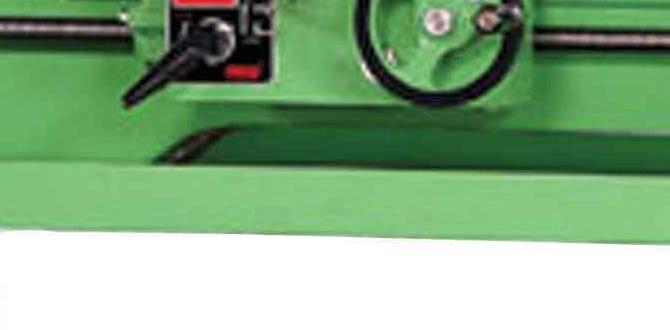

Have you ever wondered how to keep your metal lathe running smoothly? Proper lathe lubrication is crucial for maintaining its performance. When a lathe is well-lubricated, it cuts through metal with ease. Imagine trying to ride a bike that has no oil on the chain—it would be tough, right? The same idea applies here.

But there’s more to it than just oiling up the parts. Many modern metal lathes come with a controller board. This board helps manage various settings. It can even optimize lubrication automatically. How cool is that?

Whether you’re a beginner or an expert, understanding lathe lubrication can improve your projects. So, let’s dive into how to keep your lathe in top shape and why that controller board is a game changer!

Effective Lathe Lubrication For Metal Lathe Controller Boards

Lathe Lubrication and Controller Boards

Lathe lubrication is essential for smooth operation and longevity. Using the right lubricant keeps the metal lathe parts functioning well and reduces wear. Did you know that over-lubricating can be just as harmful as not lubricating at all? A metal lathe controller board manages the machine’s operations, including speed and feed settings. Proper maintenance of both the lathe and its controller board ensures precise cuts and safer working conditions. This knowledge can help both beginners and experts achieve better results in their projects.Importance of Lathe Lubrication

Discuss the role of lubrication in metal lathes.. Explain how proper lubrication enhances machine efficiency and lifespan..Keeping your metal lathe happy is all about lubrication. Think of it as giving your machine a refreshing spa day! Proper lubrication reduces friction. This means your lathe runs smoother, just like butter on hot toast. In fact, a well-lubricated lathe can last longer and work better. It’s like magic—only without the rabbits! A little oil goes a long way, ensuring you finish projects faster and keep your tools in tip-top shape.

| Benefit | Description |

|---|---|

| Increased Efficiency | Less friction means quicker work. |

| Longer Lifespan | Good lubrication helps prevent wear. |

Types of Lubricants for Metal Lathes

Outline different lubricant options (oil, grease, etc.).. Discuss the pros and cons of each type..When it comes to keeping your metal lathe moving smoothly, you have several lubricant options, each with its own perks and quirks. For example, oil flows easily and offers great coverage but may drip under heat. On the flip side, grease sticks around longer and fights off dirt but can be too thick for some machines. Let’s break it down with a handy table!

| Type | Pros | Cons |

|---|---|---|

| Oil | Easy to apply, good coverage | Can drip, may need frequent reapplication |

| Grease | Stays in place, great for high stress | Thick, can attract dirt |

| Dry Lubricant | Clean, no mess, good for dusty areas | Less effective under heavy loads |

Now you know! Choose wisely, and your lathe will thank you with smooth operations. Don’t forget, your metal lathe needs a little love too—after all, what’s the point of cutting metal if it’s squeaking like a mouse?

Best Practices for Lathe Lubrication

Detail a stepbystep lubrication routine.. Include tips on frequency and methods of application..Keeping your lathe well-lubricated helps it run smoothly. Follow this simple routine:

- **Clean the Machine:** Remove any dust or debris.

- **Choose the Right Oil:** Use the recommended lubricant for your model.

- **Apply Oil Regularly:** Lubricate every 4-6 hours of use.

- **Check Oil Levels:** Ensure there’s enough oil before starting your work.

Remember, good lubrication increases the life of your lathe. It also helps with precision in your projects. So, don’t skip this important step!

How often should you lubricate a lathe?

It’s best to lubricate **every 4-6 hours** of use. This helps keep parts moving freely and reduces wear.

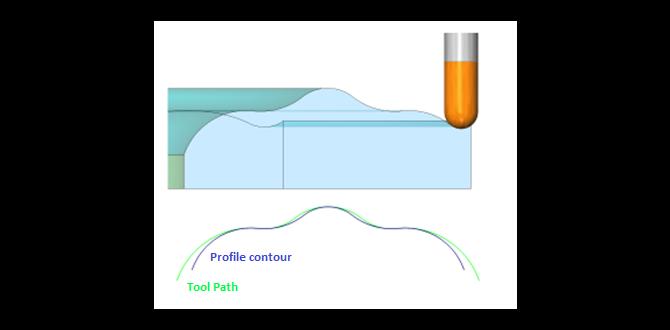

Lubrication Systems for Metal Lathes

Explore manual vs. automatic lubrication systems.. Discuss the compatibility of lubrication systems with controller boards..Keeping your metal lathe happy means understanding lubrication systems. There are two main types: manual and automatic. Manual systems require you to be a hands-on mechanic, while automatic systems are like having a helpful robot that does the job for you! Automatic systems save time and ensure even lubrication. Now, let’s talk compatibility. Not every lubrication system works with all controller boards, so make sure they play nice together. Wouldn’t want your lathe’s “best friend” to be a total mismatch!

| System Type | Pros | Cons |

|---|---|---|

| Manual | Cost-effective, user-controlled | Requires more time and effort |

| Automatic | Efficient, consistent lubrication | Higher initial cost |

Common Mistakes in Lathe Lubrication

Highlight frequent errors to avoid in the lubrication process.. Provide solutions to these common mistakes..Many people make simple mistakes when lubricating their lathe. One common error is using the wrong type of oil. Always check your lathe manual for the best lubricant. Another mistake is applying too much oil. It’s like giving your pet too many treats; it can get messy! Use just enough to keep things running smoothly. Remember to clean the lathe before adding oil, or dirt will gum up the works. Here’s a quick guide to help:

| Mistake | Solution |

|---|---|

| Using wrong oil | Check the manual for recommended oils |

| Over-lubricating | Apply a small amount; less is often more! |

| Ineffective cleaning | Clean thoroughly before lubrication |

Choosing the Right Controller Board for Lubrication Control

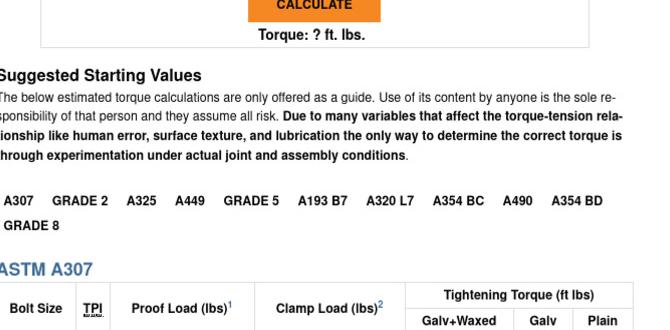

Discuss features to look for in a controller board related to lubrication.. Compare popular controller boards on the market..Picking a controller board for lubrication isn’t rocket science, but it might feel like it! Look for good features like automatic lubrication timing and easy adjustments. Some boards even offer smart sensors to monitor oil levels—talk about high-tech! Here’s a quick comparison of some popular options:

| Controller Board | Automatic Timing | Smart Sensors | Ease of Use |

|---|---|---|---|

| Board A | ✔️ | ✔️ | Easy Peasy |

| Board B | ✔️ | ❌ | Medium |

| Board C | ❌ | ✔️ | Challenging |

Board A takes the crown for best features overall. Always check reviews to be sure you’re not buying a ‘paperweight’! Remember, a good controller can save you from some messy mishaps!

Maintaining Lubrication in Challenging Conditions

Address how to adapt lubrication practices in extreme environments.. Suggest lubricants ideal for tough working conditions..Keeping things slick in tough spots is key to your lathe’s health. Extreme temperatures or dusty jobs can put a strain on your lubrication habits. Special lubricants are like superhero sidekicks for your tools. They help prevent wear and tear even in harsh conditions. Don’t shy away from oils with additives that resist oxidation. For tricky environments, consider using silicone-based or graphite lubricants. They stay slippy where regular options might fail!

| Lubricant Type | Ideal Conditions |

|---|---|

| Silicone-Based | High heat and moisture |

| Graphite | Dusty or dry areas |

| Extreme Pressure Oil | High-load applications |

Remember, a well-lubricated lathe is a happy lathe. Keep it moving smoothly, and your projects will shine!

Frequently Asked Questions (FAQs) about Lathe Lubrication

List common queries and concise answers regarding lubrication practices.. Include troubleshooting tips for lubricationrelated issues..Many people wonder about the best ways to keep their lathes running smoothly. Here are some common questions and their answers:

| Question | Answer |

|---|---|

| How often should I lubricate my lathe? | Every few hours of use is ideal. Think of it as giving your lathe a refreshing drink! |

| What type of oil should I use? | Use a light machine oil. Choose something that won’t leave your lathe slippy-sloppy! |

| What if it makes weird noises? | Check for low lubrication. It could be cranky from thirst! |

| Can I over-lubricate? | Yes! Too much oil can mix with chips and create a gooey mess. |

Remember, keeping your lathe well-lubricated is like giving it a little spa day—everyone deserves that! If things go wrong, don’t panic. Check the oil level first, then look for clogs. A small fix can save a big headache!

Conclusion

In summary, proper lathe lubrication is vital for smooth operation and tool longevity. A metal lathe controller board helps manage functions effectively. Keeping your lathe well-lubricated improves performance and prevents damage. Remember to check the lubrication regularly. For more tips on lathe maintenance and controller boards, explore more resources to enhance your skills. Let’s keep our lathes running smoothly!FAQs

Certainly! Here Are Five Related Questions Regarding Lathe Lubrication And The Metal Lathe Controller Board:Sure! Here are answers about lathe lubrication and the controller board. 1. **Why do we need to lubricate a lathe?** Lubricating a lathe helps it run smoothly. It also keeps parts from getting damaged. 2. **How do you know when to add lubrication?** Check the lathe regularly. If it sounds noisy or has a hard time moving, it might need more oil. 3. **What type of oil should I use?** You should use oil made for machines. Look for what the lathe’s instructions recommend. 4. **What does the controller board do?** The controller board helps control the lathe’s movements. It makes sure everything works as it should. 5. **Can I fix the controller board myself?** You can try to fix it, but it’s tricky. It’s best to ask a grown-up for help.

Sure! Please provide the question you want me to answer.

What Are The Best Practices For Lubricating A Metal Lathe To Ensure Optimal Performance And Longevity?To keep your metal lathe running well, follow these tips for lubrication. First, use the right oil for your lathe. Check the manual for recommendations. Next, apply oil to moving parts regularly to prevent rust and wear. Make sure to clean off old oil before adding new oil. Lastly, inspect and refill oil levels often to keep everything running smoothly.

How Does The Controller Board Of A Metal Lathe Interact With Lubrication Systems To Maintain Precision And Efficiency During Operation?The controller board of a metal lathe helps keep the machine running smoothly. It tells the lubrication system when to add oil. This oil keeps the parts moving easily and helps them not wear out. When the right amount of oil is used, the lathe remains more precise and efficient. So, the controller and lubrication system work together to make sure everything runs well.

What Types Of Lubricants Are Recommended For Different Components Of A Metal Lathe, And How Do They Impact The Machining Process?For a metal lathe, you can use different lubricants for different parts. Oil is great for moving parts, like the spindle and slides. Grease is better for parts that need to stay put, like gears. Using the right lubricant helps the machine work smoothly and last longer. This makes it easier and safer for you to create things.

How Can A User Troubleshoot Lubrication Issues In A Metal Lathe That May Be Affecting The Performance Of The Controller Board?To fix lubrication problems in a metal lathe, first check the oil level. Make sure there is enough oil in the tank. Next, look for any blocked or leaky tubes. Clean or replace them if you find any issues. Lastly, run the lathe for a bit and listen for strange noises. If you hear any, it might mean you need more oil or a fix.

Are There Any Specific Lubrication Maintenance Schedules Or Indicators To Monitor For Users Of Cnc Metal Lathes Equipped With Advanced Controller Boards?Yes, you should check the oil levels regularly. Look for signs like squeaking or lagging movements. It’s a good idea to change the oil every six months. You can also set reminders on your calendar. This helps keep your machine running smoothly!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions Regarding Lathe Lubrication And The Metal Lathe Controller Board:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are answers about lathe lubrication and the controller board. 1. **Why do we need to lubricate a lathe?** Lubricating a lathe helps it run smoothly. It also keeps parts from getting damaged. 2. **How do you know when to add lubrication?** Check the lathe regularly. If it sounds noisy or has a hard time moving, it might need more oil. 3. **What type of oil should I use?** You should use oil made for machines. Look for what the lathe’s instructions recommend. 4. **What does the controller board do?** The controller board helps control the lathe’s movements. It makes sure everything works as it should. 5. **Can I fix the controller board myself?** You can try to fix it, but it’s tricky. It’s best to ask a grown-up for help.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Lubricating A Metal Lathe To Ensure Optimal Performance And Longevity?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your metal lathe running well, follow these tips for lubrication. First, use the right oil for your lathe. Check the manual for recommendations. Next, apply oil to moving parts regularly to prevent rust and wear. Make sure to clean off old oil before adding new oil. Lastly, inspect and refill oil levels often to keep everything running smoothly.”}},{“@type”: “Question”,”name”: “How Does The Controller Board Of A Metal Lathe Interact With Lubrication Systems To Maintain Precision And Efficiency During Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The controller board of a metal lathe helps keep the machine running smoothly. It tells the lubrication system when to add oil. This oil keeps the parts moving easily and helps them not wear out. When the right amount of oil is used, the lathe remains more precise and efficient. So, the controller and lubrication system work together to make sure everything runs well.”}},{“@type”: “Question”,”name”: “What Types Of Lubricants Are Recommended For Different Components Of A Metal Lathe, And How Do They Impact The Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For a metal lathe, you can use different lubricants for different parts. Oil is great for moving parts, like the spindle and slides. Grease is better for parts that need to stay put, like gears. Using the right lubricant helps the machine work smoothly and last longer. This makes it easier and safer for you to create things.”}},{“@type”: “Question”,”name”: “How Can A User Troubleshoot Lubrication Issues In A Metal Lathe That May Be Affecting The Performance Of The Controller Board?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix lubrication problems in a metal lathe, first check the oil level. Make sure there is enough oil in the tank. Next, look for any blocked or leaky tubes. Clean or replace them if you find any issues. Lastly, run the lathe for a bit and listen for strange noises. If you hear any, it might mean you need more oil or a fix.”}},{“@type”: “Question”,”name”: “Are There Any Specific Lubrication Maintenance Schedules Or Indicators To Monitor For Users Of Cnc Metal Lathes Equipped With Advanced Controller Boards?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you should check the oil levels regularly. Look for signs like squeaking or lagging movements. It’s a good idea to change the oil every six months. You can also set reminders on your calendar. This helps keep your machine running smoothly!”}}]}