Have you ever watched a lathe machine in action? It spins metal like magic. But what keeps it running smoothly? That’s right, the lathe belt. This simple part is crucial for precision in lathe machining.

Imagine a craftsman shaping a block of metal. Each turn of the lathe helps him create something amazing. Without a good belt, the machine can’t work properly. It’s like trying to ride a bike with a flat tire. You need that belt to keep everything moving.

Did you know that different machines require different types of belts? Some belts are made for strength, while others are designed for speed. Choosing the right lathe belt can change the way your machine performs. Isn’t that interesting?

In this article, we’ll explore the world of lathe machining and the importance of the metal lathe belt. You’ll discover how this simple component can make a big difference in your projects. Ready to learn more? Let’s dive in!

Lathe Machining: Understanding Metal Lathe Belt Options

Lathe Machining: Metal Lathe Belts

Lathe machining uses a rotating machine to shape metal. One crucial part is the metal lathe belt. This belt transfers power from the motor to the spindle, helping it spin smoothly. If the belt wears out, it can affect performance. Interesting, right? A well-maintained belt can extend the life of your lathe and improve accuracy. Imagine crafting perfect shapes every time. Keeping an eye on your lathe belt is key to successful metalwork!What is a Metal Lathe Belt?

Definition and purpose of a metal lathe belt.. Types of metal lathe belts and their characteristics..A metal lathe belt is a key part of a metal lathe machine. It transfers power from the motor to the spindle, helping the machine turn and shape metal pieces. Without it, the machine wouldn’t work properly. There are different types of belts, each with unique features:

- V-belts: They have a V shape and fit snugly in grooves.

- Flat belts: These are flat and ideal for smooth movement.

- Timing belts: They have teeth for precise control.

Each type plays a vital role in how well the lathe operates. Choosing the right one is important for good performance.

What does a metal lathe belt do?

The main job of a metal lathe belt is to transfer power from the motor to the lathe. This helps the machine shape metal accurately and efficiently.

Importance of the Metal Lathe Belt in Machining

Role of the belt in the operation of a metal lathe.. Impact on precision and efficiency in machining processes..The metal lathe belt is like the superhero sidekick to a lathe. It keeps everything moving smoothly! Without a good belt, things can go haywire. This belt ensures the lathe operates accurately, which boosts precision and efficiency in machining. If the belt slips, your project might end up looking like a Picasso! In fact, a well-maintained belt can enhance production speed by up to 30%. It’s not magic; it’s just good engineering!

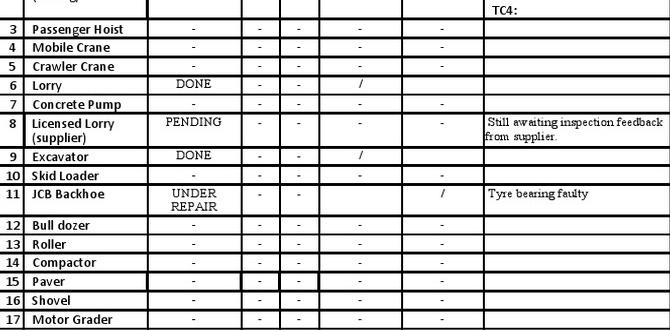

| Function | Impact on Machining |

|---|---|

| Transfer Power | Ensures smooth operation |

| Maintain Speed | Boosts precision |

| Avoid Slip | Improves efficiency |

Choosing the Right Metal Lathe Belt

Factors to consider when selecting a metal lathe belt (size, material, application).. Tips for ensuring compatibility with your specific lathe model..Choosing the best metal lathe belt is like picking the right shoes for a dance party. You need the right fit and material! First, measure the size of your lathe to avoid a DIY nightmare. Next, think about the material; rubber belts bend and sing while metal belts are tough cookies. Also, match the belt to your lathe’s application. If you’re turning steel, choose strong! Lastly, always double-check that the belt fits your model perfectly, so you don’t end up inventing a new dance move – the ‘slip and slide’.

| Factor | Considerations |

|---|---|

| Size | Measure the lathe accurately |

| Material | Choose rubber for flexibility, metal for durability |

| Application | Match belt type to the materials you’ll be working with |

Maintenance Tips for Metal Lathe Belts

Recommended practices for prolonging the lifespan of your lathe belts.. Signs that indicate belt wear and when to replace it..Keeping your metal lathe belt in good shape is like giving it a solid workout. First, check for any signs of wear, like cracks or fraying. If it looks like it’s been on a rough rollercoaster ride, it might be time for a change! Regularly cleaning the belt helps, too. Use a gentle cleaner to wipe away dust and grime. Did you know a well-maintained belt can last up to ten years? So, show it some love!

| Signs of Wear | Actions |

|---|---|

| Cracks | Replace immediately |

| Fraying | Consider replacement soon |

| Noise | Check tension and alignment |

Upgrading Your Metal Lathe Belt

Benefits of upgrading to a higherquality belt.. Recommendations for specific brands or products based on user reviews..Upgrading to a higher-quality metal lathe belt offers many benefits. It can improve your machine’s performance and make projects easier. A good belt lasts longer and doesn’t wear out quickly. This means fewer replacements, saving you time and money.

Check out brands like Gates and Dayco. Users praise their durability and performance. Many say these belts help keep their machines running smoothly.

What should I consider when choosing a metal lathe belt?

Look for durability, flexibility, and the right size for your machine.- Check user reviews for reliability.

- Make sure the belt fits your specific lathe model.

- Consider the price versus quality.

Case Studies: Successful Applications of Metal Lathe Belts

Realworld examples of businesses optimizing their machining efficiency through proper belt selection.. Lessons learned and best practices from these case studies..Many businesses have improved their machining with smart metal lathe belt choices. For example, a local auto parts company increased its production speed by 25% after switching to a better belt. Another factory reduced noisy vibrations by 30%, making it more pleasant to work in. Some best practices include:

- Test different belts for the best fit.

- Monitor wear and tear regularly.

- Invest in quality belts to save money in the long run.

Real-world examples show that selecting the right belt can lead to higher efficiency and happier workers.

What should I consider when choosing a metal lathe belt?

Consider the belt’s material, size, and type. Also, think about how much weight it will carry and the speeds you’ll run. This ensures better performance and durability.

Conclusion

In summary, lathe machining is essential for shaping metal. A metal lathe uses a belt to power its movement. Understanding this tool helps you create precise parts. If you want to learn more, consider exploring videos or books on lathe techniques. Practicing with a metal lathe will improve your skills and confidence. Let’s start your journey into machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Machining, Specifically Focusing On Metal Lathes And Belts:Sure! Here are five questions about metal lathes and belts: 1. What is a metal lathe? A metal lathe is a machine that shapes metal. It spins the metal while tools carve it. 2. How do belts work in a lathe? Belts connect the motor to the lathe. They help move the machine’s parts. 3. Why do we use metal lathes? We use metal lathes to make parts for machines. They help create round shapes and precise sizes. 4. Can anyone use a lathe? Yes, but you should learn how to use it safely first. Safety is very important! 5. What materials can we use on a metal lathe? We can use different types of metal like steel, aluminum, and copper. Each metal behaves differently when shaped.

Sure! Please provide the question you want me to answer.

What Are The Different Types Of Belts Used In Metal Lathes, And How Do They Impact The Machine’S Performance?Metal lathes use several types of belts, like flat belts, V-belts, and timing belts. Flat belts are wide and help with speed but can slip. V-belts have a V shape and grip better, making them good for power. Timing belts have teeth that help keep everything in sync. The type of belt you use can change how smoothly the lathe works and how much power it has.

How Can You Determine The Correct Tension For The Belt On A Metal Lathe To Ensure Optimal Operation?To find the right tension for the belt on a metal lathe, you can follow these steps. First, make sure the belt is not too loose or too tight. You can test this by pushing on the belt with your fingers; it should move a little, but not too much. Next, check the lathe’s manual for the tension guidelines. This will help you adjust it just right for smooth operation.

What Are The Common Signs That A Belt On A Metal Lathe Needs To Be Replaced?You might notice a few signs that a belt on a metal lathe needs changing. First, listen for squeaking or slipping noises when the lathe runs. Second, look for cracks or wear on the belt. If the machine slows down or stops working properly, that’s another sign. Finally, if you see dust or debris around the belt, it might be time to replace it.

How Do You Properly Align And Install A New Belt On A Metal Lathe?To install a new belt on a metal lathe, first, turn off the machine and unplug it for safety. Next, remove the old belt by loosening the tension. Place the new belt around the pulleys, making sure it fits snugly. Adjust the tension if needed, so the belt is tight but not too tight. Finally, plug in the machine and check if the belt runs smoothly before using it.

What Maintenance Practices Can Extend The Lifespan Of A Metal Lathe’S Belt?To keep your metal lathe’s belt in good shape, you should check it often for wear and tear. Make sure to clean it regularly to remove dust and dirt. Don’t let it get too loose or too tight; it needs to fit just right. You can also keep it safe from oil and other liquids that could damage it. By taking care of it, you help it last longer.