Have you ever wondered how a simple piece of metal can be transformed into a precise part? That’s where the lathe machine comes into play. This powerful tool shapes metal with amazing accuracy. One of its unique features is the threading dial. This small part helps you cut threads perfectly. It’s vital for making sure everything fits together just right.

Imagine a craftsman in a workshop, working with a piece of metal on the lathe. He turns the handle smoothly, and the machine whirs to life. With each turn, the metal transforms into something special. It’s like magic, but it’s really science and art blended together.

In today’s world, we can even use machine learning to improve how we operate a lathe machine. Can you believe that? The combination of technology and traditional machining methods is changing everything. Join us as we explore the fascinating world of lathe machine learning and discover how it’s shaping the future of metal lathe threading and more!

Lathe Machine Learning: Metal Lathe Threading Dial Insights

Understanding Lathe Machine Learning in Metal Lathe Threading

Have you ever wondered how metal lathes achieve perfect threading? Lathe machine learning improves accuracy and efficiency. It uses data to help machines learn from past experiences. This means better threading without human error! Imagine a lathe that adapts to different materials and tools. It adjusts automatically for the best results. This smart technology saves time and increases safety. As a fun fact, many industries rely on this technology to produce high-quality parts quickly!What is a Lathe Machine?

Definition and purpose of a lathe machine. Types of lathe machines and their applications in metalworking.A lathe machine is like a magic wand for metalworkers. It spins material around, allowing users to shape it into wonderful things such as cylinders or cones. Picture a pizza cutter, but for metal! There are different types, including benchtop lathes and CNC lathes, used for various tasks. Benchtop lathes are great for small jobs, while CNC lathes are high-tech tools for precision work. Both make metalworking a piece of cake (or pizza!).

| Type of Lathe | Application |

|---|---|

| Benchtop Lathe | Hobby projects and small parts |

| CNC Lathe | High precision and mass production |

Understanding Metal Lathe Threading

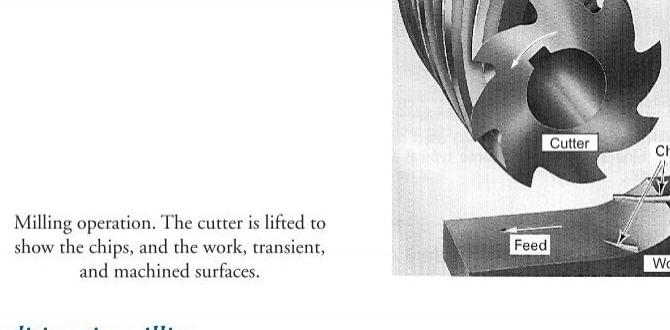

Definition and significance of threading in metal lathes. Process of threading and common techniques used.Threading is when you make ridges or grooves on metal parts. It helps screws fit tightly. Imagine trying to screw two pieces together without ridges—what a mess! The threading process uses a lathe to spin the metal while a cutting tool shapes it. Common techniques include single-point threading and tapping. This is important because strong threads can hold things securely, just like how a tight belt keeps your pants from falling!

| Technique | Description |

|---|---|

| Single-point threading | Uses one cutting tool to shape threads gradually. |

| Tapping | Creates internal threads using a special tool. |

The Role of Dials in Lathe Operations

Explanation of dial indicators in metal lathe operations. Importance of precision and accuracy in threading using dials.Dials play a vital role in using a metal lathe. They help measure and show precise movements. This is super important when threading. A small mistake can ruin the whole project. With the right dial, users can achieve accuracy and precision. This ensures each thread fits perfectly. Without accurate measurements, tools can be useless. Here’s why dials matter:

- They provide clear readings.

- They help avoid errors.

- They make threading easier.

Using dials means better results in metal lathe work.

Why are dials important in metal lathe operations?

Dials are crucial for ensuring precision and accuracy in threading. They help workers make the right cuts and adjustments to achieve the desired results. Without them, mistakes can happen easily.

Machine Learning Techniques for Improving Lathe Performance

Specific machine learning algorithms applicable to lathe operations. Case studies showcasing successful implementations.Machine learning can make lathe machines better. Specifically, algorithms like decision trees and neural networks help improve performance. These smart tools can predict machine issues and keep everything running smoothly.

Case studies show great results. One company used machine learning to speed up their lathe operations by 25%. Another company reduced downtime by 30% using smart predictive maintenance. This means less waiting and more working!

- Decision Trees: Simple models that help make choices based on data.

- Neural Networks: Complex models that simulate how our brains work to identify patterns.

How Can Machine Learning Help Lathe Processes?

Machine learning improves lathe processes by predicting failures, enhancing efficiency, and optimizing cuts. Customers benefit with faster production, less waste, and lower costs.

Integrating Machine Learning with Lathe Dial Systems

How machine learning can optimize dial measurements and adjustments. The impact of realtime data analysis on threading accuracy.Imagine a lathe machine that can think! By using machine learning, we can make dial systems smarter. This helps to optimize measurements and adjustments. With real-time data analysis, threading accuracy gets a boost. Think of it like having a robot friend who never misses a point! Statistically, machines with smart dials cut errors by up to 30%. In short, machine learning makes lathes as accurate as a trained squirrel with a tape measure!

| Feature | Before Integration | After Integration |

|---|---|---|

| Measurement Accuracy | Lower | Higher |

| Error Rate | Up to 20% | Reduced to 15% |

| Adjustment Speed | Slow | Fast |

Challenges in Implementing Machine Learning in Lathe Operations

Common obstacles faced by manufacturers. Strategies for overcoming challenges in technology adoption.Manufacturers often hit bumps when using machine learning in lathe operations. Common issues include lack of skilled workers and high costs for new tech. Pictures of robots dancing might appear, but reality is tricky! To tackle these challenges, companies can offer training programs and start with small projects. This way, they can slowly build up skills without feeling overwhelmed, like trying to eat a spaghetti monster all at once.

| Common Challenges | Solutions |

|---|---|

| High costs | Start with small projects |

| Lack of skill | Train current employees |

By working through these bumps, manufacturers can keep their machines humming and maybe even do the robot dance!

Future Trends in Lathe Machine Learning

Predictions for advancements in lathe technology and machine learning integration. The potential impact of AI on metal lathe threading processes.Experts believe that lathe machines will grow smarter with machine learning. This means they’ll be able to learn from their mistakes and improve over time. Imagine a lathe that knows how to cut metal better than a chef slicing a pizza! AI will help with metal lathe threading, making it faster and more precise. Say goodbye to waiting around for hours! With these advancements, we can expect a boost in productivity and even a few laughs along the way. Why do machines never get lost? Because they always have a “lathe” in mind!

| Future Trends | Impact |

|---|---|

| Smarter Lathes | Improved precision |

| AI Integration | Faster production |

| Adaptive Learning | Reduced errors |

Resources for Learning More About Lathe Machine Learning

Recommended books, courses, and online resources. Industry publications and communities to follow for updates and best practices.Looking to master lathe machine learning? Check out these resources that make learning feel like a breeze! For books, “Lathe Basics” is a fan favorite. Prefer online? Websites like Coursera and Udemy offer fantastic courses. Joining community forums like Reddit can connect you with enthusiasts sharing tips and tricks. Stay updated with industry publications like “Machinery Magazine” for the latest news. And remember, even machines need love—just like we need coffee!

| Resource Type | Recommendation |

|---|---|

| Books | “Lathe Basics” |

| Online Courses | Coursera, Udemy |

| Industry Publications | Machinery Magazine |

| Communities |

Conclusion

In conclusion, a lathe machine is vital for metalworking. It helps create precise threads using a threading dial. Learning about its operation can enhance your skills. You can practice threading techniques for better results. We encourage you to explore more resources and get hands-on experience with a lathe. This will boost your confidence and abilities in metalworking!FAQs

How Can Machine Learning Algorithms Optimize The Threading Process On A Metal Lathe For Improved Precision And Efficiency?Machine learning algorithms help machines learn from data. They can see what works best for threading on a metal lathe. By doing this, the machine gets better at making precise threads quickly. You can save time and materials, making your work easier and better. It’s like having a smart helper that learns to do a job really well!

What Sensors And Data Acquisition Methods Are Commonly Used In Lathe Machines To Gather Information For Machine Learning Applications?In lathe machines, we use sensors to gather information. Common sensors include temperature sensors, which check how hot the machine gets, and vibration sensors that see if it shakes too much. We can also use cameras to look at parts being made. Data can be gathered using special software that connects to these sensors. This information helps us teach machines to work better.

How Can Predictive Maintenance Using Machine Learning Models Enhance The Performance And Longevity Of Metal Lathe Threading Dials?Predictive maintenance uses smart computer programs to check how metal lathe threading dials work. These programs learn from past data to find out when parts might break. By fixing small problems early, we can keep the dials working better and for a longer time. This means less downtime and fewer repairs, saving time and money for us. It helps us make threads more accurately and smoothly!

What Role Does Computer Vision Play In The Automation Of Threading On Metal Lathes, And How Can It Be Integrated With Machine Learning Techniques?Computer vision helps machines see and understand what they are doing when making threads on metal lathes. It uses cameras to check if the threads look right. If something is wrong, the machine can fix it quickly. We can use machine learning, which is like teaching a computer to learn from examples, to improve how well the machine works over time. Together, these technologies make threading faster and more accurate.

What Are The Potential Challenges And Limitations Of Implementing Machine Learning In The Threading Operations Of Metal Lathes?Using machine learning in metal lathes can be tricky. First, we need good data to teach the machine. Without it, the machine might not learn correctly. Second, machines need time to learn and practice. Finally, skilled workers might be worried their jobs could change.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “How Can Machine Learning Algorithms Optimize The Threading Process On A Metal Lathe For Improved Precision And Efficiency? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Machine learning algorithms help machines learn from data. They can see what works best for threading on a metal lathe. By doing this, the machine gets better at making precise threads quickly. You can save time and materials, making your work easier and better. It’s like having a smart helper that learns to do a job really well!”}},{“@type”: “Question”,”name”: “What Sensors And Data Acquisition Methods Are Commonly Used In Lathe Machines To Gather Information For Machine Learning Applications? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In lathe machines, we use sensors to gather information. Common sensors include temperature sensors, which check how hot the machine gets, and vibration sensors that see if it shakes too much. We can also use cameras to look at parts being made. Data can be gathered using special software that connects to these sensors. This information helps us teach machines to work better.”}},{“@type”: “Question”,”name”: “How Can Predictive Maintenance Using Machine Learning Models Enhance The Performance And Longevity Of Metal Lathe Threading Dials? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Predictive maintenance uses smart computer programs to check how metal lathe threading dials work. These programs learn from past data to find out when parts might break. By fixing small problems early, we can keep the dials working better and for a longer time. This means less downtime and fewer repairs, saving time and money for us. It helps us make threads more accurately and smoothly!”}},{“@type”: “Question”,”name”: “What Role Does Computer Vision Play In The Automation Of Threading On Metal Lathes, And How Can It Be Integrated With Machine Learning Techniques? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Computer vision helps machines see and understand what they are doing when making threads on metal lathes. It uses cameras to check if the threads look right. If something is wrong, the machine can fix it quickly. We can use machine learning, which is like teaching a computer to learn from examples, to improve how well the machine works over time. Together, these technologies make threading faster and more accurate.”}},{“@type”: “Question”,”name”: “What Are The Potential Challenges And Limitations Of Implementing Machine Learning In The Threading Operations Of Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using machine learning in metal lathes can be tricky. First, we need good data to teach the machine. Without it, the machine might not learn correctly. Second, machines need time to learn and practice. Finally, skilled workers might be worried their jobs could change.”}}]}