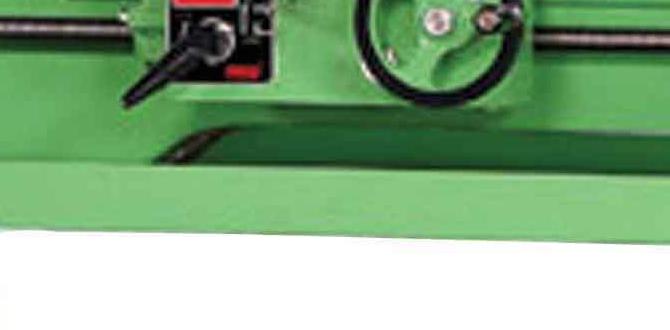

Have you ever wondered how a lathe machine works? It’s fascinating! A lathe helps shape metal into amazing pieces. But to keep it running smoothly, it needs the right kind of oil. That’s where lathe machine oil comes in. This special oil ensures that parts move without any hiccups.

Now, think about a puppet on string. The better the strings, the smoother the show. It’s similar with a lathe machine. Good oil means better performance. It allows the machine to cut and shape metal with precision.

But there’s more! Many modern lathes come with a metal lathe controller board. This board helps you control the machine easily. Imagine being able to shape metal just like a pro with a few simple buttons!

In this article, we will explore the best oil for your lathe. We’ll also look at how a controller board can make your projects easier and more fun. Are you ready to dive into the world of lathe machines?

Lathe Machine Oil For Metal Lathe Controller Board Maintenance

Understanding Lathe Machine Oil and Metal Lathe Controller Boards

Lathe machine oil is crucial for keeping your metal lathe running smoothly. It reduces friction and protects against wear. If you don’t use the right oil, you might notice strange noises or overheating. Have you heard of a metal lathe controller board? This device manages the lathe’s functions, allowing precise control and better performance. Using both the right oil and a good controller board makes your projects easier and more enjoyable. Discover how they can transform your metalworking experience!What is Lathe Machine Oil?

Definition and purpose of lathe machine oil. Types of lathe machine oil and their properties.Lathe machine oil is a special type of oil used to keep metal lathes running smoothly. Its main job? To reduce friction and keep parts cool! Think of it as a smoothie for your machine—essential for a smooth operation. It comes in various types, each with its own special powers. Some oils are thicker for heavy-duty jobs, while others are thinner for lighter tasks. Here’s a fun comparison:

| Oil Type | Viscosity | Best Use |

|---|---|---|

| Bulk Oil | Thick | Heavy machining |

| Cutting Fluid | Thin | Light cutting |

Choosing the right lathe oil helps parts last longer and machines work better. And now your lathe won’t be feeling all “grumpy” from lack of lubrication!

The Importance of Lubrication in Metal Lathes

How lubrication affects machine performance. Consequences of inadequate lubrication on machinery.Lubrication plays a big role in how well metal lathes run. A little oil can make a huge difference! It keeps parts moving smoothly and helps them last longer. Without enough lubrication, machines can overheat or get damaged. Imagine a person without water—machines feel the same without oil!

| Consequences of Inadequate Lubrication | Machine Performance |

|---|---|

| Overheating | Reduced Speed |

| Increased Wear | Lower Accuracy |

| Frequent Breakdowns | Higher Costs |

In short, keep that lathe well-oiled! A happy machine means happy operators, and nobody likes a grumpy lathe!

Choosing the Right Lathe Machine Oil

Factors to consider when selecting oil (viscosity, type, etc.). Recommended brands and products for metal lathes.Picking the right oil for your lathe is like choosing the perfect frosting for a cake—too thick, and it’s a mess! Viscosity is key; it should flow smoothly without slipping away. You also want to match the oil type to your lathe’s needs. Some brands are better than others. For metal lathes, we recommend products like “Mobil Vactra” and “Shell Tellus.” They keep things running sweetly. Here’s a little table to help:

| Brand | Type | Viscosity |

|---|---|---|

| Mobil Vactra | Way Oil | ISO 32 |

| Shel Tellus | Hydraulic Oil | ISO 46 |

So remember, happy lathe, happy maker!

How to Properly Apply Lathe Machine Oil

Techniques for oil application on lathe machines. Maintenance tips for ensuring optimal usage.Keeping your lathe machine happy is like making sure a pet is well-fed. Apply lathe machine oil carefully. Use a clean cloth or oil can to add a few drops where metal meets metal. Remember, no one likes a sticky situation! To keep things running smoothly, check the oil regularly—every few hours of use is usually good. If your lathe starts sounding like a rusty door hinge, it’s time to add some more oil. Let’s face it, nobody wants a grumpy lathe!

| Technique | Tip |

|---|---|

| Application | Use a clean cloth or oil can. |

| Frequency | Check oil every few hours of use. |

| Signs | Listen for squeaking or grinding noises. |

Common Problems with Lathe Machine Oil

Issues caused by using the wrong type of oil. Signs that lathe oil needs to be changed.Using the wrong oil can lead to trouble. It might cause parts to wear out faster or even break. Signs that it’s time to change your lathe oil include:

- Oil looks dirty or cloudy.

- Strange smells or fumes.

- Machine runs louder than normal.

Keeping an eye on your oil can help your lathe work better and last longer.

What are common signs the lathe oil needs changing?

Look for signs like cloudy oil, strange smells, or increased noise. These hints mean it’s time to change your oil.

Maintenance Practices for Longevity of Lathe Machines

Regular inspection and servicing tips. Keeping oil contamination out of the system.Keeping your lathe machine happy is like keeping a cat entertained. Regular check-ups are key. Look over the machine parts often, and watch out for any wear and tear. You can avoid silly problems with a simple inspection. Think of it as giving your metal buddy a little check-up. Keep oil contamination at bay by using clean oil and sealing any leaks. Dirty oil can turn your lathe into a grumpy machine!

| Tip | Description |

|---|---|

| Inspect Regularly | Check for loose parts and wear. |

| Use Clean Oil | Only use fresh oil to keep the system clean. |

| Seal Leaks | Fix leaks to avoid contamination. |

FAQs on Lathe Machine Oil and Controller Boards

Addressing common queries and misconceptions. Expert recommendations on maintenance and products.Many people wonder about the best practices for lathe machine oil and controller boards. Here are some clear answers and expert tips:

What is the best oil for lathe machines?

The best oil depends on your machine. Use high-quality, non-detergent oil to reduce wear and tear. This keeps the lathe running smoothly.

How often should I service my lathe?

Service your lathe regularly to avoid damage. Check the oil every month and change it as needed.

Common Tips:

- Always read the manual for specific oil types.

- Keep the controller board clean for better performance.

- Don’t hesitate to ask a professional for advice.

Maintaining your lathe with the right oil will ensure it lasts longer and works better, making your projects easier and more fun.

Conclusion

In summary, lathe machine oil keeps your metal lathe running smoothly. A good controller board helps you adjust settings easily for better results. Remember to use the right oil and maintain your equipment well. If you want to learn more, check out guides and videos online. Taking care of your lathe will improve your projects and skills.FAQs

Sure! Here Are 5 Related Questions On The Topic Of Lathe Machine Oil, Metal Lathe, And Controller Board:Lathe machine oil helps keep machines running smoothly. It reduces friction and prevents rust. You should always check the oil level before using the lathe. A metal lathe shapes metal into different forms, like knobs or tools. The controller board makes sure everything works together correctly, like a conductor leading an orchestra.

Of course! Please give me the question you would like me to answer.

What Type Of Oil Is Recommended For Lubricating A Metal Lathe, And How Does It Affect The Performance Of The Machine?For a metal lathe, you should use light machine oil. This oil helps keep the moving parts working smoothly. When we use the right oil, the lathe runs better and lasts longer. It also helps prevent rust and keeps everything clean. So, using good oil is important for a happy machine!

How Can A Controller Board Enhance The Precision And Efficiency Of A Metal Lathe Operation?A controller board helps a metal lathe work better. It tells the lathe exactly how fast and where to cut. This makes the cuts more accurate and smooth. You can also save time because the lathe runs faster and doesn’t need as much fixing. Overall, it makes your work easier and better!

What Are The Signs That Indicate It’S Time To Change The Oil In A Lathe Machine?You should change the oil in a lathe machine if you see thick sludge in the oil. If the oil smells bad or looks dirty, that’s also a sign. Listen for any strange noises while the machine runs. Finally, if the machine runs hot or slows down, it’s time for new oil. Changing the oil helps keep the lathe working well.

What Features Should You Look For In A Controller Board For A Cnc Lathe Compared To A Manual Lathe?When choosing a controller board for a CNC lathe, look for easy controls. You want buttons or a screen that are simple to use. It should connect well with your computer, so you can program it easily. A good board can move the machine precisely, making accurate parts. Finally, check if it has safety features to keep you safe while working.

How Does The Selection Of Lathe Machine Oil Differ Between Various Types Of Machining Operations, Such As Turning, Milling, Or Grinding?When we choose oil for a lathe machine, it depends on the job we’re doing. For turning, we need oil that cools and protects the metal. If we’re milling, the oil should also help with smooth movement and cutting power. For grinding, we want oil that can clean and reduce dust. Each type of oil is like a special helper for different tasks!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are 5 Related Questions On The Topic Of Lathe Machine Oil, Metal Lathe, And Controller Board:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe machine oil helps keep machines running smoothly. It reduces friction and prevents rust. You should always check the oil level before using the lathe. A metal lathe shapes metal into different forms, like knobs or tools. The controller board makes sure everything works together correctly, like a conductor leading an orchestra.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please give me the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Lubricating A Metal Lathe, And How Does It Affect The Performance Of The Machine?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For a metal lathe, you should use light machine oil. This oil helps keep the moving parts working smoothly. When we use the right oil, the lathe runs better and lasts longer. It also helps prevent rust and keeps everything clean. So, using good oil is important for a happy machine!”}},{“@type”: “Question”,”name”: “How Can A Controller Board Enhance The Precision And Efficiency Of A Metal Lathe Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A controller board helps a metal lathe work better. It tells the lathe exactly how fast and where to cut. This makes the cuts more accurate and smooth. You can also save time because the lathe runs faster and doesn’t need as much fixing. Overall, it makes your work easier and better!”}},{“@type”: “Question”,”name”: “What Are The Signs That Indicate It’S Time To Change The Oil In A Lathe Machine?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should change the oil in a lathe machine if you see thick sludge in the oil. If the oil smells bad or looks dirty, that’s also a sign. Listen for any strange noises while the machine runs. Finally, if the machine runs hot or slows down, it’s time for new oil. Changing the oil helps keep the lathe working well.”}},{“@type”: “Question”,”name”: “What Features Should You Look For In A Controller Board For A Cnc Lathe Compared To A Manual Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a controller board for a CNC lathe, look for easy controls. You want buttons or a screen that are simple to use. It should connect well with your computer, so you can program it easily. A good board can move the machine precisely, making accurate parts. Finally, check if it has safety features to keep you safe while working.”}},{“@type”: “Question”,”name”: “How Does The Selection Of Lathe Machine Oil Differ Between Various Types Of Machining Operations, Such As Turning, Milling, Or Grinding?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we choose oil for a lathe machine, it depends on the job we’re doing. For turning, we need oil that cools and protects the metal. If we’re milling, the oil should also help with smooth movement and cutting power. For grinding, we want oil that can clean and reduce dust. Each type of oil is like a special helper for different tasks!”}}]}