Have you ever wondered how metal parts are made so perfectly? The answer often lies in a process called lathe machining. This fascinating method shapes metal, using a machine called a lathe.

Imagine a big piece of metal slowly spinning while a sharp tool carves it into a precise shape. That’s exactly what happens in lathe machining. The lathe machine works like a magician, turning raw metal into parts for cars, airplanes, and even toys!

What’s even cooler is how modern technology connects with this age-old craft. With metal lathe CAD design, engineers create blueprints on computers. They can experiment and tweak designs before even touching any metal. This makes the process faster and more accurate.

Join us as we explore the world of lathe machining, metal lathes, and CAD design. You’ll discover how these elements combine to create amazing products and push the boundaries of what’s possible in manufacturing!

Lathe Machining: Metal Lathe Cad Design Techniques Explained

Understanding Lathe Machining and CAD Design

Lathe machining is a key process in shaping metal. It involves rotating the metal while tools cut and shape it. Have you ever wondered how perfectly round parts are made? That’s the magic of a metal lathe! CAD design plays an essential role in this process. It helps create precise blueprints before any metal starts spinning. This technology enables engineers to visualize and modify designs easily. With lathe machining and CAD, creating strong, accurate metal parts becomes simple and efficient.Understanding Lathe Machining

Definition and purpose of lathe machining. Types of lathe machines and their applications.Lathe machining is a fun way to shape metal! It uses a machine to spin metal while cutting it down to size. This process helps make parts for cars, airplanes, and even toys. There are different types of lathes, such as engine lathes and CNC lathes, each with its special tricks. Engine lathes are great for simple jobs, while CNC lathes are like robots, following computer instructions. Who knew metalworking could be this cool?

| Type of Lathe | Application |

|---|---|

| Engine Lathe | General purpose, simple tasks |

| CNC Lathe | Complex designs, precise cuts |

| Turret Lathe | Mass production, repeat jobs |

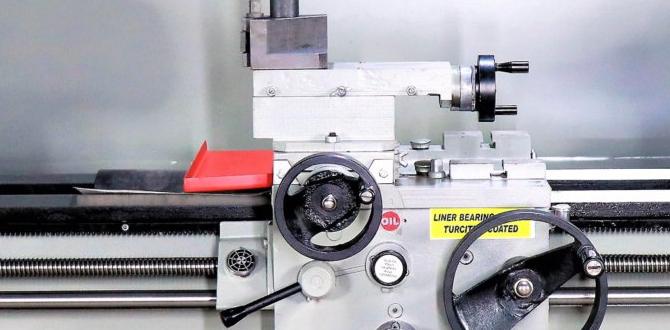

The Basics of Metal Lathe Operations

Key components of a metal lathe. Fundamental machining processes involved.A metal lathe is like a magic wand for metal! It changes raw pieces into neat shapes. Key parts of a metal lathe include the headstock, tailstock, and carriage. The headstock holds the motor and spindle. The tailstock helps in drilling holes. The carriage moves tools to cut and shape metal. Common processes are turning, facing, and threading. Each one shapes the metal into something useful.

| Part | Function |

|---|---|

| Headstock | Holds the spindle and motor |

| Tailstock | Holds tools for boring |

| Carriage | Moves tools for cutting |

Now, isn’t it cool how metal turns into art? It’s not just for wizards, but for anyone who loves to create!

Step-by-Step Guide to Creating CAD Designs for Metal Lathe

Initial setup and considerations in CAD software. Detailed steps for modeling and simulating lathe processes.Before starting your CAD design for a metal lathe, set up your software correctly. Check for system requirements and install any necessary updates. Consider your project’s scope. Will it be simple or complex? Next, model the components. Use features like extrusion and revolution for shaping parts.

When simulating lathe processes, follow these steps:

- Choose the right material.

- Define cutting paths.

- Run simulations to check for errors.

- Adjust settings as needed.

Finally, save your design. A well-prepared model boosts your chances of success.

What are the key steps in CAD design for metal lathes?

The key steps are initial setup, modeling components, and simulating processes. Ensuring correct settings helps you create precise designs.

Best Practices for Efficiency in Lathe Machining

Techniques to optimize material usage. Maintenance tips for enhancing lathe performance.If you want to make the most out of your lathe, try some clever tricks. First, optimize your material usage by cutting shapes that leave little waste. Remember, a tiny scrap can still ruin a perfectly good sandwich! For maintenance, keep your lathe clean and greased; this ensures smooth operations. Always check the alignment, or your lathe might end up doing the cha-cha when it should be cutting straight. A happy lathe is a productive lathe!

| Best Practices | Description |

|---|---|

| Optimize Material Usage | Cut shapes to minimize waste. |

| Regular Maintenance | Keep it clean and greased for smooth performance. |

| Check Alignment | Ensure tools are aligned to avoid errors. |

Common Mistakes in Lathe Machining and How to Avoid Them

Frequent errors in CAD design and machining. Troubleshooting tips for common machining issues.Lathe machining is a fun but tricky game! Common mistakes happen, especially in CAD design and machining. One error is having the wrong dimensions. Always double-check those numbers! Another issue is improper tool speed. Slow isn’t always good; speed it up, but not too much! If you hear a weird noise, it might be time to troubleshoot. Here are some quick tips:

| Common Mistakes | How to Avoid |

|---|---|

| Wrong Dimensions | Measure twice, cut once! |

| Incorrect Speed | Follow recommended settings. |

| Tool Wear | Check tools regularly and replace as needed. |

Remember, it’s okay to make mistakes; that’s how we learn! Just keep those tips in your back pocket for next time.

Future Trends in Lathe Machining and CAD Technology

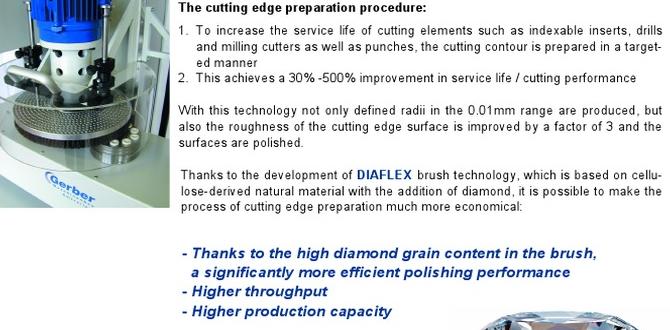

Innovations in CAD design for metal lathes. Expected advancements in lathe machining techniques.New tools are changing how we design and use metal lathes. CAD design is getting smarter. It now allows us to see exact details before we make anything. This saves time and reduces mistakes. Innovations like 3D modeling make it easy to visualize parts. As for lathe machining, we can expect faster machines that work with less energy. They will make stronger parts in less time.

- 3D modeling helps visualize designs.

- Machines will use less energy.

- Faster speeds will boost productivity.

What are the expected advancements in lathe machining techniques?

Faster machines and more accurate tools will lead to better products. Adopting computer-guided systems will enhance precision. This means parts will fit better and last longer.

Resources for Further Learning

Recommended books and online courses. Forums and communities for lathe machining enthusiasts.Want to dive deeper into lathe machining? There are some great resources out there for you. Check out these recommended books that make metal spinning sounds almost musical. Online courses can turn you from a newbie into a lathe whiz in no time. Plus, forums are like chat rooms for metal enthusiasts! You can share tips, ask questions, and maybe even find a friend who loves lathes just as much as you do.

| Resource Type | Recommendation |

|---|---|

| Book | Machining Made Simple – A friendly guide to get you started. |

| Online Course | Lathe Mastery 101 – Beginners welcomed with open arms! |

| Forum | Lathe Lovers Unite – A fun place to chat and learn! |

With these tools, you’ll be spinning metal like a pro in no time. Just remember: every expert was once a beginner, probably making a mess with shavings flying everywhere!

Conclusion

In summary, lathe machining and metal lathes are vital tools for shaping materials. Using CAD design helps you plan and visualize your projects. With practice, you can create precise and creative designs. Explore more tutorials and guides to improve your skills. Remember, the more you learn, the better your projects will become! Let’s start making something amazing!FAQs

What Are The Key Design Considerations To Keep In Mind When Creating A Cad Model For Parts Intended For Machining On A Metal Lathe?When making a CAD model for parts to be machined on a metal lathe, you need to think about a few important things. First, make sure the sizes and shapes are correct so the part fits well. Next, keep the design simple, with fewer tiny details that can be hard to cut. Also, remember the tool’s reach so it can easily make all the cuts. Finally, think about the type of metal you will use, as it affects how you should design the part.

How Can Cam Software Be Integrated With Cad Designs To Optimize The Machining Process On A Lathe?We can use Computer-Aided Manufacturing (CAM) software with Computer-Aided Design (CAD) drawings to make working on a lathe easier. First, you create a design in CAD. Then, you import that design into CAM. The CAM software helps plan how to cut or shape the material. This makes the process faster and helps avoid mistakes, so your project turns out just right!

What Are The Common Materials Used For Metal Lathe Machining, And How Do Their Properties Influence Cad Design?Common materials used for metal lathe machining are aluminum, steel, and brass. Aluminum is light and easy to shape. Steel is strong and durable but can be heavier. Brass is shiny and good for making parts that need to look nice. Knowing these properties helps us design in CAD (Computer-Aided Design) by choosing the right material for our project.

How Can Simulation Tools In Cad Software Help Predict Potential Issues During The Metal Lathe Machining Process?Simulation tools in CAD (Computer-Aided Design) software let us create a virtual version of a metal part. We can test how the part will be made on the lathe machine. This helps us see problems before we start working. For example, we can find where the tool might get stuck or cut too deep. It saves time and helps us make better parts!

What Are Some Best Practices For Setting Up A Lathe Machining Project Based On A Cad Design To Ensure Precision And Efficiency?To set up a lathe machining project, start by checking your CAD design carefully. Make sure all the measurements are correct. Next, gather the right tools and materials you need before you begin. Set the lathe to the right speed for your material. Lastly, keep your workspace clean and organized to avoid mistakes. This helps you work better and faster!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Design Considerations To Keep In Mind When Creating A Cad Model For Parts Intended For Machining On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When making a CAD model for parts to be machined on a metal lathe, you need to think about a few important things. First, make sure the sizes and shapes are correct so the part fits well. Next, keep the design simple, with fewer tiny details that can be hard to cut. Also, remember the tool’s reach so it can easily make all the cuts. Finally, think about the type of metal you will use, as it affects how you should design the part.”}},{“@type”: “Question”,”name”: “How Can Cam Software Be Integrated With Cad Designs To Optimize The Machining Process On A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use Computer-Aided Manufacturing (CAM) software with Computer-Aided Design (CAD) drawings to make working on a lathe easier. First, you create a design in CAD. Then, you import that design into CAM. The CAM software helps plan how to cut or shape the material. This makes the process faster and helps avoid mistakes, so your project turns out just right!”}},{“@type”: “Question”,”name”: “What Are The Common Materials Used For Metal Lathe Machining, And How Do Their Properties Influence Cad Design? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common materials used for metal lathe machining are aluminum, steel, and brass. Aluminum is light and easy to shape. Steel is strong and durable but can be heavier. Brass is shiny and good for making parts that need to look nice. Knowing these properties helps us design in CAD (Computer-Aided Design) by choosing the right material for our project.”}},{“@type”: “Question”,”name”: “How Can Simulation Tools In Cad Software Help Predict Potential Issues During The Metal Lathe Machining Process? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Simulation tools in CAD (Computer-Aided Design) software let us create a virtual version of a metal part. We can test how the part will be made on the lathe machine. This helps us see problems before we start working. For example, we can find where the tool might get stuck or cut too deep. It saves time and helps us make better parts!”}},{“@type”: “Question”,”name”: “What Are Some Best Practices For Setting Up A Lathe Machining Project Based On A Cad Design To Ensure Precision And Efficiency? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a lathe machining project, start by checking your CAD design carefully. Make sure all the measurements are correct. Next, gather the right tools and materials you need before you begin. Set the lathe to the right speed for your material. Lastly, keep your workspace clean and organized to avoid mistakes. This helps you work better and faster!”}}]}