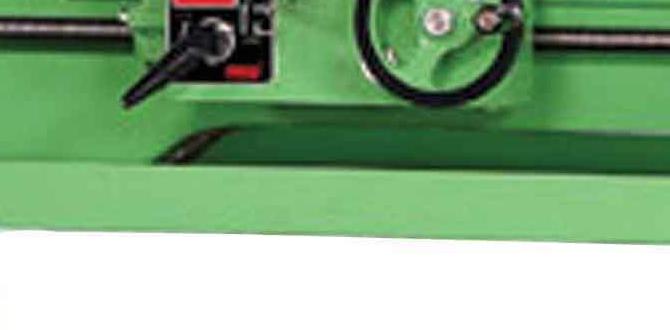

Have you ever wondered how a metal lathe machine works? It’s fascinating! At the heart of this machine is the lathe headstock. This part holds the spindle, guiding the workpiece as it spins. But what keeps it running smoothly? The answer lies in the headstock bearing.

Imagine trying to ride a bike with wobbly wheels. It would be difficult, right? The same goes for a lathe machine. The lathe headstock bearing is essential for stability and precision. Proper bearings help reduce friction and wear, ensuring a smooth operation.

Did you know that a well-maintained metal lathe machine can last for decades? Regular checks on the lathe headstock bearing can make all the difference. So, why not dive deeper into this important part? You might find out how to extend the life of your lathe and improve your projects!

Understanding Lathe Headstock Bearing In Metal Lathe Machine Metal Lathe Machines Are Essential Tools In Various Manufacturing And Machining Processes, Allowing Craftsmen To Shape And Modify Metal Components With Precision. One Of The Critical Components Of A Metal Lathe Machine Is The Headstock Bearing, Which Plays A Vital Role In The Machine’S Performance And Longevity. In This Article, We Will Explore The Function Of Lathe Headstock Bearings, Their Types, And How They Can Affect The Overall Efficiency Of Your Metal Lathe Machine. What Is A Lathe Headstock Bearing? The Lathe Headstock Bearing Is A Crucial Part Of The Lathe That Supports The Spindle, Allowing It To Rotate Smoothly While Minimizing Friction And Wear. The Quality And Type Of Bearing Used Can Significantly Impact The Accuracy, Speed, And Reliability Of The Lathe Machine. Types Of Lathe Headstock Bearings Lathe Headstock Bearings Come In Various Types, Including: 1. **Ball Bearings**: These Are Common In Many Lathe Machines Due To Their Ability To Reduce Friction Efficiently. They Are Ideal For High-Speed Applications. 2. **Roller Bearings**: These Bearings Are Known For Their Ability To Handle Heavy Loads And Are Often Used In Industrial Lathes. They Provide A Larger Contact Area, Improving Stability. 3. **Plain Bearings (Sleeve Bearings)**: These Bearings Offer Minimal Friction By Relying On Sliding Contact. They Are Often Used In Lower-Speed Applications. Importance Of Quality Bearings Using High-Quality Lathe Headstock Bearings Is Essential For The Following Reasons: – **Precision Machining**: The Bearings Directly Influence The Spindle’S Alignment And Smooth Operation, Which Is Critical For Achieving Accurate Cuts. – **Increased Longevity**: Quality Bearings Can Withstand Wear And Stress, Extending The Life Of The Lathe Machine. – **Operational Efficiency**: Bearings That Perform Well Contribute To Smoother Operations, Reducing Downtime And Maintenance Costs. Maintenance Tips For Lathe Headstock Bearings To Ensure The Longevity And Performance Of Your Lathe Headstock Bearings, Follow These Maintenance Tips: – **Regular Inspection**: Periodically Check For Signs Of Wear Or Damage, Such As Unusual Noises Or Vibrations During Operation. – **Proper Lubrication**: Ensure That Bearings Are Maintained With The Appropriate Lubricant, Which Helps Reduce Friction And Wear. – **Dust And Debris Prevention**: Keep The Lathe Machine Clean And Free From Dust And Debris That May Affect Bearing Performance. Conclusion Understanding The Role Of Lathe Headstock Bearings In Metal Lathe Machines Is Fundamental For Anyone Looking To Optimize Their Machining Operations. By Selecting The Right Type Of Bearing And Adhering To Proper Maintenance Practices, Machinists Can Enhance The Performance And Lifespan Of Their Lathe Machines. Whether You’Re A Hobbyist Or A Professional, Ensuring Optimal Bearing Functionality Will Translate Into Better Precision And Efficiency In Your Projects.

Lathe Headstock Bearing: Essential for Metal Lathe Machines

Lathe headstock bearings play a vital role in metal lathe machines. They support the spindle, allowing it to rotate smoothly. If the bearings wear out, it can lead to inaccuracies in cutting metal. Did you know that even a slight misalignment can ruin a workpiece? Regular maintenance and lubrication of these bearings can extend their life. Choosing the right type of bearing enhances performance and precision. Understanding their importance is key for any metalworking enthusiast.What is a Lathe Headstock Bearing?

Definition and purpose of headstock bearings in lathe machines. Different types of lathe headstock bearings.A lathe headstock bearing is a crucial part of a lathe machine. It supports the spindle and allows it to rotate smoothly. This helps create precise shapes on metal or wood. There are different types of headstock bearings, mainly:

- Plain Bearings

- Ball Bearings

- Roller Bearings

Each type has its own benefits. For instance, ball bearings are great for high-speed tasks, while plain bearings are simple and reliable.

What is the purpose of lathe headstock bearings?

They provide support and reduce friction during operation, ensuring accurate machining.

Importance of Quality Bearings in Metal Lathes

The role of bearings in machine performance and accuracy. Impact of bearing quality on longevity and maintenance.Bearings are vital parts of metal lathes. They help the machine spin smoothly. Quality bearings ensure better performance and accuracy. If they are good, your projects will look neat and precise. Poor bearings can lead to problems over time. They may wear out quickly and need more repairs. Here’s why quality matters:

- Improved machine performance: Better bearings help the lathe run faster and more accurately.

- Longer lifespan: Quality bearings last longer, saving you money on replacements.

- Less maintenance: Good bearings reduce breakdowns, meaning less hassle for you.

Why do bearings matter in a metal lathe machine?

Bearings ensure smooth operation and accurate results. Quality bearings lead to fewer repairs, helping your metal lathe work better and last longer.

How to Choose the Right Headstock Bearing

Key factors to consider when selecting bearings. Importance of compatibility with lathe specifications.Choosing the right bearing for your lathe is like picking the best dance partner. You want a good match to avoid stepping on toes! First, check compatibility with your machine’s specifications. Mismatched parts can lead to a wobbly performance. Next, consider load capacity and material. A sturdy bearing will last longer and keep your lathe running smoothly. Remember, not all bearings are created equal, and a little research goes a long way!

| Factor | Importance |

|---|---|

| Compatibility | Ensures smooth operation |

| Load Capacity | Prevents premature wear |

| Material | Determines durability |

Common Issues with Lathe Headstock Bearings

Signs of wear and tear in bearings. Troubleshooting tips for common bearing problems.Lathe headstock bearings can face problems over time. Look for signs like unusual noises, wobbling parts, or increased vibrations. These signals mean wear and tear is happening. Regular checks can help catch issues early.

Here are some tips to troubleshoot common problems:

- Listen for strange sounds.

- Check for tightness or looseness.

- Inspect for rust or dirt buildup.

- Lubricate regularly to reduce friction.

Taking care of these bearings means smoother operation for your lathe machine.

What are signs of bad bearings?

Watch for noise, vibration, or heat. These are all clues something is wrong.

How can I fix bearing issues?

Start by cleaning and lubricating them. If problems persist, consider replacing them.

Maintenance Tips for Longevity of Headstock Bearings

Recommended lubrication practices. Routine checks and replacements.Keeping headstock bearings in top shape is key for a metal lathe machine. First, always remember to apply the right kind of lubrication. Think of it like giving your lathe a nice spa day. Use quality oil, and make sure to check it often—like a birthday reminder but for your machine! Routine checks can catch small problems before they become big headaches.

| Tip | Frequency |

|---|---|

| Lubricate Bearings | Every 25 hours |

| Check for Wear | Weekly |

| Replace Bearings | Every 1-3 years |

Being proactive can save time and money. Think of it like cleaning your room—avoid the mess before it happens!

Upgrading vs. Replacing Headstock Bearings

When to consider upgrading bearing types. Costbenefit analysis of replacement vs. upgrading options.Updating your lathe’s headstock bearings can save you time and money. If your bearings are worn out, upgrading to better types can improve machine performance. Think about cost-effectiveness—replacing old bearings might cost less, but a good upgrade can last longer and work better. Be like a wise owl: a small investment in quality might prevent future headaches.

| Option | Cost | Longevity | Performance |

|---|---|---|---|

| Replacement | Lower | Short-term | Standard |

| Upgrading | Higher | Long-term | Enhanced |

Choosing wisely means considering both options. You want your lathe to spin like a well-oiled party. After all, nobody likes a squeaky machine!

Case Studies: Bearing Performance in Metal Lathes

Examples of successful bearing implementations. Lessons learned from bearing failures in metal lathes.Many machine shops have stories about their bearings. The good examples show how strong bearings keep lathes running well. For instance, there was a shop that used top-quality bearings. They reported less downtime and smoother operations. But not every story is great! Some shops faced trouble with cheap bearings, leading to *grinding* noises and major headaches. In fact, one shop learned that a poor choice cost them over $5,000 in repairs!

| Case Study | Outcome |

|---|---|

| High-Quality Bearings | Less downtime, smooth operations |

| Poor Quality Choice | Major repairs, grinding noises |

These cases remind us that good bearings make all the difference. Choose wisely and save your wallet from *yelling* at you later!

Conclusion

In summary, the lathe headstock bearing is crucial for a metal lathe machine. It supports the spindle and ensures smooth rotation. Understanding this part helps you maintain your lathe better. Remember to check the bearings regularly for wear and tear. For more tips on lathe maintenance, consider reading guides or watching tutorial videos. Keep learning and improve your skills!FAQs

What Types Of Bearings Are Commonly Used In The Headstock Of A Metal Lathe Machine, And How Do They Differ In Application And Performance?In the headstock of a metal lathe machine, we usually find two types of bearings: ball bearings and plain bearings. Ball bearings have small balls inside that help them roll smoothly. They work well for high-speed spinning. Plain bearings, on the other hand, are simpler and often use a sliding motion, which is good for heavy loads but not as fast. Each type helps the machine run in different ways, depending on the job you need to do.

How Does The Condition Of The Headstock Bearings Affect The Precision And Accuracy Of A Metal Lathe’S Machining Operations?The headstock bearings are like the wheels on a bike. If they’re in good shape, they help the lathe spin smoothly. This makes our cuts cleaner and more exact. If the bearings are worn out, the lathe might shake or wobble. That can mess up our work and make it less accurate.

What Are The Signs Of Wear Or Failure In Lathe Headstock Bearings, And How Can These Issues Be Diagnosed And Addressed?You can spot wear or failure in lathe headstock bearings by listening for strange noises. If the lathe vibrates or the spindle feels rough, those are warning signs too. To check, you can move the spindle gently and feel for any play or looseness. If you find problems, we should replace the bearings. Regular maintenance helps catch these issues early!

How Do Lubrication Methods For Headstock Bearings Impact The Longevity And Efficiency Of A Metal Lathe Machine?Lubrication helps keep headstock bearings running smoothly. When we use the right oil, the machine works better and lasts longer. Good lubrication reduces friction, which can wear out parts. If we take care of the bearings, our metal lathe will be more efficient and need fewer repairs. This means we save time and money!

What Parameters Should Be Considered When Selecting Replacement Bearings For The Headstock Of A Metal Lathe?When choosing new bearings for a metal lathe, we should think about a few important things. First, the size of the bearings needs to match the old ones. Next, we consider the type of material, like steel or ceramics, which affects how strong they are. We also check how fast they can spin without breaking. Lastly, look at how well they can handle heat and dirt. These points help us pick the best bearings for our lathe.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Types Of Bearings Are Commonly Used In The Headstock Of A Metal Lathe Machine, And How Do They Differ In Application And Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In the headstock of a metal lathe machine, we usually find two types of bearings: ball bearings and plain bearings. Ball bearings have small balls inside that help them roll smoothly. They work well for high-speed spinning. Plain bearings, on the other hand, are simpler and often use a sliding motion, which is good for heavy loads but not as fast. Each type helps the machine run in different ways, depending on the job you need to do.”}},{“@type”: “Question”,”name”: “How Does The Condition Of The Headstock Bearings Affect The Precision And Accuracy Of A Metal Lathe’S Machining Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The headstock bearings are like the wheels on a bike. If they’re in good shape, they help the lathe spin smoothly. This makes our cuts cleaner and more exact. If the bearings are worn out, the lathe might shake or wobble. That can mess up our work and make it less accurate.”}},{“@type”: “Question”,”name”: “What Are The Signs Of Wear Or Failure In Lathe Headstock Bearings, And How Can These Issues Be Diagnosed And Addressed? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can spot wear or failure in lathe headstock bearings by listening for strange noises. If the lathe vibrates or the spindle feels rough, those are warning signs too. To check, you can move the spindle gently and feel for any play or looseness. If you find problems, we should replace the bearings. Regular maintenance helps catch these issues early!”}},{“@type”: “Question”,”name”: “How Do Lubrication Methods For Headstock Bearings Impact The Longevity And Efficiency Of A Metal Lathe Machine? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lubrication helps keep headstock bearings running smoothly. When we use the right oil, the machine works better and lasts longer. Good lubrication reduces friction, which can wear out parts. If we take care of the bearings, our metal lathe will be more efficient and need fewer repairs. This means we save time and money!”}},{“@type”: “Question”,”name”: “What Parameters Should Be Considered When Selecting Replacement Bearings For The Headstock Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing new bearings for a metal lathe, we should think about a few important things. First, the size of the bearings needs to match the old ones. Next, we consider the type of material, like steel or ceramics, which affects how strong they are. We also check how fast they can spin without breaking. Lastly, look at how well they can handle heat and dirt. These points help us pick the best bearings for our lathe.”}}]}