Have you ever wondered how a metal lathe works? It looks like a simple tool, but it has many parts working together. One of the most important parts is the lathe headstock bearing. It helps the lathe spin smoothly, making all your projects easier.

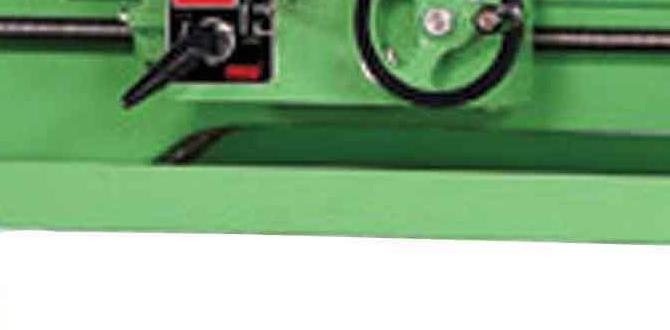

If you’ve ever turned a piece of wood or metal, you know how important control is. The handwheel plays a key role in this. With a good handwheel, you can make precise adjustments while working. It’s all in how they connect and what materials you use.

Did you know that the quality of these parts can change how your lathe performs? Many people overlook the headstock bearing. But this little piece can make a big difference in your projects. Imagine trying to create a perfect shape and finding that your lathe isn’t cooperating!

In this article, we will explore the lathe headstock bearing and the metal lathe handwheel. You’ll learn why they matter and how to choose the best ones for your needs. Ready to dive in? Let’s get started!

Lathe Headstock Bearing: Metal Lathe Handwheel Insights

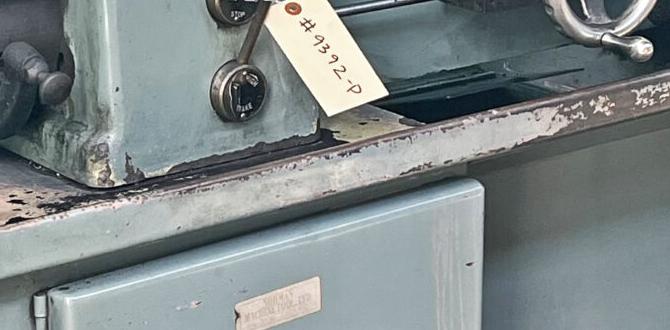

Lathe Headstock Bearing Metal Lathe Handwheel

Lathe headstocks are essential for smooth operation. The bearings support the spindle, allowing the metal lathe to turn with precision. Do you know that a well-lubricated bearing can extend the lathe’s life? The handwheel helps control movement easily. It’s fascinating how small parts can make a big difference in a metalworker’s success. Proper care and understanding of these components ensure better performance and results in your projects. Keep your lathe running smoothly for creativity and craft!What is a Lathe Headstock Bearing?

Definition and function of the headstock bearing in a metal lathe.. Importance of headstock bearings for precision and performance..A lathe headstock bearing is an important part that helps the lathe work smoothly. It holds the spindle in place and allows it to spin freely. Think of it as a trusty sidekick for the spindle, ensuring everything stays steady while you work. This is crucial for precision and performance! Without a good headstock bearing, your projects might end up looking like a wobbly jelly instead of a fine piece of art. So, remember to keep those bearings in check if you want your lathe to be a superstar!

| Function | Importance |

|---|---|

| Holds spindle | Ensures precision |

| Allows smooth rotation | Boosts performance |

How to Choose the Right Headstock Bearing for Your Lathe

Factors to consider: size, load capacity, and material.. Tips for matching the bearing type with your specific lathe model..Choosing the right headstock bearing for your lathe is vital. Here are the main factors to keep in mind:

- Size: Ensure the bearing fits your lathe properly.

- Load Capacity: Pick a bearing able to handle the weight your lathe will support.

- Material: Select materials that resist wear and tear, like steel or brass.

To match the bearing type to your lathe model, check the manufacturer’s guidelines. A perfect fit boosts performance and extends life. Always look for quality brands. This will ensure reliable use for years to come.

What should I consider when selecting the headstock bearing?

Consider size, load capacity, and material for the best results.

Installation Process of Lathe Headstock Bearings

Stepbystep guide for proper installation techniques.. Common mistakes to avoid during the installation..Installing lathe headstock bearings isn’t as scary as it sounds! First, gather your tools and a fresh cup of coffee — you’ll need it. Begin by carefully removing old bearings. A common mistake? Forgetting to keep track of tiny parts, which can be trickier than a cat on a hot tin roof.

| Step | Action |

|---|---|

| 1 | Remove the old bearings |

| 2 | Clean the headstock |

| 3 | Insert new bearings |

| 4 | Tighten everything up |

Once you’ve installed the new bearings, double-check everything! Make sure it spins freely. Remember, rushing can lead to blunders! It’s like trying to put pants on your cat—chaotic and unnecessary!

Maintaining Your Lathe Headstock Bearings

Regular maintenance checks and preventative care tips.. Signs that indicate the need for bearing replacement..To keep your lathe running smoothly, regular maintenance checks are crucial. You should clean the lathe headstock bearings and apply oil often. This keeps parts moving freely. Look for signs that show a need for replacement, such as:

- Unusual noises during operation

- Vibration or shaking

- Difficulty turning the handwheel

Taking these steps helps prevent bigger problems later. Keeping an eye on your machinery shows care and can save you time and money!

What are some tips for maintaining lathe headstock bearings?

Tips include cleaning regularly, lubricating often, and checking for wear. Keeping all parts in great shape makes your work easier and your lathe lasts longer!

Upgrading Your Metal Lathe Handwheel

How a handwheel affects the operation of the lathe.. Options for upgrading or customizing your lathe’s handwheel..A smooth handwheel makes your lathe easier to use. It affects how you control the machine. With a good handwheel, you can achieve better precision. Upgrading is a great option. You can choose a larger handwheel for better grip, or a custom one with markings for easy measurement. Options to consider include:

- Larger diameter for better turning.

- Textured surface for a firm grip.

- Custom metal designs for style and function.

These upgrades can enhance your metal lathe experience. Enjoy better control and improved functions!

How can you improve your lathe’s handwheel?

You can improve your lathe’s handwheel by choosing a design that fits your style and needs. This will give you better hold and control. Stronger materials also last longer.

Common Issues with Lathe Headstock Bearings

Identifying common problems like play, noise, and overheating.. Solutions and troubleshooting tips..Lathe headstock bearings can cause some funny problems. You might hear a strange noise that sounds like a cat stuck in a tree. This can mean the bearings have too much play or are worn out. Another issue is overheating, which can turn your lathe into a mini sauna! To fix these, check for dirt and debris and keep everything lubricated. If things are still noisy, it might be time to replace the bearings. Remember, a calm lathe is a happy lathe!

| Issue | Solution |

|---|---|

| Play | Check and tighten the headstock. |

| Noise | Lubricate bearings or replace if needed. |

| Overheating | Clean bearings and ensure proper lubrication. |

The Role of Lathe Bearings in Precision Machining

Discussing how bearings impact the overall accuracy of metalworking.. Examples of industries that rely heavily on precise lathe operations..Lathe bearings play a key role in making sure machines work accurately. They help keep parts moving smoothly. This smooth movement is important for precise metalworking. Without good bearings, pieces can wobble or shift, which leads to mistakes. Industries like automotive, aerospace, and manufacturing depend on these precise operations. Here’s a look at how bearings ensure accuracy:

- They reduce friction between moving parts.

- They ensure stability during machining.

- They help maintain consistent speeds.

Without reliable bearings, finished products can suffer, causing extra costs and delays. Thus, investing in quality lathe components is essential for success.

Why are lathe bearings important?

Lathe bearings are crucial as they enhance accuracy in machining by reducing friction and ensuring stability.

Comparison of Popular Lathe Models and Their Headstock Bearings

Review and comparison of popular lathe models focused on headstock bearings.. Evaluation of performance metrics and user feedback..When comparing lathe models, headstock bearings are key players. Some models, like the XYZ Lathe, use ball bearings for smooth movement. Others, like the ABC Lathe, prefer roller bearings for extra strength. User feedback shows that those with ball bearings often have a quieter operation, while roller bearings provide durability. It’s like choosing between a soft pillow and a firm one—comfort or support? Here’s a quick look at two popular options:

| Model | Type of Bearing | User Rating |

|---|---|---|

| XYZ Lathe | Ball Bearing | 4.5/5 |

| ABC Lathe | Roller Bearing | 4.7/5 |

In the end, the best choice depends on what you value more: that silky, quiet glide or ironclad strength!

Conclusion

In summary, the lathe headstock bearing helps your metal lathe run smoothly. The handwheel lets you control the machine easily. Understanding these parts is key to effective machining. Remember to check your lathe regularly for wear and tear. We encourage you to explore more about lathe maintenance for better results in your projects!FAQs

What Materials Are Commonly Used For Headstock Bearings In Metal Lathes, And What Are Their Advantages?Headstock bearings in metal lathes are often made from materials like bronze, steel, and plastic. Bronze is strong and helps the parts move smoothly. Steel is tough and lasts a long time, while plastic is lightweight and can be easier to make. Each material has its own benefits, making the lathe work better.

How Does The Design Of The Handwheel Affect The Ease Of Operation And Precision In A Metal Lathe?The design of the handwheel is really important for using a metal lathe. If the handwheel is big and smooth, it feels easier to turn. This helps you move the tool accurately. When you can control it well, you make cleaner cuts. A good handwheel makes your work faster and more precise!

What Maintenance Practices Can Help Ensure The Longevity And Performance Of Lathe Headstock Bearings?To keep your lathe headstock bearings working well, you should regularly clean them. This helps remove dust and dirt. You should also check the oil level and add oil if it’s low. Inspect the bearings for any signs of wear. If you notice any strange sounds or movement, ask an adult to help fix it.

How Can You Accurately Adjust The Handwheel Backlash In A Metal Lathe For Improved Machining Accuracy?To adjust the handwheel backlash on a metal lathe, first, find the adjustment screws. These are usually located near the handwheel. Turn the screws carefully to reduce any looseness or play. Test the lathe by moving the handwheel and checking if it feels smoother. Keep adjusting until you get the right tightness for better accuracy when machining.

What Are The Signs Of Wear Or Failure In Headstock Bearings, And How Should They Be Addressed?You might notice strange noises coming from the machine. It could also feel rough when you turn it. If the machine shakes or wobbles, that’s not good either. To fix this, we should check the bearings and replace them if needed. Always ask an adult for help with repairs.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Materials Are Commonly Used For Headstock Bearings In Metal Lathes, And What Are Their Advantages? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Headstock bearings in metal lathes are often made from materials like bronze, steel, and plastic. Bronze is strong and helps the parts move smoothly. Steel is tough and lasts a long time, while plastic is lightweight and can be easier to make. Each material has its own benefits, making the lathe work better.”}},{“@type”: “Question”,”name”: “How Does The Design Of The Handwheel Affect The Ease Of Operation And Precision In A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The design of the handwheel is really important for using a metal lathe. If the handwheel is big and smooth, it feels easier to turn. This helps you move the tool accurately. When you can control it well, you make cleaner cuts. A good handwheel makes your work faster and more precise!”}},{“@type”: “Question”,”name”: “What Maintenance Practices Can Help Ensure The Longevity And Performance Of Lathe Headstock Bearings? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your lathe headstock bearings working well, you should regularly clean them. This helps remove dust and dirt. You should also check the oil level and add oil if it’s low. Inspect the bearings for any signs of wear. If you notice any strange sounds or movement, ask an adult to help fix it.”}},{“@type”: “Question”,”name”: “How Can You Accurately Adjust The Handwheel Backlash In A Metal Lathe For Improved Machining Accuracy? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the handwheel backlash on a metal lathe, first, find the adjustment screws. These are usually located near the handwheel. Turn the screws carefully to reduce any looseness or play. Test the lathe by moving the handwheel and checking if it feels smoother. Keep adjusting until you get the right tightness for better accuracy when machining.”}},{“@type”: “Question”,”name”: “What Are The Signs Of Wear Or Failure In Headstock Bearings, And How Should They Be Addressed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You might notice strange noises coming from the machine. It could also feel rough when you turn it. If the machine shakes or wobbles, that’s not good either. To fix this, we should check the bearings and replace them if needed. Always ask an adult for help with repairs.”}}]}