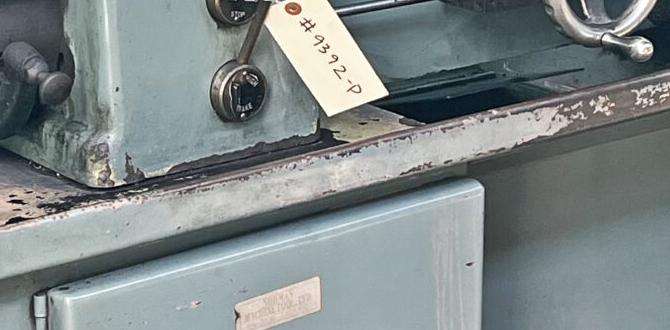

Have you ever wondered how a metal lathe works? Imagine a machine that spins metal at high speeds. It’s powerful and precise, but it also needs care. That’s where lathe lubrication comes in. Proper lubrication keeps the machine running smoothly and prevents damage.

Think of a metal lathe like a car engine. Without oil, an engine can get damaged quickly. It’s the same with a lathe. It needs the right amount of lubrication for better torque and control. This way, the lathe can cut metal cleanly, just how you want it.

Did you know that using the wrong lubricant can lead to problems? It can make machines heat up or wear down faster. So, understanding lathe lubrication is important. It can save you time, money, and frustration.

In this article, we’ll explore how to choose the right lubricant. We’ll also discuss how to apply it effectively. This knowledge will help you work smarter with your metal lathe. Ready to dive in? Let’s get started!

Essential Guide To Lathe Lubrication For Metal Lathe Torque

Lathe Lubrication and Torque: Key Insights

Proper lathe lubrication is crucial for keeping your metal lathe in top shape. With the right lubrication, you reduce wear and tear, enhancing tool performance and lifespan. Did you know that the wrong lubricant can lead to increased torque? This can cause unnecessary strain on your machine. Regular checks can prevent major repairs and maintain efficiency. By understanding these key points, you can keep your lathe running smoothly and efficiently for longer.Understanding Lathe Lubrication

Importance of lubrication in metalworking. Types of lubricants used in lathes.Lubrication is very important in metalworking. It keeps the lathe running smoothly. Good lubrication reduces friction. This helps prevent wear and tear on the machine. There are different types of lubricants used in lathes:

- Oil: Provides a thin layer for smooth movement.

- Grease: Stays in place and protects against dirt.

- Dry lubricants: Useful for areas with high heat.

Using the right lubricant can extend the life of your lathe. It also keeps your workpieces looking great!

What is the role of lubrication in metal lathes?

Lubrication reduces heat and friction. This makes cutting easier and lasts longer.

How Lubrication Affects Torque in Metal Lathes

Relationship between lubrication and tool performance. Impact of inadequate lubrication on torque and wear.Lubrication plays a big role in how metal lathes work. Think of it as the oil in your car’s engine – without it, things get sticky. Proper lubrication helps tools run smoothly, improving performance. If there isn’t enough oil, the torque drops, leading to wear and tear. Imagine your tools complaining, “Hey, I’m thirsty!” This extra strain can break down parts faster than you can say “lathe.” Keep your lathe happy and well-lubricated!

| Lubrication | Effect on Torque | Impact on Wear |

|---|---|---|

| Good lubrication | Increases torque | Reduces wear |

| Poor lubrication | Decreases torque | Increases wear |

Best Practices for Lathe Lubrication

Recommended lubrication schedules and techniques. Tips for applying lubricant effectively.Keeping your lathe well-lubricated is key for smooth operation. Follow these simple techniques for the best results:

- Check and lubricate every day if you use the lathe often.

- Use a high-quality oil designed for metal lathes.

- Apply lubricant in small amounts to avoid mess.

- Wipe off excess oil with a clean cloth.

- Focus on areas where metal parts touch to reduce friction.

These practices help maintain lathe lubrication and extend your machine’s life.

How often should I lubricate my lathe?

You should lubricate your lathe daily if you use it frequently. For less use, a weekly check will do.

Tips for Effective Lubrication

- Always read product labels for instructions.

- Keep a maintenance log to track your lubrication schedule.

- Store your lubricant in a cool, dry place.

Signs of Insufficient Lubrication

Indicators of poor lubrication affecting lathe performance. Regular maintenance checks to ensure optimal lubrication.When a lathe runs low on lubrication, problems can arise quickly. Here are some signs to watch for:

- Strange noises, like grinding or squeaking.

- Overheating of parts, making them hard to touch.

- Poor performance, resulting in uneven cuts.

- Frequent tool wear and tear.

To keep a lathe working well, do regular checks. Add oil when needed. This helps ensure smooth operation and saves time and money in the long run.

What are signs of poor lubrication?

Signs include

strange noises, overheating, and uneven cuts. Regular checks are crucial to keep everything running smoothly.

Advanced Lubrication Techniques

Incorporating automated lubrication systems. Innovations in lubricant formulations for enhanced performance.Keeping your metal lathe in top shape is like giving it a spa day. One way to achieve this is by using automated lubrication systems. These nifty devices save you time and keep everything running smoothly. Imagine a robot pampering your machine while you enjoy a snack! Plus, thanks to newer lubricant formulas, performance gets a serious upgrade. These advanced solutions help reduce wear and tear, meaning your lathe can last longer and work better.

| Type of Lubricant | Benefit |

|---|---|

| Grease | Stays put, ideal for heavy loads |

| Oil | Reduces friction, great for fast-moving parts |

| Synthetic | Powerful, resists breakdown in heat |

With these techniques, your lathe will run like a well-oiled machine—literally! So, let’s give your metal lathe the lubrication love it deserves!

Choosing the Right Lubricant for Your Metal Lathe

Factors to consider when selecting lubricants. Manufacturer recommendations and industry standards.Picking the best lubricant for your metal lathe is like choosing the right ice cream flavor. You want something that works well! Think about the type of work you do and what’s recommended by the manufacturer. They know their machines best! Also, keep an eye on industry standards. These can guide you on what to use for different tasks. A little research goes a long way, and your lathe will thank you for it!

| Factor | Consideration |

|---|---|

| Work Type | Heavy-duty or light machining? |

| Manufacturer’s Advice | Follow the tips directly from the source! |

| Industry Standards | Stick to what’s widely accepted! |

Environmental Considerations in Lathe Lubrication

Ecofriendly lubricant options and their benefits. Proper disposal of lubricants and waste management practices.Choosing the right lubricant can be a big deal for our planet. Eco-friendly options help keep nature happy while keeping your lathe running smoothly. Plus, it’s nice to know you’re not greasing up the world with harmful chemicals! Don’t forget, throwing away used lubricants isn’t as easy as tossing out your lunch scraps. Proper waste management practices are vital. Always recycle and dispose of these materials safely. Remember, a clean workshop is a happy workshop!

| Eco-Friendly Lubricants | Benefits |

|---|---|

| Biodegradable Oils | Break down naturally, less harm to wildlife |

| Soy-based Lubricants | Renewable and often non-toxic |

| Vegetable Oils | Good for the environment and safe for workers |

Next time you pick a lubricant, think green! Your machines and Mother Earth will thank you. After all, who doesn’t love a good oil spill when it’s just a drizzle of happiness?

Conclusion

In summary, proper lathe lubrication is essential for running a metal lathe efficiently. It reduces friction and wear, helping to maintain torque. By keeping your tools well-lubricated, you can enhance performance and extend their life. To learn more, check out guides on lathe maintenance or talk to experienced users. Remember, a well-lubricated lathe is a happy lathe!FAQs

Here Are Five Related Questions On The Topic Of Lathe Lubrication And Metal Lathe Torque:Lubricating a lathe is important. It helps the machine work smoothly and last longer. You need to use the right oil for this. Check the lathe’s manual to know what type to use. Regularly adding oil can keep everything running well!

Sure! Please give me the question you would like me to answer.

What Types Of Lubricants Are Commonly Used For Metal Lathes, And How Do They Contribute To Overall Performance?For metal lathes, we commonly use oil and grease as lubricants. Oil helps keep the machine parts moving smoothly. Grease protects metal from rust and wear. Both types reduce friction, which means less heat and less chance of damage. Using the right lubricant makes your lathe work better and last longer!

How Does Proper Lubrication Affect The Torque Output Of A Metal Lathe During Cutting Operations?Proper lubrication helps a metal lathe work better when cutting metal. It reduces friction, which is when pieces rub against each other and slow down. Less friction means the machine can turn faster and use less force. This makes the cutting smoother and easier, which helps us get a better finish on the metal. So, good lubrication is important for making the lathe work well.

What Are The Signs Of Inadequate Lubrication In A Lathe, And How Can They Impact Torque And Machine Performance?You can tell a lathe needs more lubrication if it makes strange noises or feels sticky when you use it. The parts might get hot or wear out too quickly. If there’s not enough oil, the machine works less smoothly. This can reduce torque, which is the turning power, and make the lathe less effective. Keeping everything well-lubed helps it run better and last longer.

How Often Should Lubrication Be Applied To A Metal Lathe, And What Maintenance Practices Can Help Ensure Optimal Torque And Functionality?You should apply lubrication to a metal lathe every time you use it. This keeps the parts moving smoothly. To help the lathe work well, you can clean it after each use. Check for any loose parts, too. Regular care helps it last longer and work better!

What Role Does The Viscosity Of The Lubricant Play In The Torque Required To Operate A Metal Lathe Effectively?The viscosity of a lubricant is how thick or sticky it is. If the lubricant is too thick, it can make it harder for the metal lathe to work. This means you will need more torque, or twisting force, to move parts. If the lubricant is just right, it helps everything move smoothly and easily. This makes it easier to use the lathe and do your work!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Lubrication And Metal Lathe Torque:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lubricating a lathe is important. It helps the machine work smoothly and last longer. You need to use the right oil for this. Check the lathe’s manual to know what type to use. Regularly adding oil can keep everything running well!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Types Of Lubricants Are Commonly Used For Metal Lathes, And How Do They Contribute To Overall Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For metal lathes, we commonly use oil and grease as lubricants. Oil helps keep the machine parts moving smoothly. Grease protects metal from rust and wear. Both types reduce friction, which means less heat and less chance of damage. Using the right lubricant makes your lathe work better and last longer!”}},{“@type”: “Question”,”name”: “How Does Proper Lubrication Affect The Torque Output Of A Metal Lathe During Cutting Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Proper lubrication helps a metal lathe work better when cutting metal. It reduces friction, which is when pieces rub against each other and slow down. Less friction means the machine can turn faster and use less force. This makes the cutting smoother and easier, which helps us get a better finish on the metal. So, good lubrication is important for making the lathe work well.”}},{“@type”: “Question”,”name”: “What Are The Signs Of Inadequate Lubrication In A Lathe, And How Can They Impact Torque And Machine Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can tell a lathe needs more lubrication if it makes strange noises or feels sticky when you use it. The parts might get hot or wear out too quickly. If there’s not enough oil, the machine works less smoothly. This can reduce torque, which is the turning power, and make the lathe less effective. Keeping everything well-lubed helps it run better and last longer.”}},{“@type”: “Question”,”name”: “How Often Should Lubrication Be Applied To A Metal Lathe, And What Maintenance Practices Can Help Ensure Optimal Torque And Functionality?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should apply lubrication to a metal lathe every time you use it. This keeps the parts moving smoothly. To help the lathe work well, you can clean it after each use. Check for any loose parts, too. Regular care helps it last longer and work better!”}},{“@type”: “Question”,”name”: “What Role Does The Viscosity Of The Lubricant Play In The Torque Required To Operate A Metal Lathe Effectively?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The viscosity of a lubricant is how thick or sticky it is. If the lubricant is too thick, it can make it harder for the metal lathe to work. This means you will need more torque, or twisting force, to move parts. If the lubricant is just right, it helps everything move smoothly and easily. This makes it easier to use the lathe and do your work!”}}]}