Have you ever watched a metal lathe spin? It’s like magic, isn’t it? One part that plays a crucial role in this process is the lathe headstock bearing. But why is it so important?

The headstock bearing helps hold the spindle in place. It allows the lathe to turn smoothly, which is key for making precise cuts. If the bearing fails, the whole machine can be at risk. Imagine trying to create something amazing, but your tools don’t work right!

Now, let’s talk about the lathe saddle. Did you know it helps move the cutting tool back and forth? This setup allows wood and metal workers to create detailed shapes and designs. It’s fascinating how these pieces work together, isn’t it?

In the world of metal lathing, understanding these mechanics can spark creativity and help you produce great projects. Ready to learn more about how these components fit into your lathe? Dive in!

Understanding Lathe Headstock Bearing And Metal Lathe Saddle

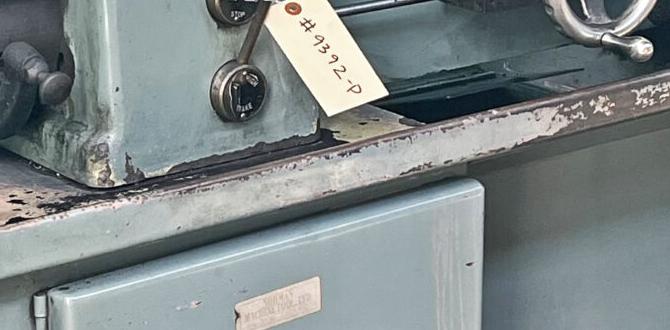

Lathe Headstock Bearing Metal Lathe Saddle

Lathe headstock bearings are vital for smooth operation. They help the spindle rotate without friction. A metal lathe saddle connects the workpiece and the cutting tool. It ensures precise cutting and shaping of materials. Did you know that a well-maintained saddle increases machine lifespan? Proper lubrication and regular checks enhance performance. Keeping these parts in good shape can save time and money in the long run, making every project easier and more fun!What is a Lathe Headstock Bearing?

Definition and function of headstock bearings in lathes. Importance of proper lubrication and maintenance.A lathe headstock bearing supports the spinning part of a lathe. It helps keep everything steady while it rotates. This part is key for smooth cuts and accuracy. Proper lubrication is crucial. It prevents wear and tear and extends the bearing’s life. Regular maintenance also ensures everything runs well. If the bearings are dry, the lathe can break down or work poorly.

Why is proper lubrication important?

Lubrication keeps the bearings cool and working smoothly. Without it, friction increases, leading to damage. Keeping things well-lubricated makes your lathe last longer.

Understanding Metal Lathe Saddles

Definition and purpose of a lathe saddle. Relationship between the saddle and headstock assembly.A lathe saddle is a key part of a metal lathe. It holds the cutting tool and moves it back and forth. This movement shapes the material. The saddle works closely with the headstock assembly. The headstock powers the machine, while the saddle guides the cutting action. Together, they ensure the lathe operates smoothly and accurately. Without them, shaping metal would be much harder.

What is the purpose of a lathe saddle?

The main purpose of a lathe saddle is to support and move the cutting tool during operation. It helps shape materials into precise forms and sizes.

Key Functions of a Lathe Saddle:

- Holds the cutting tool securely

- Moves the tool accurately

- Works with the headstock for smooth operation

By understanding the lathe saddle, you can appreciate how important it is in machining and metalworking.

Factors Affecting Headstock Bearing Performance

Materials used in bearings and their impact on performance. Environmental factors influencing bearing longevity.Bearings are crucial for smooth lathe operation. The materials used in bearings directly affect their performance. For example, steel is strong but can rust. Plastic is lightweight but may wear out quickly. Even ceramics are used for their durability.

Environmental factors also play a role. Temperature, moisture, and dust can shorten a bearing’s life. Regular cleaning and maintenance help prevent problems. Keeping bearings in a dry place enhances their lifespan.

What materials are used in lathe bearings?

Common materials include steel, plastic, and ceramics. Each type offers unique benefits like strength or lightness.

Key Environmental Factors:

- Moisture can lead to rust.

- Temperature affects performance.

- Dust can cause wear and tear.

Installation and Maintenance Tips

Stepbystep guide for installing headstock bearings correctly. Regular maintenance practices to optimize performance.Installing headstock bearings correctly is key for a smooth ride. Start by gathering your tools. Remove the old bearings carefully. Place the new bearings in their correct spots, ensuring a snug fit. Finally, check for any movement. Regular maintenance helps too. Here are some tips:

- Clean the bearings every month.

- Check for wear every few weeks.

- Lubricate according to the manufacturer’s advice.

- Listen for unusual noises while operating.

These steps will help keep your metal lathe saddle in top shape.

How often should I maintain my lathe headstock bearings?

You should maintain your lathe headstock bearings every month. This keeps them running smoothly and helps catch any issues early. A little care goes a long way!

Signs of Headstock Bearing Wear and Tear

Common symptoms indicating bearing issues. Diagnostic techniques for identifying problems.A worn-out bearing can be a sneaky troublemaker. Look for signs like strange noises or vibrations when using your lathe. If your workpiece seems to wobble a bit too much, that’s a red flag.

To diagnose the issue, try these techniques:

| Signs | Possible Diagnostic Techniques |

|---|---|

| Unusual Sounds | Listen for grinding or rattling noises. |

| Vibrations | Feel for extra shakes while operating. |

| Wobbling | Inspect the workpiece for unevenness. |

| Heating | Touch the bearings—if they’re too hot, that’s bad news! |

Keeping an eye out for these issues can save you from bigger problems later. Remember, a little prevention goes a long way—like checking if you’ve brushed your teeth before bed!

Upgrading Your Lathe Bearing System

When to consider upgrading your lathe’s bearing system. Benefits of modern bearing technologies for metal lathes.Upgrading your lathe’s bearing system can feel like getting a new pair of shoes. You know they’ll fit better and let you run faster! If your lathe starts making strange noises or vibrations, it’s time for a change. Modern bearing technologies can make your metal lathe smoother and more efficient. They help reduce friction and wear, meaning you spend less time fixing things and more time creating. Think of it as a spa day for your lathe—everyone deserves a little pampering!

| When to Upgrade | Benefits of Modern Bearings |

|---|---|

| Unusual sounds, signs of wear, or vibrations | Smoother operation and less friction |

| Your lathe is over 10 years old | Longer lifespan of parts |

DIY vs. Professional Bearing Replacement

Pros and cons of DIY headstock bearing replacement. When to seek professional help for repairs.Replacing headstock bearings can be a fun project, but it has its ups and downs. On the bright side, DIY can save you cash and teach you cool skills. Plus, you can wear your favorite old T-shirt and pretend you’re a mechanic! However, if you mess up, you might end up in a pickle, and that’s no laughing matter. Sometimes, the best choice is to call in the pros. They have the tools and know-how to fix things without adding drama.

| Pros of DIY | Cons of DIY |

|---|---|

| Cost-effective | Risk of mistakes |

| Learn something new | Time-consuming |

| Control over the process | No professional guarantee |

Use your tools wisely! If you feel unsure or your lathe acts like a moody cat, it’s time to seek help. The pros can tackle tricky jobs quickly. Remember, a little help can turn a disaster into a delight!

Potential Troubleshooting Scenarios

Common issues and their solutions related to headstock bearings. Tips for preventing potential problems in the first place.Headstock bearings can sometimes cause issues. Knowing how to fix them can save time and effort. Common problems include strange noises and vibrations. These signs mean it’s time to check your bearings. Regular maintenance is key to avoiding issues. Here are some tips:

- Keep bearings clean and lubricated.

- Check for wear and tear regularly.

- Make sure everything is properly aligned.

Taking these steps helps your lathe run smoothly.

What are the common issues with headstock bearings?

The most common problems include noise, excessive heat, and vibrations. Regular checks can help catch these issues early.

Conclusion

In summary, the lathe headstock, bearing, and metal lathe saddle are vital parts for smooth machining. They help keep your work steady and precise. Remember to check these components regularly for wear and tear. If you want to learn more, consider reading guides on lathe maintenance or safety tips. Happy machining!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing, Metal Lathe, And Saddle:Sure! A lathe is a machine that helps shape metal. The headstock is the part that holds the motor and helps the lathe spin. The bearing in the headstock helps everything move smoothly. The saddle is the piece that holds the tool and moves it back and forth. Together, they make working with metal easier and more precise!

Sure! Please share the question you’d like me to answer.

What Are The Key Factors To Consider When Selecting Bearing Types For The Headstock Of A Metal Lathe?When choosing bearings for the headstock of a metal lathe, you need to think about a few important things. First, consider the weight of the lathe and the tools it will hold. Next, look at how fast you want the lathe to spin. You also need to think about how much heat is made during use. Finally, check how easy it is to keep the bearings clean and in good shape.

How Do Different Saddle Designs Impact The Precision And Stability Of A Metal Lathe During Machining?Different saddle designs help keep a metal lathe steady while it works. If the saddle is wide, it gives better balance, which helps you make accurate cuts. A strong saddle can also hold the tools tight, so they don’t move around. This means you get smoother shapes in your metal pieces. Good saddle designs make everything work better and last longer.

What Is The Typical Maintenance Procedure For Lathe Headstock Bearings To Ensure Optimal Performance And Longevity?To keep lathe headstock bearings working well, you should regularly check them for wear. First, clean the bearings to remove dust or oil. Next, add fresh oil to keep them smooth. You should also look for any damage or strange sounds when the lathe runs. Regular checks help make sure your lathe lasts longer and works better!

How Do The Materials Used For Lathe Saddles Influence Their Wear Resistance And Performance Under Heavy Loads?The materials used for lathe saddles are very important. Strong materials like cast iron or steel help them last longer. They resist wear, meaning they don’t get damaged easily over time. When we use heavy loads, these strong materials make sure the lathe works well and doesn’t break. This way, you can keep using it for a long time!

What Are The Common Signs Of Wear Or Failure In Lathe Headstock Bearings, And How Can They Be Diagnosed And Addressed?You might notice strange noises when using the lathe. If it vibrates more than usual, that’s a red flag. Also, check for rough movement in the machine. To diagnose, listen closely and feel for bumps as you turn the lathe. If you find problems, you can fix it by replacing the bearings or adjusting them. Always make sure to follow safety rules when doing repairs!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Headstock Bearing, Metal Lathe, And Saddle:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that helps shape metal. The headstock is the part that holds the motor and helps the lathe spin. The bearing in the headstock helps everything move smoothly. The saddle is the piece that holds the tool and moves it back and forth. Together, they make working with metal easier and more precise!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Factors To Consider When Selecting Bearing Types For The Headstock Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing bearings for the headstock of a metal lathe, you need to think about a few important things. First, consider the weight of the lathe and the tools it will hold. Next, look at how fast you want the lathe to spin. You also need to think about how much heat is made during use. Finally, check how easy it is to keep the bearings clean and in good shape.”}},{“@type”: “Question”,”name”: “How Do Different Saddle Designs Impact The Precision And Stability Of A Metal Lathe During Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different saddle designs help keep a metal lathe steady while it works. If the saddle is wide, it gives better balance, which helps you make accurate cuts. A strong saddle can also hold the tools tight, so they don’t move around. This means you get smoother shapes in your metal pieces. Good saddle designs make everything work better and last longer.”}},{“@type”: “Question”,”name”: “What Is The Typical Maintenance Procedure For Lathe Headstock Bearings To Ensure Optimal Performance And Longevity?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep lathe headstock bearings working well, you should regularly check them for wear. First, clean the bearings to remove dust or oil. Next, add fresh oil to keep them smooth. You should also look for any damage or strange sounds when the lathe runs. Regular checks help make sure your lathe lasts longer and works better!”}},{“@type”: “Question”,”name”: “How Do The Materials Used For Lathe Saddles Influence Their Wear Resistance And Performance Under Heavy Loads?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The materials used for lathe saddles are very important. Strong materials like cast iron or steel help them last longer. They resist wear, meaning they don’t get damaged easily over time. When we use heavy loads, these strong materials make sure the lathe works well and doesn’t break. This way, you can keep using it for a long time!”}},{“@type”: “Question”,”name”: “What Are The Common Signs Of Wear Or Failure In Lathe Headstock Bearings, And How Can They Be Diagnosed And Addressed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You might notice strange noises when using the lathe. If it vibrates more than usual, that’s a red flag. Also, check for rough movement in the machine. To diagnose, listen closely and feel for bumps as you turn the lathe. If you find problems, you can fix it by replacing the bearings or adjusting them. Always make sure to follow safety rules when doing repairs!”}}]}