Imagine working on a project with your metal lathe. You turn a few knobs and get the perfect cut. But what makes that possible? It’s mainly the lathe headstock bearing and its control panel.

Many people don’t know how important the headstock bearing is. It helps the machine spin smoothly and accurately. Without it, your projects could turn out badly.

Have you ever wanted to learn more about how a metal lathe works? Understanding the control panel is key. It allows you to control speed and direction. Once you grasp these basics, your confidence will grow.

In this article, we’ll explore the lathe headstock bearing and its control panel in detail. Get ready to dive in and discover how these parts work together to create amazing items!

Lathe Headstock Bearing: Metal Lathe Control Panel Insights

Lathe Headstock Bearing and Control Panel Insights

Have you ever wondered how a metal lathe works? The lathe headstock bearing plays a crucial role in smooth operation. It supports the spindle, allowing it to rotate effectively. A well-maintained bearing enhances precision and reduces wear. The control panel is another key element. It lets operators adjust speed and settings easily. Knowing how these components work together ensures better projects. Fun fact: taking care of your lathe can make it last for years!What is a Lathe Headstock Bearing?

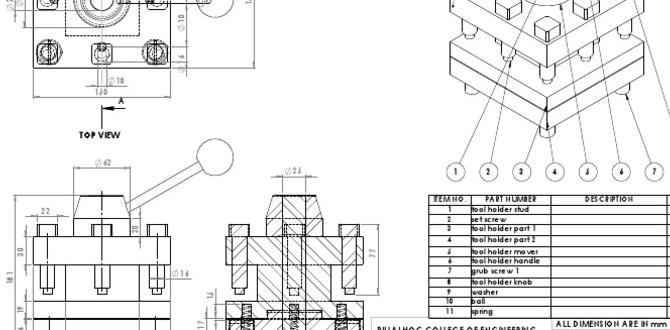

Definition and function of headstock bearings. Types of headstock bearings used in metal lathes.A lathe headstock bearing supports the spindle of the lathe. It helps the spindle rotate smoothly. This allows for accurate cutting and shaping of materials. There are different types of headstock bearings used in metal lathes:

- Ball Bearings

- Roller Bearings

- Magnetic Bearings

Each type has its own benefits. Ball bearings are common and reliable. Roller bearings handle heavier loads. Magnetic bearings offer less friction. This keeps things running smoothly!

What is the purpose of headstock bearings?

The primary purpose of headstock bearings is to support the lathe spindle and ensure smooth rotation. This helps the lathe perform better and improves accuracy in machining tasks.

The Importance of Headstock Bearings in Lathe Performance

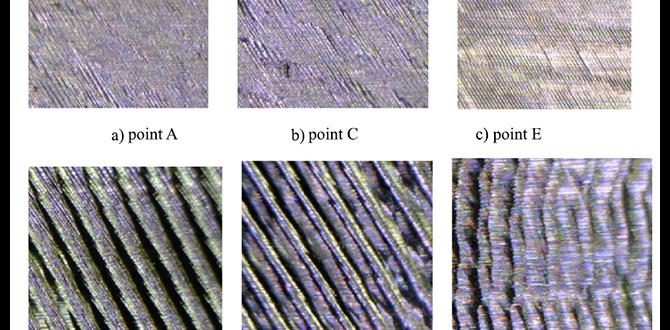

Impact on precision and accuracy. Role in the longevity and reliability of the lathe.Headstock bearings play a huge role in how well a lathe works. They help keep the machine running smoothly and accurately. Good bearings mean cutting tools move with precision. This ensures clean cuts and the best results. Also, quality bearings add to the lathe’s lifespan. They reduce wear and tear, making the machine reliable over time. This means fewer repairs and more time for projects.

Why are headstock bearings crucial for lathe machines?

Precision and accuracy are key factors in lathe operations. These bearings help parts move without wobbling, which leads to better craftsmanship. Plus, they ensure the lathe lasts, giving you more bang for your buck.

Key Benefits:

- Improved cutting accuracy

- Reduced wear leads to longer life

- Greater reliability for heavy use

How to Choose the Right Headstock Bearing

Factors to consider when selecting bearings. Compatibility with various lathe models.Selecting the right headstock bearing is like choosing the perfect cupcake: you need the right ingredients! First, think about compatibility. Not all bearings fit every lathe. Check your model’s specs! Next, consider the material. Metal, for example, is strong and durable. You want something that lasts longer than a cookie in the cookie jar! Also, don’t forget about size. A great fit means smooth operation. Here’s a little table to help:

| Factor | Details |

|---|---|

| Compatibility | Check if it fits your lathe model |

| Material | Metal is strong; avoid flimsy stuff! |

| Size | Correct size ensures smooth running |

Adjusting and Maintaining Lathe Headstock Bearings

Stepbystep guide on proper adjustment. Maintenance tips to ensure smooth operation.Adjusting lathe headstock bearings is simpler than fixing a wobbly chair! Start by loosening the lock nuts on the bearings. Next, use a dial gauge to check the alignment. If it’s off, gently adjust until it’s spot on. Tighten the nuts back up. For smooth sailing, remember to clean and oil your bearings regularly. This keeps them happy and humming along like an excited bee!

Here’s a quick maintenance tip checklist:

| Task | Frequency |

|---|---|

| Check alignment | Monthly |

| Clean bearings | Weekly |

| Oil bearings | Every two weeks |

Keep these steps in mind, and your lathe will perform like a pro. Remember, a well-maintained lathe can be the difference between a fun project and a “what did I do?” moment!

How the Control Panel Influences Lathe Operation

User interface and ease of use. Safety features and operational controls.The control panel plays a big role in using a lathe. It acts like a bridge between the user and the machine. A clear user interface makes it easy to operate. This helps even beginners feel comfortable. Safety features keep everyone protected. Controls are simple, allowing quick adjustments. Here are some key aspects:

- User Interface: Intuitive buttons and screens.

- Ease of Use: Simple settings for different tasks.

- Safety Features: Emergency stops and alerts.

- Operational Controls: Smooth adjustments for speed and power.

What are key features of the control panel?

Important features of the control panel include simple controls for speed regulation and emergency shutdown buttons to ensure safety during operation.

Troubleshooting Common Issues with Headstock Bearings and Control Panels

Signs of bearing failure and how to address them. Common control panel malfunctions and solutions.Headstock bearings can be tricky! If you hear strange noises or feel wobbly parts, your bearings might be waving a red flag. To fix this, check for wear and tear. Regular maintenance can save you from surprises. Now, control panel issues can feel like finding Waldo in a crowd; frustrating, right? If buttons stick or the display goes dark, unplug and restart the machine. A little reset can go a long way!

| Issue | Signs | Solution |

|---|---|---|

| Bearing Failure | Strange noises, wobbling | Inspect and replace |

| Control Panel | Sticking buttons, dark screen | Unplug and restart |

Upgrading or Replacing Bearings and Control Panels

When to consider upgrades or replacements. Best practices for upgrading components for improved performance.Upgrading your metal lathe components can greatly improve performance. Consider upgrades when your lathe shows signs of wear. This includes unusual noises, vibrations, or decreased accuracy. Replacing the lathe headstock bearing or control panel can make a big difference.

Follow these best practices:

- Inspect parts regularly.

- Choose high-quality, compatible components.

- Install parts carefully for the best fit.

When should you replace your lathe’s parts?

Replace parts if you notice strange sounds, vibrations, or if accuracy drops.

Tips for Improvement:

- Check the bearings first for wear.

- Upgrade the control panel for better usability.

Regular upgrades keep your lathe running smooth and accurate. Take care of your machine, and it will take care of you!

Conclusion

In conclusion, understanding the lathe headstock, bearing, and control panel is crucial for effective metal lathe use. These parts help your lathe run smoothly and accurately. By learning about them, you can improve your skills and projects. Remember to explore more tutorials or guides for deeper knowledge. Let’s keep making and learning together!FAQs

What Are The Common Types Of Bearings Used In Lathe Headstocks, And What Factors Influence Their Selection?In lathe headstocks, we often find ball bearings and roller bearings. Ball bearings are round and help things spin smoothly. Roller bearings are like small cylinders that can handle heavy loads. When choosing a bearing, we think about how much weight it will hold and how fast it needs to spin. These choices help the lathe work well and last a long time.

How Does The Design Of A Lathe Headstock Affect Precision Machining And The Longevity Of The Bearing?The headstock of a lathe is very important for making precise items. When it’s well designed, it helps the machine stay stable while working. This stability keeps the parts moving exactly as they should, so you get a better finish. A good design also helps the bearings last longer by reducing wear and tear. This means your lathe will work better and last for many years.

What Are The Essential Components Of A Lathe Control Panel, And How Do They Interact With The Headstock Bearing System?A lathe control panel has a few important parts. First, it has buttons to start and stop the machine. It also includes knobs to change how fast the lathe spins. These controls send signals to the headstock, which holds the spinning part. The headstock bearing system helps keep everything steady and smooth while it works.

How Can Vibration And Noise Levels In A Lathe Be Minimized, Particularly In Relation To The Headstock And Bearings?To make a lathe quieter and less shaky, we can do a few things. First, make sure the lathe is on a strong, flat surface. This helps keep it steady. Next, regularly check and oil the bearings to keep them smooth. We can also use special padding to absorb sound and vibration. Finally, if parts are worn out, we should replace them to keep everything working well.

What Maintenance Practices Are Recommended For Lathe Headstock Bearings To Ensure Optimal Performance And Prevent Mechanical Failure?To keep lathe headstock bearings working well, you should regularly clean them. Use a soft cloth to remove dust and dirt. You also need to check for oil and add more if it looks low. Make sure to listen for strange noises and fix any problems right away. This way, your lathe will work better and last longer!