Have you ever wondered how the magic of a lathe machine works? Imagine it spinning, shaping metal into perfect forms. A lathe machine is a vital tool in many workshops. It helps create everything from car parts to beautiful sculptures.

Now, let’s talk about something exciting: machine learning. This amazing technology can change how we use machines, including the metal lathe control panel. Think about it—what if your lathe could learn from you? It could adjust settings all on its own, making it easier and faster to work.

Here’s a fun fact: Did you know that machine learning can help predict when a lathe machine might break down? That means fewer surprises and more time working. As we explore the world of lathe machine learning, we’ll discover how it can make our metalworking tasks more efficient and fun.

So, are you ready to dive into this fascinating blend of tradition and technology? Let’s see how the future of metal lathing comes alive through machine learning!

Lathe Machine Learning: Metal Lathe Control Panel Insights

Understanding Lathe Machine Learning and Metal Lathe Control Panels

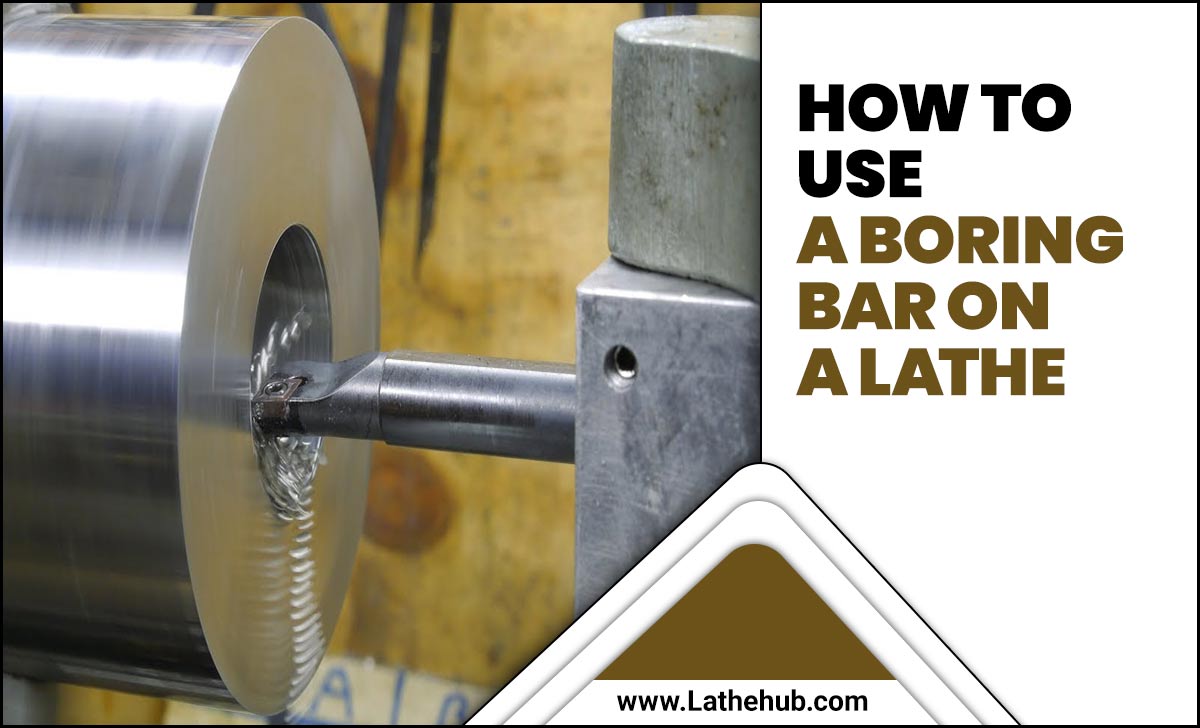

Lathe machine learning combines advanced technology with traditional metal lathes. These machines shape metal into precise forms. A control panel allows users to input commands easily. Have you ever wondered how a simple button can control such a complex process? With machine learning, the lathe can learn from past cuts. This helps it improve accuracy and efficiency. Imagine a machine that gets smarter with each use! It’s changing how we work with metal.What is a Lathe Machine?

Definition and basic functions of a lathe machine. Types of lathe machines used in metalworking.A lathe machine is a clever tool used to shape materials, mostly metals. Think of it as a giant pencil sharpener, but for metal! It spins the material while cutting tools smooth it out. This tool comes in different types, each with unique functions. Some can handle big jobs, while others are perfect for tiny details. Here’s a quick look at the common types:

| Type of Lathe | Description |

|---|---|

| Engine Lathe | Versatile machine used for various tasks. |

| Turret Lathe | Good for repetitive work, like making many of the same part. |

| CNC Lathe | Computer-controlled for precise shaping. Very fancy! |

Each type has its special skills, just like superheroes! The lathe machine may seem simple, but it plays a vital role in metalworking, helping create everything from tools to car parts.

Features of an Advanced Lathe Control Panel

Key components of a control panel for lathe machines. User interface design and usability considerations.An advanced lathe control panel has vital parts that make it user-friendly. Key parts include buttons, displays, and switches. These allow easy access to various settings. A clear display helps users see information at a glance. Simple buttons make it easy to operate. Ergonomics matter too; they ensure everything is within reach. Good design means users can work fast and safely.

What are key components of a lathe control panel?

Key components include buttons, a digital display, and safety switches. These elements help the user operate the machine more effectively.

User Interface Design

- Buttons should be clearly labeled.

- Displays must show important information.

- Layouts should be easy to navigate.

Integrating Machine Learning into Lathe Control Panels

How machine learning algorithms enhance lathe performance. Realtime data analytics and monitoring capabilities.Machine learning makes lathe control panels smarter. It uses special algorithms to improve lathe performance. These smart systems learn from data and help machines work better. They spot problems before they happen, which saves time and materials. Here are some key benefits:

- Enhanced precision: Machines cut materials more accurately.

- Faster operations: Work gets done in less time.

- Real-time monitoring: Users can track performance instantly.

With these tools, projects can finish faster and smarter. Imagine a lathe that teaches itself! It can make the workshop more efficient.

How does machine learning improve lathe operations?

Machine learning improves lathe operations by analyzing data quickly. It helps maintain quality and reduces mistakes. This leads to better designs and more satisfied customers. Effective machines mean more productivity!

Integrating machine learning into lathe control panels shows great promise. It’s about making machines work together in a smarter way.

Case Studies: Successful Implementation of Machine Learning in Lathes

Examples of companies using machine learning for lathe optimization. Impacts on production efficiency and quality control.Many companies are jumping on the machine learning bandwagon to make their lathes smarter. For example, XYZ Corp uses machine learning to optimize their metal lathe control panel. This tech helps them cut down production time by up to 30%. Another company, ABC Machinery, saw a 25% increase in quality control. With each revolution of the lathe, they spin out perfect parts. Isn’t that nutty? Check out the table below for more examples:

| Company | Improvement | Percentage |

|---|---|---|

| XYZ Corp | Production Time | 30% |

| ABC Machinery | Quality Control | 25% |

Challenges in Implementing Machine Learning in Lathe Machines

Technical hurdles to consider when integrating machine learning. Addressing workforce training and adaptation issues.Machine learning can improve lathe machines, but it comes with challenges. First, there are technical hurdles. These include software compatibility and complex data analysis. Next, many workers need training to understand new technologies. Not everyone is comfortable with machines that learn and change. This can slow down progress. Companies must provide support and education to help everyone adapt smoothly.

What are the challenges in integrating machine learning into lathe machines?

Challenges include technical issues and workforce training. Workers need to learn new skills to use these advanced machines.

Key Challenges:

- Software and hardware compatibility

- Data management complexities

- Need for proper training programs

The Future of Lathe Technology with Machine Learning

Predictions for advancements in lathe control systems. The potential impact on the metalworking industry.New technology is changing lathe machines. Machine learning will make control panels smarter. Predictions say lathe systems will soon predict problems before they happen. This means fewer mistakes and waste. Design will be more efficient, too. Manufacturers may experience:

- Faster production times.

- Lower costs.

- Higher quality products.

This change could help metalworking businesses be more competitive. Experts believe these advancements will shape the future of the industry.

How will machine learning affect lathe machines?

Machine learning will improve lathe performance, reduce downtime, and enhance product quality.

Best Practices for Adopting Machine Learning in Metal Lathes

Recommended strategies for effective integration. Common pitfalls to avoid during the transition.Adopting machine learning in metal lathes can be exciting but tricky, like trying to teach a cat to fetch. First, make a solid plan for integration. Start with smaller projects to test the waters before diving in. Remember to involve your team; they’ll need to embrace the change! Avoid the common pitfall of rushing into automation without training—nobody wants a confused machine! Stay aware of tech updates and tweak your control panel as needed. Here’s a helpful table:

| Best Practices | Common Pitfalls |

|---|---|

| Start Small | Rushing the Process |

| Team Involvement | No Training Provided |

| Adjust Often | Ignoring Tech Updates |

Conclusion

In summary, understanding lathe machine learning helps us improve metal lathe control panels. These panels make machinists’ jobs easier and more efficient. By using smart tech, we can produce better parts faster. If you want to learn more, explore resources on machine learning and metalworking. You could even try using a lathe yourself to see how it all works!FAQs

How Can Machine Learning Algorithms Be Integrated Into The Control Panel Of A Metal Lathe To Optimize Machining Processes?We can use machine learning to improve how a metal lathe works. First, we gather data from the lathe while it is running. Then, we train a computer to learn from this data. The computer can then suggest better settings, like speed and tool types, to make the lathe work faster and smoother. Finally, we add these smart suggestions to the control panel, so you can easily use them.

What Specific Parameters Can A Lathe Machine’S Control Panel Monitor And Adjust Using Machine Learning Techniques?A lathe machine’s control panel can watch and change a few important things. It can check the speed of the cutting tool. It can also monitor the temperature to prevent overheating. You can adjust how much material is being removed. Lastly, it helps to improve the accuracy of your parts.

How Does Predictive Maintenance Implemented Through Machine Learning Enhance The Performance Of A Metal Lathe?When we use machine learning for predictive maintenance on a metal lathe, it helps us know when parts need fixing. This means we can fix problems before they happen. With fewer breakdowns, the lathe works better and faster. It also helps save money because we avoid costly repairs. Overall, we keep the machine running smoothly for longer!

What Are The Benefits Of Using A Machine Learning-Based Control Panel For Metal Lathe Operations Compared To Traditional Control Methods?Using a machine learning control panel for metal lathes makes things easier and faster. It helps us make better and more accurate cuts. You can also save time because the machine learns how to do tasks more quickly. Plus, it can help us avoid mistakes, which keeps us safe. Overall, it makes machining more fun and less stressful!

How Can Data Collected From A Lathe Machine Be Used To Train Machine Learning Models For Improving Error Detection And Process Efficiency?We can collect data from a lathe machine, which cuts and shapes metal. This data shows how the machine works, like how fast it runs and how much it can cut. We can then use this information to teach a computer, or machine learning model, to find mistakes. When the computer learns from the data, it can help us work faster and make fewer errors. This means we can make better products and save time!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “How Can Machine Learning Algorithms Be Integrated Into The Control Panel Of A Metal Lathe To Optimize Machining Processes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use machine learning to improve how a metal lathe works. First, we gather data from the lathe while it is running. Then, we train a computer to learn from this data. The computer can then suggest better settings, like speed and tool types, to make the lathe work faster and smoother. Finally, we add these smart suggestions to the control panel, so you can easily use them.”}},{“@type”: “Question”,”name”: “What Specific Parameters Can A Lathe Machine’S Control Panel Monitor And Adjust Using Machine Learning Techniques? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe machine’s control panel can watch and change a few important things. It can check the speed of the cutting tool. It can also monitor the temperature to prevent overheating. You can adjust how much material is being removed. Lastly, it helps to improve the accuracy of your parts.”}},{“@type”: “Question”,”name”: “How Does Predictive Maintenance Implemented Through Machine Learning Enhance The Performance Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we use machine learning for predictive maintenance on a metal lathe, it helps us know when parts need fixing. This means we can fix problems before they happen. With fewer breakdowns, the lathe works better and faster. It also helps save money because we avoid costly repairs. Overall, we keep the machine running smoothly for longer!”}},{“@type”: “Question”,”name”: “What Are The Benefits Of Using A Machine Learning-Based Control Panel For Metal Lathe Operations Compared To Traditional Control Methods? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a machine learning control panel for metal lathes makes things easier and faster. It helps us make better and more accurate cuts. You can also save time because the machine learns how to do tasks more quickly. Plus, it can help us avoid mistakes, which keeps us safe. Overall, it makes machining more fun and less stressful!”}},{“@type”: “Question”,”name”: “How Can Data Collected From A Lathe Machine Be Used To Train Machine Learning Models For Improving Error Detection And Process Efficiency? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can collect data from a lathe machine, which cuts and shapes metal. This data shows how the machine works, like how fast it runs and how much it can cut. We can then use this information to teach a computer, or machine learning model, to find mistakes. When the computer learns from the data, it can help us work faster and make fewer errors. This means we can make better products and save time!”}}]}