Have you ever wondered how machines carve and shape metal? One important tool for this task is a lathe. Lathe machining is essential in many industries. It helps create everything from metal parts to simple toys. But did you know that regular maintenance keeps these machines running smoothly?

Imagine a car that never gets an oil change. It might start making funny noises or even break down. A metal lathe needs care just like that car. Proper lathe maintenance ensures accuracy and extends the machine’s life. This might sound a bit boring, but the truth is exciting!

When a lathe is well-maintained, it works better and lasts longer. Every small checkup matters. This article will show you why lathe machining and maintenance go hand in hand. You might even discover tips to make your lathe shine like new!

Essential Metal Lathe Maintenance For Optimal Lathe Machining

Lathe Machining Metal Lathe Maintenance

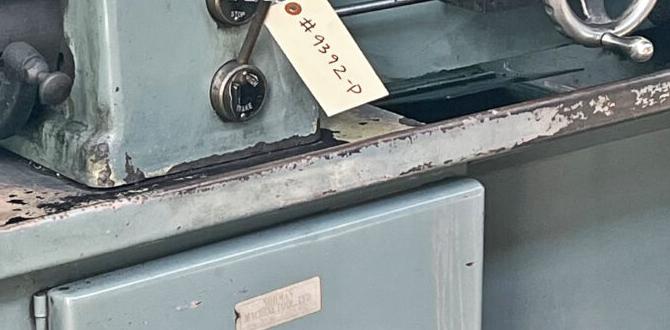

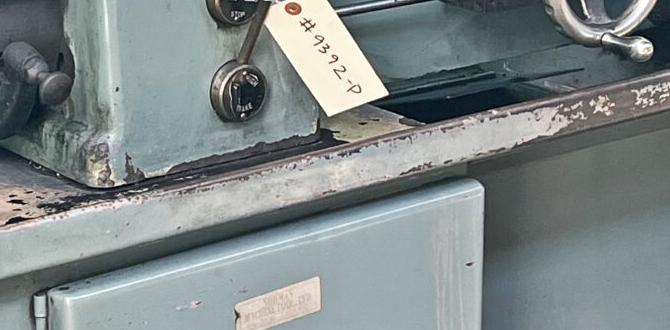

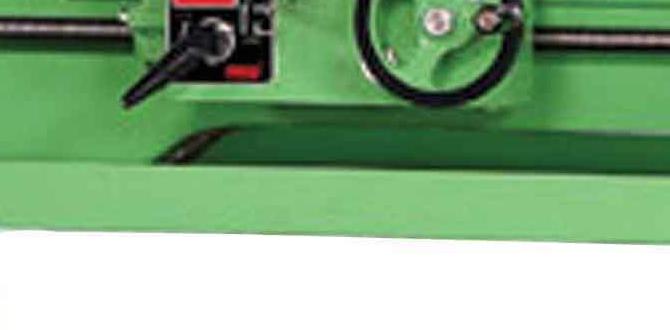

Maintaining a metal lathe is essential for smooth operation. Regular cleaning prevents dirt buildup, which can lead to issues. Checking and changing oil keeps your lathe running smoothly. Tightening loose parts ensures accuracy in your work. Did you know that a well-maintained lathe can last decades? Taking care of your equipment not only saves money but also improves safety. Don’t let neglect ruin your projects; keep your lathe in top shape to make your machining tasks easier and more enjoyable!Components of a Metal Lathe

Detailed description of key components (bed, spindle, tailstock, etc.).. Explanation of the function of each component in the machining process..A metal lathe is like a superhero for shaping metal. Its main sections are important! First, we have the bed, which holds everything together like a trusty sidekick. Then comes the spindle, the spinning star that makes the magic happen. The tailstock is like a helpful friend that can slide in and out, holding the other end of the metal part. Together, these components work to create cool, precise shapes. Imagine transforming a plain rod into a shiny sword! Below is a table showing their main functions:

| Component | Function |

|---|---|

| Bed | Supports and keeps everything aligned |

| Spindle | Spins the workpiece for cutting |

| Tailstock | Holds the workpiece and provides extra support |

Each piece has a special job, making the lathe a powerful tool in metalworking. So next time you see a metal lathe, remember—it’s more than just a bunch of parts; it’s a teamwork dream!

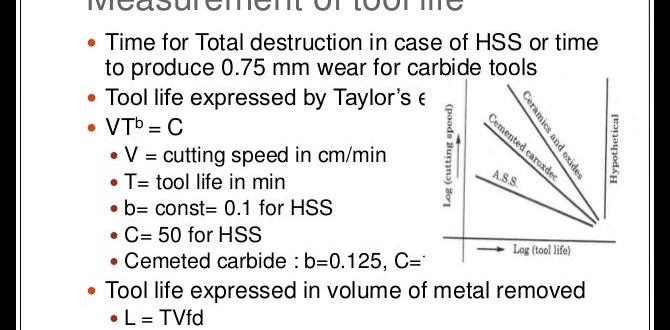

Basic Operating Principles of a Lathe

Explanation of the machining process involving workpiece rotation and tool movement.. Key variables affecting machining performance and quality..A lathe is like a magician’s wand for metal! It spins a workpiece while a tool moves against it to shape the material. This process is key in machining. You can create cool things like parts for cars or even fancy table legs. Speed, feed rate, and tool material are variables that affect how well the machining goes. Want the perfect finish? Keep those factors in check, or your project may end up looking like Swiss cheese!

| Variable | Impact |

|---|---|

| Speed | Affects smoothness of cut |

| Feed Rate | Determines how fast the tool moves |

| Tool Material | Influences durability and precision |

Metal Lathe Maintenance Basics

Importance of regular maintenance for tool longevity and performance.. Common signs of wear and damage to look out for..Regular maintenance is key for keeping your metal lathe in top shape. Good care helps your tools last longer and work better. When you ignore maintenance, problems can grow and lead to costly repairs.

Look for these signs of wear:

- Strange noises during operation

- Inconsistent cuts on metal

- Rust or visible damage on parts

Taking time for maintenance can save you money and improve performance. A well-kept lathe makes tasks easier and more fun!

Why is lathe maintenance important?

Regular maintenance improves tool life and performance. It ensures your lathe works well and produces better results.

What are common signs of lathe wear?

- Strange noises

- Inconsistent cuts

- Rusty parts

Daily Maintenance Procedures for Metal Lathes

Stepbystep guide on daily checks and cleaning routines.. Tips for lubricating moving parts and checking alignment..To keep your metal lathe in great shape, daily checks are key. Start by cleaning the machine. Remove dust and shavings with a soft cloth. Next, check the levels of oil in the lubrication system. Make sure moving parts slide smoothly. Regularly align the lathe to ensure it works properly.

- Wipe down surfaces and remove debris.

- Check oil levels and add oil where needed.

- Tighten loose bolts.

- Inspect belts and change if worn out.

- Ensure alignment using a level tool.

What are the basic steps for lathe maintenance?

Clean, lubricate, and check alignment daily. These steps keep your lathe running smoothly.Infrequent Maintenance Tasks

List of maintenance tasks to perform weekly or monthly.. Importance of checking and replacing worn parts..Keeping machines in good shape is like taking care of your favorite toy. Regular checks help prevent big problems. Here’s a list of tasks to do every week or month:

- Inspect belts and pulleys.

- Clean chips and dust from the machine.

- Check oil levels and add more if needed.

- Look for any worn-out parts to replace.

Worn parts can make machines work poorly. Replacing these parts helps the machine run smoothly. Plus, it can save money on repairs later!

Why is checking worn parts important?

Regularly checking for worn parts is key. Replacing them on time keeps the machine running safely and effectively.

Best Practices for Enhanced Lathe Longevity

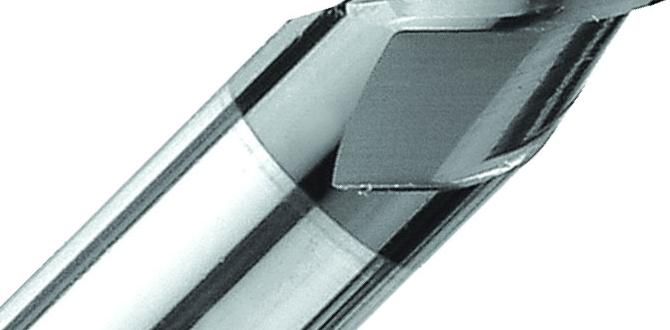

Strategies for prolonging the lifespan of lathe machines.. Recommendations for tool selection and usage techniques..To keep your lathe running smoothly, follow these simple tips. Regular cleaning helps remove chips and dust. Good lubrication keeps the parts moving easily. Always check the alignment of the machine. Using the right tools can also make a big difference. Here are some key strategies:

- Select high-quality cutting tools.

- Use tools that match your material type.

- Change worn tools promptly to avoid damage.

These practices can help extend the life of your lathe machine.

How can I make my lathe last longer?

To make your lathe last longer, keep it clean, well-lubricated, and aligned. Choose the right tools and replace them as needed. Regular checks can prevent bigger issues later.

Resources for Further Learning

Suggested manuals, online courses, and workshops for lathe operation and maintenance.. Communities and forums for machinists to exchange knowledge and experiences..If you want to dive deeper into lathe operations, there are many resources at your fingertips! Consider picking up a few helpful manuals that explain everything from basic operation to advanced maintenance. You can also explore online courses that offer step-by-step guides—you’ll be turning metal like a pro in no time!

Don’t forget about workshops! They provide hands-on experience, and the chance to laugh at your own mistakes. Plus, communities and forums are gold mines for tips. It’s like having a bunch of wise friends sharing stories and helping you avoid their past mishaps.

| Resource Type | Names/Topics |

|---|---|

| Manuals | Machining Principles, Lathe Maintenance Guide |

| Online Courses | Udemy Lathe Training, Coursera Metalworking |

| Workshops | Community College Courses, Local Makerspaces |

| Forums | Machinist Network, Reddit’s r/Machinists |

These places have a wealth of information. You can learn from others, ask questions, and share your own experiences. The lathe world is vast, and with the right resources, you’ll excel in no time!

Conclusion

In conclusion, regular maintenance of your metal lathe ensures it runs smoothly and lasts longer. Always clean your lathe after use and check for wear and tear on parts. Lubricating moving components keeps everything working well. We encourage you to read more about lathe care and practice these tips. Happy machining, and take good care of your tools!FAQs

What Are The Essential Steps For Performing Routine Maintenance On A Metal Lathe?To take care of a metal lathe, you should follow these steps. First, clean the machine to remove dust and chips. Second, check the oil levels and add more if needed. Third, tighten any loose screws or parts. Lastly, inspect the belts and replace them if they look worn out. This keeps the lathe working well!

How Can I Identify And Troubleshoot Common Issues That Arise During Lathe Operation?To identify and fix problems when using a lathe, first listen for unusual sounds. Check if the machine is working smoothly. Look for any loose parts or pieces. You can also check the speed settings and make sure they are right. If something doesn’t feel or look right, ask for help from someone more experienced.

What Lubricants And Cleaning Agents Are Recommended For Maintaining A Metal Lathe?To take care of a metal lathe, you should use special oil for its moving parts. This oil helps everything run smoothly. For cleaning, use a soft cloth and a gentle cleaner that won’t hurt the metal. Make sure to keep the lathe free of dust and dirt. Always follow the instructions to keep it in good shape.

How Often Should The Bed, Carriage, And Tailstock Of A Metal Lathe Be Aligned And Calibrated?You should align and calibrate the bed, carriage, and tailstock of a metal lathe regularly. It’s a good idea to do this every few weeks. If you use the lathe a lot, check it more often. Always look for problems after big projects. Keeping everything aligned helps you make better pieces.

What Are The Safety Precautions To Consider While Maintaining And Cleaning A Metal Lathe?When you maintain and clean a metal lathe, always wear safety glasses to protect your eyes. Keep your hands away from moving parts. Make sure the machine is turned off and unplugged before you start cleaning it. Use a brush or cloth to remove dirt, and don’t use your hands to wipe it. Finally, keep your work area tidy to avoid tripping or accidents.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Steps For Performing Routine Maintenance On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To take care of a metal lathe, you should follow these steps. First, clean the machine to remove dust and chips. Second, check the oil levels and add more if needed. Third, tighten any loose screws or parts. Lastly, inspect the belts and replace them if they look worn out. This keeps the lathe working well!”}},{“@type”: “Question”,”name”: “How Can I Identify And Troubleshoot Common Issues That Arise During Lathe Operation? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To identify and fix problems when using a lathe, first listen for unusual sounds. Check if the machine is working smoothly. Look for any loose parts or pieces. You can also check the speed settings and make sure they are right. If something doesn’t feel or look right, ask for help from someone more experienced.”}},{“@type”: “Question”,”name”: “What Lubricants And Cleaning Agents Are Recommended For Maintaining A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To take care of a metal lathe, you should use special oil for its moving parts. This oil helps everything run smoothly. For cleaning, use a soft cloth and a gentle cleaner that won’t hurt the metal. Make sure to keep the lathe free of dust and dirt. Always follow the instructions to keep it in good shape.”}},{“@type”: “Question”,”name”: “How Often Should The Bed, Carriage, And Tailstock Of A Metal Lathe Be Aligned And Calibrated? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should align and calibrate the bed, carriage, and tailstock of a metal lathe regularly. It’s a good idea to do this every few weeks. If you use the lathe a lot, check it more often. Always look for problems after big projects. Keeping everything aligned helps you make better pieces.”}},{“@type”: “Question”,”name”: “What Are The Safety Precautions To Consider While Maintaining And Cleaning A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you maintain and clean a metal lathe, always wear safety glasses to protect your eyes. Keep your hands away from moving parts. Make sure the machine is turned off and unplugged before you start cleaning it. Use a brush or cloth to remove dirt, and don’t use your hands to wipe it. Finally, keep your work area tidy to avoid tripping or accidents.”}}]}