Have you ever wondered how a lathe machine shapes metal with precision? Imagine a giant tool spinning really fast. It whirs as the metal gets carved into a perfect design. This magic often happens with a tool called a lathe.

But what if we added another layer? What if we mixed in machine learning? This new tech can make metal lathes even smarter.

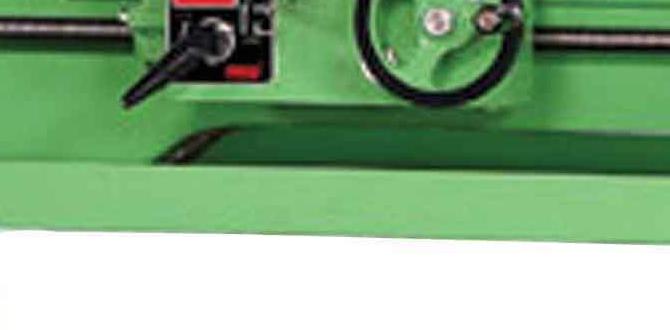

Picture this: You have a metal lathe with a handwheel. You turn the handwheel to guide the metal. Now, imagine if the lathe could learn from your moves. It could adapt and improve as you work. Wouldn’t that be amazing?

In the world of metalworking, the combination of a lathe and intelligent technology is like a superhero team. They make tasks easier and results better. Join us as we explore how lathe machine learning and the handwheel work together to create incredible results.

Lathe Machine Learning: Enhancing Metal Lathe Handwheel Precision

Understanding Lathe Machines and Their Handwheels

Lathe machines are essential tools in metalworking, shaping materials with precision. Their handwheels play a crucial role in controlling movement and adjustments. Have you ever wondered how these machines create such smooth finishes? By using advanced techniques and learning, lathes can produce intricate designs. When properly used, they help craftsmen bring their ideas to life. Discover how mastering the handwheel’s functions can enhance your skills and make metalworking more enjoyable.The Functionality of Handwheels in Lathe Machines

Description of handwheel components and their specific functions.. The role of handwheels in precision and efficiency during machining..The handwheel is a crucial part of lathe machines, like a steering wheel for a car. Each one has its components, such as the wheel itself, the spindle, and the locking mechanism. These pieces work together to help move the machine parts smoothly. When you turn the handwheel, it controls the cutting tool with great precision, allowing you to create perfect shapes.

Imagine trying to carve a turkey with a giant spoon! The handwheel makes sure that every cut is just right. This means more efficiency and less waste. It’s a little part that makes a big difference in machining, ensuring that your project ends up looking sharp!

| Component | Function |

|---|---|

| Handwheel | Controls movement of the cutting tool |

| Spindle | Holds cutting tools securely |

| Locking Mechanism | Prevents unwanted movement |

How Machine Learning Enhances Lathe Operations

Examples of machine learning applications in lathe operations.. Case studies showcasing improvements in efficiency and productivity..Machine learning is changing how lathe machines work. It can help operators make better cuts and avoid mistakes. For example, systems use sensors to learn about different materials. This helps in choosing the best speed for cutting. A study showed that using machine learning increased productivity by 30% in some factories. Operators saved time and reduced waste. Here are a few applications:

- Predictive maintenance to avoid machine breakdowns.

- Quality control for checking finished products quickly.

- Automating tasks for consistent results.

What are examples of machine learning in lathe operations?

Machine learning uses data to improve lathe operations, enhancing efficiency and cutting quality.

Implementing Machine Learning in Metal Lathe Systems

Requirements for integrating machine learning in lathe equipment.. Steps for upgrading existing machines to support machine learning capabilities..Integrating machine learning into metal lathe systems is an exciting challenge! First, you need the right tools. Ensure your lathe is compatible with new tech. Think of it like upgrading your toy car with super-fast wheels. Next, install sensors and data processors. It’s like giving your lathe a brain. After that, you can start training your machine. Teach it to learn from its mistakes—like that time you tried to bake cookies but ended up with a charred disaster.

| Requirements | Steps |

|---|---|

| Compatible lathe | Install sensors |

| Data processing software | Train the system |

| Good internet connection | Regular updates |

With these steps, you’ll be on your way to a smarter, more efficient lathe. Remember, learning takes time. Don’t be surprised if your lathe has a few “oops” moments, just like us!

Challenges and Solutions in Integrating Machine Learning

Common challenges manufacturers face when adopting machine learning.. Potential solutions and best practices to overcome these hurdles..Manufacturers often encounter a few hurdles with machine learning. First, data quality can be a sneaky gremlin. If the data is poor, the models won’t work well. Next, many workers may feel unsure about using new tech. People might think machines will steal their jobs instead of help. To tackle these issues, training is key. A little education goes a long way! Moreover, having good data is vital. Pairing smart tech with wise humans can lead to exciting solutions.

| Challenge | Potential Solution |

|---|---|

| Poor Data Quality | Invest in data cleaning tools |

| Worker Resistance | Provide hands-on training workshops |

Remember, the goal is teamwork between machines and humans. Together, they can achieve amazing things! The future of manufacturing looks bright with machine learning!

Future Trends in Lathe Machine Technology

Predictions for the evolution of lathe machines with machine learning.. Potential impact on the industry and new opportunities for manufacturers..Imagine a world where lathe machines can think for themselves! With machine learning, this could become reality. In the future, robots might use data to predict problems before they happen. This means fewer mistakes and more shiny metal parts for everyone. For manufacturers, this opens up exciting new opportunities. They could save time and money while making products that are smoother than a fresh jar of peanut butter! Isn’t that nuts?

| Trend | Impact |

|---|---|

| Smart Lathes | Less downtime and improved accuracy |

| Predictive Maintenance | Fewer breakdowns and lower costs |

Conclusion

In conclusion, using a lathe machine enhances your metalworking skills, especially with features like a handwheel. You can control the cutting precisely, making your projects smoother. We encourage you to explore more about lathe techniques and machine learning applications in manufacturing. With practice, you’ll create amazing pieces. Keep learning and experimenting to improve your skills!FAQs

How Can Machine Learning Algorithms Be Utilized To Improve The Precision And Efficiency Of Metal Lathe Operations?We can use machine learning, which is a way for computers to learn from data, to make metal lathe operations better. By watching how the lathe works, the computer can find the best ways to cut metal. This helps make cuts more precise, so the metal shapes are just right. It can also save time and materials by making fewer mistakes. This way, we get more good parts faster!

What Role Does Sensor Data From The Lathe Handwheel Play In Training Machine Learning Models For Predictive Maintenance?Sensor data from the lathe handwheel helps us understand how the machine works. It tells us how fast or slow the handwheel turns. We can use this information to spot when something might go wrong. By training machine learning models with this data, we learn to predict when the machine needs fixing. This way, we can prevent big problems before they happen.

How Can We Use Machine Learning To Optimize The Feed Rate And Cutting Parameters In Metal Lathe Machining?We can use machine learning to make metal lathe machining better. First, we collect data about how the machine works. Then, we teach a computer program to understand this data. The program helps us find the best speed and settings for cutting metal. This way, we can make parts faster and more easily!

What Are The Challenges Of Integrating Machine Learning With Traditional Metal Lathe Controls, Particularly Concerning The Handwheel?Integrating machine learning with traditional metal lathe controls can be tricky. The handwheel, which you use to turn and shape metal, is very precise. Machine learning needs data to learn, but it can be hard to collect enough accurate data from the handwheel. Also, machines need to work together smoothly, so we have to make sure the new system can talk to the old one. Lastly, some people might find it hard to trust new technology with something they have always used manually.

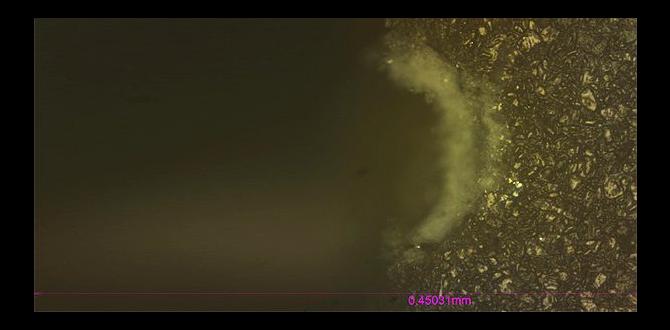

How Can Computer Vision And Machine Learning Techniques Enhance The Monitoring Of Workpieces On A Metal Lathe During Operation?Computer vision helps us see the workpieces on a metal lathe, which is a machine that shapes metal. It uses cameras to spot problems, like pieces that are too big or out of shape. Machine learning, which teaches computers to learn from data, helps us find patterns in how the metal is being used. This means we can catch mistakes early and make better parts more quickly. Together, they make working with metal easier and safer!