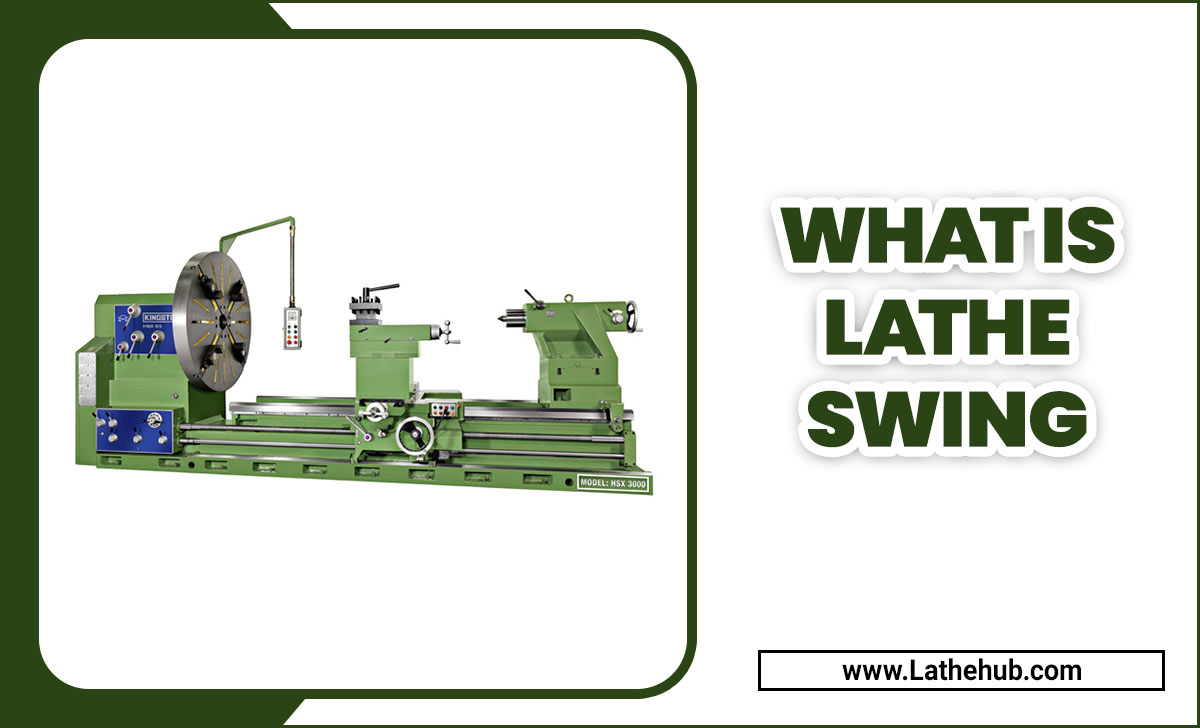

Have you ever watched a lathe machine spin? It’s like magic! A simple block of metal can turn into beautiful shapes. But what goes into making those shapes? One of the secrets lies in machine learning. Imagine a computer helping a lathe machine make perfect cuts. It can learn from past mistakes and get better with each use.

Now, here’s another interesting fact: coolant plays a big role in this process. When cutting metal, heat builds up quickly. Coolant keeps the metal cool and helps it last longer. Have you ever noticed how ice can make things less hot? Coolant does the same for metal lathes. It keeps everything running smoothly.

In this article, we will explore how machine learning and coolant impact lathe machines. These innovations can change how we work with metal forever. Are you curious about how this all works together? Let’s dive in and discover the exciting world of lathe machine learning and metal lathe coolant!

Lathe Machine Learning: Optimizing Metal Lathe Coolant Usage

Lathe Machine Learning: Metal Lathe Coolant Insights

A lathe machine transforms raw metal into precise shapes. Did you know coolant is crucial for this process? It keeps the metal cool and helps prevent damage. However, many overlook its importance. Learning about the right coolant can enhance tool life and improve finish quality. By choosing the right type, users can save time and avoid costly mistakes. Understanding how lathe machine learning impacts coolant use can lead to better craftsmanship and efficiency.Understanding Lathe Machines

Definition and purpose of metal lathe machines. Types of lathe machines and their applications.Lathe machines are like the superheroes of metalworking. They help shape metal into useful parts, making the manufacturing world go round. There are different types of lathe machines, each with its own superpower! Let’s look at some:

| Type of Lathe | Application |

|---|---|

| Engine Lathe | General machining tasks |

| CNC Lathe | Complex shapes and precision work |

| Turret Lathe | High-volume production |

In short, these machines turn big chunks of metal into pretty amazing creations. Who knew metal could be so entertaining, right? Whether it’s creating parts for a spaceship or just a cool chair, lathe machines have got it covered!

The Role of Coolant in Metal Lathe Operations

Importance of coolant in machining processes. Types of coolants used in metal lathes (e.g., waterbased, oilbased).Coolant is vital for metal lathe operations. It helps keep the machine cool and prevents damage. Without coolant, parts can overheat and wear out quickly. There are different types of coolants used in machining. They include:

- Water-based coolants: These are great for cooling and flushing away debris.

- Oil-based coolants: These provide excellent lubrication and protect against rust.

Using the right coolant can increase the machine’s lifespan and improve machining quality. Remember, coolant isn’t just a liquid; it’s a key to success!

Why is coolant important in metal lathe operations?

Coolant helps prevent overheating, maintains tool life, and improves surface finish. It also flushes away chips, keeping the work area clean and safe.

Machine Learning Applications in Lathe Operations

Predictive maintenance and its impact on machine efficiency. Data analysis for optimizing cutting parameters and reducing defects.Machine learning helps improve lathe operations in a big way. One key benefit is predictive maintenance. This means machines can tell us when they need fixing before they break. Doing this boosts machine efficiency. Data analysis also plays a role by finding the best cutting settings. This leads to fewer defects, saving time and money.

- Predictive maintenance keeps the machines running smoothly.

- Analyzing data helps choose better cutting conditions.

- Fewer defects lead to higher quality products.

What impact does predictive maintenance have on machines?

Predictive maintenance prevents breakdowns and keeps machines efficient. When machines work better, companies save money and time.

By using these smart technologies, businesses can create products faster and with better quality.

Optimizing Coolant Usage through Machine Learning

Techniques for analyzing coolant effectiveness using data analytics. Strategies for reducing coolant waste and improving sustainability.Machine learning helps us use coolant better. We can look at data to see how effective it is. For example, data analytics shows which types of coolant work best. It can also find ways to save coolant. This helps the environment! Here are some tips:

- Track coolant usage closely.

- Analyze cooling temperatures.

- Test different coolant types.

- Adjust coolant flow based on need.

By using these techniques, we can reduce waste and improve sustainability. Every drop counts!

Why is analyzing coolant important?

Analyzing coolant helps identify waste and improves cooling efficiency. This ensures machines run smoothly while using less coolant.

Case Studies of Successful Integration

Examples of manufacturers using machine learning for lathe operations. Impact of coolant management on production efficiency.Many factories use machine learning to make lathe operations better. For example, companies track how cooling fluids affect their machines. Using machine learning, they predict when the coolant needs a change. This helps keep machines running smoothly and can boost safety. The results can be impressive:

- Up to 30% less coolant waste.

- 20% increase in production speed.

- Fewer machine breakdowns by 15%.

This smart use of technology helps businesses save money and time.

How does coolant management impact production efficiency?

Coolant management ensures machines run smoothly. Efficient coolant usage keeps tools cool and reduces wear and tear. It leads to better cutting performance and longer tool life.

Future Trends in Lathe Machine Technology

Advances in machine learning for manufacturing and machining. Innovations in coolant technology and their potential impact on lathe operations.New technology is changing how lathe machines work. Machine learning helps to improve manufacturing. It can predict problems before they happen. This makes production smoother and faster.

Coolant technology is also advancing. New coolants help keep machines cool and running well. They can reduce waste and improve safety. These improvements can make lathe operations more efficient.

- Machine learning can find patterns in data.

- Advanced coolants protect against overheating.

- Both technologies reduce costs and time wasted.

What innovations are changing coolant technology?

New coolants can last longer and work better. They help prevent rust and keep machines in top shape.

Conclusion

In summary, lathe machines are essential for shaping metal. Using the right coolant helps improve performance and protects tools. You can explore different coolant options to find what works best for your projects. Remember to always follow safety guidelines. If you want to learn more, check out resources on lathe maintenance and coolant selection for deeper insights.FAQs

Sure! Here Are Five Related Questions About Lathe Machines, Machine Learning, And Metal Lathe Coolant:Sure! A lathe machine is a tool that helps shape metal or wood into different forms. Machine learning is when computers learn to do things by themselves, like recognizing pictures or understanding words. Metal lathe coolant is a special liquid that cools the machine while it works, preventing it from getting too hot. It also helps make smoother cuts. Together, these things help us make cool stuff, like toys or tools!

Sure! Please go ahead and ask your question.

How Can Machine Learning Algorithms Be Utilized To Optimize The Performance Of Coolant Systems In Metal Lathe Machining Processes?We can use machine learning to make coolant systems work better in metal lathes. First, we collect data on how the machines run. Then, the computer looks for patterns to see when the coolant should be used more or less. This helps keep the metal cool and saves energy. In the end, it makes the machines run smoothly while saving money and resources.

What Are The Benefits Of Using Advanced Coolant Management Systems In Cnc Lathes, And How Can Machine Learning Improve Their Efficiency?Using advanced coolant management systems in CNC lathes helps keep the machines cool while they work. This means the machines can run longer without getting too hot. We can also save money because these systems use less coolant and help us recycle it. Machine learning can make these systems smarter. It learns when to add more coolant or when to clean the machine, which helps everything run better.

How Does Coolant Selection Affect The Machining Parameters And Surface Finish In Metal Lathe Operations, And Can Machine Learning Help Predict The Best Options For Different Materials?Choosing the right coolant helps keep the metal cool and makes it easier to cut. This can make your work smoother and look nicer. If we use the best coolant, we get a better finish on the metal. Machine learning can help us find the best coolant for different materials by looking at lots of information. This means we can make better choices faster!

In What Ways Can Real-Time Data Analytics And Machine Learning Contribute To Reducing Coolant Consumption While Maintaining Machining Quality In Lathe Processes?Real-time data analytics helps us see how much coolant we really need. Machine learning learns from past results, telling us when to use less coolant. This way, we save coolant while still keeping our pieces smooth and nice. By using these tools, you can make better choices during the lathe process. In the end, we waste less and keep our work quality high!

How Can Predictive Maintenance Supported By Machine Learning Help Identify Issues With Coolant Circulation In Lathe Machines, Thereby Preventing Downtime And Enhancing Productivity?Predictive maintenance uses machine learning to check how well coolant flows in lathe machines. It looks at data from the machines to spot problems early. If we see issues, we can fix them before they cause trouble. This helps keep the machines running longer and working better. In turn, this means more work gets done without stopping!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions About Lathe Machines, Machine Learning, And Metal Lathe Coolant:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe machine is a tool that helps shape metal or wood into different forms. Machine learning is when computers learn to do things by themselves, like recognizing pictures or understanding words. Metal lathe coolant is a special liquid that cools the machine while it works, preventing it from getting too hot. It also helps make smoother cuts. Together, these things help us make cool stuff, like toys or tools!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please go ahead and ask your question.”}},{“@type”: “Question”,”name”: “How Can Machine Learning Algorithms Be Utilized To Optimize The Performance Of Coolant Systems In Metal Lathe Machining Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use machine learning to make coolant systems work better in metal lathes. First, we collect data on how the machines run. Then, the computer looks for patterns to see when the coolant should be used more or less. This helps keep the metal cool and saves energy. In the end, it makes the machines run smoothly while saving money and resources.”}},{“@type”: “Question”,”name”: “What Are The Benefits Of Using Advanced Coolant Management Systems In Cnc Lathes, And How Can Machine Learning Improve Their Efficiency?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using advanced coolant management systems in CNC lathes helps keep the machines cool while they work. This means the machines can run longer without getting too hot. We can also save money because these systems use less coolant and help us recycle it. Machine learning can make these systems smarter. It learns when to add more coolant or when to clean the machine, which helps everything run better.”}},{“@type”: “Question”,”name”: “How Does Coolant Selection Affect The Machining Parameters And Surface Finish In Metal Lathe Operations, And Can Machine Learning Help Predict The Best Options For Different Materials?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Choosing the right coolant helps keep the metal cool and makes it easier to cut. This can make your work smoother and look nicer. If we use the best coolant, we get a better finish on the metal. Machine learning can help us find the best coolant for different materials by looking at lots of information. This means we can make better choices faster!”}},{“@type”: “Question”,”name”: “In What Ways Can Real-Time Data Analytics And Machine Learning Contribute To Reducing Coolant Consumption While Maintaining Machining Quality In Lathe Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Real-time data analytics helps us see how much coolant we really need. Machine learning learns from past results, telling us when to use less coolant. This way, we save coolant while still keeping our pieces smooth and nice. By using these tools, you can make better choices during the lathe process. In the end, we waste less and keep our work quality high!”}},{“@type”: “Question”,”name”: “How Can Predictive Maintenance Supported By Machine Learning Help Identify Issues With Coolant Circulation In Lathe Machines, Thereby Preventing Downtime And Enhancing Productivity?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Predictive maintenance uses machine learning to check how well coolant flows in lathe machines. It looks at data from the machines to spot problems early. If we see issues, we can fix them before they cause trouble. This helps keep the machines running longer and working better. In turn, this means more work gets done without stopping!”}}]}