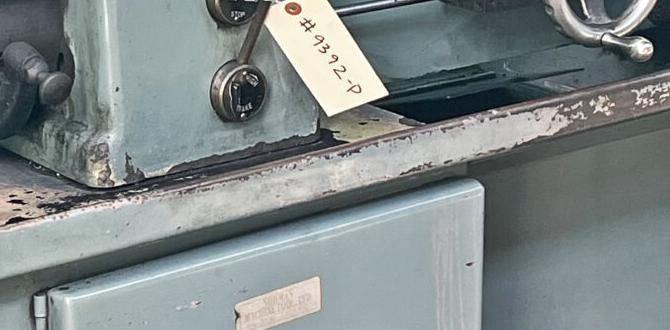

Have you ever wondered how metal lathes work? These machines are powerful tools that help shape and cut metal. They can create amazing things, from tiny screws to large parts. But with power comes responsibility. Safety is very important when using a lathe.

The lathe headstock is a crucial part of this machine. It holds the spindle and supports the bearings. These bearings make the lathe run smoothly. However, if they are not cared for properly, they can cause accidents. Did you know that many injuries happen due to unsafe lathe practices?

Imagine you are working on a project. You’re focused on getting it just right when suddenly, something goes wrong. That’s why it is essential to know about lathe headstock bearing safety. With the right knowledge, you can protect yourself and others.

In this article, we will explore how to keep safe while using a metal lathe. We will share tips, tricks, and simple practices that you can follow. Let’s dive in and keep those fingers safe!

Lathe Headstock Bearing: Ensuring Metal Lathe Safety

Lathe Headstock Bearing Metal Lathe Safety

Using a lathe can be fun but it also comes with risks. Understanding your lathe headstock bearing helps keep you safe while working. Always check for wear and tear. Did you know that a loose bearing can lead to dangerous accidents? Regular maintenance is key. It’s like taking care of your bike—if it’s not running smoothly, you could crash! Remember, safety first when using any metal lathe for your projects. Stay alert and stay safe!Understanding Lathe Headstock Bearings

Definition and purpose of headstock bearings in metal lathes. Types of bearings commonly used in lathe headstocks.Headstock bearings play a vital role in metal lathes. They help keep the spindle spinning smoothly. Without these trusty bearings, your lathe would make a noise like a tired old cat! There are two main types of bearings used: ball bearings, which are great for high speeds, and roller bearings, known for handling heavy loads. Each type has its own purpose, making it easier to create that perfect piece. Think of it like having the right tool for your next art project!

| Type of Bearing | Best For |

|---|---|

| Ball Bearings | High speeds |

| Roller Bearings | Heavy loads |

Key Safety Concerns When Using Metal Lathes

Common hazards associated with metal lathe operation. Importance of risk assessment and safety compliance.Working with metal lathes can be fun, but safety is key. Some common hazards include flying metal chips, sharp tools, and moving parts. These can hurt our hands or eyes. Always check your machine before use. Risk assessment helps spot dangers. It ensures safety rules are followed. This keeps everyone safe while working. Remember, safety first!

What are common hazards when using a metal lathe?

Common hazards include cuts from sharp tools, flying debris, and entanglement in moving parts.

Why is risk assessment important?

- It identifies potential dangers.

- It ensures workers follow safety rules.

- It reduces accidents and injuries.

Personal Protective Equipment (PPE) for Lathe Operators

Essential protective gear for safe lathe operation. Best practices for maintaining and using PPE.Staying safe while using a lathe is super important. The right protective gear makes a big difference. Essential items include safety goggles, gloves, and ear protection. Goggles stop flying bits from ruining your vision. Gloves grip tools better, but make sure they are snug to avoid getting caught. Ear protection helps you avoid that annoying ringing sound that happens after loud noises. When using gear, check for wear and tear. Toss out anything that looks like it’s been through a wood chipper!

| Protective Equipment | Purpose |

|---|---|

| Safety Goggles | Shield eyes from debris |

| Gloves | Improve grip and protect hands |

| Ear Protection | Reduce exposure to loud noise |

Proper Setup and Maintenance of Lathe Headstock Bearings

Importance of accurate setup for safety and efficiency. Regular maintenance procedures to ensure optimal performance.Getting your lathe headstock bearings set up correctly is key for safety and smooth operations. A well-aligned setup keeps accidents at bay and helps your metal lathe run like a dream. Regular maintenance is just as important; think of it as the lathe’s gym time. Without it, performance can take a nosedive. Follow these tips to keep everything spinning happily:

| Maintenance Task | Frequency |

|---|---|

| Check Lubrication | Every use |

| Inspect Bearings for Wear | Weekly |

| Tighten Fasteners | Monthly |

By staying on top of these tasks, you ensure a safe workspace and a lathe that performs at its best. Remember, a happy lathe means a happy you!

Operational Safety Measures When Using a Metal Lathe

Safe operating techniques to prevent accidents. Emergency procedures and first aid measures.Using a metal lathe wisely can keep you safe and sound. Always wear protective gear, like goggles and gloves, to shield yourself from flying metal bits. Don’t forget to check that all parts are secure before starting. In case something goes wrong, knowing what to do is crucial. Make sure to have a first aid kit nearby, just in case you need it. Also, remember to stop the machine and seek help if someone is hurt. Safety first, fun later!

| Emergency Procedures | First Aid Measures |

|---|---|

| Stop the lathe immediately. | Apply pressure to stop bleeding. |

| Call for help. | Keep the injured person calm. |

| Follow safety guidelines. | Use ice for swelling. |

Common Mistakes to Avoid When Operating a Metal Lathe

Missteps that can lead to safety issues. Tips for cultivating a safe operational mindset.Using a metal lathe can be a bit tricky, and mistakes can lead to safety issues. One common error is ignoring proper gear. Always check the lathe’s headstock bearing to ensure it’s in good shape. Another mistake? Forgetting to wear safety gear! Those goggles aren’t just for fashion. It’s also smart to keep your work area tidy. A clean space reduces accidents. Remember, those chips of metal can turn into ninjas! Always maintain a safe mindset while operating, because trust me, your fingers will thank you!

| Common Mistakes | Safety Tips |

|---|---|

| Ignoring equipment health | Check headstock bearings regularly |

| Not wearing safety gear | Use goggles and work gloves |

| Cluttered workspace | Keep tools organized and neat |

Conclusion

In summary, using a lathe headstock bearing is vital for safety. Always check the bearing for wear and tear. Remember to wear safety gear, like goggles and gloves, when working. Stay alert and keep your workspace tidy. We all can work safely by following these steps. For more in-depth tips on lathe safety, consider reading additional resources or guides.FAQs

What Are The Common Signs Of Wear Or Damage In Lathe Headstock Bearings That Indicate The Need For Inspection Or Replacement?You can spot problems in lathe headstock bearings by watching for a few signs. If you hear strange noises, like grinding or rattling, it’s time to check. You might also see a lot of grease or oil leaks. If the lathe feels wobbly or hard to turn, the bearings may be damaged. Always inspect them when you notice these things!

How Can Proper Lubrication Of Headstock Bearings Enhance Safety And Performance While Operating A Metal Lathe?Proper lubrication of headstock bearings helps everything move smoothly. When the lathe runs better, it’s safer for you to use. It prevents parts from getting too hot or breaking. This means your work can be more precise and last longer. Regularly checking the lubrication keeps your lathe in top shape!

What Safety Precautions Should Be Followed When Performing Maintenance On Lathe Headstock Bearings?When you work on lathe headstock bearings, always turn off the machine first. This keeps you safe from moving parts. Wear safety glasses to protect your eyes from dust. Use gloves to keep your hands safe from sharp edges. Lastly, make sure your workspace is clean and organized so you don’t trip or slip.

How Does The Alignment Of The Headstock Affect The Operation And Safety Of A Metal Lathe?The headstock holds the machine’s main part that spins. If it’s aligned correctly, it helps the lathe cut metal smoothly. This means your work will look nice and not wobble. If it’s off, the metal might break or hurt you while you work. Keeping it straight keeps you safe!

What Steps Can Be Taken To Prevent Overheating Of Headstock Bearings During Prolonged Use Of A Metal Lathe?To prevent headstock bearings from overheating on a metal lathe, you can do a few things. First, make sure you keep the machine clean. Dust and chips can block airflow and trap heat. Second, check the oil level regularly and change it when needed. Good lubrication helps the bearings stay cool. Lastly, take breaks during long projects to let the machine cool down.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Common Signs Of Wear Or Damage In Lathe Headstock Bearings That Indicate The Need For Inspection Or Replacement? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can spot problems in lathe headstock bearings by watching for a few signs. If you hear strange noises, like grinding or rattling, it’s time to check. You might also see a lot of grease or oil leaks. If the lathe feels wobbly or hard to turn, the bearings may be damaged. Always inspect them when you notice these things!”}},{“@type”: “Question”,”name”: “How Can Proper Lubrication Of Headstock Bearings Enhance Safety And Performance While Operating A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Proper lubrication of headstock bearings helps everything move smoothly. When the lathe runs better, it’s safer for you to use. It prevents parts from getting too hot or breaking. This means your work can be more precise and last longer. Regularly checking the lubrication keeps your lathe in top shape!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Followed When Performing Maintenance On Lathe Headstock Bearings? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you work on lathe headstock bearings, always turn off the machine first. This keeps you safe from moving parts. Wear safety glasses to protect your eyes from dust. Use gloves to keep your hands safe from sharp edges. Lastly, make sure your workspace is clean and organized so you don’t trip or slip.”}},{“@type”: “Question”,”name”: “How Does The Alignment Of The Headstock Affect The Operation And Safety Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The headstock holds the machine’s main part that spins. If it’s aligned correctly, it helps the lathe cut metal smoothly. This means your work will look nice and not wobble. If it’s off, the metal might break or hurt you while you work. Keeping it straight keeps you safe!”}},{“@type”: “Question”,”name”: “What Steps Can Be Taken To Prevent Overheating Of Headstock Bearings During Prolonged Use Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To prevent headstock bearings from overheating on a metal lathe, you can do a few things. First, make sure you keep the machine clean. Dust and chips can block airflow and trap heat. Second, check the oil level regularly and change it when needed. Good lubrication helps the bearings stay cool. Lastly, take breaks during long projects to let the machine cool down.”}}]}