Have you ever wondered how metal lathes work smoothly? The secret often lies in the lathe headstock bearing. This small part plays a big role in how well your lathe performs. Regular maintenance can keep your machine running for years.

Imagine using a lathe for your project. Suddenly, it starts to make strange noises. It might be an easy fix if you pay attention to the headstock bearing.

Did you know that even a tiny bit of dirt can cause problems? Keeping the bearing clean is just one part of proper maintenance. This simple task can improve performance and extend the life of your lathe.

In this article, we’ll explore tips for lathe headstock bearing metal lathe maintenance. You’ll learn how to keep your machine in top shape. Get ready to dive into some helpful advice that will make your projects more enjoyable!

Lathe Headstock Bearing: Essential Metal Lathe Maintenance

Lathe Headstock Bearing Metal Lathe Maintenance

Keeping your lathe’s headstock bearing in good shape is essential for smooth operation. Regular maintenance helps avoid costly repairs. Did you know that even a bit of dirt can cause significant issues? Start by cleaning the bearings regularly. Use the right lubricant to reduce friction. Check for wear and replace parts as needed. A well-maintained lathe provides better accuracy and a longer life. Wouldn’t it be nice to work without unexpected troubles?Understanding Lathe Headstock Bearings

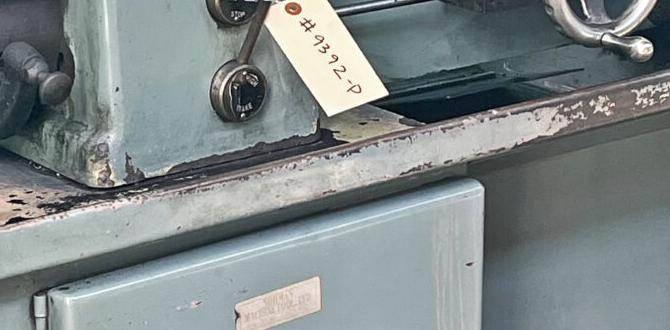

Definition and function of headstock bearings. Types of bearings commonly used in metal lathes.Headstock bearings are crucial parts of a lathe. They help the spindle spin smoothly, like oil on popcorn! These bearings come in different types. Some common ones include ball bearings and sleeve bearings. Ball bearings are like tiny spinning friends, while sleeve bearings hug the spindle closely. Choosing the right one helps keep your lathe running happily. A well-maintained lathe can last for years, almost as long as your favorite superhero movie marathon!

| Type of Bearing | Description |

|---|---|

| Ball Bearing | Tiny balls that help with smooth spinning. |

| Sleeve Bearing | Clings close to the spindle for stability. |

Importance of Maintenance for Lathe Headstock Bearings

Impact of proper maintenance on lathe performance. Consequences of neglecting bearing maintenance.Keeping lathe headstock bearings in tip-top shape is like giving your machine a warm hug! Proper maintenance makes your lathe run smoothly and efficiently, preventing those pesky vibrations and noise. Neglecting this maintenance, however, can lead to serious issues. You might face uneven cuts or even a complete breakdown. Yikes! Think of it like forgetting to feed your pet – your lathe won’t perform if it’s not cared for.

| Maintenance Impact | Neglect Consequences |

|---|---|

| Improves performance | Causes vibrations |

| Extends lifespan | Leads to breakdowns |

| Ensures precision | Creates uneven cuts |

So, treat your lathe with love. Remember, a happy lathe makes for happy projects!

Signs Your Lathe Headstock Bearings Need Attention

Common symptoms indicating bearing wear or damage. Regular inspection practices to identify issues.Many signs show that your lathe headstock bearings need help. Look out for strange noises or vibrations while using the lathe. If your projects don’t turn out smooth, that’s another clue. Regular inspections can help spot these problems early. Check for:

- Noise during operation

- Unusual vibration

- Inconsistent cutting quality

Taking action quickly can prevent bigger problems. Keep your lathe running well!

How can I tell if my lathe bearings are worn?

Watch for replacements of bearings every 1,000 hours of use.

Tools and Materials Needed for Maintenance

Essential tools for lathe headstock bearing maintenance. Recommended lubricants and cleaning materials.Keeping your lathe headstock in tip-top shape requires some handy tools and materials. First, every toolbox needs a set of wrenches and screwdrivers to tighten loose parts. Don’t forget grease or oil for lubrication; they’re the lifeblood of your machine. A clean, lint-free cloth helps get rid of dirt. Oh, and a brush? It’s perfect for those hard-to-reach spots! Check out the essentials in the table below:

| Tool/Material | Purpose |

|---|---|

| Wrenches | Tighten bolts |

| Screwdrivers | Adjust parts |

| Grease/Oil | Lubrication |

| Lint-Free Cloth | Cleaning |

| Brush | Dust removal |

With these tools in hand, maintenance becomes easier. Remember, a little care makes your lathe run like a dream!

Step-by-Step Maintenance Process for Lathe Headstock Bearings

Detailed instructions for cleaning and lubricating bearings. Removing and replacing worn bearings.Keeping your lathe headstock bearings in good shape is vital for smooth operation. Here’s how to maintain them effectively:

- Cleaning the Bearings: Use a soft cloth and a cleaning solution. Wipe away dirt and old grease.

- Lubricating: Apply fresh grease to the bearings. This helps them move easily.

- Removing Worn Bearings: Carefully take out the old bearings. Use a bearing puller if needed.

- Replacing Bearings: Insert the new bearings firmly. Make sure they fit snugly.

Regular maintenance keeps your lathe running smoothly and extends its life. Let’s keep your projects moving forward!

How do I clean and lubricate lathe headstock bearings?

Clean the bearings with a soft cloth, then apply fresh grease to ensure smooth operation.

What should I do if my lathe bearings are worn?

Remove the old bearings and replace them with new ones for best performance.

Common Mistakes to Avoid in Lathe Headstock Maintenance

Frequent errors that can lead to bearing damage. Best practices to ensure longlasting performance.Many people overlook simple steps in lathe headstock maintenance. These common mistakes can damage your precious bearings. For example, failing to clean the bearings regularly can lead to grime buildup. Yikes! This might sound funny, but a dirty bearing is like trying to run a race in muddy shoes.

Another error is using the wrong lubricant. Always check your machine’s manual for the proper type. Using the wrong oil is like putting ketchup on ice cream – not a good idea! Regularly inspecting and replacing worn bearings can keep your lathe running smoothly.

| Common Mistakes | Best Practices |

|---|---|

| Skipping regular cleaning | Clean bearings frequently |

| Using incorrect lubricants | Follow the manual’s recommendations |

| Ignoring wear signs | Inspect bearings regularly |

Keeping these tips in mind will help your lathe last longer and run better. Remember, a happy lathe makes for a smooth workday!

Advanced Maintenance Tips for Experienced Users

Techniques for enhancing bearing longevity. Upgrading bearings for improved performance.To keep your lathe running smoothly, try these expert tips. Start with regular cleanings. Dust and grime can harm your bearings. You can also use high-quality lubricants to reduce wear. This helps to extend bearing life.

Upgrading to better bearings can improve performance. New materials can handle more stress and last longer. For a smooth upgrade, check the size and fit of your new bearings. Always follow the manufacturer’s advice.

- Use clean lubricants

- Regularly inspect bearings

- Choose durable materials

How can I increase the life of my lathe bearings?

Keep them clean and well-lubricated. Check for wear and replace old ones when needed. This way, your lathe will run better and last longer.

Frequency of Maintenance: How Often Should You Service Your Lathe?

Guidelines for regular maintenance schedules. Factors that may affect maintenance frequency.Regular maintenance is key for your lathe. It helps keep it working well and lasts longer. Most users should check their lathe every few months. This depends on how often you use it. Here are some guidelines:

- Use the lathe daily? Check every month.

- Use it weekly? Service every three months.

- Only occasionally? Inspect twice a year.

Factors like usage, dust, and lubrication can change these schedules. Keep a close eye on your lathe for the best results.

How often should you service your lathe?

Service your lathe based on usage: If you use it often, maintain it more frequently. If not, a simple check-up will do.

Resources for Further Learning

Recommended books and online resources for deeper knowledge. Community forums and support for lathe enthusiasts.For anyone wanting to dive deeper into lathe maintenance, there are great resources available. Check out some helpful books and online courses. You can also find community forums where lathe enthusiasts share tips and support each other. Here are some suggestions:

- Books about lathe operations and maintenance.

- Online courses for hands-on learning.

- Forums like “The Home Machinist” for expert advice.

- Videos on platforms like YouTube that offer valuable insights.

What are some good resources for lathe maintenance?

Good resources include instructional books, online courses, and community forums. These places provide valuable tips and guidance for both beginners and seasoned lathe users.

Conclusion

In conclusion, taking care of your lathe headstock bearing is vital for smooth operation. Regularly clean and lubricate the bearing to prevent wear. Check for any unusual sounds or vibrations. By following these maintenance tips, you can extend the life of your metal lathe. For more detailed advice, explore reliable resources or guides on lathe care!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing Metal Lathe Maintenance:Sure! Here are five questions about taking care of the headstock bearing on a metal lathe. 1. Why is it important to keep the lathe headstock clean? Keeping it clean helps it work better and last longer. 2. How often should you check the bearings? You should check the bearings every few months to make sure they are not worn out. 3. What happens if the bearings are not lubricated? If they are not lubricated, they can get hot and wear out quickly. 4. Can I use any oil for lubrication? No, you should use a special oil made for metal lathes. 5. What tools do I need for maintenance? You need a wrench, some oil, and a cloth for cleaning.

Sure! Please go ahead and ask your question.

What Are The Common Signs Of Wear In Lathe Headstock Bearings That Indicate Maintenance Is Needed?You might notice a few signs that your lathe headstock bearings need help. First, listen for strange noises like grinding or squeaking when you use it. Second, if the lathe feels wobbly or shaky while spinning, that’s a clue. Lastly, check for any oil leaks or spots that could mean the bearings are worn out. If you see these signs, it’s time for some maintenance!

How Do You Properly Lubricate The Bearings In A Lathe Headstock To Ensure Optimal Performance?To lubricate the bearings in a lathe headstock, you first need to clean them. Remove old grease or oil using a cloth. Then, apply fresh lubricant made for machine parts. You should put just enough to cover the bearings without overflowing. Finally, run the lathe for a moment to spread the lubricant evenly.

What Are The Steps Involved In Replacing A Worn-Out Headstock Bearing On A Metal Lathe?First, you unplug the lathe to keep it safe. Next, you remove any covers on the headstock. Then, take out the old bearing carefully. After that, you put in the new bearing and make sure it’s snug. Finally, replace the covers and plug the lathe back in. You’re done!

How Often Should Lathe Headstock Bearings Be Inspected And Maintained For Extended Tool Life?You should check and take care of lathe headstock bearings every few months. If you use the lathe a lot, check them every month. Keeping them clean helps your tools last longer. Always listen for strange noises while using the lathe. If you hear anything weird, it’s time to inspect them sooner!

What Types Of Materials Are Typically Used For Headstock Bearings In Metal Lathes And How Do They Affect Maintenance Requirements?Metal lathes usually use bearing materials like brass, bronze, or high-quality steel. These materials are strong and help the machine run smoothly. With good materials, you may need less maintenance. However, you still need to check and clean them regularly to keep everything working well.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing Metal Lathe Maintenance:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about taking care of the headstock bearing on a metal lathe. 1. Why is it important to keep the lathe headstock clean? Keeping it clean helps it work better and last longer. 2. How often should you check the bearings? You should check the bearings every few months to make sure they are not worn out. 3. What happens if the bearings are not lubricated? If they are not lubricated, they can get hot and wear out quickly. 4. Can I use any oil for lubrication? No, you should use a special oil made for metal lathes. 5. What tools do I need for maintenance? You need a wrench, some oil, and a cloth for cleaning.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please go ahead and ask your question.”}},{“@type”: “Question”,”name”: “What Are The Common Signs Of Wear In Lathe Headstock Bearings That Indicate Maintenance Is Needed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You might notice a few signs that your lathe headstock bearings need help. First, listen for strange noises like grinding or squeaking when you use it. Second, if the lathe feels wobbly or shaky while spinning, that’s a clue. Lastly, check for any oil leaks or spots that could mean the bearings are worn out. If you see these signs, it’s time for some maintenance!”}},{“@type”: “Question”,”name”: “How Do You Properly Lubricate The Bearings In A Lathe Headstock To Ensure Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To lubricate the bearings in a lathe headstock, you first need to clean them. Remove old grease or oil using a cloth. Then, apply fresh lubricant made for machine parts. You should put just enough to cover the bearings without overflowing. Finally, run the lathe for a moment to spread the lubricant evenly.”}},{“@type”: “Question”,”name”: “What Are The Steps Involved In Replacing A Worn-Out Headstock Bearing On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “First, you unplug the lathe to keep it safe. Next, you remove any covers on the headstock. Then, take out the old bearing carefully. After that, you put in the new bearing and make sure it’s snug. Finally, replace the covers and plug the lathe back in. You’re done!”}},{“@type”: “Question”,”name”: “How Often Should Lathe Headstock Bearings Be Inspected And Maintained For Extended Tool Life?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check and take care of lathe headstock bearings every few months. If you use the lathe a lot, check them every month. Keeping them clean helps your tools last longer. Always listen for strange noises while using the lathe. If you hear anything weird, it’s time to inspect them sooner!”}},{“@type”: “Question”,”name”: “What Types Of Materials Are Typically Used For Headstock Bearings In Metal Lathes And How Do They Affect Maintenance Requirements?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes usually use bearing materials like brass, bronze, or high-quality steel. These materials are strong and help the machine run smoothly. With good materials, you may need less maintenance. However, you still need to check and clean them regularly to keep everything working well.”}}]}