Have you ever wondered what makes a lathe tick? A lathe is an exciting tool that helps us shape wood and metal. You can use it to make cool projects like furniture, tools, or even art. But not all lathes are the same. There are two main types: metal lathes and wood lathes.

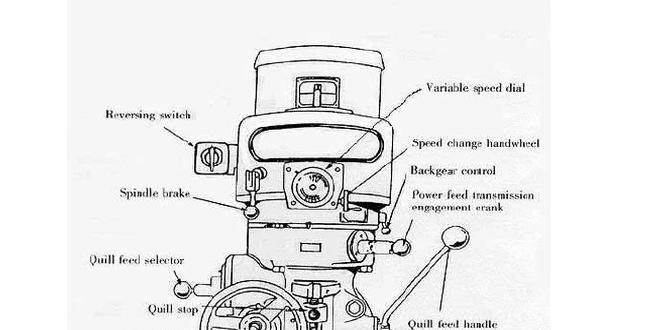

One of the key parts of any lathe is the headstock bearing. It helps keep everything in line and running smoothly. But what’s the real difference when we talk about lathe headstock bearing in metal lathes versus wood lathes? It’s a fascinating topic!

Imagine you’re making a wooden toy. You’d probably reach for a wood lathe, right? But what if you’re crafting a metal part for a machine? You’d pick a metal lathe instead. Each type has its strengths!

Discovering how these lathes work can help you choose the right one for your project. Did you know that wood lathes are generally lighter and easier to set up? Meanwhile, metal lathes are built to handle tougher materials.

Stick around as we dive deeper into the world of lathe headstock bearings. You might be surprised by what you learn!

Lathe Headstock Bearing: Metal Lathe Vs Wood Lathe Explained — Introduction When It Comes To Precision Machining And Woodworking, Understanding The Differences Between A Metal Lathe And A Wood Lathe—Or More Specifically, The Lathe Headstock Bearing In Both—Can Greatly Impact Your Projects. Each Type Of Lathe Serves Specific Purposes And Utilizes Different Technologies And Designs, Making The Choice Crucial For Achieving The Desired Results. Understanding Lathe Headstock Bearings The Headstock Of A Lathe Is A Vital Component That Houses The Motor And Drives The Spindle, Which Ultimately Determines The Rotation And, Consequently, The Accuracy Of The Machining Or Turning Process. The Bearings Play A Crucial Role In Supporting The Spindle And Ensuring Smooth Operation. Metal Lathe Bearings Metal Lathes Often Utilize High-Precision Ball Bearings, Designed To Withstand Heavy Loads And Operate At High Speeds. These Bearings Ensure Minimal Friction, Which Allows For Fine-Tuning Of Metal Work Pieces. The Robustness Of Metal Lathe Bearings Contributes To Their Longevity, Enabling Them To Handle Hard Materials Like Steel And Aluminum Effectively. Wood Lathe Bearings Wood Lathes, On The Other Hand, Typically Use Simpler Bearing Designs, Such As Plain Or Sleeve Bearings. Since Woodworking Processes Involve Softer Materials, The Requirements For Bearing Strength And Speed Are Less Demanding Compared To Metal Lathes. However, High-Quality Wood Lathe Bearings Still Play A Significant Role In Ensuring Smooth Operation And Sustainable Performance. Key Differences Between Metal Lathe And Wood Lathe Headstock Bearings 1. **Material Compatibility**: – Metal Lathes Are Suited For Durable, Tough Metals, While Wood Lathes Focus On Softer Woods. 2. **Speed And Load Bearing**: – Metal Lathe Bearings Are Designed For High-Speed Rotation And Heavy Loads. Wood Lathes Prioritize Stability And Consistent Operation With Lower Loads. 3. **Maintenance And Longevity**: – Metal Lathe Bearings Often Require More Maintenance Due To Their High-Performance Demands, While Wood Lathe Bearings Can Function Effectively With Less Upkeep. Conclusion Choosing Between A Metal Lathe And A Wood Lathe Largely Depends On The Materials You Plan To Work With And The Types Of Projects You Intend To Undertake. Understanding The Role Of The Lathe Headstock Bearing In Both Scenarios Can Help You Make The Right Choice, Ensuring That Your Lathe Meets Your Specific Needs For Precision And Durability. Whether Diving Into Woodworking Or Embracing Metalworking, Selecting The Appropriate Lathe Can Significantly Impact Your Craftsmanship Quality And Efficiency.

Lathe Headstock Bearing: Metal Lathe vs. Wood Lathe

Metal lathes and wood lathes differ mainly in their headstock bearing design. Metal lathes usually have stronger bearings to handle tough materials. They can spin at high speeds, making them ideal for precision work. Wood lathes, on the other hand, often have lighter bearings. This design suits softer materials and allows for smoother turning at lower speeds. Did you know that the type of lathe you choose can affect your project’s finish? Understanding these differences helps you pick the right lathe for your creative work!Understanding Lathe Headstock Bearings

Definition and function of the headstock bearing. Importance of bearings in lathe performance.Headstock bearings are essential components of a lathe. They help the spindle turn smoothly. This smooth rotation is crucial because it affects how well the lathe performs. Without good bearings, the lathe might shake or wobble, making it hard to create precise shapes. High-quality bearings can improve both speed and accuracy, making your work easier and more enjoyable.

Why Are Bearings Important?

Bearings help reduce friction. This means less wear and tear. With better bearings, your lathe lasts longer. Properly functioning bearings also improve overall safety while working.

| Benefit | Effect on Performance |

|---|---|

| Smooth Spindle Movement | Improved Precision |

| Reduced Friction | Longer Lifespan |

| Better Support | Safer Operation |

Material Differences: Metal vs. Wood Lathe Headstocks

Material composition of headstocks in metal lathes. Material composition of headstocks in wood lathes.Headstocks of metal and wood lathes are made from different materials. Metal lathes often use strong metals like cast iron or steel. These materials provide durability and reduce vibrations. On the other hand, wood lathes typically use aluminum or plastic, making them lighter. Each material has its strengths, serving the needs of different projects.

What materials are used in metal and wood lathe headstocks?

Metal lathes use heavy metals like steel or cast iron. Wood lathes utilize lighter materials like aluminum or plastic.

Performance and Efficiency Comparisons

Speed and precision in metal lathes. Speed and precision in wood lathes.When it comes to speed and precision, metal lathes and wood lathes perform differently. Metal lathes spin quickly and allow for exact cuts. This precision is key in creating parts that fit perfectly together. On the other hand, wood lathes focus more on smooth shaping rather than speed. They tend to work at slower speeds but create beautiful furniture and decorative pieces.

- Metal Lathes: High speed, excellent precision.

- Wood Lathes: Moderate speed, great for detailed shapes.

How do speed and precision differ between metal and wood lathes?

Metal lathes are faster and more precise, while wood lathes prioritize detail over speed. This makes each type great for their specific jobs.

Maintenance Requirements for Headstocks

Maintenance for metal lathe bearings. Maintenance for wood lathe bearings.Headstocks need regular care to work well. For a metal lathe, checking the bearings often is key. Clean them and apply oil to keep them smooth. For wood lathes, it’s vital to look for wear and tear. Dust can harm the bearings, so a quick clean helps a lot.

- Check and clean bearings every month.

- Lubricate with appropriate oil regularly.

- Look for signs of wear after heavy use.

How often should I maintain my lathe headstock bearings?

You should maintain your lathe headstock bearings at least once a month for best results. Regular checks help catch problems early and keep your lathe working smoothly.

Cost Analysis: Metal vs. Wood Lathe Bearings

Price range of metal lathe headstock bearings. Price range of wood lathe headstock bearings.When it comes to lathe bearings, the price can vary like a roller coaster ride. For metal lathe headstock bearings, you can expect to pay between $50 and $200, depending on size and quality. On the flip side, wood lathe headstock bearings tend to be a bit friendlier for your wallet, usually ranging from $30 to $100. So, if you’re feeling thrifty, consider going with a wood lathe. Remember, saving money is just as sweet as making sawdust!

| Type of Lathe | Price Range |

|---|---|

| Metal Lathe Bearings | $50 – $200 |

| Wood Lathe Bearings | $30 – $100 |

Common Problems and Solutions

Issues with metal lathe headstock bearings. Issues with wood lathe headstock bearings.Lathe machines can face headstock bearing issues. For metal lathes, the common trouble is excessive wear. This can cause those awful grinding sounds. Regular checking can help! Meanwhile, wood lathes might deal with gumming up from sawdust. It’s like sticky glue for your machine! Use a good cleaner during maintenance to avoid problems. Remember, a well-maintained lathe is a happy lathe!

| Lathe Type | Common Issues | Solutions |

|---|---|---|

| Metal Lathe | Excessive Wear | Regular checking |

| Wood Lathe | Gumming Up | Use a good cleaner |

Choosing the Right Lathe for Your Needs

Factors to consider when selecting a metal lathe. Factors to consider when selecting a wood lathe.Picking the right lathe is important. You need to think about what you will make. For a metal lathe, consider:

- Material type: Metal needs strong machines.

- Size: Bigger projects need bigger lathes.

- Speed options: Faster speeds help with different metals.

For a wood lathe, look at:

- Wood type: Softwoods are easier to shape.

- Length: Longer wood pieces need longer lathes.

- Function: Consider how you want to use it.

Think about what you will create to choose well.

What factors should I consider when selecting a lathe?

Consider your material, size of projects, and speed needs.Conclusion

In conclusion, understanding lathe headstock bearings helps you choose between metal and wood lathes. Metal lathes offer precision for hard materials, while wood lathes excel with softer woods. Remember these differences when selecting your lathe. For hands-on learning, consider visiting a workshop or reading more online. Your projects will thank you! Happy turning!FAQs

Here Are Five Related Questions On The Topic Of Lathe Headstock Bearings In Metal Lathes Versus Wood Lathes:Metal lathes and wood lathes have different headstock bearings. Metal lathes need strong bearings because they cut harder materials. Wood lathes, on the other hand, work with softer wood, so they can use lighter bearings. This makes metal lathes better for heavy-duty work, while wood lathes are great for smooth finishes on wood. You should choose the right lathe based on what you want to make.

Sure! Please provide the question you want me to answer.

What Are The Key Differences In The Design And Function Of Headstock Bearings In Metal Lathes Compared To Wood Lathes?Headstock bearings help hold the spinning part of the lathe. In metal lathes, these bearings are usually stronger because metal is harder. They need to handle heavy forces from cutting metal. Wood lathes use lighter bearings since wood is softer and easier to shape. This difference helps each lathe do its job better.

How Do The Materials Used In Lathe Headstock Bearings Affect The Performance And Durability Of Metal Lathes Versus Wood Lathes?The materials in lathe headstock bearings are really important. For metal lathes, we need strong and durable materials like steel. They handle heavy work and stay in good shape longer. Wood lathes can use lighter materials because wood is easier to turn. So, the bearings make a big difference in how well the lathe works and how long it lasts.

What Are The Common Types Of Headstock Bearings Used In Metal Lathes, And How Do They Differ From Those Used In Wood Lathes In Terms Of Lubrication And Maintenance?In metal lathes, you usually find ball bearings or roller bearings. These help the machine turn smoothly and last a long time. Wood lathes often use plain bearings, which are simpler and cheaper. Metal lathes need special oil for lubrication, while wood lathes might just need grease. This difference means metal lathes might need more careful maintenance.

How Does The Weight And Balance Of The Workpiece Influence The Selection Of Headstock Bearings In Metal Lathes Versus Wood Lathes?The weight and balance of the workpiece are very important for choosing headstock bearings in lathes. In metal lathes, we often work with heavier pieces, so we need stronger bearings. These bearings must handle the weight without wobbling. In wood lathes, workpieces are usually lighter, so we can use simpler bearings. This helps the lathe spin smoothly and make nice, even cuts.

In What Ways Do Headstock Bearing Configurations Impact The Precision And Finishing Capabilities Of Metal Lathes As Opposed To Wood Lathes?The headstock bearing on a lathe holds and supports the spinning part. In metal lathes, these bearings are usually tighter and stronger, which helps make very precise cuts. This means the metal pieces can fit together better and look nice. Wood lathes have looser bearings, so they work well for shaping wood, but they aren’t as precise as metal lathes. So, metal lathes help you create better finished parts.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Headstock Bearings In Metal Lathes Versus Wood Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes and wood lathes have different headstock bearings. Metal lathes need strong bearings because they cut harder materials. Wood lathes, on the other hand, work with softer wood, so they can use lighter bearings. This makes metal lathes better for heavy-duty work, while wood lathes are great for smooth finishes on wood. You should choose the right lathe based on what you want to make.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Differences In The Design And Function Of Headstock Bearings In Metal Lathes Compared To Wood Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Headstock bearings help hold the spinning part of the lathe. In metal lathes, these bearings are usually stronger because metal is harder. They need to handle heavy forces from cutting metal. Wood lathes use lighter bearings since wood is softer and easier to shape. This difference helps each lathe do its job better.”}},{“@type”: “Question”,”name”: “How Do The Materials Used In Lathe Headstock Bearings Affect The Performance And Durability Of Metal Lathes Versus Wood Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The materials in lathe headstock bearings are really important. For metal lathes, we need strong and durable materials like steel. They handle heavy work and stay in good shape longer. Wood lathes can use lighter materials because wood is easier to turn. So, the bearings make a big difference in how well the lathe works and how long it lasts.”}},{“@type”: “Question”,”name”: “What Are The Common Types Of Headstock Bearings Used In Metal Lathes, And How Do They Differ From Those Used In Wood Lathes In Terms Of Lubrication And Maintenance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In metal lathes, you usually find ball bearings or roller bearings. These help the machine turn smoothly and last a long time. Wood lathes often use plain bearings, which are simpler and cheaper. Metal lathes need special oil for lubrication, while wood lathes might just need grease. This difference means metal lathes might need more careful maintenance.”}},{“@type”: “Question”,”name”: “How Does The Weight And Balance Of The Workpiece Influence The Selection Of Headstock Bearings In Metal Lathes Versus Wood Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The weight and balance of the workpiece are very important for choosing headstock bearings in lathes. In metal lathes, we often work with heavier pieces, so we need stronger bearings. These bearings must handle the weight without wobbling. In wood lathes, workpieces are usually lighter, so we can use simpler bearings. This helps the lathe spin smoothly and make nice, even cuts.”}},{“@type”: “Question”,”name”: “In What Ways Do Headstock Bearing Configurations Impact The Precision And Finishing Capabilities Of Metal Lathes As Opposed To Wood Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The headstock bearing on a lathe holds and supports the spinning part. In metal lathes, these bearings are usually tighter and stronger, which helps make very precise cuts. This means the metal pieces can fit together better and look nice. Wood lathes have looser bearings, so they work well for shaping wood, but they aren’t as precise as metal lathes. So, metal lathes help you create better finished parts.”}}]}