Have you ever wondered how metal parts are made? It might surprise you to learn that a lathe machine plays a big role in this process. A lathe is an impressive tool that shapes and cuts metal with great precision.

Imagine a metal lathe spinning a piece of metal like a top. As it turns, sharp tools carve away at the surface. This creates all sorts of parts, from simple knobs to complex gears. These machines are fascinating because they can make both small and large items!

But what if we could use machine learning with lathe machines? It sounds like science fiction, right? In reality, this technology helps to improve how lathe machines operate. By using data, they can become smarter and more efficient.

In this article, we’ll dive into the exciting world of lathe machines and metal parts. We’ll explore how traditional methods work alongside modern machine learning. Join us on this journey to discover the art of metalworking!

Understanding Lathe Machine Learning: Metal Lathe Parts Explained

Understanding Lathe Machine Learning and Metal Lathe Parts

Lathe machine learning focuses on how computers help create metal lathe parts more efficiently. Imagine turning a block of metal into a perfectly shaped tool. With machine learning, lathes can learn from past projects, improving accuracy and reducing waste. Did you know that these machines can even predict when a part might break? This way, operators can fix issues before they happen. As technology grows, lathe machines become smarter and more useful in manufacturing.The Role of Lathe Machines in Manufacturing Processes

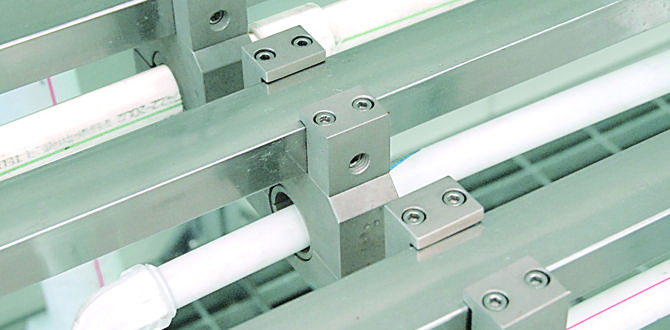

Description of how lathe machines operate and their key components.. Importance of precision in metal lathe parts production..Lathe machines are like magic wands for metal! They spin materials while sharp tools carve them into shapes. The key parts include the bed, headstock, tailstock, and carriage. Precision is very important here. Imagine trying to fit a square peg into a round hole—doesn’t work, right? Accurate metal lathe parts help create everything from tiny screws to heavy machinery. Without them, your favorite gadgets might just fall apart. Now that would be a messy disaster!

| Key Components | Function |

|---|---|

| Bed | Foundation and support for other parts |

| Headstock | Holds and drives the workpiece |

| Tailstock | Supports the opposite end of the workpiece |

| Carriage | Houses the cutting tools and can move along the bed |

Integration of Machine Learning with Lathe Operations

How machine learning algorithms can optimize lathe operations.. Benefits of using machine learning for predictive maintenance on lathes..Machine learning helps lathes work better. Algorithms can analyze data fast. They find patterns that improve cutting speed and precision. This means parts are made more accurately. Predictive maintenance is another perk. It helps fix machines before they break. This saves time and money. You won’t have to halt production as much. Overall, using machine learning in lathe operations is smart and efficient.

How does machine learning benefit lathe operations?

Machine learning optimizes operations by increasing accuracy and reducing downtime. Algorithms can learn from past data to enhance performance and predict maintenance needs.

Key benefits of using machine learning:

- Improved precision in cutting

- Reduced machine downtime

- Lower repair costs

- Increased overall productivity

Common Metal Lathe Parts and Their Functions

Breakdown of essential metal lathe parts and their roles in machining.. Insights into the wear and tear of lathe parts and implications for performance..A metal lathe has several important parts that help it work. Each part plays a special role in creating metal pieces.

- Bed: It supports all other parts and keeps everything stable.

- Headstock: This part holds the spindle and powers the lathe.

- Tailstock: It can move and helps hold material for cutting.

- Carriage: This moves tools back and forth. It helps shape the metal.

- Tool Post: It holds cutting tools in place during operation.

With frequent use, lathe parts can wear out. This wear affects their performance. Regular checks help keep the lathe working well. Replace worn parts to maintain quality.

What are common metal lathe parts and their functions?

Common metal lathe parts include the bed, headstock, tailstock, carriage, and tool post. Each part has a unique role that contributes to the lathe’s overall function.

Challenges in Implementing Machine Learning in Lathes

Discussion of potential obstacles faced when integrating machine learning with existing lathe technologies.. Solutions and strategies to overcome these implementation challenges..Integrating machine learning with lathe machines can be tricky. Many current machines are old and not ready for new tech. This can create compatibility issues. Plus, workers may need special training to use the new systems well. Data security is also a concern. However, there are ways to tackle these challenges:

- Upgrade machines slowly to ensure everyone keeps up.

- Provide training workshops for workers to boost skills.

- Focus on software solutions that fit current machines.

- Carry out tests to ensure safety and effectiveness.

With patience and the right approach, we can overcome these hurdles. Success may bring better productivity and efficiency in the long run.

What are the common obstacles faced with machine learning in lathes?

Some common obstacles include outdated equipment, lack of training for workers, and data security issues.

How can these challenges be solved?

Challenges can be solved by upgrading machines gradually, providing training, and ensuring data protection.

Future Trends in Lathe Machines and Machine Learning

Predictions on the evolution of lathe machines with advancing machine learning technologies.. Potential impact on the manufacturing industry and workforce dynamics..Lathe machines are changing fast. With machine learning, they become smarter every day. Predictions show that these machines will work better and faster. They may even learn from their mistakes, reducing errors. This will help makers create parts with higher quality.

The impact on the manufacturing world is huge. Workers might need new skills. They may find jobs that focus on working with these advanced machines. Here are some key trends to watch:

- Increased automation: Machines will take over simple tasks.

- Improved precision: Parts will be made more accurately.

- Faster production: Jobs will be done more quickly.

- Specialized roles: New jobs will emerge for experts in machine learning.

As technology grows, workers will adapt, ensuring the future of manufacturing shines bright.

How will machine learning affect lathe machines?

Machine learning will make lathe machines smarter, leading to better accuracy and faster production. This change will reshape how workers operate, shifting their roles in the industry.

Conclusion

In summary, using machine learning with lathe machines can improve how we manufacture metal parts. You can expect better accuracy and efficiency. This means less waste and more profits. To learn more, explore online resources or take a workshop. Understanding this technology opens new doors in the machining world. So, dive in and discover the exciting possibilities!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Machine Learning And Metal Lathe Parts:Sure! Here’s a short answer about lathe machines and metal parts. A lathe machine is a tool that spins metal to shape it. We can use machine learning to help this tool work better. Machine learning is when computers learn from data. This helps us make parts faster and with fewer mistakes.

Sure! Just ask your question, and I will give you a clear and simple answer.

How Can Machine Learning Algorithms Be Used To Optimize The Machining Process In Metal Lathe Operations?We can use machine learning to make metal lathes work better. First, we collect data on how the machine cuts metal. Then, the computer learns from this data to find the best speeds and settings. This helps us make smoother cuts and use less energy. In the end, we can create parts faster and save money!

What Role Does Predictive Maintenance Powered By Machine Learning Play In Prolonging The Lifespan Of Lathe Machines And Their Components?Predictive maintenance uses smart computers to keep lathe machines running longer. These computers look for signs that tell us when parts might break. By fixing things early, we prevent bigger problems. This helps the lathe machines last longer and work better. It’s like giving them regular check-ups to stay healthy!

How Can Machine Learning Techniques Be Applied To Detect Defects In Machined Parts Produced By A Metal Lathe?We can use machine learning to find problems in metal parts made by a lathe. First, we collect pictures of good and bad parts. Then, we teach a computer program to spot differences between them. This helps the program learn what to look for. Finally, we can use this program to check new parts and find defects quickly.

What Are Some Of The Key Data Points That Should Be Collected When Implementing Machine Learning In Lathe Manufacturing Processes?When using machine learning in lathe manufacturing, we should collect important data. First, we need the size of the parts being made. It helps us understand what we’re working with. Next, we need the speed of the lathe, which shows how fast it works. We should also track how much material we use, as it affects everything. Finally, we collect any errors that happen during production to learn and improve.

How Can Computer Vision Combined With Machine Learning Improve The Quality Control Of Parts Machined On Lathes?We can use computer vision and machine learning together to check parts made on lathes. Computer vision helps us see things clearly and find mistakes. Machine learning learns from past data to get better at spotting problems. This way, we can catch any errors early and make sure all parts are strong and safe to use. It helps us make high-quality products more easily!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Machine Learning And Metal Lathe Parts:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here’s a short answer about lathe machines and metal parts. A lathe machine is a tool that spins metal to shape it. We can use machine learning to help this tool work better. Machine learning is when computers learn from data. This helps us make parts faster and with fewer mistakes.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I will give you a clear and simple answer.”}},{“@type”: “Question”,”name”: “How Can Machine Learning Algorithms Be Used To Optimize The Machining Process In Metal Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use machine learning to make metal lathes work better. First, we collect data on how the machine cuts metal. Then, the computer learns from this data to find the best speeds and settings. This helps us make smoother cuts and use less energy. In the end, we can create parts faster and save money!”}},{“@type”: “Question”,”name”: “What Role Does Predictive Maintenance Powered By Machine Learning Play In Prolonging The Lifespan Of Lathe Machines And Their Components?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Predictive maintenance uses smart computers to keep lathe machines running longer. These computers look for signs that tell us when parts might break. By fixing things early, we prevent bigger problems. This helps the lathe machines last longer and work better. It’s like giving them regular check-ups to stay healthy!”}},{“@type”: “Question”,”name”: “How Can Machine Learning Techniques Be Applied To Detect Defects In Machined Parts Produced By A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use machine learning to find problems in metal parts made by a lathe. First, we collect pictures of good and bad parts. Then, we teach a computer program to spot differences between them. This helps the program learn what to look for. Finally, we can use this program to check new parts and find defects quickly.”}},{“@type”: “Question”,”name”: “What Are Some Of The Key Data Points That Should Be Collected When Implementing Machine Learning In Lathe Manufacturing Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using machine learning in lathe manufacturing, we should collect important data. First, we need the size of the parts being made. It helps us understand what we’re working with. Next, we need the speed of the lathe, which shows how fast it works. We should also track how much material we use, as it affects everything. Finally, we collect any errors that happen during production to learn and improve.”}},{“@type”: “Question”,”name”: “How Can Computer Vision Combined With Machine Learning Improve The Quality Control Of Parts Machined On Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use computer vision and machine learning together to check parts made on lathes. Computer vision helps us see things clearly and find mistakes. Machine learning learns from past data to get better at spotting problems. This way, we can catch any errors early and make sure all parts are strong and safe to use. It helps us make high-quality products more easily!”}}]}