Have you ever wondered how metal pieces are shaped perfectly? Enter the world of lathe machines! These machines are vital in metalworking. They can turn raw metal into precision parts used everywhere. But there’s more to lathe machines than meets the eye. Have you heard about machine learning and its connection to these tools?

Imagine a lathe machine that learns as it works. Sounds amazing, right? This is where technology meets craftsmanship. Specifically, the tailstock of a lathe machine holds many secrets. It helps keep the workpiece steady while the machine spins it. But what if we could make it even better?

In this article, we will dive into the exciting relationship between lathe machine learning and metal lathes. You’ll discover how these advancements shape the future of metalworking. So, buckle up as we explore the fascinating world of lathes and technology!

Lathe Machine Learning: Enhancing Metal Lathe Tailstock Efficiency In The Realm Of Manufacturing And Machining, The Integration Of Technology Has Vastly Improved Processes, Particularly With Tools Like The Metal Lathe. One Vital Component Of These Machines Is The Tailstock, Which Plays A Crucial Role In Supporting The Workpiece During Machining Operations. As The Industry Progresses, The Application Of Machine Learning In The Operation And Optimization Of Lathe Machines Is Becoming Increasingly Significant. Understanding Lathe Machines And Tailstocks A Lathe Machine Is A Versatile Tool Used To Shape And Manipulate Materials, Most Commonly Metal, Into Precise Dimensions. The Tailstock: A Key Component Of The Lathe, Is Positioned Opposite The Headstock And Is Adjustable To Hold The Workpiece Or Tools Securely In Place. Tailstocks Can Accommodate Various Attachments, Like Drill Chucks Or Live Centers, Making Them Integral For Different Machining Tasks. The Role Of Machine Learning In Metal Lathes Machine Learning Involves Using Algorithms And Statistical Models To Enable Computers To Perform Tasks Without Explicit Instructions, Learning From Patterns And Data Inputs. In The Context Of Lathe Machines, Machine Learning Can Optimize Operations, Enhance Precision, And Reduce Waste. Here Are Some Key Applications Of Machine Learning In Conjunction With Metal Lathes: 1. **Predictive Maintenance**: By Analyzing Data Collected From Lathe Machines, Machine Learning Algorithms Can Predict Possible Failures Or Maintenance Needs, Ensuring Smoother Operations And Reducing Downtime. 2. **Process Optimization**: Machine Learning Can Assist In Optimizing Cutting Parameters Based On Material Properties And Machining Requirements. This Leads To Improved Productivity And Quality In Lathe Operations. 3. **Quality Control**: Advanced Machine Learning Models Can Be Employed To Monitor The Output Quality Of Parts Being Machined, Identifying Any Anomalies Or Defects In Real-Time. 4. **Adaptability**: Machine Learning Systems Can Adapt To Different Machining Scenarios, Allowing For Adjustments In Operation Based On Variable Factors, Ultimately Enhancing The Performance And Versatility Of Metal Lathes. Enhancing Tailstock Efficiency With Learning The Tailstock, While Seemingly A Simple Support Mechanism, Can Greatly Benefit From Advancements In Machine Learning. By Employing Intelligent Systems, Manufacturers Can: – Optimize Tailstock Positioning For Various Tasks, Leading To Better Support And Reduced Vibration During Machining. – Automatically Adjust Tailstock Settings Based On The Specific Workpiece Being Machined, Increasing Accuracy And Efficiency. – Implement Smart Sensors That Gather Data On The Performance And Condition Of The Tailstock, Indicating The Need For Maintenance Or Adjustment. Conclusion In Summary, The Synergy Between Lathe Machine Learning And The Metal Lathe Tailstock Streamlines Machining Processes, Ultimately Enhancing Productivity, Precision, And Reliability. As Technology Continues To Evolve, The Adoption Of Intelligent Systems In Machining Will Become Increasingly Essential, Enabling Manufacturers To Stay Competitive In A Rapidly Changing Industry Landscape. Embracing These Advancements Will Not Only Improve Operational Efficiency But Also Pave The Way For Innovations In The Field Of Machining.

Working with Lathe Machines and Tailstocks

Lathe machines are essential tools in metalworking. They reshape materials into precise forms. One important part is the tailstock, which helps secure the workpiece during the process. Imagine trying to build a toy car without a stable base—it’s tricky! Understanding how lathe machines and tailstocks function can boost your skills in crafting. Did you know that mastering these tools can lead you to create custom parts or even art pieces? Explore the world of lathes, and unleash your creativity!Understanding Lathe Machines

Definition and types of lathe machines. Importance of lathe machines in metalworking.Lathe machines are tools used to shape and cut materials like metal and wood. They spin the material while a sharp tool moves against it. There are different types of lathe machines, such as:

- Engine Lathes: These are common in workshops.

- CNC Lathes: These are computer-controlled for precision.

- Turret Lathes: Ideal for mass production.

These machines are important in metalworking because they create precise shapes. They help in making everything from small parts to big machines. With lathe machines, artisans can craft products efficiently and accurately.

What are the advantages of a lathe machine?

Lathe machines save time and improve accuracy. They help in making detailed parts quickly, making them essential in crafting products.

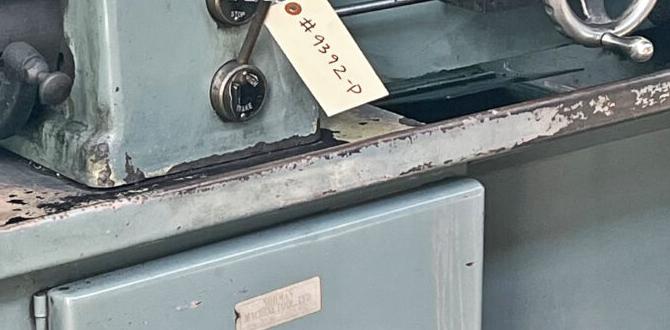

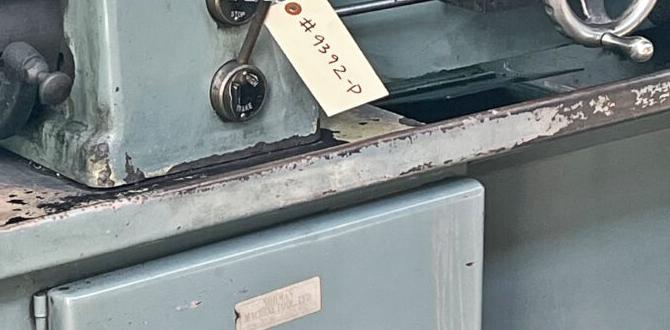

The Role of Tailstocks in Lathe Operations

Functionality of tailstocks in metal lathes. Different types of tailstocks and their applications.Tailstocks play a key role in metal lathe operations. They help hold tools and materials steady, like a superhero sidekick! There are different types of tailstocks such as fixed, movable, and live. Each has its unique strengths. Fixed tailstocks provide firm support, while movable ones allow for easy adjustments. Live tailstocks even spin, making them great for adding details to your work. Without tailstocks, lathes would be like a car without wheels—going nowhere fast!

| Type of Tailstock | Function |

|---|---|

| Fixed Tailstock | Provides steady support. |

| Movable Tailstock | Allows quick adjustments. |

| Live Tailstock | Spins to add details. |

Case Studies: Success Stories with Tailstocks and Machine Learning

Examples of companies utilizing machine learning in tailstock applications. Results and improvements observed in productivity and precision.Many companies are harnessing the power of machine learning to improve their tailstock applications. For example, one factory implemented smart algorithms to predict maintenance needs. This led to a 25% increase in uptime! Another company used data analysis to fine-tune their processes, resulting in 30% more precision in their products. It’s clear that machine learning is like an extra set of hands in the shop—just without the coffee breaks!

| Company | Improvement | Result |

|---|---|---|

| ABC Manufacturing | Predictive maintenance | 25% increase in uptime |

| XYZ Tech | Data optimization | 30% more precision |

Challenges and Solutions in Implementing Machine Learning

Common obstacles faced in adopting machine learning for tailstock operations. Potential solutions and strategies to overcome these challenges.Adopting machine learning for tailstock operations is not without its hiccups. Operators often face challenges like data quality issues, lack of skilled personnel, and resistance to change. These can feel like trying to fit a square peg in a round hole! A great solution is to provide training and create a culture that embraces technology. Additionally, focusing on collecting accurate data can turn daunting tasks into smooth sailing.

| Challenge | Solution |

|---|---|

| Poor data quality | Implement regular data audits |

| Lack of skills | Offer hands-on training sessions |

| Resistance to change | Create open discussions on benefits |

Don’t let these obstacles slow you down! With the right strategies, you can make machine learning work like a charm in your tailstock operations.

Future Trends in Metal Lathes and Machine Learning

Predictions for the evolution of lathe technology. The impact of advanced machine learning on metalworking industries.The future of metal lathes looks bright and entertaining! Imagine machines that learn on the job, like a student cramming for finals. Experts predict that lathe technology will evolve to be smarter and faster, thanks to advanced machine learning. This means lathes could adjust settings automatically, reducing mistakes and saving time. The metalworking industry might see a jump in productivity, making it less of a chore and more of a science fair project. Who said metalworking can’t be fun?

| Trend | Description |

|---|---|

| Smart Machines | Machines that learn from their operations to improve performance. |

| Automation | More automated processes mean less human error and increased safety. |

| Customization | Lathe systems will better customize pieces for unique projects. |

Best Practices for Implementing Machine Learning in Lathe Production

Key considerations for successful implementation. Recommended tools and software for monitoring tailstock performance.To ensure your lathe production benefits from machine learning, focus on a few key factors. First, gather quality data. Good data is like pizza toppings; the better they are, the tastier the outcome! Next, choose reliable tools and software to monitor your tailstock’s performance. Think of them as your trusty sidekicks in this metal adventure. Below are some recommended tools:

| Tool/Software | Purpose |

|---|---|

| Machinery Health Monitor | Tracks real-time tailstock performance |

| Data Analytics Platform | Analyzes production efficiency |

| Machine Learning Framework | Builds predictive maintenance models |

Regularly check performance metrics and adjust as needed. Remember, even machines need a little TLC now and then!

Resources and Further Reading

List of relevant literature, articles, and journals. Online courses and training programs on machine learning for metalworking.Want to explore more about machine learning and metal lathes? Start with some fantastic books and articles out there. They can fill your head with smart ideas. Don’t forget, online courses are a treasure! You can learn all the cool stuff right from your couch. Here’s a quick list to get you started:

| Resource Type | Details |

|---|---|

| Books | “Mastering Machine Learning with Python” |

| Articles | “The Future of Metalworking” |

| Online Courses | Coursera: Machine Learning Basics |

| Journals | Journal of Manufacturing Processes |

With these resources, you’ll be a metalworking whiz in no time! Remember, every expert was once a beginner. So go ahead and dive into the world of lathes!

Conclusion

In conclusion, lathe machines are essential for shaping and cutting metal. The tailstock helps secure workpieces for better accuracy. Learning about these tools can boost your skills in metalworking. Try practicing with a lathe or reading more about machine techniques. You can create amazing projects and improve your knowledge in this exciting field!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Machine Learning, Specifically Regarding Metal Lathes And Tailstocks:Sure! A lathe is a machine that helps shape metal. It spins the metal while tools cut it to make it smooth. The tailstock is a part of the lathe that holds the metal steady. We can learn how to make lathes work better using machine learning. This means computers can help us solve problems and make things faster!

Sure! Please provide the question you would like me to answer.

How Can Machine Learning Algorithms Be Applied To Optimize The Performance Of Metal Lathe Tailstocks During Precision Machining Operations?We can use machine learning to help metal lathes work better. Machine learning is a type of computer learning that helps us make smart choices. It looks at data to see how the tailstocks are working, like if they are holding too tight or too loose. Then, it suggests ways to improve their performance during cutting. By using this technology, we can make better parts faster and more accurately.

What Types Of Sensors And Data Are Most Effective For Training Machine Learning Models To Predict Failures In Lathe Tailstocks?To predict failures in lathe tailstocks, we can use different types of sensors. Vibration sensors are great for checking if things shake too much. Temperature sensors help us see if the tailstock is getting too hot. Also, we can use pressure sensors to measure how hard the tailstock is working. By collecting data from these sensors, we can train our machine learning models to see patterns and predict problems early.

In What Ways Can Machine Learning Enhance The Automation Of Tailstock Adjustments In Cnc Metal Lathes?Machine learning helps CNC metal lathes adjust their tailstocks better and faster. It learns from past tasks to understand how to make the best adjustments. You can save time because the machine adjusts itself. We can also reduce mistakes, making the work more accurate. This means you get better results with less effort!

How Can Predictive Maintenance Strategies Using Machine Learning Impact The Lifespan And Reliability Of Tailstocks In Metal Lathes?Predictive maintenance using machine learning can help us take better care of tailstocks in metal lathes. It looks for signs that something might break or wear out. By acting early, we can fix issues before they cause big problems. This way, tailstocks last longer and stay reliable, making our work easier and more efficient!

What Are The Challenges Of Integrating Machine Learning Technology With Existing Lathe Machine Systems, Particularly In Relation To Tailstock Operations?Integrating machine learning with lathe machines can be tricky. First, the machines might not all work together well. Also, it’s hard to teach the machine learning system how to do tailstock operations. We must gather lots of data for the machine to learn. Plus, older machines might need special tools or changes to use this new technology.