Have you ever wondered how metal parts are shaped? Maybe you have seen a lathe machine in action. This cool tool helps create round, precise objects. Think of things like wheels, knobs, or the perfect pulley. But did you know that technology is changing how we use lathe machines?

Imagine a lathe machine that learns from its own work. That’s right! Machine learning is getting into the world of metal lathes. It helps make the process faster and smarter. The machine can analyze what it creates and improve over time.

Now, consider this: a metal lathe and a pulley working together. They can make everything from bike parts to engine components. The combination of human skill and machine learning creates amazing results. This is an exciting time for anyone who loves technology and engineering!

Join us as we explore how a lathe machine, combined with machine learning, reshapes our understanding of metalworking. Get ready to dive into a world where precision meets innovation!

Lathe Machine Learning: Insights On Metal Lathe Pulley Design

Exploring Lathe Machines and Their Learning

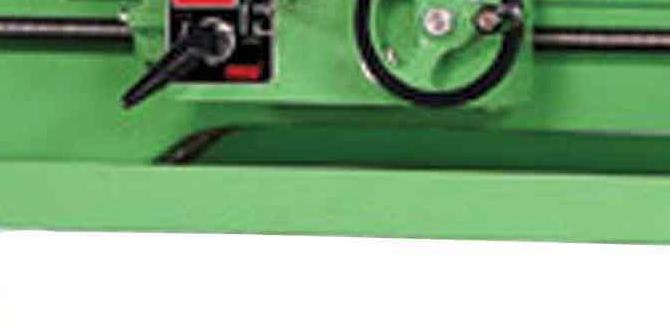

Lathe machines play a vital role in shaping metal and creating precise parts. Learning about them helps you understand how they work, from turning to polishing. Did you know that a simple pulley system can greatly enhance the productivity of these machines? Using a metal lathe with proper programming can lead to amazing project outcomes. Imagine crafting your own custom pieces! It’s fascinating how technology transforms traditional methods into innovative solutions.Role of Metal Lathe Pulley in the Machining Process

Importance of pulleys in lathe machines.. Types of metal lathe pulleys and their functions..Pulleys are key parts of metal lathe machines. They help connect the motor to the spindle, allowing smooth operation. Without pulleys, the lathe would struggle to function properly. There are different types of pulleys. Each has a unique job that helps with the machining process.

- Flat Pulleys: These handle belt drive systems.

- V-Pulleys: These keep the belt centered and stable.

- Sheaves: These are used for changing speeds in the machine.

Using the right pulley helps machines run efficiently and accurately, making it easier for workers to create high-quality parts.

Why are metal lathe pulleys important?

Metal lathe pulleys are important because they help control speed and power in machining processes.

Integrating Machine Learning with Lathe Operations

How machine learning algorithms can improve efficiency in lathe processes.. Case studies of successful implementations in the industry..Machine learning can make lathe operations faster and better. By using smart algorithms, workers can spot problems before they happen. For example, some companies have seen a 20% increase in production just by adding these tools. Here are a few success stories:

- One factory reduced waste by 30% using predictive analysis.

- Another company improved safety by monitoring machines in real time.

- A third found ways to save over 15% in costs through better scheduling.

These examples show that machine learning can really boost lathe processes!

What improvements can be achieved with machine learning in lathe operations?

Machine learning can improve speed, reduce waste, and enhance worker safety in lathe operations.

Data Collection and Management for Machine Learning in Lathe Machinery

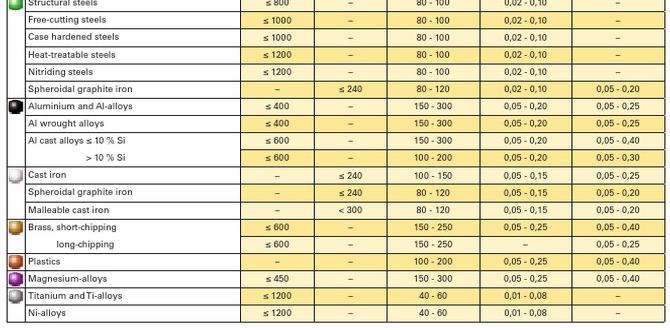

Types of data required for training machine learning models.. Best practices for data collection and management in lathe operations..Collecting data for machine learning in lathe operations is like finding the right ingredients for a recipe. You need the best materials! Common data types include machine settings, production speed, and workpiece dimensions. Best practices ensure your data isn’t a hot mess. Keep it tidy, simple, and organized! A well-structured database helps machines learn faster. Here’s a sneak peek at what to gather:

| Data Type | Description |

|---|---|

| Machine Settings | Data about speed, feed rate, and tool type. |

| Production Speed | How fast the lathe is running. |

| Workpiece Dimensions | Sizes and shapes of the materials being used. |

Tip: Keep your data fresh and regular. Never let it gather dust, like an old toolbox! Data should be current, clean, and easy to access. With good data, your lathe machine will become smarter than your average bear!

Common Challenges and Solutions in Implementing Machine Learning

Discuss common obstacles faced during implementation.. Strategies to overcome these challenges and optimize performance..Implementing machine learning can be tricky. Many face common issues during this process. Here are some challenges:

- Data Quality: Bad data leads to poor results.

- Lack of Understanding: Team members may not grasp the technology.

- Resource Limits: Time and money can be tight.

To solve these problems, teams can:

- Invest in training.

- Focus on cleaning data.

- Use project management tools to stay organized.

These steps can help make machine learning work better for everyone.

What are some common challenges when implementing machine learning?

Common challenges include data quality issues, lack of understanding among team members, and limited resources.What solutions can help optimize machine learning performance?

Effective solutions include:

- Investing in proper training.

- Cleaning and preparing data effectively.

- Utilizing project management tools.

Future Trends: The Evolution of Lathe Machines with AI

Predictions on the future integration of AI and machine learning in machining.. Potential advancements in lathe technology influenced by machine learning..Many believe that AI will change lathe machines. Soon, these tools could automatically learn and adapt. This means less time fixing mistakes. Imagine a lathe machine that predicts problems before they happen! Machine learning may help in designing better pulleys too. The new tech can make parts with higher precision and speed. This change will make jobs easier and safer.

- Machines that learn from past work will improve quality.

- AI can help save energy by optimizing processes.

- Smart machines could communicate with each other for better teamwork.

What are future trends for lathe machines?

Future trends include smarter machines and AI integration for efficiency. This leads to faster production and fewer errors.

Conclusion

In summary, a lathe machine is a powerful tool for shaping metal. Learning how to use its pulley system can improve your projects. With practice, you can create precise parts easily. We encourage you to explore more about lathe techniques and safety. Watching tutorials or reading guides online can help you get started. Let’s dive into the world of metalworking together!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Machines, Machine Learning, And Metal Lathe Pulleys:Sure! Here are five questions about lathe machines. 1. What is a lathe machine? A lathe machine is a tool that shapes metal. It spins the metal while a sharp tool cuts it. 2. How do you use a lathe machine? You put the metal on the lathe, turn it on, and carefully move the cutting tool. 3. What are metal lathe pulleys? Pulleys help move the lathe’s machine parts. They make it easier for the metal to spin correctly. 4. Can machine learning help with lathe machines? Yes! Machine learning can help make lathe machines smarter. They can learn from patterns to improve how they work. 5. Why is safety important when using a lathe? Safety is important because the machine spins fast. You can get hurt if you’re not careful around it.

Of course! Please go ahead and ask your question, and I’ll be happy to help you with a short answer.

How Can Machine Learning Algorithms Optimize The Machining Process Of Metal Lathe Pulleys For Improved Precision And Efficiency?We can use machine learning to make making metal lathe pulleys better. These smart computers learn from past work. They can tell us how to cut metal more accurately. This helps us make fewer mistakes and save time. In the end, we get better pulleys faster!

What Are The Key Parameters To Measure When Using Machine Learning To Monitor The Performance Of A Metal Lathe During Pulley Production?When using machine learning to check how well a metal lathe works while making pulleys, we look at a few key things. First, we measure how fast the lathe is spinning. Next, we check the temperature to see if it’s too hot. We also watch for any unusual sounds or vibrations. Finally, we look at the sizes of the pulleys to make sure they are just right. These checks help us ensure everything is working well.

How Can Predictive Maintenance Techniques Powered By Machine Learning Reduce Downtime In Lathe Machining Operations For Pulleys?Predictive maintenance uses smart tools to help us check machines like lathes before they break. These tools learn from the machine’s past to tell us when it might have a problem. By fixing issues early, we stop the machine from breaking down. This means we can keep working on making pulleys without long waits. So, we can create more pulleys and have less downtime!

What Types Of Data Are Most Relevant For Training Machine Learning Models To Predict Defects In Metal Lathe Pulley Manufacturing?To predict problems in making metal lathe pulleys, we need important data. First, we should collect information about the materials used. Next, we can look at the machine settings and how they work. We also need to gather data on past mistakes, like where defects happened. Finally, keeping track of how skilled the workers are will help us understand the process better.

How Can Integrating Machine Learning With Cnc Lathe Machines Enhance The Customization Capabilities For Different Pulley Designs?By using machine learning with CNC (Computer Numerical Control) lathe machines, we can make pulleys that fit exactly what you need. Machine learning helps the machines understand different designs faster. This means you can create many unique pulley shapes and sizes quickly and easily. It also makes it easier to fix mistakes, so pulleys come out just right. This way, customization becomes simple and fun!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Machines, Machine Learning, And Metal Lathe Pulleys:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about lathe machines. 1. What is a lathe machine? A lathe machine is a tool that shapes metal. It spins the metal while a sharp tool cuts it. 2. How do you use a lathe machine? You put the metal on the lathe, turn it on, and carefully move the cutting tool. 3. What are metal lathe pulleys? Pulleys help move the lathe’s machine parts. They make it easier for the metal to spin correctly. 4. Can machine learning help with lathe machines? Yes! Machine learning can help make lathe machines smarter. They can learn from patterns to improve how they work. 5. Why is safety important when using a lathe? Safety is important because the machine spins fast. You can get hurt if you’re not careful around it.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please go ahead and ask your question, and I’ll be happy to help you with a short answer.”}},{“@type”: “Question”,”name”: “How Can Machine Learning Algorithms Optimize The Machining Process Of Metal Lathe Pulleys For Improved Precision And Efficiency?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use machine learning to make making metal lathe pulleys better. These smart computers learn from past work. They can tell us how to cut metal more accurately. This helps us make fewer mistakes and save time. In the end, we get better pulleys faster!”}},{“@type”: “Question”,”name”: “What Are The Key Parameters To Measure When Using Machine Learning To Monitor The Performance Of A Metal Lathe During Pulley Production?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using machine learning to check how well a metal lathe works while making pulleys, we look at a few key things. First, we measure how fast the lathe is spinning. Next, we check the temperature to see if it’s too hot. We also watch for any unusual sounds or vibrations. Finally, we look at the sizes of the pulleys to make sure they are just right. These checks help us ensure everything is working well.”}},{“@type”: “Question”,”name”: “How Can Predictive Maintenance Techniques Powered By Machine Learning Reduce Downtime In Lathe Machining Operations For Pulleys?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Predictive maintenance uses smart tools to help us check machines like lathes before they break. These tools learn from the machine’s past to tell us when it might have a problem. By fixing issues early, we stop the machine from breaking down. This means we can keep working on making pulleys without long waits. So, we can create more pulleys and have less downtime!”}},{“@type”: “Question”,”name”: “What Types Of Data Are Most Relevant For Training Machine Learning Models To Predict Defects In Metal Lathe Pulley Manufacturing?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To predict problems in making metal lathe pulleys, we need important data. First, we should collect information about the materials used. Next, we can look at the machine settings and how they work. We also need to gather data on past mistakes, like where defects happened. Finally, keeping track of how skilled the workers are will help us understand the process better.”}},{“@type”: “Question”,”name”: “How Can Integrating Machine Learning With Cnc Lathe Machines Enhance The Customization Capabilities For Different Pulley Designs?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “By using machine learning with CNC (Computer Numerical Control) lathe machines, we can make pulleys that fit exactly what you need. Machine learning helps the machines understand different designs faster. This means you can create many unique pulley shapes and sizes quickly and easily. It also makes it easier to fix mistakes, so pulleys come out just right. This way, customization becomes simple and fun!”}}]}