Have you ever wondered how metal sits perfectly in place while a lathe spins it? The secret often lies in the lathe headstock bearing and a simple tool called a chuck key. These two components work together to create amazing precision in metalworking.

Imagine you’re in a workshop, watching a metal lathe in action. The spinning piece of metal catches your eye. With a turn of the chuck key, the metal locks securely. Why is that important? It ensures safety and a smooth cut every time.

Here’s a fun fact: Did you know that the right lathe headstock bearing can make your lathe last longer? It’s true! This tiny part supports the spindle, helping it turn with ease and accuracy. Without it, your lathe would struggle to perform tasks effectively.

In this article, we will explore how these elements work together. You’ll learn why choosing the right lathe headstock bearing and chuck key is essential for your projects. Ready to dive in? Let’s discover the world of metal lathes together!

Lathe Headstock Bearing And Metal Lathe Chuck Key Explained

Lathe Headstock Bearing: Understanding Metal Lathe Chuck Key

The lathe headstock bearing is vital for smooth operation. It holds the spindle and keeps it rotating accurately. Without this bearing, your lathe could struggle, leading to poor work quality. The metal lathe chuck key is essential too. It tightens and loosens the chuck, securing your workpiece in place. Imagine trying to carve wood without your piece held steady! Using the right bearings and key can transform your crafting experience. Don’t underestimate these small yet crucial tools!What is a Lathe Headstock?

Definition and function of the headstock in a lathe.. Importance of headstock bearings in lathe operation..A lathe headstock is a key part of a lathe machine. It holds the spindle and lets it rotate. This helps shape materials like wood or metal. The headstock also controls speed and direction. Headstock bearings are important. They reduce friction, making the machine run smoothly. Proper bearings help create better finished products. Without good bearings, the lathe may not work well, which can lead to mistakes.

What does the headstock do?

The headstock keeps everything in place while the machine operates. It allows users to adjust speeds for different tasks.

Key Functions

- Holds the spindle

- Controls rotation

- Adjusts speed and direction

Key Features of Headstock Bearings

Load capacity and its impact on lathe performance.. Importance of precision and tolerances in bearing design..Headstock bearings play a vital role in how well a lathe works. Their load capacity helps determine how much weight they can handle. This affects the lathe’s performance significantly. Precision and tolerances in bearing design ensure smooth operation. Any mismatches can lead to vibrations and unwanted noises during machining. Properly designed bearings keep everything running smoothly.

Why is load capacity important for lathe performance?

High load capacity allows lathes to handle heavier materials without breaking down. This results in better quality work and longer machine life.

What does precision mean in bearing design?

- Precision ensures parts fit perfectly.

- Tolerances keep movements smooth and reduced vibration.

- Accurate design affects the overall lifespan of the lathe.

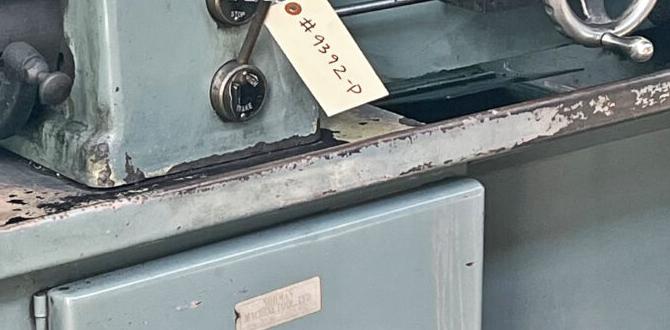

Maintaining Lathe Headstock Bearings

Best practices for lubrication and cleaning.. Signs of wear and how to inspect bearings..Keeping your lathe headstock bearings in good shape is key to smooth operation. Regularly check for oil or grease in the bearings. Clean them often to remove dust and debris. Look out for signs of wear, like unusual noises or rough movement. If you see any cracks or feel roughness, it’s time to replace them. Proper lubrication helps prevent damage and extends their life. Take good care of your bearings, and they will take care of you!

How do I know when to clean or replace bearings?

Watch for noises and feel for roughness. These signs mean it’s time to pay attention. Also, clean them with a soft cloth regularly to keep them working well.

Tips for Maintenance:

- Lubricate bearings regularly.

- Check for wear and tear consistently.

- Use the right type of oil.

Understanding Metal Lathe Chuck Keys

Definition and role of chuck keys in lathe operation.. Different types of chuck keys and their uses..Chuck keys are the trusty sidekicks of metal lathes. They help tighten and loosen the chuck, which holds the workpiece in place. Without them, your workpiece might wobble more than a puppy on a skateboard! There are several types of chuck keys, each serving a unique purpose.

| Type of Chuck Key | Use |

|---|---|

| Hex Key | For small chucks, perfect for tight spaces. |

| Universal Key | Works with multiple chucks for versatility. |

| Keyless Chuck | No key required! Just twist to lock. |

In short, chuck keys make sure everything stays secure while you work your magic. They are small but mighty!

Common Issues with Chuck Keys

Problems related to improper use and fitting.. How to troubleshoot issues with lathe chuck keys..Using a lathe chuck key is important for metal lathes. Common issues arise from improper use and fitting. Misalignment can lead to loose grips on workpieces. If you experience slipping or vibration, check the fit of your chuck key. A misfit can cause wear and tear, making tasks harder. Follow these steps to troubleshoot:

- Check for any damage on the key or chuck.

- Ensure a snug fit with the chuck key.

- Replace old keys to avoid further problems.

Keeping your tools in good shape makes work easier and safer. Always inspect your lathe chuck key before use. A little care goes a long way!

What should I do if my chuck key doesn’t fit?

If your chuck key doesn’t fit properly, check for damage or wear. It’s best to replace it if needed. Make sure to use the right size for your lathe to avoid future issues.

Upgrading Your Lathe Headstock Bearings and Chuck Keys

When and why to consider upgrading.. Recommendations for highquality replacements and modifications..Upgrade your lathe headstock bearings and chuck keys when you notice noise or vibrations. These signs can show wear. A smooth lathe helps your projects. Consider replacements that are durable and smooth. High-quality options can improve performance significantly. Here are some recommendations:

- Look for ceramic bearings, which resist wear.

- Choose a good quality chuck key to ensure a tight grip.

- Consider lubrication options to keep everything running smoothly.

Why should you upgrade your lathe parts?

Upgrading is essential for maintaining precision in your work. Old bearings can cause mistakes and rough finishes. New parts help keep your lathe in top shape.

Other tips for upgrading:

- Inspect bearings regularly for dirt or rust.

- Replace parts as soon as you notice issues.

Conclusion

In summary, the lathe headstock bearing is crucial for keeping your metal lathe running smoothly. The chuck key helps you secure different tools and materials on the lathe. Understanding these parts is essential for safe and effective lathe operation. As you continue learning, explore how to maintain your lathe for the best results. Happy machining!FAQs

What Types Of Bearings Are Commonly Used In The Headstock Of A Metal Lathe, And How Do They Affect The Machine’S Performance?Metal lathes usually use two types of bearings: plain bearings and ball bearings. Plain bearings are smooth and allow the spindle to turn easily. Ball bearings have little balls inside that help reduce friction. Both types help the lathe run better, making it faster and smoother when you work with metal. Good bearings mean better cuts and less wear on the machine.

How Do You Properly Maintain And Lubricate The Bearings In A Lathe Headstock To Ensure Optimal Performance?To keep the bearings in a lathe headstock working well, you need to clean them regularly. First, turn off the lathe and unplug it. Then, take off the cover to reach the bearings. Clean any dirt and old oil with a soft cloth. After that, add a few drops of fresh oil to the bearings. Make sure not to use too much. Finally, put everything back together and you’re done!

What Factors Should Be Considered When Selecting A Chuck Key For A Metal Lathe Chuck?When picking a chuck key for a metal lathe chuck, you should think about a few things. First, check the size of the chuck. The key needs to fit perfectly. Next, look at the shape; some keys are T-shaped, while others are different. Finally, consider how comfortable it is to use. You want a key that feels good in your hand so you can turn it easily.

How Do Different Designs Of Lathe Chucks Impact The Effectiveness And Ease Of Use Of The Chuck Key?Different lathe chucks have various designs that can change how we use the chuck key. Some chucks are easy to turn with the key, which helps us tighten or loosen pieces quickly. Others might be tricky and require more effort, making our job harder. A better design fits the key well, so we can work faster and with less fuss. Choosing a good chuck design can save us time and make our work easier.

What Are Some Common Problems Associated With Lathe Headstock Bearings, And How Can They Be Diagnosed And Resolved?Lathe headstock bearings can have several problems. You might hear strange noises, feel rough movement, or see uneven cuts on the metal. To check for issues, listen carefully and feel how the lathe moves. If you notice problems, we can clean or replace the bearings. This helps the lathe work smoothly again.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Types Of Bearings Are Commonly Used In The Headstock Of A Metal Lathe, And How Do They Affect The Machine’S Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes usually use two types of bearings: plain bearings and ball bearings. Plain bearings are smooth and allow the spindle to turn easily. Ball bearings have little balls inside that help reduce friction. Both types help the lathe run better, making it faster and smoother when you work with metal. Good bearings mean better cuts and less wear on the machine.”}},{“@type”: “Question”,”name”: “How Do You Properly Maintain And Lubricate The Bearings In A Lathe Headstock To Ensure Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the bearings in a lathe headstock working well, you need to clean them regularly. First, turn off the lathe and unplug it. Then, take off the cover to reach the bearings. Clean any dirt and old oil with a soft cloth. After that, add a few drops of fresh oil to the bearings. Make sure not to use too much. Finally, put everything back together and you’re done!”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting A Chuck Key For A Metal Lathe Chuck? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When picking a chuck key for a metal lathe chuck, you should think about a few things. First, check the size of the chuck. The key needs to fit perfectly. Next, look at the shape; some keys are T-shaped, while others are different. Finally, consider how comfortable it is to use. You want a key that feels good in your hand so you can turn it easily.”}},{“@type”: “Question”,”name”: “How Do Different Designs Of Lathe Chucks Impact The Effectiveness And Ease Of Use Of The Chuck Key? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different lathe chucks have various designs that can change how we use the chuck key. Some chucks are easy to turn with the key, which helps us tighten or loosen pieces quickly. Others might be tricky and require more effort, making our job harder. A better design fits the key well, so we can work faster and with less fuss. Choosing a good chuck design can save us time and make our work easier.”}},{“@type”: “Question”,”name”: “What Are Some Common Problems Associated With Lathe Headstock Bearings, And How Can They Be Diagnosed And Resolved? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe headstock bearings can have several problems. You might hear strange noises, feel rough movement, or see uneven cuts on the metal. To check for issues, listen carefully and feel how the lathe moves. If you notice problems, we can clean or replace the bearings. This helps the lathe work smoothly again.”}}]}