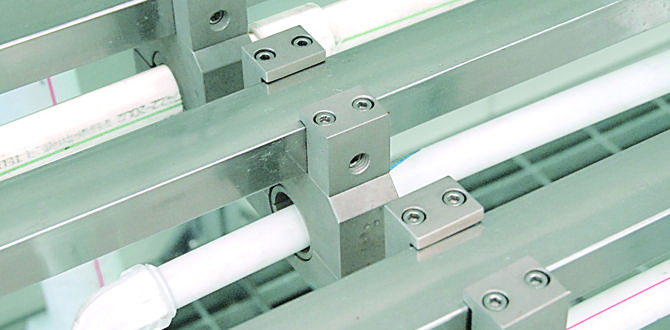

Definition and function of headstock bearings in metal lathes. Importance of bearing selection for machining performance.Headstock bearings are important parts in metal lathes. They help support the lathe spindle, allowing it to turn smoothly. This ensures precise cutting and shaping of materials. Selecting the right bearings is crucial. Poor choices can lead to vibrations and inaccuracies during machining.

- Efficiency: Good bearings enhance machine performance.

- Durability: High-quality bearings last longer.

- Precision: They ensure accurate operations.

Why are headstock bearings critical for metal lathes?

Headstock bearings affect both speed and quality of work. If bearings are weak, they cannot hold the spindle still. This can ruin a project! Quality bearings save time and materials, making them a smart choice.

Key Factors in Lathe Headstock Bearing Design

Load capacity and performance requirements. Material selection for durability and precision.When designing lathe headstock bearings, two key factors stand out: load capacity and material selection. First, load capacity is crucial, as it ensures the bearing can handle forces during operation. Strong bearings lead to better performance. Next, choosing the right materials promotes durability and precision. For example, using strong metals can reduce wear and tear, extending the life of the bearing. Remember, a good design combines both load capacity and quality materials.

What are the important factors in lathe headstock bearing design?

Key factors include:

- Load Capacity: Supports heavy machining tasks.

- Material Selection: Ensures durability and accuracy.

Good design leads to better results on the lathe. With the right bearings, your machine will work smoothly and last longer.

CAD Design Principles for Lathe Headstock Bearings

Essential CAD software tools and features for designing bearings. Stepbystep process for creating a headstock bearing model in CAD.Designing lathe headstock bearings in CAD can be exciting and rewarding. To start, choose the right CAD software. Popular tools include SolidWorks, AutoCAD, and Fusion 360. Look for features like 3D modeling and assembly tools. Follow these simple steps:

- Create a new project.

- Choose the bearing type.

- Sketch the base shape.

- Add dimensions and details.

- 3D model the design.

- Run simulations for testing.

- Save and export your model.

By following these steps, you can easily create an effective headstock bearing model. Ready to start your design journey?

What are key features for CAD design of bearings?

Essential CAD features include 3D modeling tools, assembly capabilities, and simulation tools. These help check the design for accuracy and performance.

Why is CAD important for lathe bearing design?

CAD allows designers to visualize, test, and improve designs quickly. This saves time and enhances product quality. Using CAD can lead to better functioning bearings.

Best Practices for Lathe Headstock Bearing Installation

Guidelines for properly installing bearings in metal lathes. Common installation mistakes to avoid.Installing bearings in a lathe headstock is important for smooth operation. Follow these simple guidelines for a great installation:

- Clean the bearing and housing well before installation.

- Use the right tools for fitting the bearings.

- Follow the manufacturer’s instructions carefully.

- Check for proper alignment to avoid problems later.

Avoid these common mistakes:

- Not cleaning surfaces.

- Over-tightening the bearings.

- Ignoring proper lubrication.

Proper installation helps keep your lathe running smoothly and lasts longer. Remember, a little care goes a long way!

What are some common mistakes during installation?

The main mistakes include not cleaning surfaces, over-tightening bearings, and neglecting lubrication. Each mistake can cause serious issues in lathe performance.

Troubleshooting Common Issues with Headstock Bearings

Identifying signs of bearing failure. Solutions and preventive maintenance tips for longevity.Headstock bearings often show signs of wear before they completely fail. Sounds strange, right? Listen for unusual noises like grinding or squeaking. These could be red flags! You might also notice vibrations or a wobbly spindle. Don’t panic! A little preventive care goes a long way. Regularly lubricate your bearings and check for dirt. Keeping them clean can save you a headache and some cash!

| Signs of Bearing Failure | Solutions |

|---|---|

| Grinding Noises | Lubricate regularly |

| Vibrations | Check for dirt or wear |

| Wobbly Spindle | Inspect alignment |

Remember, keeping a close eye means you won’t need to wrestle with bigger problems later. With a little love and care, your lathe will thank you with smooth operations!

Case Studies: Successful CAD Designs of Lathe Headstock Bearings

Examples of innovative headstock bearing designs. Analysis of design improvements and their impact on lathe performance.Innovative designs for lathe headstock bearings can transform how machines perform. For example, one design used high-quality materials that reduced friction. This made lathes run smoother and last longer. Another design improved the shape of the bearing. This change led to better balance and less vibration during operation. These advances make lathe work easier and more efficient. In short, smart designs keep the lathes happy and humming!

| Design Feature | Impact on Performance |

|---|---|

| Material Quality | Reduces friction |

| Shape Improvements | Enhances balance |

| Vibration Reduction | Makes operation smoother |

Future Trends in Lathe Headstock Bearing Design and Technologies

Emerging technologies affecting bearing design (e.g., 3D printing, smart materials). Predictions for the next generation of metal lathe bearings.New technologies are changing how we make lathe headstock bearings. 3D printing allows for quick and easy designs. It can create strong parts that fit better. Smart materials can adapt to different conditions. This might help bearings last longer and work better. In the future, we might see lighter and more efficient bearings. These will improve metal lathe performance, leading to more precise work.

What are the new trends in lathe bearing design?

The new trends focus on speed, strength, and smart technology. Bears are getting lighter and use less energy. Many designs are made on computers to ensure they fit perfectly.

Key Predictions:

- More use of 3D-printed parts.

- Stronger smart materials.

- Improved energy efficiency.

Conclusion

In conclusion, understanding lathe headstock bearing in CAD design helps you create better metal lathes. You gain insights into how bearings affect performance and durability. Remember to consider material selection and precision in your designs. By practicing these tips, you can improve your metalworking projects. Keep exploring CAD tools and resources to enhance your skills further!FAQs

What Materials Are Most Commonly Used For Lathe Headstock Bearings In Metal Lathe Cad Designs, And What Are Their Advantages And Disadvantages?Common materials for lathe headstock bearings are bronze, steel, and plastic. Bronze is strong and lasts a long time, but it can be expensive. Steel is tough and affordable, but it may rust. Plastic is light and cheap, but it wears out faster than metal. Choosing the right material depends on what you need for your lathe.

How Does The Design Of The Lathe Headstock Bearing Affect The Precision And Accuracy Of Machining Operations?The design of the lathe headstock bearing helps keep the spinning part steady. If it’s well-designed, the machine can cut materials accurately. This means our finished pieces will fit together better. A strong bearing reduces wobbling, making our work look nice and neat. So, good design is very important for precise machining!

What Cad Software Features Are Essential For Designing An Effective Lathe Headstock Bearing Assembly?To design a lathe headstock bearing assembly, you need helpful CAD software features. First, you should have 3D modeling tools to create the parts in three dimensions. Next, use simulation tools to test how the parts will move. It’s also good to have drawing tools for making clear plans and labels. Finally, easy-to-use organizing features help you keep everything neat and in order.

How Do You Determine The Appropriate Bearing Size And Type For A Specific Metal Lathe Design In A Cad Model?To find the right bearing size for a metal lathe, we start by checking the lathe’s design in CAD, which stands for Computer-Aided Design. We look at how much weight the bearing needs to hold and how fast the parts will move. Then, we choose a type of bearing that can handle those needs. Finally, we measure and adjust the size so it fits perfectly in the design.

What Are The Common Challenges Faced During The Cad Design Of Lathe Headstock Bearings, And How Can They Be Overcome?When designing lathe headstock bearings using CAD (Computer-Aided Design), we face some common problems. One challenge is making sure the parts fit together correctly. To fix this, we can use accurate measurements and double-check our designs. Another issue is choosing strong materials. We can overcome this by researching materials that work well for our project. Lastly, testing the designs on the computer helps us find and fix problems before making real parts.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Materials Are Most Commonly Used For Lathe Headstock Bearings In Metal Lathe Cad Designs, And What Are Their Advantages And Disadvantages? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common materials for lathe headstock bearings are bronze, steel, and plastic. Bronze is strong and lasts a long time, but it can be expensive. Steel is tough and affordable, but it may rust. Plastic is light and cheap, but it wears out faster than metal. Choosing the right material depends on what you need for your lathe.”}},{“@type”: “Question”,”name”: “How Does The Design Of The Lathe Headstock Bearing Affect The Precision And Accuracy Of Machining Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The design of the lathe headstock bearing helps keep the spinning part steady. If it’s well-designed, the machine can cut materials accurately. This means our finished pieces will fit together better. A strong bearing reduces wobbling, making our work look nice and neat. So, good design is very important for precise machining!”}},{“@type”: “Question”,”name”: “What Cad Software Features Are Essential For Designing An Effective Lathe Headstock Bearing Assembly? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To design a lathe headstock bearing assembly, you need helpful CAD software features. First, you should have 3D modeling tools to create the parts in three dimensions. Next, use simulation tools to test how the parts will move. It’s also good to have drawing tools for making clear plans and labels. Finally, easy-to-use organizing features help you keep everything neat and in order.”}},{“@type”: “Question”,”name”: “How Do You Determine The Appropriate Bearing Size And Type For A Specific Metal Lathe Design In A Cad Model? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right bearing size for a metal lathe, we start by checking the lathe’s design in CAD, which stands for Computer-Aided Design. We look at how much weight the bearing needs to hold and how fast the parts will move. Then, we choose a type of bearing that can handle those needs. Finally, we measure and adjust the size so it fits perfectly in the design.”}},{“@type”: “Question”,”name”: “What Are The Common Challenges Faced During The Cad Design Of Lathe Headstock Bearings, And How Can They Be Overcome? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When designing lathe headstock bearings using CAD (Computer-Aided Design), we face some common problems. One challenge is making sure the parts fit together correctly. To fix this, we can use accurate measurements and double-check our designs. Another issue is choosing strong materials. We can overcome this by researching materials that work well for our project. Lastly, testing the designs on the computer helps us find and fix problems before making real parts.”}}]}