Have you ever wondered how a metal lathe works? It seems like magic when you see it cutting, shaping, and smoothing metal. One key part of this machine is the lathe headstock. But what makes it run so smoothly?

The answer lies in the lathe headstock bearing. This part helps the spindle rotate without wobbling. Without it, the quill—where you place your tool—wouldn’t work properly. It’s like riding a bike with wobbly wheels. Not fun, right?

Did you know that a well-maintained bearing can last for years? Just think about how important it is for precision in your projects. Whether you’re a hobbyist or a professional, understanding this part can help you create better work. Let’s dive deeper into the fascinating world of lathe headstock bearings!

Lathe Headstock Bearing: Essential For Metal Lathe Quill

Summary of Lathe Headstock Bearing Metal Lathe Quill

Lathe headstock bearing and metal lathe quill work together to improve precision in metalworking. A lathe’s quill holds the tool, allowing for smooth movement and stability. Did you know that proper maintenance of the headstock bearing can extend the life of your lathe? Regularly checking and replacing worn bearings ensures better performance. Understanding these components can help you achieve the best results in your projects. Isn’t it fascinating how small parts make a big difference?What is a Lathe Headstock Bearing?

Definition and purpose of headstock bearings in lathes. Different types of bearings used in lathe headstocks.A lathe headstock bearing is a special part that helps the lathe spin smoothly. Think of it as the cozy bed for the spindle. It keeps everything aligned and running without a hitch. There are different types of bearings, like ball bearings and roller bearings, each with their own perks. Ball bearings are great for speed, while roller bearings handle heavier loads. The right bearing can make your machining way more fun and less noisy, like a party for your tools!

| Type of Bearing | Advantages |

|---|---|

| Ball Bearings | High speed and smooth rotation |

| Roller Bearings | Handles heavy loads well |

Types of Bearings in Metal Lathe Quills

Explanation of ball bearings vs. roller bearings. Pros and cons of various bearing types used in quills.Bearings are essential in metal lathe quills. There are two main types: ball bearings and roller bearings. Ball bearings use small balls to reduce friction. They are great for high speeds but can wear out faster. Roller bearings use cylinder-shaped rollers. They handle heavy loads better but might be less efficient at speed.

- Ball Bearings: Pros – Smooth motion, high speed. Cons – Less load capacity.

- Roller Bearings: Pros – Better load support. Cons – Can be slower.

Choosing the right one matters for your lathe’s performance!

What are the advantages of using ball bearings in metal lathe quills?

Ball bearings provide smooth operation and high speed. They are ideal for tasks needing precision. This makes them popular in metal lathes!

What are the pros also cons of roller bearings?

Roller bearings are strong, allowing them to handle heavy loads well. However, they may not spin as fast as ball bearings. This trade-off needs consideration.

Signs of Wear and Tear in Headstock Bearings

Common symptoms of failing bearings in lathe quills. Techniques to diagnose bearing issues.When headstock bearings begin to fail, they send out clear signals. Some common signs include:

- Unusual noises like grinding or buzzing.

- Increased vibration during operation.

- Difficulty in moving the lathe quill smoothly.

- Visible wear, such as grooves or pitting on the bearing surface.

What are the signs of bad lathe bearings?

Bad lathe bearings often show signs like noise, vibration, and movement issues. Always examine them during regular maintenance to prevent bigger problems down the line.

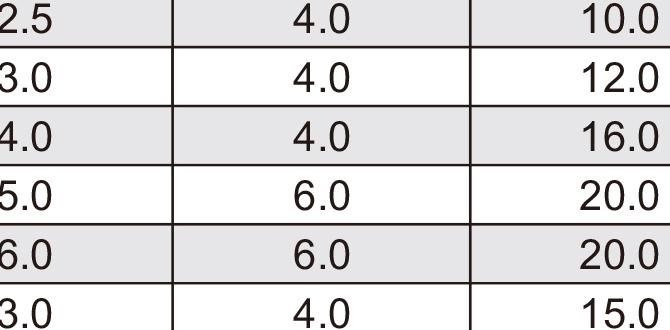

Maintaining Lathe Headstock Bearings

Best practices for regular maintenance. Importance of lubrication and cleaning.Keeping lathe headstock bearings in top shape is like brushing your teeth—skip it, and things can get messy! Regular maintenance is key to a smooth operation. Always check for dust or grime and give them a good cleaning. And lubrication? It’s like the oil on a squeaky door; it keeps everything running well. Use proper oil and keep it clean to prevent wear and tear. Your lathe will thank you! Plus, a well-maintained lathe can last longer, saving you money in the long run.

| Maintenance Task | Frequency | Importance |

|---|---|---|

| Clean Bearings | Every 3 months | Prevents buildup |

| Lubricate | Monthly | Reduces friction |

| Check Alignment | Every 6 months | Ensures accuracy |

Upgrading Your Lathe Headstock Bearings

Indicators for when to upgrade bearings. Options for highperformance bearings and their benefits.Knowing when to upgrade your lathe headstock bearings can help you work better. Here are some signs:

- Strange noises during use

- Excessive wear on the old bearings

- Visible rust or damage

What signs show I need new lathe bearings?

Signs to look for include unusual sounds, rough movements, or visible damage. Regular checks can help catch problems early.

Benefits of high-performance bearings:

- Less friction for smoother operation

- Better precision during work

- Increased lifespan reduces replacement costs

Common Issues and Solutions for Lathe Headstock Bearings

Analysis of frequent problems faced by users. Stepbystep troubleshooting guide.Lathe headstock bearings can have a few common problems. Users often report issues like noise, wobbling, or feeling stiff. These problems can be fixed with some simple steps. First, check for dirt or debris that might block movement. Next, look for loose screws or damage. Tightening or replacing parts can solve many issues.

- **Noise:** Clean or replace the bearings.

- **Wobbling:** Check alignment and tighten screws.

- **Stiffness:** Add lubricant or replace old bearings.

These steps can help keep your lathe running smoothly.

What should I do if my lathe quill is stuck?

To fix a stuck lathe quill, check for debris and clean the area. Add lubrication if needed. If it still won’t move, consider replacing the quill.

Future Trends in Lathe Headstock Technology

Innovations in bearing technology and materials. Predictions for advancements in metal lathe design.Exciting times are ahead for lathe headstock technology! Innovations in bearing technology are making machines smoother and faster. New materials are stronger and last longer, reducing wear and tear. Imagine using a lathe that’s as quiet as a mouse, but spins like a race car! Predictions say metal lathe designs will become more customizable, letting users add their special touch. Soon, we might all be working with lathes that think for themselves—without needing a coffee break!

| Innovation | Benefit |

|---|---|

| Advanced Bearings | Smoother operation & less maintenance |

| Durable Materials | Longer lifespan & better performance |

| Custom Designs | More personal & fun to use |

Conclusion

In conclusion, the lathe headstock bearing and quill play vital roles in metal lathes. They help the machine run smoothly, ensuring precision. Understanding these parts can improve your lathe skills. We encourage you to explore more about metal lathes and their components. With practice, you can become a pro in no time! Keep learning and experimenting!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing And Metal Lathe Quill:Sure! A lathe headstock bearing is a part that helps the lathe turn smoothly. It holds the main shaft in place. The quill is a part of the lathe that can move in and out. You can use the quill to adjust how deep you cut the metal. Overall, these parts help make precise metal shapes.

Sure! Please provide me with the question you’d like me to answer.

What Types Of Bearings Are Commonly Used In The Headstock Of Metal Lathes, And How Do They Affect Performance?Metal lathes often use two types of bearings: plain bearings and ball bearings. Plain bearings let things slide smoothly, while ball bearings roll to reduce friction. These bearings help the lathe spin accurately and last longer. Good bearings make it easier to work with metal and create better shapes. When we use high-quality bearings, our projects turn out even better!

How Do You Determine The Appropriate Quill Diameter For A Specific Lathe Application?To pick the right quill diameter for a lathe, you need to think about what you’re making. First, look at the material you want to work with. If it’s hard, you might need a thicker quill. You also need to check the size of your tools. Bigger tools often require a bigger quill to hold them safely. Finally, always follow the lathe’s instructions for the best results.

What Are Some Common Signs Of Wear Or Failure In Lathe Headstock Bearings, And How Can They Be Prevented?You might notice strange sounds coming from the lathe when the headstock bearings wear out. If the lathe shakes or feels rough when you use it, that’s a sign too. To keep the bearings in good shape, always clean them and add oil regularly. Also, check them often to catch problems early. Taking care of your lathe helps it last longer!

How Does The Design Of The Lathe Quill Influence The Accuracy And Stability Of Machining Operations?The lathe quill is a part that holds the tool while it spins. If the quill is strong and fits well, it keeps the tool steady. This steadiness helps us make precise cuts. A well-designed quill reduces wobbles, so our work comes out just right. Overall, a good quill helps us do our jobs better and faster.

What Maintenance Practices Should Be Followed To Ensure The Longevity Of Headstock Bearings And The Quill On A Metal Lathe?To keep the headstock bearings and quill of a metal lathe in good shape, you should do a few things. First, always clean the parts regularly to remove dirt and dust. Next, check and add oil to the bearings as needed to keep them running smoothly. Also, make sure to tighten any loose screws or parts. Lastly, avoid forcing the lathe to work too hard, so it lasts longer.