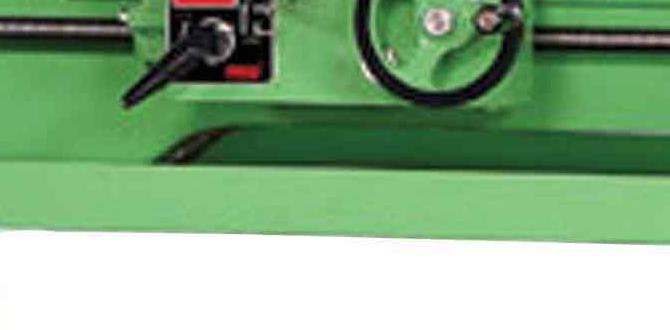

Have you ever wondered how metal parts are shaped with such precision? Machine shops often use a tool called a lathe. This trusty machine can spin metal and carve it into many different forms. But did you know you can turn an old lathe into a modern marvel? That’s where lathe machining and CNC retrofit come into play.

Imagine finding an old metal lathe in your garage. It looks tired and dusty. But what if you could give it a second chance? By adding CNC (Computer Numerical Control) features, you can bring this machine to life. It can learn to create complex shapes that were once impossible.

Many hobbyists and businesses are discovering the joys of retrofitting. This process not only saves money but also makes older machines work like new. Plus, with the right setup, you could be creating amazing projects in no time. So, what do you think? Are you ready to take a journey into the world of lathe machining with CNC retrofitting?

Lathe Machining: Enhancing Metal Lathe With Cnc Retrofit Techniques

Lathe Machining: Unlocking CNC Retrofit Potential

Lathe machining is a skill that turns metal into precise parts. Did you know you can upgrade your traditional lathe to a CNC (Computer Numerical Control) system? A CNC retrofit enhances speed and accuracy. It makes projects easier for hobbyists and professionals alike. Imagine achieving complex designs effortlessly! Whether you’re creating custom pieces or small batches, CNC retrofitting transforms the way you work with metal. Get ready to explore new possibilities in your machining journey!Understanding Lathe Machining

Definition and basic principles of lathe machining. Types of lathes: Manual vs. CNC.Lathe machining is a cool way to shape metal. It spins the metal around, letting sharp tools slice it into different shapes. Think of it like a spinning top getting a makeover! There are two main types of lathes. Manual lathes need a skilled person to control them, while CNC lathes do the work automatically. CNC stands for Computer Numerical Control, so it’s like having a robot do the job for you. Who wouldn’t want a robot helping out? In fact, CNC machines can be more accurate than manual ones, making them super popular in factories.

| Type of Lathe | Control Method |

|---|---|

| Manual Lathe | Operator Controlled |

| CNC Lathe | Computer Controlled |

Benefits of CNC Retrofitting

Enhancements in precision and accuracy. Increased production efficiency and automation.CNC retrofitting brings many great benefits to metal lathe machines. First, it enhances precision and accuracy. This means pieces come out just right more often. Second, it boosts production efficiency and helps with automation. Machines can work faster and without as many breaks.

- More detailed work with fewer mistakes

- Machines can run longer and produce more

- Less time is wasted on manual tasks

How does CNC retrofitting improve production?

CNC retrofitting improves production by making machines faster and more precise. This means businesses can create more items in less time. It allows for better planning and less waste, which is good for profits and our planet!

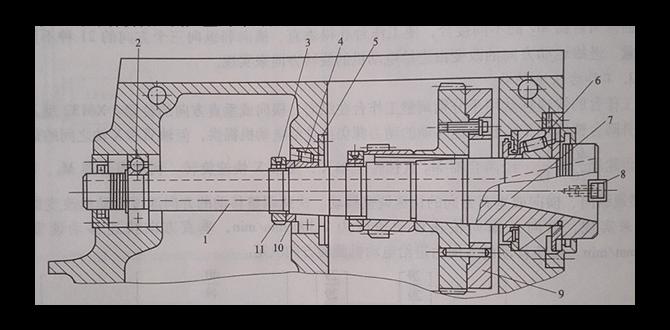

Components of a CNC Retrofit Kit

Key elements included in a retrofit kit. Importance of software and control systems.A CNC retrofit kit brings new life to old machines. This kit usually has key parts like stepper motors, drives, and a control box. Each piece is like a puzzle, fitting together to make magic happen. The software is just as important; it’s what helps you control the machine. Without it, your lathe would be as lost as a sock in the laundry! And let’s not forget about the control systems—they steer the whole operation. You can think of them as the team captain, guiding your metal lathe to victory!

| Component | Function |

|---|---|

| Stepper Motors | Power the movement of the lathe |

| Drives | Control speed and torque |

| Control Box | Houses the brain of the operation |

| Software | Controls machine operations |

It’s important to remember that a good CNC retrofit kit can make your old lathe as useful as a Swiss Army knife—versatile and powerful! Plus, it saves money compared to buying a new machine. So, if you want to level up your lathe game, a retrofit kit is the way to go!

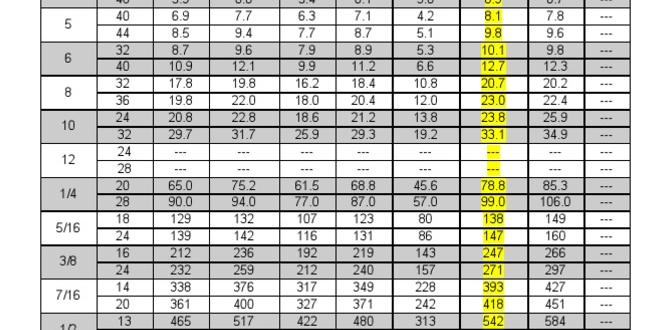

Choosing the Right Retrofit Kit for Metal Lathes

Factors to consider: compatibility, features, and price. Comparing popular CNC retrofit kits on the market.Picking the perfect retrofit kit can feel like trying to find a needle in a haystack. First up, check for compatibility. Will it fit your metal lathe? Next, consider the features. Some kits come with all the bells and whistles, while others are more basic. Lastly, don’t forget about price. You don’t want to break the bank! Here’s a quick look at some popular CNC retrofit kits:

| Kit Name | Compatibility | Features | Price |

|---|---|---|---|

| Retrofit Pro 3000 | Universal | High precision, easy setup | $500 |

| CNC Hero | Specific Models | Speed control, software included | $750 |

| Budget CNC Kit | Older Models | Basic controls | $299 |

So, take your time choosing. A good retrofit kit can turn your lathe into a metal-cutting superhero!

Technical Challenges and Solutions in CNC Retrofit

Common issues encountered during retrofitting. Troubleshooting tips and expert solutions.Retrofitting a CNC machine can have some common hiccups. You might face issues like software bugs, unresponsive controls, or alignment troubles. Each problem can be tricky but solvable. Here are some troubleshooting tips:

- Check connections regularly.

- Update software to the latest version.

- Calibrate your machine often.

- Seek expert help if problems persist.

Finding the right solution makes a big difference. Many users find using online forums helpful, too. They share their stories and solutions. Remember, you are not alone in this journey!

What are common issues in CNC retrofit?

Software bugs, control issues, and alignment problems are typical challenges when retrofitting CNC machines.

Troubleshooting Tips

- Update your machine’s software regularly.

- Verify that all connections are secure.

- Consult manuals and online communities for help.

Applications of CNC Retrofitted Lathes

Industries that benefit from CNC retrofitted lathes. Specific use cases for enhanced machining capabilities.CNC retrofitting makes lathes smarter. Many industries use these advanced machines for different tasks, improving their work. Here are some fields that benefit greatly:

- Aerospace: Makes precise parts that are safe and reliable.

- Automotive: Creates engine components faster and with less waste.

- Medical: Produces tools needed for surgeries.

- Manufacturing: Enhances production speed and accuracy.

With CNC retrofitted lathes, businesses can achieve better quality and efficiency. Imagine making hundreds of parts quickly and perfectly! This technology leads to higher profits and happier customers.

What Industries Use CNC Retrofitted Lathes?

Aerospace, automotive, medical, and manufacturing industries greatly benefit from CNC retrofitted lathes.

Future Trends in Lathe Machining and CNC Technology

Emerging technologies influencing lathe machining. Predictions for the future of CNC retrofitting in manufacturing.Exciting changes are on the horizon for lathe machining and CNC technology. New tools, like 3D printing, are shaking things up. Imagine a CNC machine that can not only cut but also print parts! Predictions say that retrofitting machines will be the norm, saving money while boosting efficiency. In fact, by 2025, retrofitting could increase in popularity by 20% as manufacturers look for cost-effective ways to keep up with demand. It’s like giving old machines a shiny new makeover without the high price tag!

| Trend | Description |

|---|---|

| 3D Printing | Combines printing and cutting for smarter production. |

| Retrofit Growth | Up to 20% more retrofitting expected by 2025! |

Conclusion

In summary, retrofitting a metal lathe with CNC technology can enhance its performance and precision. It allows you to automate tasks, save time, and improve projects. If you’re interested, you can explore DIY retrofit kits or professional services. Start small by researching different options, and see how this upgrade can benefit your work and creativity!FAQs

What Are The Key Benefits Of Retrofitting A Conventional Metal Lathe With Cnc Capabilities?Retrofitting a metal lathe with CNC (Computer Numerical Control) makes it easier to use. You can create more precise shapes and designs. It saves time because the machine can run by itself after you set it up. This upgrade also lets you make more complicated pieces that are hard to do by hand. Overall, it helps you work faster and better!

What Components Are Typically Required For A Successful Cnc Retrofit Of A Manual Lathe?To successfully change a manual lathe into a CNC (Computer Numerical Control) lathe, you need a few key components. First, you need a CNC controller, which helps run the machine. Second, you need motors to move the tools accurately. You will also need new software to design the parts you want to make. Finally, don’t forget the power supply to keep everything running smoothly!

How Does The Accuracy And Precision Of Machining Change After Retrofitting A Lathe With Cnc Technology?When we retrofit a lathe with CNC (Computer Numerical Control) technology, it becomes very accurate. This means the machine can make parts that fit together perfectly. CNC helps us create shapes that are hard to do by hand. We can also repeat the same piece many times without mistakes. Overall, the newer machine makes better and more consistent parts!

What Challenges Might One Face During The Retrofit Process Of A Metal Lathe, And How Can They Be Overcome?When you retrofit a metal lathe, you may face some challenges. One challenge is finding the right parts that fit. You can solve this by measuring carefully and checking online or at stores. Another challenge is understanding how to connect new parts. You can overcome this by watching videos or reading simple guides. Finally, you might feel unsure about your skills. Practicing with small projects can help build your confidence.

Can You Provide Examples Of Software Options Suitable For Programming A Cnc Retrofitted Lathe?Sure! You can use software like Mach3, which is popular for CNC machines. Another good option is LinuxCNC, which is free and open-source. If you want something simple, consider GRBL, which works well for smaller machines. Each of these programs helps control your retrofitted lathe easily.