Have you ever watched a lathe machine in action? It’s like magic. A simple block of metal transforms into beautiful shapes. But what happens when things go wrong? Troubleshooting a metal lathe can be tricky. Many people face this challenge when starting out. They may feel frustrated and unsure about how to fix it.

In this article, we will explore the world of lathe machine learning. You will learn how to troubleshoot common problems that occur with metal lathes. Why is this important? Because understanding how a lathe works helps you become a better craftsman.

Did you know that even experts sometimes encounter issues? They can be as simple as a loose screw. With the right knowledge, you can solve these problems quickly. Imagine getting your lathe running smoothly again! You’ll be amazed by what you can create.

So, let’s dive in! Together, we will unravel the mysteries of lathe troubleshooting. Get ready to take your skills to the next level!

Lathe Machine Learning: Metal Lathe Troubleshooting Guide

Lathe Machine Learning Metal Lathe Troubleshooting

Discover how lathe machine learning can enhance metal lathe troubleshooting. This technology uses data to predict problems before they happen. Have you ever wondered why your lathe jams or produces uneven cuts? With machine learning, you can analyze past patterns to improve performance. Imagine fixing issues faster, which saves time and money. Learning how to leverage this tool makes your work easier and more efficient. Dive into the world of lathe automation to unlock new potential in your projects!Understanding Lathe Machines

Definition and types of lathe machines. Key components and their functions.Lathe machines are clever tools that shape metal and wood into amazing objects. They spin materials around quickly while cutting them down to size. Think of them like a giant pencil sharpener for big projects! There are different types, like engine lathes for general use and CNC lathes, which are controlled by computers for precision work. Key parts include the headstock that holds the spinning piece, the tailstock that supports the other end, and the carriage that moves the tool in and out. Each part plays a role, like a team of superheroes saving the day!

| Type of Lathe | Main Use |

|---|---|

| Engine Lathe | General shaping and cutting |

| CNC Lathe | Precise, computer-controlled work |

| Turret Lathe | Mass production of parts |

Using Machine Learning for Troubleshooting

How machine learning algorithms can identify lathe issues. Case studies of successful machine learning implementations.Machine learning uses data to find problems with lathe machines. It can spot issues faster than humans. Algorithms learn from past mistakes and suggest fixes. Here are some successful examples:

- In one case, a factory used machine learning to cut downtime by 30%.

- Another study found that predicting failures saved companies thousands of dollars.

These stories show how helpful machine learning can be. It makes fixing metal lathes easier and more efficient.

How can machine learning help with troubleshooting lathe machines?

Machine learning helps by analyzing data to find patterns and suggest fixes. This speeds up troubleshooting and makes it more accurate.

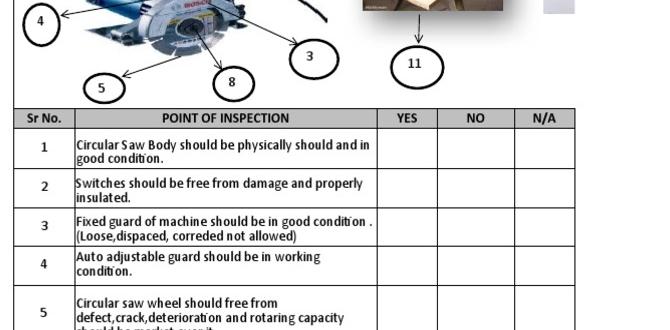

Step-by-Step Troubleshooting Guide

Initial assessment of metal lathe performance. Troubleshooting specific issues using machine learning data.Start by checking the metal lathe’s performance. Look for strange noises or odd vibrations—your lathe shouldn’t sound like a rock concert! Use machine learning data to spot patterns in issues. Analyzing this data can help you find specific problems faster than a magician pulls a rabbit from a hat.

| Issue | Potential Cause | Solution |

|---|---|---|

| Uneven cuts | Worn tools | Replace blades |

| Excessive noise | Loose components | Tighten screws |

| Stopped working | Power supply issue | Check connections |

Refer to this table for quick help. Remember, a little troubleshooting goes a long way in keeping your lathe happy and your projects on track!

Improving Lathe Performance with Machine Learning

Techniques to optimize lathe operations. Key performance indicators for lathe efficiency.To boost lathe performance, use machine learning techniques. These tools help find the best ways to operate lathes efficiently. Data analysis can point out issues and improve operations. Key performance indicators (KPIs) can show how well a lathe is working. Important KPIs include:

- Production speed

- Material waste

- Downtime

- Energy consumption

Using machine learning helps tailor solutions, making lathes more reliable and efficient.

What techniques can optimize lathe operations?

Techniques include regular monitoring, predictive maintenance, and data collection. These methods help find and fix problems fast.

Tools and Software for Lathe Machine Learning

Recommended software solutions for troubleshooting. Comparison of tools available in the market.For anyone working with a lathe machine, having the right tools can make a big difference. Several software solutions help troubleshoot issues effectively. Here are some top recommendations:

- Fusion 360: Great for design and machining simulation.

- Mastercam: Popular for its easy-to-use interface.

- SolidWorks: Excellent for 3D modeling and problem-solving.

These tools vary in features and costs. Knowing which one suits your needs is key. Researching and comparing options can lead you to the best choice.

What should I consider when choosing software for lathe troubleshooting?

Focus on user-friendliness, compatibility, and specific features. This ensures the software can assist in solving problems effectively.

Future Trends in Lathe Machine Learning

Emerging technologies in lathe troubleshooting. Predictions for the evolution of lathe machine learning solutions.Exciting changes are on the way for lathe machines! New technologies are making troubleshooting faster and easier. Imagine a robot whispering tips to fix your lathe before it starts acting up! Artificial intelligence will soon predict problems, so you can avoid surprises. Experts believe that soon, lathes will talk to us like a friend at a coffee shop, sharing advice and updates. Who knew metal could be so charming?

| Emerging Technology | Benefits |

|---|---|

| AI Algorithms | Quick detection of issues |

| Sensor Technology | Real-time monitoring |

| Predictive Maintenance | Prevents breakdowns |

Conclusion

In conclusion, understanding lathe machine troubleshooting is essential for success. You can learn common issues like alignment and speed problems. We can improve our skills by practicing and reading more guides. Don’t hesitate to explore videos or articles to deepen your knowledge. With patience and practice, you’ll become proficient in using metal lathes effectively.FAQs

Sure! Here Are Five Questions Related To Machine Learning Applications In Troubleshooting Metal Lathes:Machine learning can help us fix metal lathes faster and better. It learns from past problems and suggests fixes. For example, if a lathe makes a strange noise, machine learning can point us to the cause. It also helps us keep track of when the machine needs maintenance. This way, we can prevent bigger problems before they happen!

Of course! Please tell me the question you would like answered.

What Are The Common Signs Of Malfunction In A Metal Lathe That Machine Learning Algorithms Can Help Identify?Common signs of trouble in a metal lathe include strange noises, vibrations, and uneven cuts. If you see smoke or feel heat, something might be wrong. Machine learning can help us recognize these signs early. It can learn from lots of data to spot problems before they get worse. This way, we keep the lathe running smoothly!

How Can Predictive Maintenance Using Machine Learning Improve The Operational Efficiency Of Metal Lathes?Predictive maintenance uses smart computers to help us care for metal lathes. These machines make metal parts by spinning and cutting. With this technology, we can see when a lathe might break. This means we can fix it before it stops working, saving time and money. By keeping everything running smoothly, we can create more parts faster and better!

What Types Of Data Should Be Collected From A Metal Lathe To Train A Machine Learning Model For Troubleshooting Purposes?To help a machine learning model learn how to fix problems with a metal lathe, we should collect certain data. First, we need to track the temperature of the machine while it works. Next, we should note the speed and feed rates, which tell us how fast and how much material is being cut. We also want to gather information about any unusual sounds or vibrations. Lastly, recording how often the machine breaks down will help us a lot.

How Can Anomaly Detection Algorithms Be Utilized To Enhance The Reliability Of Metal Lathe Operations?We can use anomaly detection algorithms to watch how the metal lathe works. These programs learn what normal sounds and actions are. If something unusual happens, like a strange noise or movement, the program alerts us. This helps us fix problems before they cause big trouble. By catching issues early, we keep our metal lathe running smoothly and safely.

What Challenges Are Faced When Implementing Machine Learning Solutions For Troubleshooting In Traditional Metal Lathe Environments?When using machine learning in metal lathe work, we face several challenges. First, gathering enough good data can be tough. We also need to teach the computer how to understand the machines. Machines can break in many ways, and it’s hard to cover them all. Finally, some workers might be unsure or worried about using new technology.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Machine Learning Applications In Troubleshooting Metal Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Machine learning can help us fix metal lathes faster and better. It learns from past problems and suggests fixes. For example, if a lathe makes a strange noise, machine learning can point us to the cause. It also helps us keep track of when the machine needs maintenance. This way, we can prevent bigger problems before they happen!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please tell me the question you would like answered.”}},{“@type”: “Question”,”name”: “What Are The Common Signs Of Malfunction In A Metal Lathe That Machine Learning Algorithms Can Help Identify?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common signs of trouble in a metal lathe include strange noises, vibrations, and uneven cuts. If you see smoke or feel heat, something might be wrong. Machine learning can help us recognize these signs early. It can learn from lots of data to spot problems before they get worse. This way, we keep the lathe running smoothly!”}},{“@type”: “Question”,”name”: “How Can Predictive Maintenance Using Machine Learning Improve The Operational Efficiency Of Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Predictive maintenance uses smart computers to help us care for metal lathes. These machines make metal parts by spinning and cutting. With this technology, we can see when a lathe might break. This means we can fix it before it stops working, saving time and money. By keeping everything running smoothly, we can create more parts faster and better!”}},{“@type”: “Question”,”name”: “What Types Of Data Should Be Collected From A Metal Lathe To Train A Machine Learning Model For Troubleshooting Purposes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To help a machine learning model learn how to fix problems with a metal lathe, we should collect certain data. First, we need to track the temperature of the machine while it works. Next, we should note the speed and feed rates, which tell us how fast and how much material is being cut. We also want to gather information about any unusual sounds or vibrations. Lastly, recording how often the machine breaks down will help us a lot.”}},{“@type”: “Question”,”name”: “How Can Anomaly Detection Algorithms Be Utilized To Enhance The Reliability Of Metal Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use anomaly detection algorithms to watch how the metal lathe works. These programs learn what normal sounds and actions are. If something unusual happens, like a strange noise or movement, the program alerts us. This helps us fix problems before they cause big trouble. By catching issues early, we keep our metal lathe running smoothly and safely.”}},{“@type”: “Question”,”name”: “What Challenges Are Faced When Implementing Machine Learning Solutions For Troubleshooting In Traditional Metal Lathe Environments?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using machine learning in metal lathe work, we face several challenges. First, gathering enough good data can be tough. We also need to teach the computer how to understand the machines. Machines can break in many ways, and it’s hard to cover them all. Finally, some workers might be unsure or worried about using new technology.”}}]}