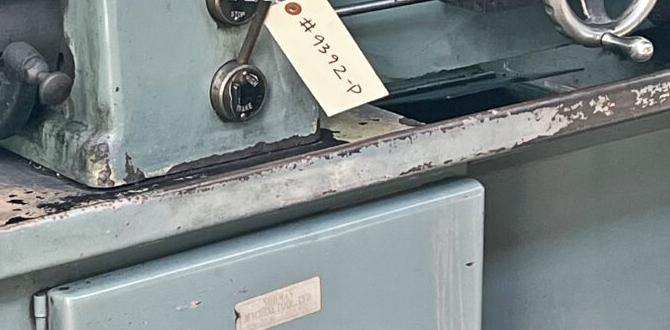

Have you ever wondered how metal lathes work? These amazing machines shape metal into useful parts. At the heart of a lathe is the headstock. It holds the motor, gears, and most importantly, the bearings. Without the right lathe headstock bearing, your machine can’t run smoothly.

The cross slide is another key part. It allows you to move the tool back and forth. The better the bearings, the easier it is to make precise cuts. Imagine trying to carve a sculpture with a dull knife. It’s tough, right? That’s why good bearings matter.

Did you know that with proper maintenance, your lathe can last for decades? Taking care of the headstock bearings keeps everything running smoothly. If you’re interested in learning more about how these parts fit together, this article will take you on a journey through their importance. Let’s dive in!

Lathe Headstock Bearing: Essential For Metal Lathe Cross Slide

Lathe Headstock Bearing and Metal Lathe Cross Slide

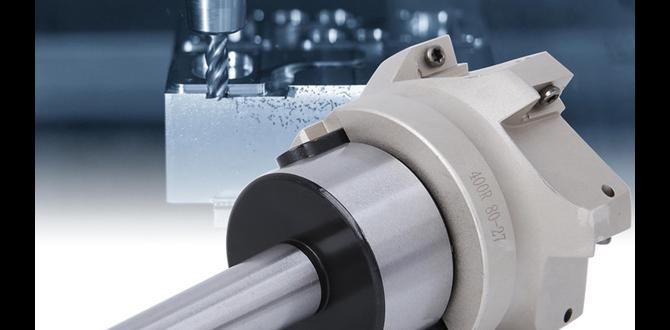

Ever wondered how a lathe works smoothly? The lathe headstock bearing holds the spindle steady for accurate cuts. It plays a crucial role in performance. The metal lathe cross slide allows you to move tools side to side. This movement is key for making precise grooves and shapes. Without these parts, achieving the perfect finish becomes tough. Understanding these components can enhance your woodworking and metalworking skills. Explore more to unlock new possibilities in crafting!What is a Lathe Headstock Bearing?

Definition and function of lathe headstock bearings. Types of bearings used in metal lathe headstocks.A lathe headstock bearing is a crucial part of a metal lathe. It holds the spindle in place, allowing it to rotate smoothly. Think of it as a supportive throne for your spinning royal! These bearings come in a few types, mostly ball bearings and roller bearings. Each type helps reduce friction and ensures precision. A good bearing keeps the lathe working like a charm, making those exciting chips of metal fly!

| Bearing Type | Function |

|---|---|

| Ball Bearings | Reduces friction for a smoother spin. |

| Roller Bearings | Handles heavier loads while maintaining speed. |

How Headstock Bearings Influence Metal Lathe Cross Slide Functionality

Relationship between headstock bear performance and cross slide accuracy. Impact of bearing quality on machining precision.The gears in a lathe might seem simple, but they depend heavily on headstock bearings. These bearings are like tiny superheroes, providing support and stability. Better bearings lead to a smoother operation, which means that the cross slide can move more precisely. This translates to better machining accuracy, allowing you to make cleaner cuts. Remember, if your bearings are worn out, you might end up with projects that look like they were made by a wobbly robot!

| Bearing Quality | Impact on Cross Slide |

|---|---|

| High Quality | Increased Precision |

| Medium Quality | Acceptable Accuracy |

| Low Quality | Unreliable Results |

Common Issues with Lathe Headstock Bearings

Typical problems faced with bearing wear and tear. Signs of failing bearings and their effects on lathe operation.Lathe headstock bearings can wear out over time. This wear causes common problems that affect how your lathe works. You might notice noise or vibrations while operating your machine. Additionally, uneven surfaces on your workpiece can signal trouble. Ignoring these signs may lead to more serious problems, halting your project. Here are typical issues:

- Noise from bearings

- Vibrations during operation

- Inconsistent cutting results

Fixing or replacing worn bearings is essential for smooth and accurate operation.

What are the signs of failing lathe headstock bearings?

Look for signs like unusual noise or vibrations. These can mean your bearings aren’t working well. Watch for uneven cuts and low quality in your work.

Choosing the Right Bearing for Your Metal Lathe

Factors to consider when selecting headstock bearings. Comparing different types of bearings for various lathe models.Picking the right bearing for your lathe can feel like choosing the right pizza topping—it’s important but can be confusing! First, consider factors like size and load. A heavy-duty job needs a tougher bearing. Comparing different types helps too; ball bearings are smooth, while roller bearings can handle heavy loads better. Here’s a simple table for a quick glimpse of your options:

| Type | Best For | Load Capacity |

|---|---|---|

| Ball Bearings | Speed | Light to Moderate |

| Roller Bearings | Heavy Loads | High |

| Magnetic Bearings | Precision | Variable |

So, next time you’re choosing bearings, keep these factors in mind. Remember, a good bearing can make all the difference in your metal lathe experience—nobody wants to stop midway!

Maintaining Lathe Headstock Bearings

Recommended maintenance practices for longevity. Tools and lubricants necessary for proper bearing care.To keep your lathe headstock bearings spinning smoothly, regular maintenance is key! First, clean the bearings gently. Use a soft cloth and a bit of lubricant. Think of it like giving your lathe a spa day! Grease and oil are your best friends here; they help reduce wear and tear. Don’t forget to check the alignment too—an unaligned bearing is like trying to dance with two left feet! Below is a handy table with some useful tools and lubricants for proper care.

| Tools | Lubricants |

|---|---|

| Soft cloth | Machine oil |

| Wrenches | Grease |

| Screwdrivers | Light oil |

Following these practices can help extend the life of your bearings. Remember, a little care goes a long way! So, keep your tools happy, and they’ll keep you happy too!

Installing and Replacing Lathe Headstock Bearings

Stepbystep guide for installation. Common mistakes to avoid during replacement.Installing lathe headstock bearings can seem tricky. Here’s a simple step-by-step guide to help. First, turn off the lathe and unplug it. Next, remove the old bearings. Clean the area carefully. Then, place the new bearings in their spot. Finally, secure everything tightly and test the lathe.

Watch out for these common mistakes:

- Not cleaning the area before installing.

- Forgetting to unplug the machine.

- Using the wrong type of bearing.

What should I check before replacing the bearings?

Check for wear and dirt. Make sure to have the right size parts.

Keep these tips in mind for a successful installation!

Future Trends in Lathe Headstock Bearing Technology

Innovations in bearing materials and design. The impact of technology on lathe performance and efficiency.Exciting changes are coming to lathe headstock bearing technology. Innovations in bearing materials lead to stronger and lighter options. This means lathes can work better and last longer. Technology boosts lathe performance, making tasks faster and easier. Think of high-tech sensors that help detect problems before they happen.

- New materials reduce friction.

- Better designs improve stability.

- Sensors enhance monitoring and control.

What are the benefits of new lathe bearings?

The benefits of new lathe bearings include longer tool life, reduced maintenance, and improved efficiency. This helps save time and costs in the workshop.

Conclusion

In summary, the lathe headstock and bearing keep your metal lathe running smoothly. The cross slide helps you position your workpiece accurately. Understanding these parts helps you improve your skills. You can explore more about lathe maintenance and operation. Remember, practice makes perfect, so don’t hesitate to keep experimenting with your lathe! Happy machining!FAQs

Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing, Metal Lathe, And Cross Slide:The headstock bearing is a part of a metal lathe. It helps the spinning piece of metal move smoothly. The cross slide holds tools and lets you move them side to side. This helps make shapes and cuts on the metal. With the right parts, your lathe works better!

Sure! Please ask me a question, and I’ll be happy to help you with a short answer.

What Are The Primary Functions Of The Headstock Bearing In A Metal Lathe, And How Do They Affect Machining Accuracy?The headstock bearing in a metal lathe helps support the spindle, which spins the metal. It keeps everything steady while you work. When the bearing is strong, your cuts are more accurate. If it’s weak, the metal can wobble, making it hard to create smooth shapes. So, a good bearing helps you make better parts!

How Can One Determine Whether The Bearings In The Headstock Of A Lathe Need To Be Replaced Or Repaired?You can check the bearings by listening for loud noises while the lathe is running. If you feel rough spots when you turn the spindle, that’s a sign. You can also look for vibrations or wobbly parts. If you notice any of these issues, it might be time to replace or repair the bearings.

What Are The Common Types Of Cross Slide Designs In Metal Lathes, And How Do They Influence The Lathe’S Performance?There are a few common types of cross slide designs in metal lathes. The most popular types are flat slide, dovetail slide, and box slide. Flat slides are easy to use and give good movement. Dovetail slides are strong and hold the tools steady. Box slides are very sturdy and help with heavy cutting. Each design helps the lathe work better, making it more precise and easier to control.

What Maintenance Practices Should Be Followed To Ensure The Longevity Of Headstock Bearings In A Metal Lathe?To help headstock bearings in a metal lathe last longer, you should keep them clean. Regularly check for dirt or dust and wipe them down. It’s important to apply the right oil to keep them moving smoothly. Make sure the lathe is leveled, so everything works correctly. Finally, don’t run the lathe too fast, as it can wear out the bearings.

How Does The Material Of The Bearings In A Lathe Headstock Impact The Overall Efficiency And Precision Of Operations?The material of the bearings in a lathe headstock is really important. Strong materials help reduce wear and tear, which keeps everything running smoothly. If the bearings are smooth, the lathe can spin quickly and accurately. This means you can make better, cleaner cuts on your projects. Good materials help us work faster and with more precision.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing, Metal Lathe, And Cross Slide:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The headstock bearing is a part of a metal lathe. It helps the spinning piece of metal move smoothly. The cross slide holds tools and lets you move them side to side. This helps make shapes and cuts on the metal. With the right parts, your lathe works better!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask me a question, and I’ll be happy to help you with a short answer.”}},{“@type”: “Question”,”name”: “What Are The Primary Functions Of The Headstock Bearing In A Metal Lathe, And How Do They Affect Machining Accuracy?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The headstock bearing in a metal lathe helps support the spindle, which spins the metal. It keeps everything steady while you work. When the bearing is strong, your cuts are more accurate. If it’s weak, the metal can wobble, making it hard to create smooth shapes. So, a good bearing helps you make better parts!”}},{“@type”: “Question”,”name”: “How Can One Determine Whether The Bearings In The Headstock Of A Lathe Need To Be Replaced Or Repaired?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can check the bearings by listening for loud noises while the lathe is running. If you feel rough spots when you turn the spindle, that’s a sign. You can also look for vibrations or wobbly parts. If you notice any of these issues, it might be time to replace or repair the bearings.”}},{“@type”: “Question”,”name”: “What Are The Common Types Of Cross Slide Designs In Metal Lathes, And How Do They Influence The Lathe’S Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “There are a few common types of cross slide designs in metal lathes. The most popular types are flat slide, dovetail slide, and box slide. Flat slides are easy to use and give good movement. Dovetail slides are strong and hold the tools steady. Box slides are very sturdy and help with heavy cutting. Each design helps the lathe work better, making it more precise and easier to control.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Followed To Ensure The Longevity Of Headstock Bearings In A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To help headstock bearings in a metal lathe last longer, you should keep them clean. Regularly check for dirt or dust and wipe them down. It’s important to apply the right oil to keep them moving smoothly. Make sure the lathe is leveled, so everything works correctly. Finally, don’t run the lathe too fast, as it can wear out the bearings.”}},{“@type”: “Question”,”name”: “How Does The Material Of The Bearings In A Lathe Headstock Impact The Overall Efficiency And Precision Of Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The material of the bearings in a lathe headstock is really important. Strong materials help reduce wear and tear, which keeps everything running smoothly. If the bearings are smooth, the lathe can spin quickly and accurately. This means you can make better, cleaner cuts on your projects. Good materials help us work faster and with more precision.”}}]}