Have you ever noticed the cool patterns on metal parts? Those patterns can come from a special technique called lathe knurling. Lathe knurling creates cross hatch patterns that not only look great but also help parts grip better. Imagine holding a tool that won’t slip from your hands because of these textured designs.

Did you know that these patterns have been used for centuries? They can be seen on everyday items, like knobs and handles. Knurling involves pressing a tool against metal as it spins. This simple action forms those amazing cross hatch designs.

So, why is this important? Knurling isn’t just about looks; it serves a purpose. It helps improve the usability of tools and parts. Next time you use a tool, take a closer look. You might just spot the unique knurling pattern and admire the craftsmanship behind it!

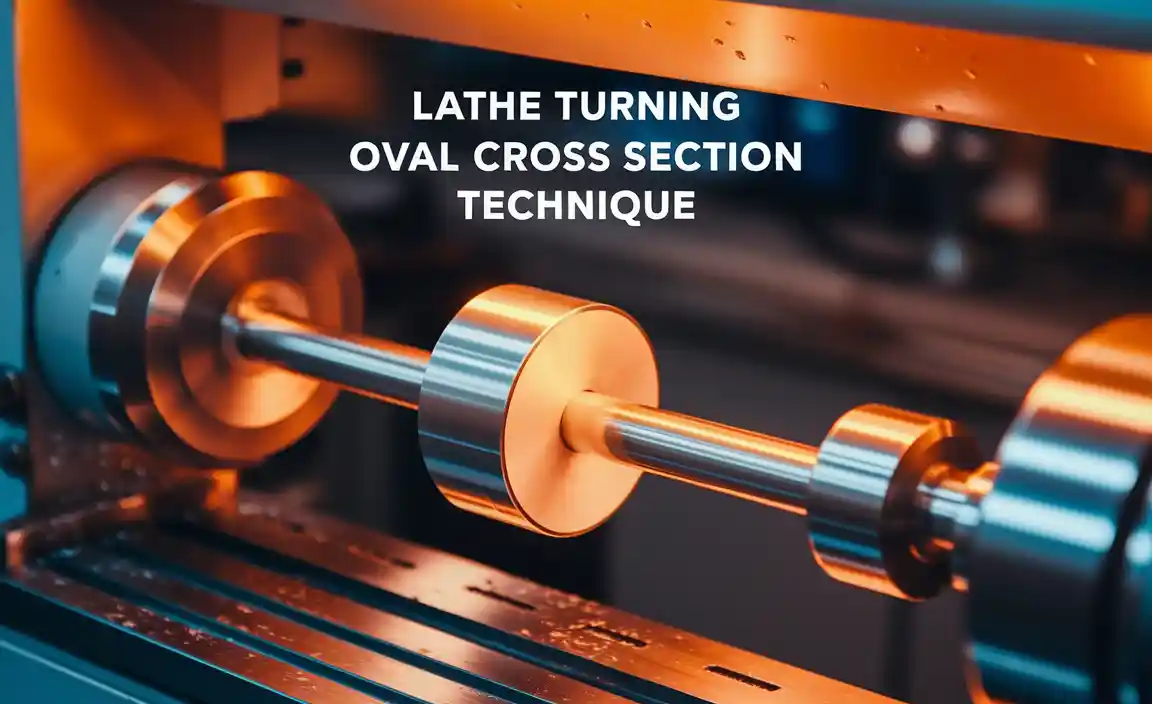

Lathe Knurling Cross Hatch Patterns: Techniques And Tips

Understanding Lathe Knurling Cross Hatch Patterns

Lathe knurling creates cool textures on metal. One common style is the cross hatch pattern. This design looks like a crisscross grid and offers better grip. Did you know that knurling can also enhance a handle’s appearance? It’s like decorating a birthday cake but for metal! Learning about lathe knurling helps you appreciate the craftsmanship behind tools and machines. With this knowledge, you’ll notice these patterns everywhere in everyday life.Understanding Knurling and Its Importance

Definition of knurling in machining. Benefits of knurling in enhancing grip and aesthetics.Knurling is a process used in machining to create patterns on a surface. It involves pressing a tool against the material, forming raised designs. Knurling improves grip on handles or knobs, making them easier to hold. It also adds a decorative touch, making objects look better. The benefits include:

- Enhanced Grip: Users find it easier to grasp.

- Improved Aesthetics: The designs make items look attractive.

Types of Knurling Patterns

Explanation of different knurling patterns: diamond, straight, cross hatch. Comparison of patterns and their applications.Knurling patterns add flair to metal surfaces. There are three main types: diamond, straight, and cross hatch. Diamond patterns look like little diamonds all over your workpiece. This design is sturdy and easy to grip. Straight knurling resembles little lines, which can be great for aesthetics without being too wild. Cross hatch patterns mix lines at angles, forming a cool crisscross that’s both functional and stylish. Each pattern serves a specific purpose, making your project not just useful but also snazzy!

| Pattern Type | Design | Best Use |

|---|---|---|

| Diamond | Diamond shapes | High grip surfaces |

| Straight | Vertical or horizontal lines | Visual appeal |

| Cross Hatch | Crisscross lines | Adding style to function |

What are Cross Hatch Patterns?

Description of cross hatch patterns and their characteristics. Common uses of cross hatch patterns in various industries.Cross hatch patterns are cool designs made from lines that crisscross each other. They resemble a checkerboard but with more flair! These patterns are often seen in manufacturing. They add grip to objects, making them easier to hold. You can find them on tools, car parts, and even in fashion! Cross hatch patterns are not just pretty; they help improve safety and functionality. Let’s look at their common uses in a handy table:

| Industry | Uses |

|---|---|

| Automotive | Tire tread designs for better traction. |

| Manufacturing | Knurling on tool handles to prevent slipping. |

| Fashion | Textured fabrics for unique styles. |

Step-by-Step Guide to Creating Cross Hatch Patterns

Detailed instructions on setting up the lathe. Techniques for achieving precise cross hatch patterns.Setting up your lathe is easy. Follow these steps for the best results:

- Check the power supply. Make sure your lathe is plugged in and ready.

- Secure the workpiece tightly in the chuck.

- Adjust the speed settings to the recommended level for your material.

For precise cross hatch patterns:

- Use a light touch while cutting.

- Keep a steady hand to ensure even lines.

- Practice different angles for unique patterns.

Remember, patience makes perfect patterns!

How can I create sharp cross hatch patterns on my lathe?

To create sharp cross hatch patterns on your lathe, start with a clean setup. Use a sharp tool and maintain a consistent speed. Practice makes it easier!

Common Mistakes and How to Avoid Them

List of frequent errors in knurling. Tips for ensuring quality results.Knurling can get tricky! Common mistakes pop up, like choosing the wrong tool or applying too much pressure. These slip-ups can leave your cross hatch patterns looking more like a potato sack than a fine finish. To avoid this, ensure your lathe speed matches your material. Also, keep the work area clean; it’s hard to make nice patterns in a messy space! If you feel overwhelmed, remember: even the best masters once faced knurling chaos.

| Error | How to Avoid |

|---|---|

| Wrong Tool | Choose the right knurling tool for your project. |

| Too Much Pressure | Apply steady, even pressure for best results. |

| Dirty Workspace | Keep your area tidy to spot problems quickly. |

Maintenance and Care for Knurling Tools

Importance of maintaining knurling tools. Best practices for cleaning and storing tools.Knurling tools need care to work well. Proper maintenance helps them last longer and perform better. Here are some useful tips:

- Always clean the tools after use. Remove dust and debris.

- Store them in a dry place. Keep them away from moisture.

- Regularly check for damage. Repair any dings or chips.

- Use a light oil to protect the surfaces. It helps prevent rust.

Taking these steps keeps your lathe knurling cross hatch patterns sharp and effective.

How often should knurling tools be cleaned?

You should clean knurling tools after every use. This helps remove dirt and keeps them in good shape.

Applications of Cross Hatch Knurling in Industries

Examples of industries that utilize cross hatch patterns. Case studies showcasing successful use of knurling.Many industries love cross hatch knurling for its grip and aesthetic appeal. For example, the automotive sector uses it on gear knobs to prevent slipping. In the tool manufacturing realm, knurling helps create better tool handles. Studies show that knurled surfaces can improve grip by up to 40%. Another case? Medical devices utilize cross hatch patterns for better control. Every smart design counts—because no one wants their screwdriver to skate away like a runaway chicken!

| Industry | Application |

|---|---|

| Automotive | Gear knobs |

| Manufacturing | Tool handles |

| Medical | Device grips |

Future Trends in Knurling Techniques

Innovations in knurling technology. Predictions for the evolution of cross hatch patterns.New tools and machines make knurling faster and more accurate. This helps create better cross hatch patterns. In the future, we might see smart technology that adjusts settings automatically. This means fewer mistakes and better designs. Here are some key predictions:

- Advanced materials for stronger patterns

- Faster production methods

- Better safety features

Exciting changes are on the way! They’ll help make knurling more efficient and creative.

What are the current trends in knurling techniques?

Current trends include using computer technology, new materials, and improved safety measures. These advancements ensure better design and less waste in production.

Conclusion

In summary, lathe knurling creates useful cross hatch patterns on metal surfaces. These patterns improve grip and appearance. You can achieve this by adjusting your lathe settings and using the right tools. We encourage you to try knurling on your projects. Explore more about lathe techniques and practice to enhance your skills. Happy machining!FAQs

Here Are Five Questions Related To Lathe Knurling Cross Hatch Patterns:Sure! A lathe is a machine that shapes metal or wood. Knurling is the process of making a pattern on the surface, like little bumps. A cross hatch pattern looks like crisscross lines. We use knurling to make grips, so things don’t slip. It helps us hold things better when we use tools.

Sure! Just let me know what question you would like me to answer.

What Are The Primary Benefits Of Using Cross Hatch Knurling Patterns On Machined Parts?Cross hatch knurling patterns make machined parts easier to grip. This means you can hold them better without slipping. They also help to make things look nice and professional. Plus, they can help prevent wear and tear, making parts last longer. Overall, these patterns improve the performance and durability of the part!

How Do Different Types Of Knurling Tools Affect The Quality And Appearance Of Cross Hatch Patterns?Different knurling tools can make patterns look unique. Some tools create deep lines, while others make them shallow. When you choose a tool, think about how you want the pattern to appear. A sharper tool might make cleaner designs, while a rougher tool gives a bumpier look. Each choice affects how nice the final product looks!

What Factors Should Be Considered When Selecting The Appropriate Pitch And Depth For Cross Hatch Knurling?When choosing the pitch and depth for cross hatch knurling, think about what you need. The pitch is how close the lines are together. If you want a smooth grip, use a smaller pitch. The depth affects how deep the lines are. Deeper lines give a stronger grip, but they might make the surface rougher.

How Can One Troubleshoot Common Issues, Such As Slippage Or Uneven Patterns, During The Knurling Process On A Lathe?To fix slippage or uneven patterns while knurling on a lathe, you can try a few things. First, check if your workpiece is held tightly. If it’s loose, it can slip. Next, make sure the knurling tool is sharp and set right. If it’s dull or not aligned, it can make uneven marks. Also, adjust the speed of the lathe; sometimes a slower speed helps.

In What Applications Is Cross Hatch Knurling Particularly Advantageous Compared To Other Knurling Styles?Cross hatch knurling is great for tools that need a good grip, like handles and knobs. It gives a better surface for your fingers to hold on to, so you won’t slip. This style looks nice, too, with its neat pattern. We often use it in products like wrenches and faucets where you want both style and safety.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Questions Related To Lathe Knurling Cross Hatch Patterns:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that shapes metal or wood. Knurling is the process of making a pattern on the surface, like little bumps. A cross hatch pattern looks like crisscross lines. We use knurling to make grips, so things don’t slip. It helps us hold things better when we use tools.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Primary Benefits Of Using Cross Hatch Knurling Patterns On Machined Parts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Cross hatch knurling patterns make machined parts easier to grip. This means you can hold them better without slipping. They also help to make things look nice and professional. Plus, they can help prevent wear and tear, making parts last longer. Overall, these patterns improve the performance and durability of the part!”}},{“@type”: “Question”,”name”: “How Do Different Types Of Knurling Tools Affect The Quality And Appearance Of Cross Hatch Patterns?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different knurling tools can make patterns look unique. Some tools create deep lines, while others make them shallow. When you choose a tool, think about how you want the pattern to appear. A sharper tool might make cleaner designs, while a rougher tool gives a bumpier look. Each choice affects how nice the final product looks!”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting The Appropriate Pitch And Depth For Cross Hatch Knurling?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing the pitch and depth for cross hatch knurling, think about what you need. The pitch is how close the lines are together. If you want a smooth grip, use a smaller pitch. The depth affects how deep the lines are. Deeper lines give a stronger grip, but they might make the surface rougher.”}},{“@type”: “Question”,”name”: “How Can One Troubleshoot Common Issues, Such As Slippage Or Uneven Patterns, During The Knurling Process On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix slippage or uneven patterns while knurling on a lathe, you can try a few things. First, check if your workpiece is held tightly. If it’s loose, it can slip. Next, make sure the knurling tool is sharp and set right. If it’s dull or not aligned, it can make uneven marks. Also, adjust the speed of the lathe; sometimes a slower speed helps.”}},{“@type”: “Question”,”name”: “In What Applications Is Cross Hatch Knurling Particularly Advantageous Compared To Other Knurling Styles?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Cross hatch knurling is great for tools that need a good grip, like handles and knobs. It gives a better surface for your fingers to hold on to, so you won’t slip. This style looks nice, too, with its neat pattern. We often use it in products like wrenches and faucets where you want both style and safety.”}}]}