Have you ever wondered how machines like metal lathes work so smoothly? The secret is often in the details, especially in the area of lathe lubrication. Proper lubrication keeps the gears and moving parts running well. What happens if you skip this step? You might end up with noisy, unhappy machines that break down easily.

Picture yourself in a workshop. You turn on a metal lathe, and instead of a smooth hum, it sounds like a grinding mess. Frightening, right? This can happen if the gear train isn’t well-lubricated. Gears need the right oil to glide and mesh perfectly. Without it, tasks like shaping metal can become a tough challenge.

Did you know that the right lubrication can even extend the life of your lathe? Think of it as giving your machine a special protective shield. In this article, we will explore the world of lathe lubrication and its impact on the metal lathe gear train. So, let’s dive in and find out how to keep your tools happy!

Essential Lathe Lubrication For Metal Lathe Gear Train

Lathe Lubrication for Metal Lathe Gear Train

Lathe lubrication is crucial for ensuring smooth operation in metal lathe gear trains. Proper lubrication reduces friction and wear, which can extend the life of the machine. Did you know that using the right oil can make cutting easier? It also helps in removing tiny metal shavings that can cause problems. Regular checks on lubrication levels help keep lathes running smoothly. Keeping your gear train well-lubricated means fewer repairs and better performance. Wouldn’t that make your projects more enjoyable?Understanding Lathe Lubrication

Definition and purpose of lathe lubrication. Importance of lubrication for gear train performance.Imagine your lathe as a well-oiled machine—a happy place where metal spins and shapes without a hitch! Lathe lubrication helps keep things running smoothly. Think of it as giving your gear train a refreshing drink. Without proper lubrication, gears can wear out and perform poorly, like a tired puppy who forgot to chase its tail! Proper lubrication not only improves performance but can also extend your lathe’s lifespan, ensuring it keeps spinning with glee.

| Benefits of Lathe Lubrication |

|---|

| Increases efficiency |

| Reduces friction |

| Extends gear life |

| Prevents rust |

Best Practices for Lubricating Gear Trains

Stepbystep guide on proper lubrication techniques. Recommended frequency of lubrication for optimal performance.Keeping your gear train happy is like giving it a warm hug! First, grab some quality lubricant. Apply it lightly to the gears—think of it as a massage, not a bath! Do this about once a month for best results. Less often may leave your gears squeaking like a rusty door! Here is a handy table for quick reference:

| Lubrication Task | Frequency |

|---|---|

| Check lubricant levels | Monthly |

| Apply lubricant | Every 1-2 months |

| Thorough clean and re-lubricate | Every 6 months |

Remember, good gear care equals smooth operation. Keep it slick, and your metal lathe will thank you with every smooth turn!

Identifying Gear Train Components for Lubrication

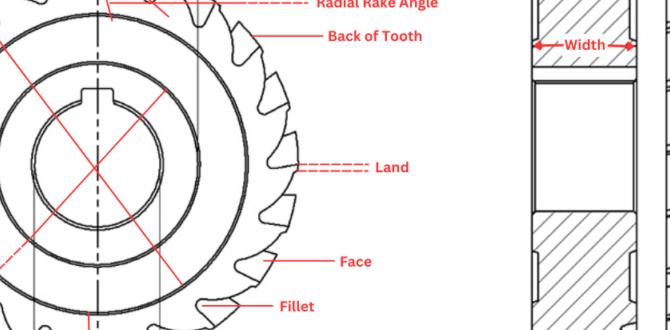

Components of a metal lathe gear train that require lubrication. Visual guide for identifying and accessing these components.To keep your lathe working smoothly, pay attention to the gear train components needing lubrication. These parts help your lathe run effectively. Here are the main components to lubricate:

- Pulleys

- Gears

- Bearings

- Screws

Finding and accessing these pieces can be tricky. A visual guide can be very helpful. Use diagrams to spot where each part is located on your lathe. This makes it easier to apply the right amount of lubrication where it’s needed most.

Why is lubrication important for gear train components?

Lubrication reduces friction, keeps parts cool, and extends the lathe’s life.Common Mistakes in Lathe Lubrication

Typical errors to avoid when lubricating gear trains. Consequences of improper lubrication on lathe function.Lubricating a lathe can feel like a race against time, but mistakes can ruin the ride. One common slip is not using enough oil. This can lead to parts sticking and grinding down like old cheese! Too much oil isn’t great either; it can attract dirt and make everything gunky. Proper lubrication keeps the gear train running smoothly. Without it, the lathe might freeze up—like my brain on a math test! Here’s a quick guide:

| Common Errors | What Happens |

|---|---|

| Not enough lubrication | Parts can wear down quickly. |

| Too much lubrication | Dust and dirt build up. |

| Ineffective lubricant | Poor gear performance. |

Remember, keeping your lathe happy with the right amount of oil is the key! This helps you avoid expensive repairs and keeps your projects on track.

Signs Your Lathe Needs Lubrication

Indicators that your metal lathe requires lubrication. How to conduct regular inspections for maintenance.Does your lathe sound like it’s auditioning for a horror movie? Squeaks or grinding noises are big hints that it needs some love—specifically, lubrication! Check for stiff movement or parts that don’t glide smoothly. Regular inspections can save you from a metal heartbreak later. Aim to look it over every month. A little oil goes a long way, so keep an eye out for signs. Remember: a happy lathe makes happy projects!

| Signs of Need | Action |

|---|---|

| Squeaking or Grinding Sounds | Apply lubrication |

| Stiff Movement | Inspect gears |

| Frequent Stalling | Check oil levels |

Environmental Factors Impacting Lubrication

Effects of temperature and humidity on lubricant effectiveness. Adjusting lubrication practices for specific working conditions.Temperature and humidity play big roles in how well lubricants work. High heat can make them thinner, while cold can thicken them up, just like your favorite ice cream on a sunny day. Humidity can also affect lubrication, causing it to break down faster. Adjusting lubrication practices for your metal lathe gear train is crucial. You want to make sure your machine runs smoothly, like a happy cat chasing a laser dot. Check the table below for tips!

| Condition | Lubrication Tips |

|---|---|

| High Temperature | Use lighter oils to prevent thinning. |

| Low Temperature | Opt for thicker lubricants to maintain protection. |

| High Humidity | Choose moisture-resistant lubricants. |

| Low Humidity | Regularly check and replace lubricants to avoid dryness. |

Choosing the Right Lubricant for Your Lathe

Factors to consider when selecting a lubricant for metal lathes. Recommendations based on brand and model of the lathe.Choosing the right lubricant is key for smooth lathe operation. Consider these factors:

- Machine brand and model

- Operating conditions (temperature or humidity)

- Type of work (heavy or light machining)

Different lathes need specific lubricants. For example, a Haas lathe may require a synthetic oil. Always check your manual for the best choices. Proper lubrication not only ensures better performance but also extends the life of your machine.

What should I consider when selecting a lubricant?

Consider machine type, conditions, and usage. Each factor affects your choice of lubricant. Matching these will keep your lathe running smoothly.

Recommendations:

- Haas Lathes: Use synthetic oils.

- Jet Lathes: Mineral oils work well.

- Grizzly Lathes: Look for heavy-duty greases.

Conclusion

In conclusion, keeping your metal lathe gear train well-lubricated is vital for smooth operation. You’ll reduce wear and tear while improving performance. Remember to use the right lubricant and check it regularly. By taking these simple steps, you’ll extend the life of your lathe and enhance your projects. For more tips, explore maintenance guides and articles on lathe care!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Lubrication And Metal Lathe Gear Trains:Sure! Here are some answers about lathe lubrication and gear trains. 1. **Why is lubrication important for lathes?** Lubrication keeps the lathe moving smoothly. It helps prevent parts from getting too hot or wearing out. 2. **What type of oil should we use for a lathe?** You should use machine oil or light oil made for machines. It helps to protect the metal parts. 3. **How often should we lubricate the lathe?** We should lubricate the lathe every time we use it. This keeps everything running well. 4. **What are gear trains in a lathe?** Gear trains are groups of gears that help the lathe spin. They change the speed and power of the machine. 5. **How do I check if my lathe needs lubrication?** You can check by looking for noise or if it feels stiff when you move it. If it feels rough, it needs oil.

Sure! Just let me know what question you’d like me to answer, and I’ll be happy to help.

What Types Of Lubricants Are Most Suitable For A Metal Lathe Gear Train To Ensure Smooth Operation And Longevity?For a metal lathe gear train, we can use oil or grease as lubricants. Light machine oil is good for most gears. It helps them move smoothly and easily. Grease can also work well, especially for parts that don’t move often. Choosing the right lubricant helps the gears last longer and run better.

How Often Should Lubrication Be Applied To The Gear Train Of A Metal Lathe, And Are There Any Signs That Indicate It Needs Maintenance?You should apply lubricant to the gear train of a metal lathe about once a month. It helps keep everything running smoothly. Look for signs like weird noises, stiffness, or jerking movements. These mean it’s time for maintenance. Keeping it well-lubricated helps your lathe work better and last longer!

What Are The Potential Consequences Of Inadequate Lubrication In A Metal Lathe Gear Train?If you don’t use enough oil on the gears in a metal lathe, they can get really hot. This can cause the gears to wear out faster. You might also hear loud noises when the lathe is working. In the worst case, the gears could break, and that would mean you can’t use the lathe anymore. So, it’s very important to keep everything well-lubricated!

Are There Specific Lubrication Methods Or Systems (Like Automatic Or Manual) Recommended For Different Types Of Metal Lathes?Yes, there are different ways to add oil to metal lathes. Some lathes use automatic systems that oil parts for you. Others need you to add oil by hand, called manual lubrication. Your choice depends on the lathe type and what you like. Always check your lathe’s instructions to find out the best way to keep it running smoothly!

How Does The Design Of The Gear Train In A Metal Lathe Affect Its Lubrication Requirements And Choices?The gear train in a metal lathe helps move the parts around. If the gears are tight, they need more oil to keep them running smoothly. You have to choose the right kind of oil based on how fast or heavy the lathe works. If gears are big and heavy, they might need thicker oil for better protection. Good lubrication helps the lathe work well and last longer.