Have you ever wondered how metal items are made? It all starts with a lathe machine. A lathe helps shape metal into beautiful parts and tools. This article explores how machine learning improves lathe operations, especially for bench lathes. Can you imagine a machine that gets smarter over time?

Meet the metal lathe. It’s like a sculptor that spins metal to create amazing shapes. But today, we add a twist. With machine learning, these machines learn from their work. They become more accurate and efficient. That’s pretty cool, right?

Stay tuned! We’ll dive into how this technology changes the world of metalworking. You might discover something surprising about these incredible machines. Who knows? You could be inspired to create your own masterpiece!

Exploring Lathe Machine Learning For Metal Lathe Bench Use

Lathe Machine Learning for Metal Lathes

Are you fascinated by how machines create precise shapes? A metal lathe is a tool that spins metal to carve it into various forms. Learning to use a lathe can be exciting and a bit challenging. With modern lathe machine learning, operators can optimize performance and improve accuracy. This technology helps predict tool wear and reduces waste. Imagine crafting something new while making the process smarter! The future of metalworking is here, blending skill and technology seamlessly.Understanding Lathe Machines

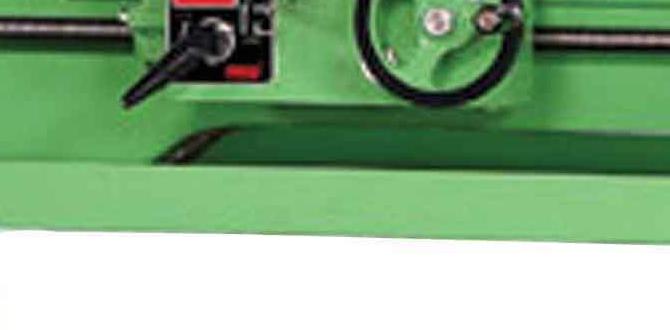

Definition and purpose of lathe machines. Types of lathe machines used in metalworking.A lathe machine is a tool used to shape materials like metal or wood. It spins the material while cutting tools remove unwanted parts. This process creates smooth surfaces and precise shapes. Many types of lathe machines are used in metalworking, including:

- **Engine Lathe**: Versatile for various tasks.

- **Turret Lathe**: Allows quick tool changes.

- **Bench Lathe**: Small and great for detailed work.

Each kind helps workers create precise parts.

What are the key purposes of lathe machines?

The main purpose of lathe machines is to shape materials accurately. They help in cutting, drilling, and sanding. They are essential for many products, from simple toys to complex car parts.

Types of Machine Learning Algorithms for Lathe Machines

Supervised learning algorithms applicable to lathe processes. Unsupervised learning for optimizing machining parameters.Machine learning brings exciting changes to lathe machines! For supervised learning, we focus on training algorithms with known data. Think of it as teaching a robot to identify the best cutting speeds and feeds based on past results. This helps make better parts faster. On the flip side, we have unsupervised learning. This is like letting the robot explore without a guide. It finds the best machining parameters by analyzing data patterns on its own. Who knew robots could be so clever?

| Learning Type | Application |

|---|---|

| Supervised Learning | Train with known data |

| Unsupervised Learning | Find patterns on its own |

Applications of Machine Learning in Lathe Operations

Predictive maintenance for increased machine longevity. Quality control improvements through anomaly detection.Machine learning helps make lathe operations better. It predicts when a machine needs maintenance. This can lead to a longer life for the equipment. Less downtime means more work done!

Another way is through quality control. Machine learning finds problems early. This special detection helps keep products at their best. Without good quality, customers may be unhappy.

- Predictive maintenance: Extends machine life.

- Anomaly detection: Improves product quality.

What are some benefits of using machine learning in lathe operations?

Machine learning boosts efficiency, reduces costs, and ensures better quality in products.

Key Benefits:

- Less breakdown time.

- Fewer defects in products.

Data Collection and Processing for Lathe Machine Learning

Essential data types for training models. Techniques for data cleaning and preprocessing.For lathe machine learning, data is crucial. You need different types of data to make models smart. Some essential data types include:

- Operating speeds

- Material types

- Cutting tools used

- Dimensions of parts

Next, cleaning and preparing your data is important. This helps avoid mistakes. Key techniques include:

- Removing duplicates

- Filling in missing values

- Normalizing data formats

Clean data leads to better results, making your models sharper and more effective.

What types of data are important for training in lathe machine learning?

Key types of data include operating speeds, material types, and cutting tools used. These datasets help in creating accurate models for improved performance.

Implementing Machine Learning in Bench Lathe Operations

Steps to integrate machine learning systems with bench lathes. Case studies of successful machine learning applications in bench lathes.Integrating machine learning into bench lathe operations can be fun and effective! First, gather data from your lathe. This data helps the machine learn how to run better. Next, use software that can analyze this data. For example, a system might predict when to change tools, saving time and effort. Case studies show factories using machine learning saw productivity rise by 20%! Now, that’s some serious lathe magic!

| Step | Description |

|---|---|

| Data Collection | Gather all relevant data from lathe operations. |

| Analysis | Use software to analyze collected data. |

| Implementation | Integrate machine learning features into your lathe. |

| Testing | Run tests to ensure everything works smoothly. |

Challenges and Solutions in Machine Learning for Metal Lathes

Common challenges faced by manufacturers. Innovative solutions and best practices to overcome these challenges.Manufacturers face several challenges in using machine learning with metal lathes. Common issues include data quality and integration. Poor data can lead to faulty results. Yet, there are innovative solutions. Using better sensors can improve data accuracy. Regular training for staff helps them adapt to new technologies. Here are some best practices:

- Invest in reliable sensors.

- Train employees regularly on system updates.

- Ensure data is clean and organized.

By addressing these challenges, manufacturers can enhance their metal lathe operations.

What are the common challenges in machine learning for metal lathes?

Challenges include poor data quality, lack of skilled workers, and system integration issues.

How can manufacturers overcome these challenges?

Employ better sensors, provide ongoing training, and ensure proper data management.

The Future of Lathe Machines with Machine Learning

Emerging trends and technologies in metalworking. Predictions for future advancements and their impact on the industry.The use of machine learning in lathe machines is changing metalworking. New tools and software help workers make better products faster. Advanced sensors can predict problems before they happen. This means less downtime and more efficiency. As technology grows, we can expect:

- Smarter machines that learn over time.

- Better safety measures for workers.

- More precise cuts and shapes.

These changes will make the metalworking industry stronger. Workers will be more skilled, and businesses will grow. It’s an exciting time for everyone involved!

How will machine learning improve lathe machines?

Machine learning will help lathe machines become smarter and more efficient. It can learn from past mistakes and adjust processes automatically. This will make metalworking safer and faster.

Conclusion

In summary, a lathe machine is a valuable tool for shaping metal. Learning how to use a metal lathe can help you create precise parts. With practice, you can improve your skills and make cool projects. Consider taking a class or reading more online to get started. Remember, exploring new tools is exciting and can lead to amazing results!FAQs

What Are The Key Features Of A Metal Lathe, And How Can Machine Learning Algorithms Improve Its Efficiency And Precision In A Bench Setup?A metal lathe shapes metal into different forms. Key features include a rotating spindle, cutting tools, and a bed for support. You can change the speed and movement for different tasks. Machine learning can help by using data to make better cuts. This means you can work faster and more accurately.

How Can Sensors And Data Collection Enhance The Performance Of A Bench Lathe Machine Through Machine Learning Models?Sensors can help a bench lathe machine work better by gathering important data. When we collect this data, it helps us understand how the machine is doing. We can use machine learning models, which are like smart programs, to learn from the data. This way, the machine can make better cuts and avoid mistakes. So, sensors and smart programs help us make the machine faster and more precise.

In What Ways Can Predictive Maintenance Powered By Machine Learning Algorithms Reduce Downtime For Metal Lathes?Predictive maintenance uses special computer programs to check metal lathes. These programs can tell us when a machine is about to break. By fixing it before it stops working, we can keep the machines running longer. This means less waiting and more time for making things. So, we can make more stuff without long breaks!

How Can Machine Learning Techniques Be Applied To Optimize Cutting Parameters And Tool Life In Metal Lathe Operations?We can use machine learning to make metal cutting better. First, we collect data about how different tools and cuts work. Then, we teach the computer to find patterns in this data. It can help us pick the best cutting speed and pressure to use. This way, our tools last longer and we do a better job!

What Challenges Do Manufacturers Face When Integrating Machine Learning Solutions Into Traditional Bench Lathe Setups, And How Can They Be Overcome?Manufacturers face a few challenges when adding machine learning to bench lathes. First, they may not know how to use the new technology. Second, old machines might not work well with new software. We can overcome these problems by training workers and upgrading machines if needed. This way, we mix the old and new to make better products!