Have you ever wondered how metal pieces are shaped into beautiful designs? The magic often happens with a lathe machine. This tool spins objects around and helps carve them into precise shapes. But did you know that just like any machine, lathe machines need proper care? Without the right maintenance, they can wear out quickly.

Imagine building a model airplane. You spend hours crafting the wings just right. Then, suddenly, you realize your tools are rusty. How frustrating would that be? That’s why learning about lathe machine maintenance is so important. It keeps your tools working well and your projects on track.

In this article, we will explore how machine learning can improve lathe machine maintenance. It’s a fascinating blend of technology and hands-on work. This approach helps predict problems before they occur. So, let’s dive deeper and discover how to keep these machines running smoothly!

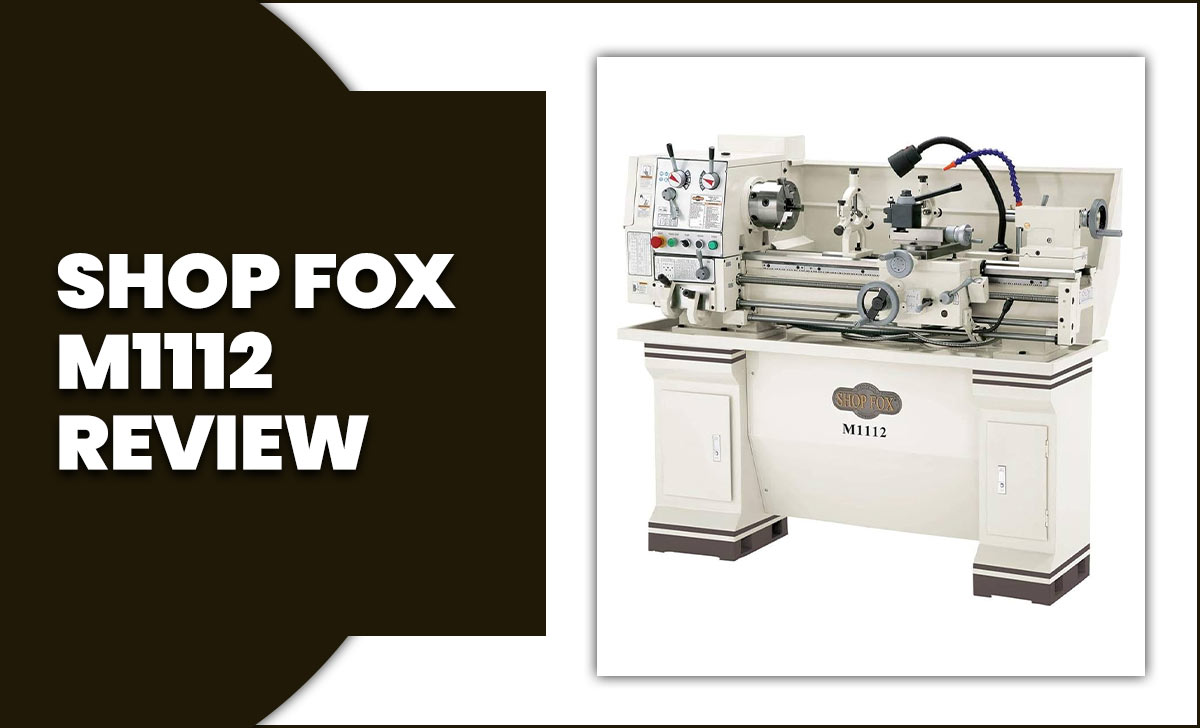

Lathe Machine Learning: Essential Metal Lathe Maintenance Tips — Introduction To Lathe Machine Learning Lathe Machines Are Invaluable In The Manufacturing Industry, Allowing Precision Shaping Of Metal, Wood, And Other Materials. As These Machines Evolve, Integrating Machine Learning Technology Can Enhance Their Efficiency, Productivity, And Maintenance. This Article Delves Into How Machine Learning Can Revolutionize Metal Lathe Maintenance, Ensuring Optimal Performance And Longevity. Understanding Lathe Machines Lathe Machines Come In Various Forms, Including Vertical Lathes, Cnc (Computer Numerical Control) Lathes, And Conventional Lathes. Each Type Serves A Specific Purpose In Shaping Materials. Regular Maintenance Of These Machines Is Vital To Prevent Downtime And Costly Repairs. The Role Of Machine Learning In Metal Lathe Maintenance Machine Learning Can Play A Significant Role In Improving The Maintenance Of Metal Lathes. Through Data Analytics And Predictive Modeling, Manufacturers Can Monitor Machine Performance, Detect Anomalies Early, And Schedule Maintenance Proactively. 1. **Predictive Maintenance**: Machine Learning Algorithms Can Analyze Historical Data To Predict When A Lathe Machine Is Likely To Require Maintenance. This Means Potential Issues Can Be Addressed Before They Lead To Machine Failure. 2. **Real-Time Monitoring**: Leveraging Iot Sensors, Machine Learning Systems Can Track The Operational Parameters Of The Lathe In Real-Time. This Data Helps In Identifying Patterns And Deviations That Could Indicate Maintenance Needs. 3. **Automated Reporting**: Machine Learning Can Automate The Reporting Of Maintenance Tasks And Machine Health Metrics, Enabling Operators And Managers To Have Access To Crucial Information Effortlessly. Benefits Of Machine Learning In Lathe Maintenance Implementing Machine Learning In Metal Lathe Maintenance Offers Several Advantages: – **Reduced Downtime**: By Predicting When Maintenance Is Needed, Manufacturers Can Minimize Unplanned Downtime. – **Enhanced Efficiency**: Continuous Monitoring Helps In Optimizing Operational Efficiency, Ensuring That Machines Are Always Running At Their Best. – **Cost Savings**: Predictive Maintenance Reduces Repair Costs By Addressing Issues Before They Escalate. Conclusion Integrating Machine Learning Into Metal Lathe Maintenance Is Not Just An Innovation; It’S A Necessary Evolution In The Manufacturing Industry. By Leveraging Technology, Manufacturers Can Ensure Their Lathe Machines Operate Efficiently, Ultimately Leading To Higher Productivity And Reduced Operational Costs. Embracing This Change Will Position Companies For Success In A Highly Competitive Market. — By Focusing On Combining Advanced Technology With Traditional Manufacturing Practices, We Can Ensure That Lathe Machines Remain Reliable Tools In The Production Process.

Lathe Machine Learning and Metal Lathe Maintenance

Lathe machines are essential for shaping metal. Regular maintenance keeps them running smoothly. Did you know that learning about these machines can actually help you work faster? Proper care includes cleaning, checking belts, and lubricating parts. Wouldn’t it be great to avoid costly repairs? Remember, a well-maintained lathe is a reliable partner in your projects. Understanding metal lathe maintenance through machine learning can also provide valuable insights. This knowledge makes your work easier and ensures better results.Understanding Lathe Machines

Definition and types of lathe machines. Applications in various industries.Lathe machines are amazing tools that shape materials like metal and wood. They work by spinning a piece of material while a sharp tool cuts away parts of it. There are different types of lathe machines, such as:

- Wood Lathes

- Metal Lathes

- CNC Lathes

- Tool Lathes

These machines are used in many industries. For example, they help make car parts, furniture, and even musical instruments. They play a big role in making products better and faster!

What are the main uses of a lathe machine?

Lathe machines are used for shaping materials, creating round shapes, and adding details. They are essential in industries like:

Key Industries:

- Automotive

- Aerospace

- Manufacturing

- Furniture

Overall, lathe machines help improve design and efficiency in many fields.

Importance of Regular Metal Lathe Maintenance

Impact of proper maintenance on performance and longevity. Common issues arising from neglecting maintenance.Keeping a metal lathe in top shape is key for smooth sailing in any workshop. Regular maintenance boosts performance and helps your lathe last longer. Think of it like a regular check-up for your car; skip it, and you might end up with a clunker! Neglect can lead to issues like uneven cuts or even tool damage, making your work a lot harder and, let’s be honest, less fun. A lathe in good condition keeps things accurate and saves you from the dreaded “oops” moments.

| Common Maintenance Issues | Impact of Neglect |

|---|---|

| Dirty components | Causes overheating |

| Worn-out bearings | Leads to vibrations |

| Misalignment | Results in poor cuts |

Essential Maintenance Tasks for Metal Lathes

Daily, weekly, and monthly maintenance routines. Specific checks and adjustments required for optimal function.Keeping your metal lathe in top shape is easy with regular tasks. Each day, check for loose parts and clean any debris. Weekly, oil the moving parts and inspect the belts for wear. Monthly, examine the alignment and calibrate the settings. Follow these steps for a smooth-running lathe:

- Daily: Spot clean and check tightness.

- Weekly: Oil parts and check belts.

- Monthly: Align and calibrate settings.

These simple steps help keep your lathe working well and can prevent bigger problems.

What are common maintenance tasks for a lathe machine?

Common tasks include checking for loose parts, oiling moving parts, and aligning settings. Regular maintenance keeps the machine in good condition.

Tools and Technologies for Enhancing Lathe Maintenance

Recommended software and hardware for monitoring lathe performance. Emerging technologies that aid in machine learning applications.Keeping lathe machines in great shape is important. Special software can help watch how well the lathe is working. Here are some tools to consider:

- Monitoring Software: Use programs like Machinery Health Monitoring to check machine health in real-time.

- Data Tracking Tools: DataLog can collect information and find patterns to improve performance.

- Emerging Tech: Explore IoT sensors that send updates on the machine’s condition anytime.

New technologies make machine learning easier. They help predict maintenance needs. This can lead to less downtime and better work!

What software helps with lathe maintenance?

Many helpful programs exist. Monitoring software tracks machine health. Data tracking tools analyze performance. These tools keep lathe machines running smoothly.

Best Practices for Metal Lathe Users

Guidelines for safe operation and upkeep. How to train staff on maintenance protocols and machine learning integration.Using a metal lathe safely is essential for anyone in a workshop. Follow these simple guidelines for operation and care:

- Always wear protective gear, like goggles and gloves.

- Keep the workspace clean to avoid accidents.

- Check the machine regularly for any damage.

- Learn how to stop the machine quickly.

Training staff on maintenance is key. Teach them to check oil levels and clean parts often. Machine learning can help by showing how the lathe performs over time. Adjustments can then be made based on this data.

What are key safety tips for lathe operation?

Key safety tips are wearing protective gear, keeping the workspace clean, and knowing how to stop the machine quickly.

Challenges and Solutions in Lathe Machine Maintenance

Common challenges faced in maintenance procedures. Innovative solutions and strategies for overcoming these challenges.Maintaining a lathe machine can be tricky. Common challenges include wear and tear, lack of proper tools, and safety issues. These problems can slow down production and make work harder. But, there are smart solutions. Regular checks can help catch issues early. Using the right equipment ensures safety and efficiency. Training staff keeps everyone safe and knowledgeable. Here are some key strategies:

- Schedule regular maintenance checks.

- Invest in high-quality tools.

- Provide safety training for workers.

What are some common problems in lathe machine maintenance?

Common problems include worn parts, inadequate lubrication, and operator errors. Regular checks and proper training can help prevent these issues.

Future Trends in Lathe Machine Learning and Maintenance

Predicted advancements in technology and their implications. The evolving role of AI in metal lathe maintenance and operations.Technology is zooming ahead! New tools and software will make lathe machines smarter. Imagine machines that can predict problems before they happen. This means less downtime and more time to make cool stuff! AI is stepping into the world of metal lathe maintenance too. With AI, machines can learn the best ways to operate. They can even offer tips like a friendly robot buddy!

| Future Trends | Implications |

|---|---|

| Smart Sensors | Quicker problem detection |

| AI Analysis | Improved operation efficiency |

| Predictive Maintenance | Less unexpected breakdowns |

In fact, experts say that by 2025, AI might help reduce maintenance costs by 30%! So, hold onto your wrenches, because the future of lathe machines is looking brighter than ever!

Conclusion

In summary, mastering lathe machine maintenance helps you keep your metal lathe in top shape. Regular checks prevent problems and extend its life. Learning about lathe machine learning can improve your skills, too. So, take action! Start a maintenance schedule and explore more resources to enhance your knowledge. Together, we can make your lathe work better and last longer!FAQs

What Are The Key Indicators Of Wear And Tear On A Lathe Machine That Machine Learning Algorithms Can Help Identify For Effective Maintenance Scheduling?You can look for signs like strange noises or vibrations when the lathe machine is running. If the machine has trouble cutting materials smoothly, that’s also a sign. Changes in temperature or the machine moving slower than usual can mean it needs care. Machine learning can help spot these problems early, so you can fix them before they become big issues.

How Can Predictive Maintenance Models Be Developed Using Machine Learning To Minimize Downtime In Metal Lathe Operations?We can build predictive maintenance models using machine learning by collecting data from metal lathes. This data tells us how the machines behave. We can look for patterns that show when a machine might break. When we know this, we can fix the machines before they stop working. This helps keep the machines running and reduces downtime.

What Types Of Sensor Data Are Most Valuable For Training Machine Learning Models Aimed At Improving Lathe Machine Maintenance?To help improve lathe machine maintenance, we can use a few types of sensor data. Temperature sensors measure how hot the machine gets, which helps us see if something is wrong. Vibration sensors check if the machine shakes too much, showing possible issues. We can also gather data on how fast the machine turns and how much it uses power. All this data helps us understand how to keep the lathe running well.

How Can Machine Learning Techniques Be Integrated Into Existing Maintenance Practices For Better Efficiency And Cost-Effectiveness In Metal Lathe Operations?We can use machine learning to make metal lathe machines smarter. First, we teach the machines to watch for problems, like strange sounds or vibrations. This way, they can warn us before a breakdown happens. We can also use machine learning to predict when parts need changing, so we can avoid wasting time and money. By doing this, we keep the machines running smoothly and save costs.

What Are The Challenges Of Implementing Machine Learning Solutions For Lathe Machine Maintenance, And How Can They Be Addressed?Using machine learning to help with lathe machine maintenance can be tough. First, we need good data about how the machines work. If the data is wrong, our results won’t help. We can fix this by closely watching the machines and collecting accurate information. Also, we need to teach people how to use these tools well. Helping everyone learn is key to making it work!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Indicators Of Wear And Tear On A Lathe Machine That Machine Learning Algorithms Can Help Identify For Effective Maintenance Scheduling? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can look for signs like strange noises or vibrations when the lathe machine is running. If the machine has trouble cutting materials smoothly, that’s also a sign. Changes in temperature or the machine moving slower than usual can mean it needs care. Machine learning can help spot these problems early, so you can fix them before they become big issues.”}},{“@type”: “Question”,”name”: “How Can Predictive Maintenance Models Be Developed Using Machine Learning To Minimize Downtime In Metal Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can build predictive maintenance models using machine learning by collecting data from metal lathes. This data tells us how the machines behave. We can look for patterns that show when a machine might break. When we know this, we can fix the machines before they stop working. This helps keep the machines running and reduces downtime.”}},{“@type”: “Question”,”name”: “What Types Of Sensor Data Are Most Valuable For Training Machine Learning Models Aimed At Improving Lathe Machine Maintenance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To help improve lathe machine maintenance, we can use a few types of sensor data. Temperature sensors measure how hot the machine gets, which helps us see if something is wrong. Vibration sensors check if the machine shakes too much, showing possible issues. We can also gather data on how fast the machine turns and how much it uses power. All this data helps us understand how to keep the lathe running well.”}},{“@type”: “Question”,”name”: “How Can Machine Learning Techniques Be Integrated Into Existing Maintenance Practices For Better Efficiency And Cost-Effectiveness In Metal Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use machine learning to make metal lathe machines smarter. First, we teach the machines to watch for problems, like strange sounds or vibrations. This way, they can warn us before a breakdown happens. We can also use machine learning to predict when parts need changing, so we can avoid wasting time and money. By doing this, we keep the machines running smoothly and save costs.”}},{“@type”: “Question”,”name”: “What Are The Challenges Of Implementing Machine Learning Solutions For Lathe Machine Maintenance, And How Can They Be Addressed? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using machine learning to help with lathe machine maintenance can be tough. First, we need good data about how the machines work. If the data is wrong, our results won’t help. We can fix this by closely watching the machines and collecting accurate information. Also, we need to teach people how to use these tools well. Helping everyone learn is key to making it work!”}}]}