Have you ever heard strange noises from a lathe? If you have a workshop, this might sound familiar. Lathe headstock noise can be puzzling and even alarming. But what causes these sounds? Is it just a normal part of using the machine, or could it mean something is wrong?

Picture this: you’re working on an exciting project, and suddenly, your lathe starts sounding like a wild animal! This can stop any woodworker or metalworker in their tracks. Understanding lathe headstock noise is not just about fixing an issue; it’s about keeping your machine running smoothly.

In this article, we’ll explore the different causes of lathe headstock noises. We’ll look at common problems and how to fix them. By the end, you’ll feel confident in tackling any strange sounds your lathe might make. Let’s dive into the world of lathe maintenance together!

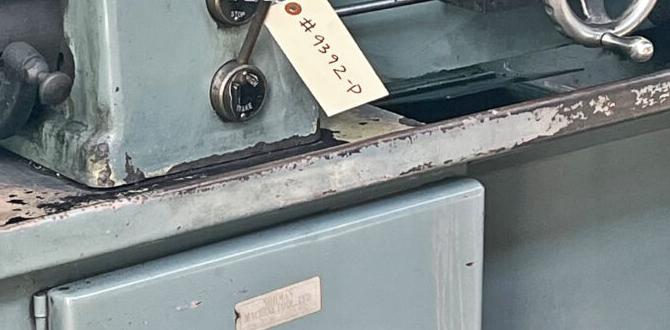

Lathe Headstock Noise Causes: Understanding The Issues

Lathe Headstock Noise Causes

Lathe headstock noise can be annoying. It often indicates a problem. One common cause is lack of lubrication. Did you know that dry bearings can create a squeaky sound? Another reason might be worn gears, which can cause grinding noises. Sometimes, loose components also create rattling sounds. Regular maintenance can help prevent these issues. To keep your lathe running smoothly, check and fix these noises early. Ignoring them may lead to bigger problems!Common Sources of Lathe Headstock Noise

Mechanical components and wear. Motor malfunctions.Lathe headstock noise often comes from a few common problems. Mechanical components can wear out over time. This can lead to rattling or grinding sounds. Motor malfunctions can also cause issues. An overheated motor can create loud noises. It’s essential to check these parts regularly. Don’t ignore unusual sounds. Early action can prevent bigger problems down the line.

What causes noise in a lathe headstock?

Noise in a lathe headstock can be caused by worn-out parts or motor issues. Regular checks can help reduce these problems.

Common causes:

- Worn bearings

- Loose screws

- Overheated motors

Impact of Lubrication on Noise Levels

Importance of proper lubrication. Effects of inadequate lubrication on headstock performance.Proper lubrication is key to a quiet lathe headstock. Good lubrication helps reduce friction. This means less noise and smoother operation. Without enough oil, parts can grind against each other. This can lead to wear and tear. Inadequate lubrication can cause:

- Increased noise levels

- Reduced efficiency

- Shorter machine lifespan

Lubricated parts work better and last longer. So, always check your oil levels!

What happens if lubrication is not enough?

If lubrication is not enough, parts wear out quickly and noise increases. Proper oil keeps machines running smoothly and quietly.

Diagnosing Vibrations and Their Causes

Identifying vibration sources. Analyzing the relationship between vibration and noise.Vibrations can be tricky. They often come from many sources. To identify these sources, check the following:

- Loose parts

- Misalignment of components

- Worn-out bearings

- Unbalanced tools

Noise is often linked to vibrations. When you see or hear strong vibrations, it may mean something is wrong. Listening carefully can help. Observing changes in noise levels can guide you to the problem. Pay attention to loud clinks or clatters. These may show what part needs fixing.

What causes vibrations in a lathe?

Some common causes of vibrations in a lathe include loose parts, misaligned components, and worn bearings. Finding the cause is essential for smooth operation and safety.

Effect of Workpiece Material on Headstock Noise

How different materials influence noise levels. Tips for selecting quieter workpieces.Various materials can create different noise levels when lathe work happens. For instance, softer metals like aluminum tend to produce less sound than harder ones like steel. If you want a quieter experience, consider using materials like plastic or wood when possible. They can help keep the peace and let you concentrate. Here’s a quick look:

| Material | Noise Level |

|---|---|

| Aluminum | Low |

| Plastic | Very Low |

| Steel | High |

| Wood | Medium |

Choosing quieter materials can save your ears from the loud symphony of metal cutting. They say silence is golden, and in this case, it can keep the work environment pleasant!

Maintenance Practices to Reduce Noise

Regular inspection and maintenance routines. Adjustments to alignments and tension settings.Keeping your lathe headstock quiet is important. Regular checks help you find problems early. Schedule inspections every few months to look for wear and tear. Make sure everything is clean and free of debris. Correct adjustments can also help reduce noise. Align parts properly and adjust tension settings carefully. This improves performance and lowers noise levels.

- Inspect every 3 months

- Keep parts clean

- Align components correctly

- Tighten tension settings

How can I reduce lathe headstock noise?

Regular maintenance, like checking alignments and tension, can help reduce noise. Taking care of your equipment ensures quieter operation and better performance.

Modifications and Upgrades for Noise Reduction

Aftermarket components for quieter operation. Benefits of vibration dampers and isolation mounts.Upgrading your lathe can make a big difference in noise levels. Adding aftermarket components is like putting a superhero cape on your machine! Vibrations can cause a racket, but vibration dampers are here to save the day. These handy gadgets reduce unwanted shaking, making your lathe whisper instead of shout. Isolation mounts can also help, soaking up vibrations like a sponge. With the right upgrades, your workspace can become a peaceful haven.

| Modification | Benefit |

|---|---|

| Vibration Dampers | Reduce noise and shaking. |

| Isolation Mounts | Absorb vibrations for quieter operation. |

Case Studies: Noise Issues in Various Lathes

Insights from common lathe brands. Solutions implemented in realworld scenarios.Different lathes can have noise problems. Each brand has unique challenges and solutions. Here are some insights:

- One common lathe had a loud noise due to a worn bearing. The owner replaced it, which fixed the issue.

- Another lathe produced noise from loose components. Tightening screws helped reduce sound.

- A brand struggled with vibration. Adding dampers solved the problem and improved performance.

Real-world examples show that simple fixes can lead to quieter machines. Owners found that regular maintenance keeps noise levels down and lathes running smoothly.

What causes lathe noise issues?

Common causes include worn parts, loose connections, and vibration. Regular checks can help prevent problems.

Solutions people use:

- Regular lubrication of moving parts

- Tightening loose fittings

- Replacing damaged components

When to Seek Professional Help

Signs that indicate a need for expert intervention. Cost considerations for repairs and upgrades.Many signs tell you it’s time to call a pro for help. If you hear unusual noises from the lathe headstock, it could mean trouble. Other signs include changes in performance or visible damage. Don’t ignore these!

Repair costs can vary widely. Sometimes, simple fixes are cheap. But major repairs may cost more. Plan ahead, so you know your budget.

- Listen for strange sounds.

- Watch for slower performance.

- Check for any cracks or breaks.

How do I know when to seek help?

Listen and watch carefully. Strange sounds, slow speeds, or visible issues are signs to act.

Keeping your lathe in good shape is important. Early help saves money later. Remember, seeking help early might prevent bigger issues down the road.

Conclusion

In conclusion, lathe headstock noise can come from worn bearings, loose parts, or improper alignment. We can find and fix these issues to improve your lathe’s performance. Always check for tight screws and clean parts regularly. If you’re unsure, consider asking a technician for help. For more tips, keep reading about lathe maintenance to ensure smooth operation!FAQs

What Are The Most Common Causes Of Noise Originating From A Lathe Headstock?The most common causes of noise from a lathe headstock are loose parts, worn bearings, and misalignment. If parts are loose, they can rattle and make noise. Worn bearings are like old wheels that don’t move smoothly. Misalignment happens when the parts don’t line up correctly. We need to fix these issues to stop the noise.

How Can Worn Bearings Affect The Sound Produced By A Lathe Headstock?Worn bearings can make your lathe headstock sound noisy or rough. When the bearings are damaged, they don’t hold things in place well. This can cause vibrations that make strange sounds. You might hear buzzing, grinding, or clicking noises. Fixing the bearings can help make your lathe run smoother and quieter.

What Maintenance Practices Can Help Reduce Noise In A Lathe Headstock?To reduce noise in a lathe headstock, you should regularly check and clean it. Make sure you oil the moving parts to keep them running smoothly. Tighten any loose screws or bolts to prevent rattling sounds. You can also replace worn-out parts. This will help your lathe work quietly and efficiently.

How Does Improper Alignment Of The Lathe Components Contribute To Headstock Noise?When the parts of a lathe aren’t lined up right, they can bump into each other. This bumping makes loud noises. You might hear clanking or grinding sounds coming from the headstock, which is the part that holds the tool. Keeping everything straight and evenly spaced helps reduce these annoying sounds. It’s like making sure your toy car’s wheels are straight for a smooth ride.

What Are The Signs Of A Failing Motor In The Lathe Headstock That May Lead To Increased Noise Levels?If your lathe motor is failing, you might hear unusual grinding or squeaking noises. You could also notice the machine shaking more than usual. It may run slower or stop suddenly. These signs mean something is wrong, and you should check it out!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Most Common Causes Of Noise Originating From A Lathe Headstock? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The most common causes of noise from a lathe headstock are loose parts, worn bearings, and misalignment. If parts are loose, they can rattle and make noise. Worn bearings are like old wheels that don’t move smoothly. Misalignment happens when the parts don’t line up correctly. We need to fix these issues to stop the noise.”}},{“@type”: “Question”,”name”: “How Can Worn Bearings Affect The Sound Produced By A Lathe Headstock? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Worn bearings can make your lathe headstock sound noisy or rough. When the bearings are damaged, they don’t hold things in place well. This can cause vibrations that make strange sounds. You might hear buzzing, grinding, or clicking noises. Fixing the bearings can help make your lathe run smoother and quieter.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Can Help Reduce Noise In A Lathe Headstock? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To reduce noise in a lathe headstock, you should regularly check and clean it. Make sure you oil the moving parts to keep them running smoothly. Tighten any loose screws or bolts to prevent rattling sounds. You can also replace worn-out parts. This will help your lathe work quietly and efficiently.”}},{“@type”: “Question”,”name”: “How Does Improper Alignment Of The Lathe Components Contribute To Headstock Noise? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When the parts of a lathe aren’t lined up right, they can bump into each other. This bumping makes loud noises. You might hear clanking or grinding sounds coming from the headstock, which is the part that holds the tool. Keeping everything straight and evenly spaced helps reduce these annoying sounds. It’s like making sure your toy car’s wheels are straight for a smooth ride.”}},{“@type”: “Question”,”name”: “What Are The Signs Of A Failing Motor In The Lathe Headstock That May Lead To Increased Noise Levels? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your lathe motor is failing, you might hear unusual grinding or squeaking noises. You could also notice the machine shaking more than usual. It may run slower or stop suddenly. These signs mean something is wrong, and you should check it out!”}}]}