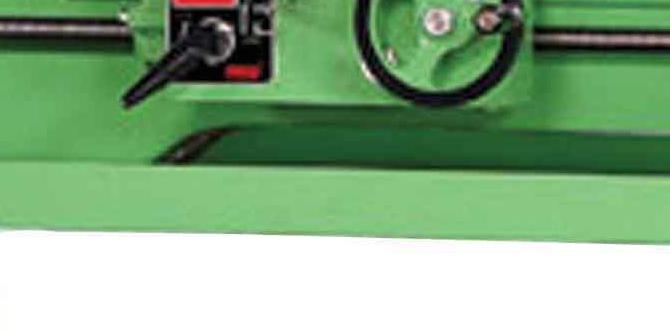

Have you ever wondered how metal parts are shaped with such precision? The secret often lies in the lathe headstock bearing and the metal lathe spindle. These components work together to create amazing tools and machines.

Using a lathe, you can turn raw metal into beautiful objects. Imagine making your own custom pieces for a project. It’s not just fun; it’s also a great way to learn about engineering and design!

Most people don’t realize how important the lathe headstock bearing is. It helps keep the metal lathe spindle spinning smoothly. Without these parts, your project could turn into a messy creation. Isn’t it surprising how small pieces can make such a big difference?

In this article, we will explore the amazing role of the lathe headstock bearing and its connection to the metal lathe spindle. Let’s dive in and uncover the fascinating world of metalworking together!

Understanding Lathe Headstock Bearing For Metal Lathe Spindle

Understanding Lathe Headstock Bearing and Spindle

Lathe headstock bearings support the spindle in a metal lathe. These components keep the spindle spinning smoothly, critical for precision work. Did you know that proper lubrication can extend the life of these bearings? Regular checks can prevent costly repairs. If your lathe produces vibrations or noise, it might be time to examine the bearings. A well-maintained lathe makes all the difference in your projects! Keep your machinery in top shape for the best results.What is a Lathe Headstock?

Definition and purpose of the headstock in a lathe machine. Importance of the headstock in achieving precision in machining.The headstock is a key part of a lathe machine. It holds the spindle, which spins the workpiece. Think of it as the brain that controls the action! The headstock ensures the machine runs smoothly, helping you achieve precision in shaping materials. Without it, your creations could look more like abstract art than the fine projects you want. Remember, a well-functioning headstock leads to a job done right – no one wants a wobbly masterpiece!

| Function | Importance |

|---|---|

| Holds Spindle | Allows for smooth rotation |

| Controls Speed | Provides accurate machining |

| Ensures Tension | Maintains material stability |

The Role of Bearings in a Lathe Headstock

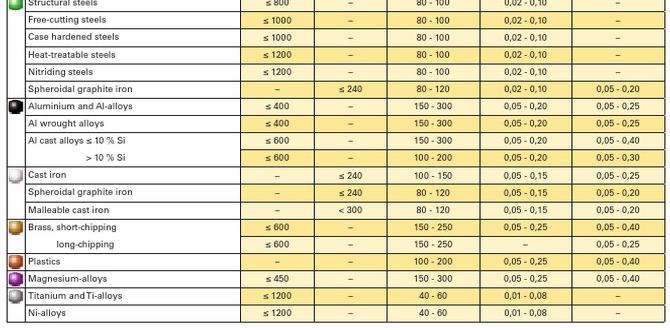

Function of bearings in supporting the spindle. Types of bearings commonly used in lathe headstocks.Bearings play a key role in any lathe headstock. They hold the spindle firmly in place, allowing it to spin smoothly. Think of them as tiny superheroes, saving the day by reducing friction! Common types of bearings used in lathe headstocks include ball bearings and roller bearings. These help the spindle rotate efficiently, making your work easier and more precise. Choosing the right bearing is like picking the best cake flavor: it can really make a difference!

| Type of Bearing | Function |

|---|---|

| Ball Bearings | Reduces friction |

| Roller Bearings | Handles heavy loads |

Understanding the Metal Lathe Spindle

Definition and function of a spindle in a metal lathe. Relationship between the spindle and workpiece machining.A spindle is the heart of a metal lathe. Think of it like a superhero’s cape, spinning gracefully while keeping things together. The spindle holds the cutting tool and spins your workpiece, shaping it into something awesome. It’s all about precision! If the spindle wobbles, your masterpiece might end up looking like a potato instead of a neat cylinder. So, in short, a sturdy spindle ensures smooth cuts for a perfect finish.

| Function | Description |

|---|---|

| Support | Holds and rotates the workpiece. |

| Precision | Ensures accurate cuts and shapes. |

Without a reliable spindle, machining would be like trying to ride a bike with flat tires. Not much fun at all! So, let’s keep that spindle spinning smoothly!

Signs of Worn Out Lathe Headstock Bearings

Common symptoms indicating bearing wear or failure. Consequences of ignoring bearing maintenance.Watch out for your lathe! If you hear strange noises, like creaking or grinding, your headstock bearings might be tired. Vibration is another telltale sign, as if your lathe is having a dance party without you. If your cuts aren’t smooth, that’s a red flag too. Ignoring these issues can lead to serious damage, costing you both time and money. Don’t wait until it’s too late—your lathe deserves better!

| Symptom | Meaning |

|---|---|

| Creaking Sounds | Bearings are worn out. |

| Excessive Vibration | Possible misalignment. |

| Uneven Cuts | Bearings need attention! |

How to Replace Lathe Headstock Bearings

Stepbystep guide on replacing worn bearings. Tools and materials required for the replacement process.Replacing worn lathe headstock bearings is important for smooth operation. Follow these steps for an easy process:

- Gather tools: wrench set, ball bearing puller, lubricating oil.

- Power off the lathe and unplug it.

- Remove the spindle from the headstock carefully.

- Use the puller to take out the old bearings.

- Clean the area and place new bearings.

- Carefully reassemble the spindle and test it.

Make sure to keep your workspace organized. This will help you work efficiently.

What tools do I need to replace lathe bearings?

You need several tools. These include a wrench set, a ball bearing puller, and lubricating oil. Having the right tools makes the job easier and faster.

Maintaining Your Lathe Spindle and Bearings

Best practices for maintaining lathe headstock bearings. Tips for prolonging the lifespan of the lathe spindle.Taking care of your lathe spindle and bearings is crucial for smooth operations. Regularly check the bearings for wear and tear. A little *oil goes a long way!* Use high-quality lubricant to keep things running smoothly. Don’t forget to clean the spindle regularly; dirt can sneak in like a ninja! Check the alignment too—no one wants a crooked spindle, right?

| Tip | Description |

|---|---|

| Regular Cleaning | Wipe down your spindle after each use to prevent buildup. |

| Proper Lubrication | Use the right oil to reduce friction and wear. |

| Check Alignment | Ensure everything is level for best performance. |

Following these tips can help extend the life of your lathe. Remember, a happy lathe means more time to create amazing projects!

Choosing the Right Lathe Headstock Bearings

Factors to consider when selecting bearings for your lathe. Comparison of different brands and models in the market.Choosing the right lathe headstock bearings is important for smooth operation. You should pay attention to the size, type, and material of the bearings. Different brands and models offer unique features and costs. Compare options to find the best match for your lathe. Consider these factors:

- Load Capacity: Can it support the weight?

- Speed Rating: Is it fast enough for your needs?

- Durability: How long will it last?

Research to find reliable brands. Some popular brands include Brand A and Brand B, known for quality and performance. Make an informed choice to enhance your lathe’s efficiency.

What should I consider when buying lathe bearings?

You need to check the specifications and compare them across brands. Look for load capacity, speed rating, and durability. Picking the right bearings can improve performance and longevity.

DIY Upgrades for Lathe Headstock and Spindle

Popular modifications for improved performance. Potential risks and benefits of DIY upgrades.Upgrading your lathe headstock and spindle can be as fun as a rollercoaster ride! Popular modifications include adding better bearings for smoother spins and increasing your spindle’s RPM for faster work. But beware! DIY upgrades can turn into a wild circus act if not done right. Always weigh the risks, like potential damage to parts. Still, the benefits, such as improved accuracy, can make it all worth it. Just remember, a little knowledge can save you from a big mess!

| Modifications | Benefits | Risks |

|---|---|---|

| Better Bearings | Smoother operation | Possible misalignment |

| Increased Spindle RPM | Faster projects | Overheating risk |

| Custom Drive Belts | Better torque | Breakage under stress |

Conclusion

In conclusion, the lathe headstock bearing and spindle are vital for smooth operation. They support the spinning parts and help you create precise shapes. If you understand how these components work, you’ll improve your lathe skills. Next, explore maintenance tips to keep your lathe in top shape. Check out more resources online to enhance your knowledge even further!FAQs

Sure! Here Are Five Questions Related To Lathe Headstock Bearing, Metal Lathe Spindle:Sure! Here are five questions you might ask about a lathe headstock bearing and metal lathe spindle: 1. What is a lathe headstock? A lathe headstock is the part of the lathe that holds the spindle and motor. It helps the lathe spin. 2. What does the spindle do? The spindle is a metal rod that holds the workpiece. It turns it so you can shape it. 3. Why are bearings important? Bearings help the spindle spin smoothly. They reduce friction and allow for nice, easy movement. 4. How do I take care of the bearings? You can take care of bearings by cleaning them and adding oil. This keeps them working well. 5. What happens if bearings wear out? If bearings wear out, the spindle won’t spin smoothly. You might need to replace them to fix the lathe.

Sure! Please provide the question you would like me to answer.

What Are The Different Types Of Bearings Used In Lathe Headstocks, And How Do They Impact Spindle Performance?Lathe headstocks use different types of bearings to help the spindle move smoothly. The most common types are ball bearings and roller bearings. Ball bearings are round and help reduce friction, making the spindle spin easily. Roller bearings are shaped like small cylinders and can handle heavier loads. Both types help the lathe work better and last longer by keeping everything running smoothly.

How Do You Identify Bearing Wear Or Failure In A Metal Lathe Spindle, And What Maintenance Practices Can Extend Their Lifespan?You can spot bearing wear by listening for loud noises or feeling vibrations when the lathe runs. Check if the spindle feels loose or hard to turn. To keep bearings working well, clean them regularly and add some grease. Also, avoid running the lathe too fast. Inspect the bearings often to catch problems early.

What Materials Are Commonly Used For Lathe Spindle Bearings, And How Do They Affect Precision And Load Capacity?Lathe spindle bearings are often made from metals like steel and bronze. These materials help the lathe spin smoothly. Steel is strong, so it can hold heavy things. Bronze reduces friction, which helps with precision. When we use the right materials, we get better accuracy and can carry more weight.

How Does The Alignment Of The Lathe’S Headstock And Spindle Bearings Influence The Overall Machining Accuracy?When we use a lathe, the headstock holds the spindle, which spins the metal. If the headstock and spindle bearings are lined up perfectly, the machine will cut better. This means your pieces will be smoother and fit together nicely. If they’re not lined up, you might get wobbly shapes or rough edges. So, good alignment makes your work more accurate!

What Are The Signs Of Improper Lubrication In Lathe Headstock Bearings, And What Lubrication Methods Are Recommended For Optimal Performance?You can tell if lathe headstock bearings need better lubrication if they make strange noises or feel hot. If you see metal dust or notice sticky spots, that’s also a sign. To keep them working well, we should use clean, fresh oil regularly. It’s best to follow the machine’s manual for how often to add oil. Always check the oil level to ensure everything runs smoothly!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Lathe Headstock Bearing, Metal Lathe Spindle:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions you might ask about a lathe headstock bearing and metal lathe spindle: 1. What is a lathe headstock? A lathe headstock is the part of the lathe that holds the spindle and motor. It helps the lathe spin. 2. What does the spindle do? The spindle is a metal rod that holds the workpiece. It turns it so you can shape it. 3. Why are bearings important? Bearings help the spindle spin smoothly. They reduce friction and allow for nice, easy movement. 4. How do I take care of the bearings? You can take care of bearings by cleaning them and adding oil. This keeps them working well. 5. What happens if bearings wear out? If bearings wear out, the spindle won’t spin smoothly. You might need to replace them to fix the lathe.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Different Types Of Bearings Used In Lathe Headstocks, And How Do They Impact Spindle Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe headstocks use different types of bearings to help the spindle move smoothly. The most common types are ball bearings and roller bearings. Ball bearings are round and help reduce friction, making the spindle spin easily. Roller bearings are shaped like small cylinders and can handle heavier loads. Both types help the lathe work better and last longer by keeping everything running smoothly.”}},{“@type”: “Question”,”name”: “How Do You Identify Bearing Wear Or Failure In A Metal Lathe Spindle, And What Maintenance Practices Can Extend Their Lifespan?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can spot bearing wear by listening for loud noises or feeling vibrations when the lathe runs. Check if the spindle feels loose or hard to turn. To keep bearings working well, clean them regularly and add some grease. Also, avoid running the lathe too fast. Inspect the bearings often to catch problems early.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used For Lathe Spindle Bearings, And How Do They Affect Precision And Load Capacity?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe spindle bearings are often made from metals like steel and bronze. These materials help the lathe spin smoothly. Steel is strong, so it can hold heavy things. Bronze reduces friction, which helps with precision. When we use the right materials, we get better accuracy and can carry more weight.”}},{“@type”: “Question”,”name”: “How Does The Alignment Of The Lathe’S Headstock And Spindle Bearings Influence The Overall Machining Accuracy?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we use a lathe, the headstock holds the spindle, which spins the metal. If the headstock and spindle bearings are lined up perfectly, the machine will cut better. This means your pieces will be smoother and fit together nicely. If they’re not lined up, you might get wobbly shapes or rough edges. So, good alignment makes your work more accurate!”}},{“@type”: “Question”,”name”: “What Are The Signs Of Improper Lubrication In Lathe Headstock Bearings, And What Lubrication Methods Are Recommended For Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can tell if lathe headstock bearings need better lubrication if they make strange noises or feel hot. If you see metal dust or notice sticky spots, that’s also a sign. To keep them working well, we should use clean, fresh oil regularly. It’s best to follow the machine’s manual for how often to add oil. Always check the oil level to ensure everything runs smoothly!”}}]}