Have you ever wondered how metal parts are shaped with such precision? The answer often lies in a special tool called a lathe. This amazing machine can do more than you think!

One key part of the lathe is the tailstock. It holds tools and helps in making sure everything spins correctly. Without the tailstock, it would be tricky to get the job done right. Imagine trying to bake a cake without a mixing bowl—it just wouldn’t work!

Did you know that lathe machining has been around for thousands of years? Ancient craftsmen used simple lathes to create beautiful wood pieces. Today, we use advanced metal lathes to make everything from bike parts to airplane engines.

In this article, we will dive into the world of lathe machining and explore the important role of the metal lathe tailstock. Whether you are curious about how lathes work or just love learning new things, you’re in the right place!

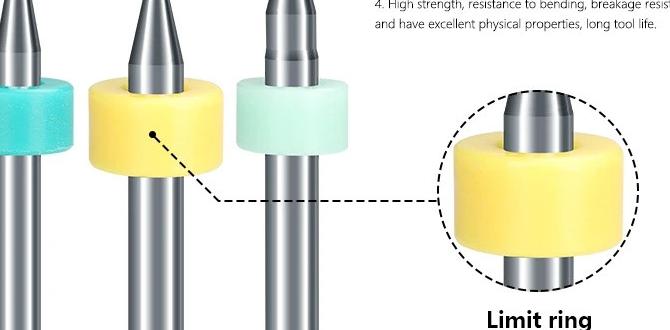

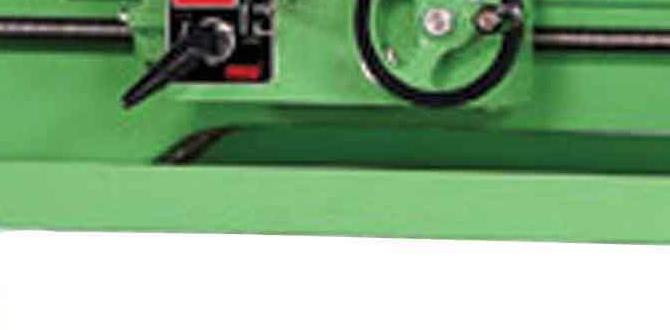

Lathe Machining: Understanding Metal Lathe Tailstock Functions Lathe Machining Is A Vital Process In Various Manufacturing Applications, Particularly In Metalworking Industries. One Of The Key Components That Plays An Essential Role In This Process Is The Metal Lathe Tailstock. The Tailstock Is Crucial For Supporting Workpieces And Accommodating Tools, Making It Indispensable For Achieving Precision And Accuracy. In This Article, We Will Delve Into The Function Of The Tailstock In Lathe Machining, Its Components, And Tips For Effective Usage. What Is A Metal Lathe Tailstock? The Tailstock Is A Movable Part Of A Lathe Machine, Located Opposite The Headstock. It Provides Support For The Workpiece And Allows For The Mounting Of Cutting Tools, Such As Drills And Reamers. The Primary Function Of The Tailstock Is To Hold The End Of The Workpiece Securely As It Rotates, Ensuring Stability During Machining Processes. Components Of The Metal Lathe Tailstock A Typical Metal Lathe Tailstock Consists Of Several Components: – **Tailstock Body**: The Main Part That Houses Other Components. – **Quill**: A Cylindrical Component That Can Move In And Out To Adjust The Position Of Tools. – **Locking Mechanism**: Usually A Handwheel Or Lever That Secures The Position Of The Quill. – **Center**: A Removable Piece That Can Hold Various Tools Or Centers For Drilling Operations. Functions Of The Tailstock In Lathe Machining 1. **Support For Workpieces**: The Tailstock Stabilizes The Workpiece, Preventing It From Flexing Or Vibrating During Machining. 2. **Tool Holding**: It Allows For The Use Of Various Tools, Enabling Additional Machining Operations Such As Drilling And Reaming. 3. **Alignment**: The Tailstock Can Help With Aligning The Workpiece With The Spindle For More Accurate Cuts. 4. **Adjustment For Length**: The Tailstock’S Adjustable Quill Allows Operators To Work On Longer Pieces, Enhancing Versatility. Tips For Using The Metal Lathe Tailstock – **Ensure Proper Alignment**: Always Check The Alignment Of The Tailstock With The Headstock Before Beginning Any Machining Operations. – **Secure The Workpiece**: Make Sure The Workpiece Is Tightly Secured In The Tailstock To Avoid Any Movement During Machining. – **Regular Maintenance**: Regularly Lubricate Moving Parts And Check For Wear To Maintain The Functionality Of The Tailstock. Conclusion The Metal Lathe Tailstock Is An Essential Component In Lathe Machining, Crucial For Achieving Precision And Stability During Operations. By Understanding Its Functions And Components, As Well As Following Best Practices For Use, Machinists Can Enhance Their Productivity And Produce High-Quality Workpieces. Whether You Are A Novice Or An Experienced Machinist, Mastering The Tailstock’S Capabilities Will Undoubtedly Improve Your Lathe Machining Skills.

Lathe Machining: Understanding the Metal Lathe Tailstock

Lathe machining plays a key role in shaping and cutting metal. The tailstock, an important part of the metal lathe, helps support the workpiece. It can hold tools like drills or centers securely in place. Did you know that the tailstock can also adjust to different lengths? This flexibility allows for various projects, making it essential in workshops. By learning about the tailstock, you can enhance your machining skills and create better designs.What is Lathe Machining?

Definition and basic principles of lathe machining. Applications in various industries.Lathe machining is a process that shapes materials, mostly metal, into a desired form using a rotating tool. Imagine a giant pencil sharpener for big people! The machine spins the material while a cutting tool removes excess bits. This technique is used in many industries, from making car parts to crafting fancy furniture. You’ll even find it in some musical instruments. A well-used lathe can work wonders, and it may just turn your metal dreams into reality!

| Industry | Application |

|---|---|

| Automotive | Manufacturing engine parts |

| Aerospace | Creating lightweight components |

| Furniture | Crafting unique table legs |

| Musical Instruments | Shaping wood and metal parts |

The Role of the Tailstock in Lathe Operations

Explanation of tailstock purpose and functionality. How the tailstock contributes to precision and stability during machining.The tailstock is a key player in lathe operations. It provides support for long workpieces, making sure they stay steady. Think of it as a trusty sidekick for your metal lathe. It holds tools like drills or reamers, enhancing precision. With the tailstock in place, your projects can become more accurate and less wobbly—like trying to balance on one leg while brushing your teeth! Without it, things could get messy, and we definitely want to avoid any metal acrobatics.

| Function | Benefit |

|---|---|

| Support for Workpieces | Enhances stability |

| Tool Holding | Improves precision |

| Adjustment | Allows ease of use |

In summary, the tailstock is vital for achieving high-quality results in machining. The role it plays should not be underestimated—think of it as the unsung hero of the lathe world!

Types of Tailstocks in Metal Lathes

Comparison of fixed and hydraulic tailstocks. Advantages and disadvantages of each type.There are two main types of tailstocks in metal lathes: fixed and hydraulic. Each has its benefits and drawbacks.

- Fixed Tailstocks: Easy to use. They are sturdy and require little maintenance. They are great for basic jobs but can’t adjust pressure easily.

- Hydraulic Tailstocks: Provide more control. They can adjust to different pressures for various tasks. However, they are more complex and may need more upkeep.

Choosing the right tailstock can make a big difference in how you work. Think about what type of projects you’ll be doing!

What is the difference between fixed and hydraulic tailstocks?

The main difference lies in their mechanism. Fixed tailstocks are simple and stable, while hydraulic tailstocks offer more flexibility and control.

No matter which type you use, understanding their features can help you make the best choice for your metalworking needs.

Setting Up the Tailstock for Machining

Stepbystep guide on tailstock alignment and adjustments. Tips for achieving optimal stability and accuracy.To set up your tailstock correctly, follow these simple steps:

- First, check if the tailstock is parallel to the lathe bed.

- Adjust the tailstock over the bed to find the right position.

- Use a dial indicator for precise measurements.

- Make small adjustments to achieve perfect alignment.

For stability, secure it tightly and check for any movement. This ensures accuracy while machining. Did you know that even a tiny misalignment can cause big problems? Keep everything straight for the best results!

What is the importance of tailstock alignment?

The tailstock alignment is crucial for producing accurate workpieces. Proper alignment prevents errors and enhances stability. Even small misalignments can lead to poor results. Always take a moment to check!

Common Issues with Lathe Tailstocks

Troubleshooting frequent problems such as misalignment or wear. Maintenance tips to prolong the life of the tailstock.Lathe tailstocks can be tricky little devils! Misalignment often happens when you don’t tighten it properly. This can lead to wobbly workpieces, which is not good. Regular checks can help you catch this early. If you notice wear, it may be time to replace parts. Maintenance is key! Simple cleaning and oiling can make your tailstock last longer. Think of it as giving your lathe a spa day. Here’s a handy table for quick tips:

| Issue | Solution |

|---|---|

| Misalignment | Tighten the tailstock. |

| Wear | Replace worn parts. |

| Sticking | Clean and oil regularly. |

Choosing the Right Tailstock for Your Metal Lathe

Key factors to consider when selecting a tailstock. Recommendations based on specific machining needs or projects.Picking the right tailstock for a metal lathe can seem tough, but it isn’t rocket science. First, think about the size you need. A good rule of thumb? Measure twice, order once! Check if the tailstock fits your lathe model. You’ll also want to consider how much force you need during operations. For heavy-duty tasks, pick a sturdy option. If you’re doing detail work, a finer one works better. Now, put on your thinking cap—let’s look at some recommendations!

| Project Type | Tailstock Recommendation |

|---|---|

| Heavy-duty machining | Look for a robust tailstock that supports high pressures. |

| Precision work | A finer, adjustable tailstock is your best buddy. |

Remember, the right choice can make your projects smoother than a freshly waxed floor!

Case Studies: Successful Applications of Tailstocks in Industry

Examples of how different industries leverage tailstock functionality. Lessons learned from practical applications and user experiences.Many industries use tailstocks for better precision and efficiency. In the automotive sector, tailstocks help in making parts fit perfectly. The aerospace industry benefits from them by ensuring safety and accuracy in components. Manufacturers report that tailstocks save time and reduce waste, leading to higher profits. Here are a few lessons learned:

- Tailstocks improve part stability during machining.

- They enhance overall machining efficiency.

- Users saw fewer errors, making operations smoother.

Conclusion

In summary, the lathe machining process, especially the tailstock, is crucial for precise metalwork. You can use the tailstock to support long materials and make accurate cuts. Understanding its function helps you improve your skills. We encourage you to explore more about lathes, practice regularly, and experiment with different projects to enhance your machining expertise. Happy learning!FAQs

What Is The Primary Function Of The Tailstock In A Metal Lathe, And How Does It Contribute To The Machining Process?The tailstock holds the other end of the metal piece we are working on. It helps keep the metal steady while we cut or shape it. This makes sure our work is smooth and accurate. Without the tailstock, the metal might wobble and not turn out right. It’s important for making good, clean pieces.

How Can You Adjust The Tailstock To Accommodate Different Workpiece Sizes And Ensure Proper Alignment During Turning Operations?You can adjust the tailstock by moving it closer or further away from the headstock. This lets you fit different sizes of workpieces. Make sure the workpiece is straight by checking the ends. Tighten the tailstock once everything looks right. This helps keep your project safe while you work.

What Are Some Common Accessories And Tools That Can Be Used With The Tailstock For Enhanced Precision In Metal Lathe Operations?Some common tools we can use with the tailstock to make our metal lathe work better are live centers and drills. Live centers help hold the metal piece steady while it spins. We can also use drill chucks to hold drill bits securely. Another useful tool is a steady rest, which supports the workpiece and keeps it straight. These tools help us make better, more accurate shapes.

How Do You Troubleshoot Common Issues That May Arise With The Tailstock, Such As Misalignment Or Difficulty In Locking It In Place?To fix problems with the tailstock, first check if it’s lined up straight. You can loosen the screws, adjust it, and tighten them again. If it’s hard to lock, look for dirt or sawdust in the lock and clean it out. Make sure the locking handle moves freely and isn’t stuck. Always test it after making changes to see if it works better!

What Safety Precautions Should Be Observed When Operating The Tailstock In A Metal Lathe To Prevent Accidents And Ensure Optimal Performance?When using the tailstock on a metal lathe, be careful. Always wear safety goggles to protect your eyes. Keep your hands and loose clothing away from moving parts. Make sure everything is tight and secure before starting. Also, always follow the machine’s instructions for safe operation.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Is The Primary Function Of The Tailstock In A Metal Lathe, And How Does It Contribute To The Machining Process? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The tailstock holds the other end of the metal piece we are working on. It helps keep the metal steady while we cut or shape it. This makes sure our work is smooth and accurate. Without the tailstock, the metal might wobble and not turn out right. It’s important for making good, clean pieces.”}},{“@type”: “Question”,”name”: “How Can You Adjust The Tailstock To Accommodate Different Workpiece Sizes And Ensure Proper Alignment During Turning Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can adjust the tailstock by moving it closer or further away from the headstock. This lets you fit different sizes of workpieces. Make sure the workpiece is straight by checking the ends. Tighten the tailstock once everything looks right. This helps keep your project safe while you work.”}},{“@type”: “Question”,”name”: “What Are Some Common Accessories And Tools That Can Be Used With The Tailstock For Enhanced Precision In Metal Lathe Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Some common tools we can use with the tailstock to make our metal lathe work better are live centers and drills. Live centers help hold the metal piece steady while it spins. We can also use drill chucks to hold drill bits securely. Another useful tool is a steady rest, which supports the workpiece and keeps it straight. These tools help us make better, more accurate shapes.”}},{“@type”: “Question”,”name”: “How Do You Troubleshoot Common Issues That May Arise With The Tailstock, Such As Misalignment Or Difficulty In Locking It In Place? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix problems with the tailstock, first check if it’s lined up straight. You can loosen the screws, adjust it, and tighten them again. If it’s hard to lock, look for dirt or sawdust in the lock and clean it out. Make sure the locking handle moves freely and isn’t stuck. Always test it after making changes to see if it works better!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Observed When Operating The Tailstock In A Metal Lathe To Prevent Accidents And Ensure Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using the tailstock on a metal lathe, be careful. Always wear safety goggles to protect your eyes. Keep your hands and loose clothing away from moving parts. Make sure everything is tight and secure before starting. Also, always follow the machine’s instructions for safe operation.”}}]}