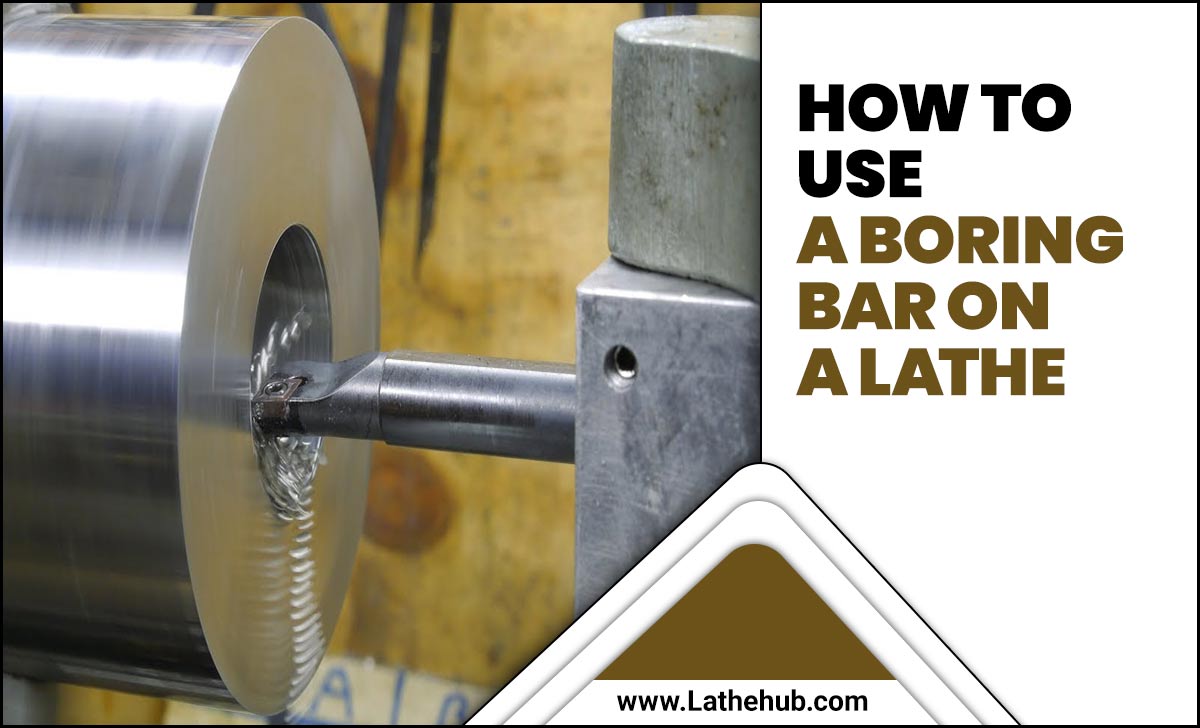

Have you ever wondered how metal parts are shaped? Imagine a machine that can spin metal and create unique shapes. That’s where the lathe machine comes in! This amazing tool has been around for centuries, helping craftsmen turn raw metal into precise pieces.

In recent years, we’ve seen an exciting twist: machine learning. It’s like giving machines a brain! When we mix lathe machines with machine learning, we can improve processes like taper turning. Taper turning is when one end of a metal piece is wider than the other. It makes parts look cool and work better.

Did you know that with the right skills, anyone can learn to use a lathe? You don’t have to be a metalworker. With machine learning helping, making complex shapes becomes easier. So, are you ready to dive into the world of lathe machine learning and see what magic happens? Let’s explore together!

Lathe Machine Learning: Metal Lathe Taper Turning Insights

Lathe Machine Learning and Taper Turning

Lathe machines are vital for crafting metal components. With taper turning, you can create shaped pieces with precision. Imagine shaping a toy part perfectly! Lathe machine learning helps optimize this process, making it faster and more accurate. Did you know that automation can reduce human error? By using smart technology, workers can focus on creativity instead of repetitive tasks. Unlocking the potential of lathe machines could change how we view metalwork. Discover this exciting blend of tradition and innovation!Role of Machine Learning in Taper Turning

How machine learning algorithms can optimize taper turning. Benefits of integrating machine learning with lathe machinery.Machine learning helps make taper turning better. It uses smart algorithms to find the best ways to shape metal. This means fewer mistakes and faster work. Integrating machine learning with lathe machines offers many benefits, like:

- Improved precision

- Reduced waste

- Faster production times

- Better surface quality

With these advantages, manufacturers can save time and money, making the process more efficient and effective.

How does machine learning improve taper turning?

Machine learning improves taper turning by analyzing data. It helps find patterns that lead to better tools and settings. This smart approach boosts efficiency in the workshop.

Case Studies of Successful Implementations

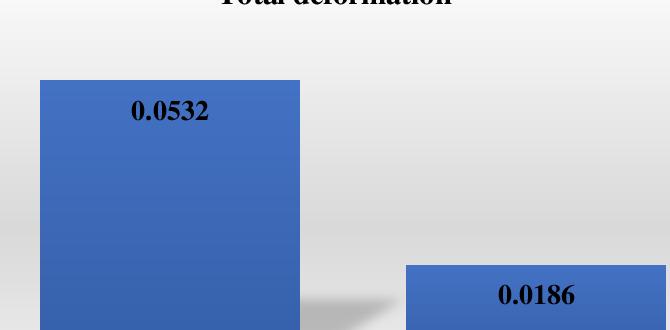

Examples of companies utilizing machine learning in taper turning. Measurable outcomes and improvements from case studies.Companies are seeing real success with machine learning in taper turning. For instance, one company improved its production speed by 30% after applying new algorithms. Another company found that using machine learning reduced mistakes by 40%. These results show how technology can make manufacturing better. Customers get high-quality products faster. Here are some measurable outcomes:

- 30% increase in production speed

- 40% fewer mistakes in products

- 20% cost savings in production

These case studies highlight how important machine learning is for today’s factories.

Challenges in Implementing Machine Learning

Common obstacles faced when adopting machine learning in lathe operations. Strategies for overcoming these challenges.Starting with machine learning in lathe operations can be tricky. Many face issues like a lack of data, skills, or proper tools. These hurdles can slow down progress. To overcome them, companies should:

- Train employees on machine learning.

- Invest in quality data and tools.

- Test small projects before big changes.

By tackling these obstacles, businesses can enjoy the benefits of machine learning with metal lathes.

What are common challenges in adopting machine learning?

Many businesses struggle with data quality and staff skills. They often lack the right infrastructure too. These issues can delay the adoption of machine learning.

Future Trends in Lathe Machine Learning

Predictions for the evolution of machine learning in manufacturing. Potential advancements in taper turning technology.The future of machine learning in manufacturing looks bright, much like a freshly polished metal lathe! Experts predict that machine learning will make processes faster and smarter. For instance, machines might soon learn to taper turn parts with precision, reducing errors and waste. Advancements in technology could lead to lathes that adjust automatically based on the metal used. Imagine a lathe that practically reads your mind! The possibilities are endless!

| Prediction | Potential Impact |

|---|---|

| Smart Lathes | Less human error, faster production |

| Advanced Taper Turning | More precise products, better quality |

| Real-time Adjustments | Increased efficiency, lower costs |

Resources for Further Learning

Recommended books, articles, and online courses. Community forums and organizations focused on lathe technology and machine learning.Learning about lathe machines can be thrilling! For those wanting more, there’s a treasure trove of resources out there. You can dive into recommended books that cover everything from basics to advanced topics. Articles and online courses can also help sharpen your skills. Plus, don’t forget to join community forums where machine enthusiasts gather. You might find your new best friend (or a talking lathe!). Here’s a quick table to guide you:

| Resource Type | Suggestions |

|---|---|

| Books | The Lathe Book, Metal Lathe for Home Machinists |

| Articles | Understanding Taper Turning, Machine Learning in Manufacturing |

| Online Courses | Coursera, Udemy |

| Forums | Practical Machinist, Reddit’s r/Machinists |

With these resources, you’ll be crafting perfect tapers in no time. Remember, every expert was once a beginner. So, keep learning and don’t forget to have fun!

Conclusion

In summary, lathe machines are essential for shaping metal, especially during taper turning. Learning about these machines helps you understand their importance in manufacturing. You can watch videos or try hands-on projects to see how they work. Exploring machine learning can also enhance your skills in this area. Keep learning, and consider practicing with a lathe to build your confidence!FAQs

Here Are Five Related Questions On The Topic Of Lathe Machine Learning, Metal Lathe, And Taper Turning:A metal lathe is a machine that shapes metal parts. It spins the metal while a cutting tool shapes it. Taper turning means making one end of the metal part thinner than the other. We can use lathe machine learning to help the machine work better and faster. This helps us make more accurate parts and saves time.

Sure! Please provide the question you’d like me to answer.

What Are The Key Advantages Of Using Machine Learning Algorithms In Optimizing Taper Turning Processes On Metal Lathes?Using machine learning helps us make taper turning on metal lathes faster and better. It learns from past data to find the best settings. You can make more pieces without mistakes. This saves time and money, making our work easier and more efficient. Overall, it helps us do a great job with less effort!

How Can Sensor Data From Metal Lathes Be Utilized To Improve The Accuracy Of Taper Turning Through Machine Learning Techniques?We can use sensor data from metal lathes to make taper turning more accurate. The sensors collect information about how the machine works. We can teach a computer, using machine learning, to find patterns in this data. By understanding these patterns, the machine can adjust itself to cut better. This helps create smoother and more precise shapes.

What Types Of Machine Learning Models Are Most Effective For Predicting Tool Wear And Tear During Taper Turning Operations?For predicting tool wear and tear in taper turning, we can use a few smart models. Decision trees show clear choices and are easy to understand. Support vector machines can separate different kinds of tool wear well. We also like neural networks because they learn patterns from lots of data. These models help us know when to change tools before they break!

How Can Machine Learning Help In The Automation Of Setting Appropriate Cutting Speeds And Feeds For Taper Turning On Different Materials?Machine learning can help us figure out the best cutting speeds and feeds for taper turning different materials. It does this by looking at lots of data from past work. We can teach it what worked well and what didn’t. So, when you use a machine, it will suggest the right settings for each job. This makes our work faster and helps us avoid mistakes!

What Challenges Do Practitioners Face When Integrating Machine Learning Solutions Into Traditional Metal Lathe Taper Turning Workflows?When we try to use machine learning in metal lathes, we face some problems. First, workers need training to understand how the new technology works. Some machines might not work well with the new system. We also need to collect a lot of data to teach the machine, which takes time. Lastly, it can be hard to trust the machine’s decisions, especially if they are different from what we usually do.