Have you ever wondered how machines shape metal? The lathe machine is a fascinating tool that does just that. It spins material like wood or metal, allowing exciting designs to form. Imagine how many items we use each day come from this one machine!

Now, with technology advancing, we see new ideas brewing. Metal lathe machines combine traditional skills with smart systems, called machine learning. What if your lathe could learn from past cuts? This means better accuracy and less waste. Isn’t that amazing?

Picture a factory humming along, where every gear runs perfectly. Thanks to innovations in lathe machine learning, we can do this. It’s like having a helper that gets smarter over time. This blend of old and new makes an exciting future for metalwork.

Curious about how this works? Join us as we dive into the world of lathe machines and their new smart features!

Lathe Machine Learning: Enhancing Metal Lathe Gear Precision

Lathe Machine Learning: Gear Up for Success

Lathe machines are tools that shape metal. They spin material to create precise parts. But did you know machine learning can make these machines better? By using data, lathe machines can learn from past experiences. This helps them work faster and smarter. Imagine a gear that adjusts automatically while you work! This technology not only saves time but also improves the quality of the finished product. Isn’t it amazing how machines can learn just like us?What is a Lathe Machine?

Definition and basic function of lathe machines.. Different types of lathe machines used in metalworking..A lathe machine shapes metal and wood. It spins the material while a tool cuts it. This helps create items like furniture and gears. There are different types of lathe machines used in metalworking:

- Engine Lathe: A common choice for many projects.

- CNC Lathe: A computer controls this for precise cuts.

- Turret Lathe: Allows quick changes of the tools.

- Bench Lathe: A smaller version for light tasks.

Understanding these machines makes metalworking easier and more fun!

What do lathe machines do?

They create shapes and sizes in metal and wood. A lathe machine lets you make many items, like gears and toys. It’s essential for building products.

The Role of Machine Learning in Metalworking

Explanation of machine learning and its applications in manufacturing.. Benefits of implementing machine learning in metalworking processes..Machine learning helps machines learn from data. In metalworking, this means using computers to improve how things are made. This technology can predict issues, save time, and make parts more accurate. Here are some benefits:

- Better quality control

- Faster production rates

- Reduced waste

With machine learning, factories can work smarter, not harder. A study showed up to 30% more efficiency in some processes. Isn’t that great?

How does machine learning improve metalworking?

Machine learning analyzes data to find patterns in metalworking processes, allowing for faster decisions and ongoing improvements.

Lathe Machine Components and Their Functions

Key components of a lathe machine and their importance.. Explanation of how these components interact in the machining process..A lathe machine has several key parts that help it work. Each part plays a special role. Here are some important components:

- Headstock – Holds the motor and controls the speed.

- Tailstock – Supports the other end of the workpiece.

- Bed – The base where everything sits.

- Carriage – Moves the cutting tool.

- Chuck – Holds the material in place.

These components work together to shape metal. The motor in the headstock spins the material. The tool on the carriage cuts into it. Together, they create precise shapes. Understanding each part helps in using a lathe effectively.

What does each part of a lathe machine do?

The headstock spins the workpiece, while the tailstock supports it. The bed is the base, and the carriage moves the tool. The chuck holds the material tight.

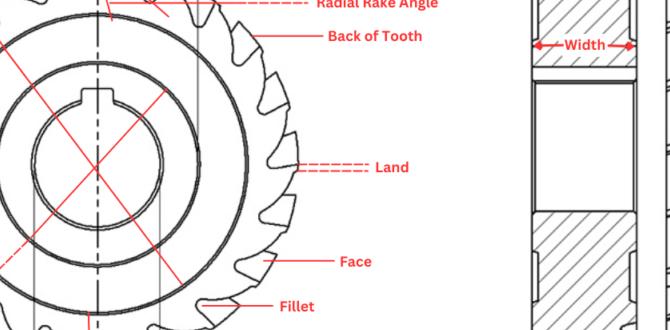

Understanding Gears in Metal Lathes

Types of gears used in metal lathes.. The significance of gear design and efficiency in lathe performance..Gears are the silent heroes in metal lathes, helping them run smoothly like a well-oiled machine. There are several types of gears, like spur gears and bevel gears, each playing a unique role. The design of these gears greatly affects how efficiently the lathe works. Good gear design means less energy wasted and more power to shape metal. Think of gears as the little dance partners of your lathe – if they trip, the whole performance is off! Here’s a quick look at common gear types and their functions:

| Type of Gear | Function |

|---|---|

| Spur Gear | Transfers power between parallel shafts. |

| Bevel Gear | Changes the direction of rotation. |

| Worm Gear | Provides high torque and reduces speed. |

So, remember, good gearing is like having a snack – it makes everything better!

How Machine Learning Enhances Gear Production

Techniques machine learning employs to improve gear manufacturing.. Case studies of successful machine learning applications in gear optimization..Machine learning changes how gears are made, making them better and faster. By using data, machines learn to spot problems and improve designs. Some popular techniques include:

- Predictive maintenance

- Quality control

- Process optimization

One case study showed how a company cut defects by 30% using smart algorithms. This made gears last longer and work better. These improvements save time and money for manufacturers.

How does machine learning optimize gear manufacturing?

Machine learning helps by finding patterns in data, predicting failures, and improving production speed.

Challenges in Implementing Machine Learning in Lathe Operations

Common obstacles faced by manufacturers.. Strategies to overcome these challenges..Manufacturers face several bumps on the road when adding machine learning to lathe operations. First, there’s the problem of data collection. Often, they struggle to gather enough quality data. It’s like trying to find a needle in a haystack, but the haystack is made of metal shavings! Improving data quality can be fixed with better sensors and tools. Another hiccup is the lack of skilled workers. Training employees can help turn this challenge into an opportunity. As the saying goes, “When life gives you metal scraps, make a masterpiece!”

| Challenges | Strategies |

|---|---|

| Data collection issues | Invest in better sensors |

| Skilled labor shortage | Empower training programs |

The Future of Lathe Machines and Machine Learning

Emerging technologies in lathe machining and machine learning.. Predictions on the integration of AI in future gear production..Lathe machines are changing fast, thanks to new technologies! Machine learning is becoming a big deal in how we make parts. Imagine a robot that thinks for you while you work. It’s like having a helpful friend who never needs snacks! AI can help produce gears more accurately and quickly. By 2030, experts believe that machines with AI will reduce errors by nearly 30%. The future looks bright, and gear-making might just get a fun upgrade!

| Predictions for AI in Gear Production | Expected Benefits |

|---|---|

| Increased efficiency | Up to 30% faster production |

| Fewer errors | 30% less mistakes |

| Better design optimization | More creative gear shapes |

Best Practices for Metal Lathe Operators

Tips for optimizing lathe operations with machine learning insights.. Maintenance and calibration recommendations for metal lathes..To optimize lathe operations, use machine learning for smart decisions. It helps you know when to cut and how to polish. Think of it as your friendly robot assistant! Regular maintenance is key; clean the gears and check the belts. If your lathe were a car, you’d want to keep it shiny, right? Here are some handy tips:

| Tip | Description |

|---|---|

| Use Machine Learning | Gain insights to improve precision and reduce waste. |

| Regular Maintenance | Check oil levels and clean filters to keep everything running smoothly. |

| Calibration | Ensure tools are properly calibrated for better results. |

Remember, a happy lathe makes for happy projects! Prioritize care, and you’ll enjoy smoother operations and great results.

Conclusion

In conclusion, a lathe machine is essential for shaping metal. Learning how to use it can boost your skills. We explored how gear design and operation work together. You can practice by creating simple projects. If you want to learn more, check out videos or books on lathe machines. Remember, hands-on experience is key to mastering this valuable tool!FAQs

Sure! Here Are Five Questions Related To The Topic Of Lathe Machine Learning In Metal Lathes And Gear Manufacturing:Sure! Here’s a short answer related to lathe machine learning in metal lathes and gear manufacturing: Machine learning is when computers learn from data. In metal lathes, this helps make parts better and faster. For gear manufacturing, it can predict problems before they happen. This means you get stronger and safer gears. Overall, it makes things easier for everyone who works with machines!

Sure! Please provide the question you would like me to answer.

How Can Machine Learning Algorithms Improve The Efficiency And Accuracy Of Metal Lathe Operations?Machine learning algorithms can help metal lathes work better and faster. They can learn what mistakes happen and suggest ways to fix them. This means fewer errors and better final products. By using these smart tools, we can save time and make everything more precise. This helps workers create great things with less effort.

What Types Of Data Are Most Valuable For Training Machine Learning Models In The Context Of Gear Machining On A Lathe?The best data for training machine learning models in gear machining includes pictures of gears and their measurements. We also need information about how fast the lathe turns and the types of materials used. You can collect notes on different settings that worked well and ones that didn’t. This data helps the model learn how to make better gears on a lathe.

How Can Predictive Maintenance Using Machine Learning Reduce Downtime In Metal Lathe Equipment?Predictive maintenance helps us fix machines before they break. We use machine learning, which is when computers learn from data. This way, we can see warning signs that tell us a part might fail. When we fix things early, we avoid big problems and keep machines running longer. This means less waiting time and more time working!

What Challenges Arise When Implementing Machine Learning Solutions In Traditional Lathe Machining Environments?When we try to use machine learning in lathe machining, we face some challenges. First, the machines might be old and not work well with new technology. Second, workers may need training to understand how to use machine learning. Lastly, collecting data can be hard because some machines don’t record information easily. These things make it tough to get the best results from machine learning.

In What Ways Can Machine Learning Contribute To The Optimization Of Gear Design And Production Processes On Metal Lathes?Machine learning helps us make better gear designs by looking for patterns in data. It can tell us what shapes and sizes work best. When we use metal lathes, machine learning can help us run machines more smoothly. This means we can make gears faster and more accurately. Overall, it makes gear production easier and helps create better products.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To The Topic Of Lathe Machine Learning In Metal Lathes And Gear Manufacturing:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here’s a short answer related to lathe machine learning in metal lathes and gear manufacturing: Machine learning is when computers learn from data. In metal lathes, this helps make parts better and faster. For gear manufacturing, it can predict problems before they happen. This means you get stronger and safer gears. Overall, it makes things easier for everyone who works with machines!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “How Can Machine Learning Algorithms Improve The Efficiency And Accuracy Of Metal Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Machine learning algorithms can help metal lathes work better and faster. They can learn what mistakes happen and suggest ways to fix them. This means fewer errors and better final products. By using these smart tools, we can save time and make everything more precise. This helps workers create great things with less effort.”}},{“@type”: “Question”,”name”: “What Types Of Data Are Most Valuable For Training Machine Learning Models In The Context Of Gear Machining On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The best data for training machine learning models in gear machining includes pictures of gears and their measurements. We also need information about how fast the lathe turns and the types of materials used. You can collect notes on different settings that worked well and ones that didn’t. This data helps the model learn how to make better gears on a lathe.”}},{“@type”: “Question”,”name”: “How Can Predictive Maintenance Using Machine Learning Reduce Downtime In Metal Lathe Equipment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Predictive maintenance helps us fix machines before they break. We use machine learning, which is when computers learn from data. This way, we can see warning signs that tell us a part might fail. When we fix things early, we avoid big problems and keep machines running longer. This means less waiting time and more time working!”}},{“@type”: “Question”,”name”: “What Challenges Arise When Implementing Machine Learning Solutions In Traditional Lathe Machining Environments?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we try to use machine learning in lathe machining, we face some challenges. First, the machines might be old and not work well with new technology. Second, workers may need training to understand how to use machine learning. Lastly, collecting data can be hard because some machines don’t record information easily. These things make it tough to get the best results from machine learning.”}},{“@type”: “Question”,”name”: “In What Ways Can Machine Learning Contribute To The Optimization Of Gear Design And Production Processes On Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Machine learning helps us make better gear designs by looking for patterns in data. It can tell us what shapes and sizes work best. When we use metal lathes, machine learning can help us run machines more smoothly. This means we can make gears faster and more accurately. Overall, it makes gear production easier and helps create better products.”}}]}