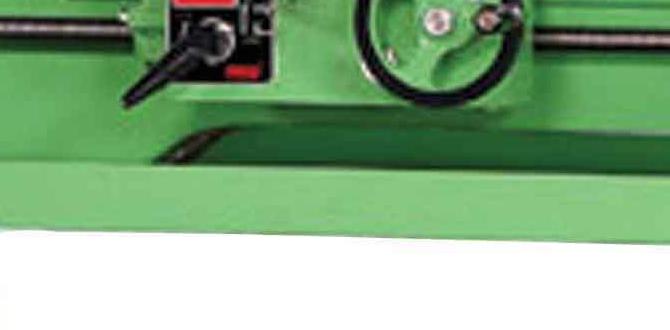

Have you ever wondered how modern machines create precise parts? The lathe machine is a key player in this process. It shapes metal with speed and accuracy. But what if we added some smart technology to it?

Imagine a metal lathe that knows what to do all by itself! This is where machine learning comes into play. With automation, machines can learn and adapt. They can make the same product over and over without mistakes. How cool is that?

Once, metalwork required a lot of time and skill. But now, thanks to automation, we can produce high-quality parts much faster. This innovation is changing how we think about manufacturing. Are you ready to explore the exciting world of lathe machines and learn how technology is shaping our future?

Lathe Machine Learning: Metal Lathe Automation Revolution

Efficient Automation with Lathe Machine Learning

Lathe machines are transforming with machine learning and automation. Imagine a robot that can carve metal just like a skilled worker! Machine learning helps these machines learn from their tasks, improving accuracy over time. This means fewer mistakes and faster production. Automation in metal lathes can cut down on labor costs, making businesses more efficient. Have you ever thought about how these technologies can enhance creativity in manufacturing? It’s an exciting adventure into a tech-driven future!The Role of Automation in Metalworking

Benefits of automation in manufacturing processes. Challenges faced without automation.When machines start working smart, magic happens! Automation in metalworking means less human error and faster production. It helps businesses save money and time. Who wouldn’t want that? But without automation, companies face challenges. They deal with long hours and tired workers, leading to more mistakes. Picture a robot making parts while humans grab coffee—now that’s teamwork!

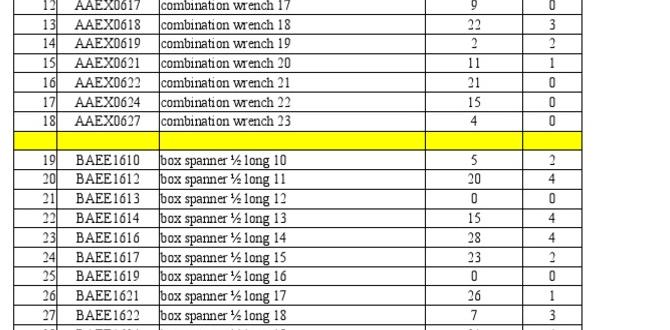

| Benefits of Automation | Challenges Without Automation |

|---|---|

| Speed: Faster production times. | Errors: More chances for mistakes. |

| Cost-Saving: Reduces labor costs. | Fatigue: Tired workers can’t keep up. |

| Quality: Consistent and reliable products. | Delays: Longer turnaround times. |

Integrating Machine Learning in Lathe Automation

Definition and principles of machine learning. How machine learning can enhance automation.Machine learning is a branch of computer science. It teaches machines to learn from data. This means they can improve over time without human help. With machine learning, automation becomes smarter. It can predict problems, optimize processes, and save time.

- Learn from experience

- Make decisions quickly

- Adapt to changes

By integrating machine learning, lathe automation becomes more efficient. Machines can work faster and produce better results. This leads to higher quality products and less waste.

How does machine learning help in automation?

Machine learning helps by making machines smarter and more efficient. They can analyze data and improve their performance automatically. This means quicker production and better quality. As machines learn, they can adapt to different tasks easily.

Real-Time Data Collection and Analysis

Importance of data in optimizing lathe operations. Tools and techniques for effective data collection.Collecting data in real-time is very important for improving lathe operations. Data helps workers know how to make machines run better. Using the right tools and techniques can really enhance this process. Here are some helpful methods:

- Use sensors to track machine speed.

- Take notes during operations to find areas to improve.

- Analyze data to make better choices for future tasks.

With better data, manufacturers can save time and money. This approach makes overall performance stronger and more reliable!

Why is data collection important for lathe operations?

Data collection helps find ways to improve speed and quality. It helps workers see patterns that can save time and resources.

What tools can help with data collection?

Sensors, software programs, and regular checklists are great tools for gathering data and improving lathe use.

Predictive Maintenance for Lathe Machines

How machine learning aids in preventive maintenance. Benefits of predictive analytics in reducing downtime.Machine learning helps keep lathe machines running smoothly. It predicts problems before they happen. This is known as predictive maintenance. Here are some benefits:

- Less downtime. Machines work longer without breaks.

- Lower repair costs. Fixing things early saves money.

- Better productivity. Workers can focus on their tasks.

Using data from machines, we can see patterns. This helps in making smart choices. Predictive analytics keeps machines efficient and reliable.

What is predictive maintenance?

Predictive maintenance means fixing machines before they break. This saves time and money.

Why is predictive maintenance important?

- It helps avoid unexpected stoppages.

- It keeps production running smoothly.

- It improves the lifespan of the machines.

Improving Production Efficiency with Machine Learning

Techniques for maximizing output through automation. Impact of machine learning on process optimization.Automation and machine learning work together like peanut butter and jelly to boost production efficiency. Implementing smart techniques can maximize output, making machines like lathes even sharper! Machine learning helps spot patterns and optimize processes. This means less downtime and more goodies getting produced. It’s like giving your lathe a brain! Check out the table below to see how these technologies can impact efficiency:

| Technique | Impact on Efficiency |

|---|---|

| Predictive Maintenance | Reduces unexpected breakdowns |

| Real-time Data Analysis | Improves decision-making speed |

| Automated Adjustments | Enhances accuracy and output |

With these cool upgrades, lathes can become productivity superheroes! So, wave goodbye to slow processes and hello to a smoother operation!

Future Trends in Metal Lathe Automation

Upcoming technologies influencing lathe operations. Predictions for the future of machine learning in manufacturing.Exciting changes are coming for metal lathe automation! New technologies, like *smart sensors* and *AI*, are stepping in to make lathe operations faster and easier. Imagine a lathe that can fix itself while you grab a snack! Sounds tasty, right? Predictions say that *machine learning* will help machines learn from their mistakes. They will be able to adapt and improve over time, making manufacturing smooth and efficient. Talk about a clever metal buddy!

| Technology | Description |

|---|---|

| Smart Sensors | These keep watch on lathe performance and send alerts. |

| AI Integration | Machines learning from data to enhance their operations. |

| Predictive Maintenance | Fixes problems before they happen, saving time and money! |

Best Practices for Implementing Machine Learning in Metal Lathes

Steps for successful integration of machine learning. Common pitfalls and how to avoid them.To smoothly add machine learning to your metal lathes, begin with a solid plan. Think like a chef preparing a stew—gather all your best ingredients. Identify areas where automation can shine, like improving precision and efficiency. Common pitfalls include ignoring data quality and underestimating training time. Avoid these by regularly checking your data, just like double-checking if you have enough cookies in the jar!

| Steps for Successful Integration | Common Pitfalls | How to Avoid Them |

|---|---|---|

| Assess Current Operations | Neglecting Data Quality | Regularly Clean Data |

| Set Clear Goals | Underestimating Training Time | Allocate Enough Resources |

| Test and Iterate | Ignoring User Feedback | Encourage Continuous Improvement |

Remember, careful planning leads to smoother operations. After all, nobody wants a lathes catastrophe, right? Stay focused, and your metal lathe automation will be a success!

Conclusion

In conclusion, lathe machines are transforming metalworking with machine learning and automation. These technologies make lathes smarter and more efficient. You can save time and reduce mistakes by understanding how they work. Explore this exciting field further, and consider trying out automation in your own projects. Together, we can embrace the future of metal machining!FAQs

How Can Machine Learning Algorithms Be Applied To Optimize The Operational Efficiency Of Metal Lathes In Manufacturing Settings?We can use machine learning to make metal lathes work better in factories. First, these computers look at how the lathes are running. They find patterns in the data to see if something can be improved. For example, they help adjust speeds and feed rates for better cuts. This way, we save time, reduce waste, and make more good parts!

What Are The Potential Benefits Of Automating Lathe Machines Using Machine Learning Technologies In Terms Of Production Speed And Accuracy?Automating lathe machines with machine learning can make them work faster. This means we can create more parts in less time. It also helps make the parts more precise, so they fit perfectly. With this technology, we can save time and produce better products. Overall, it makes our work easier and improves our results.

In What Ways Can Predictive Maintenance Powered By Machine Learning Improve The Uptime And Reliability Of Automated Metal Lathes?Predictive maintenance uses smart technology to check metal lathes for problems before they happen. This helps us fix issues early, so machines don’t break down during work. By keeping the lathes in good shape, they can run longer without stopping. This means we can make things faster and better, which is great for everyone!

How Do Sensors And Data Acquisition Systems Integrate With Machine Learning Models To Enhance The Performance Of Automated Lathe Operations?Sensors are devices that collect information about how a lathe machine is working. They measure things like temperature and speed. We then use this data in a computer system called data acquisition. Machine learning models learn from this data to help the lathe work better. Together, sensors and these smart models help the lathe operate faster and safer.

What Challenges Might Manufacturers Face When Implementing Machine Learning For Automation In Lathe Machining Processes, And How Can These Be Addressed?Manufacturers might have trouble getting enough good data for machine learning. If the data is bad, the machines won’t learn correctly. Another challenge is that workers may worry about losing their jobs. We can help by showing workers how machine learning can make their jobs easier instead. Training and clear communication are important to solve these problems.