Imagine you are in a workshop filled with machines. There’s a large, shiny tool sitting in the center. This tool is a metal lathe, and it helps shape metal into amazing forms. Have you ever wondered how this works?

The magic of lathe machining is in its details. One important feature is the threading dial. This small dial helps you create precise threads on metal pieces. Do you know why threads are so important? Threads allow parts to fit together tightly, making them stronger and more reliable.

Learning about lathe machining can feel like uncovering a treasure. It’s not just about turning metal; it’s about creating. Whether building machines or making art, this skill has endless possibilities. Would you like to know more about how the lathe machine works and how the threading dial plays a role? Let’s dive into the world of metal lathes together!

Mastering Lathe Machining: Metal Lathe Threading Dial Techniques

Lathe Machining: Understanding Metal Lathe Threading Dial

Lathe machining is vital for shaping metal. The metal lathe threading dial makes it easier to create precise threads. By using this tool, you can produce accurate parts for many projects. Imagine making a screw that fits perfectly every time. It’s like solving a puzzle! Interestingly, many people don’t realize how essential threading is in everyday items. Whether it’s a bicycle or a shelf, threaded parts hold them together. Learning about this process opens new possibilities in metalworking.Understanding Lathe Machining

Definition of lathe machining and its importance in metalworking. Types of lathes and their applications in various industries.Lathe machining shapes and cuts metal to create parts. It spins the material, using tools to remove unwanted bits. This method is essential in metalworking and helps make smooth, precise pieces. There are several types of lathes:

- Engine Lathes: Great for general work.

- CNC Lathes: Automated for high production.

- Turret Lathes: For rapid tool changes.

- Bench Lathes: Small and used for light projects.

Industries like automotive, aerospace, and manufacturing rely on lathe machining. It allows for accuracy and efficiency, making it a key part of production processes.

What is lathe machining used for?

Lathe machining is used to create various parts, tools, and shapes in many industries, including automotive, woodworking, and aerospace.

Getting Started with Metal Lathe Threading

Explanation of threading and its significance in machining. Types of threads created with a metal lathe.Threading is a crucial technique in machining. It creates grooves in materials like metal, allowing parts to fit together. It’s like making a screw! There are different types of threads:

- External threads: These are on the outside of a cylinder, like a bolt.

- Internal threads: Found inside a hole, like in a nut.

- Unified threads: Commonly used in the U.S. for screws and fasteners.

- Metric threads: Used worldwide, measured in millimeters.

Knowing threading is key for precise work. It helps build strong and functional parts in machines.

What is threading in machining?

Threading is the process of cutting precise grooves in metal to make screws and bolts fit tightly.

Setting Up Your Lathe for Threading

Stepbystep guide to preparing the lathe for threading operations. Importance of tool selection and setup for successful threading.Before threading, you must prepare your lathe properly. Start by choosing the right tools. This choice affects the threading quality. Next, ensure the lathe is clean and all parts are working well. Follow these steps:

- Check the lathe for any damage.

- Set the correct speed for your material.

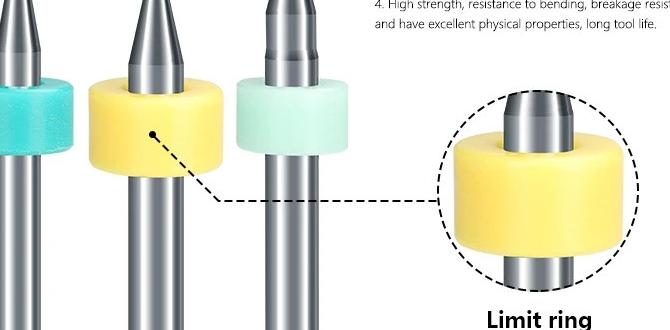

- Adjust the threading dial to the right position.

- Install the threading tool securely.

Each step is important for smooth threading. Take your time to do it right!

What tools do I need for lathe threading?

You will need a threading tool, a cutting tool, and essential measuring tools. Choosing the right tool ensures better results and smoother threads.

Calibrating the Threading Dial

Detailed instructions on calibrating the threading dial for accuracy. Common issues during calibration and how to troubleshoot them.To calibrate the threading dial, start by measuring the current settings. Align the dial to zero. Then, make minor adjustments until the dial reads correctly during threading. Common problems include incorrect readings or dial sticking. If this happens, check for dirt or loose parts. Clean the dial and ensure everything is tight. Remember, accuracy matters for clean threads!

What are common issues during calibration?

Common issues include inaccurate readings or the dial getting stuck. Clean the area and check for loose connections to fix these problems.Tips for Troubleshooting:

- Check for debris on the dial.

- Ensure all connections are tight.

- Reset the dial to zero for accurate calibration.

Threading Techniques and Best Practices

Discussion of various threading techniques applicable to metal lathes. Tips for achieving precision and consistency in threading.It’s threading time! Metal lathes can do some cool tricks with different threading techniques. You’ve got the classic single-point threading, perfect for simple jobs. Want to impress? Try lead screw threads for a smoother ride! To make precision your best buddy, always check your settings and keep that sharp tool close. A little tip? Turn your dial slowly and watch for those shiny threads to pop out. Remember, it’s not a race; it’s a dance!

| Technique | Best For | Tip |

|---|---|---|

| Single-Point | Basic projects | Keep it steady! |

| Lead Screw Threads | Smoother finishes | Slow and steady wins! |

Maintenance and Care for Metal Lathes

Recommended maintenance practices to prolong the lifespan of your lathe. Signs that indicate the need for repairs or professional servicing.To keep your metal lathe in great shape, regular maintenance is essential. Simple steps can extend its life. Check for loose parts and clean the machine often. Lubricate moving parts to prevent wear. Look for signs like strange noises or rough movements. These can mean it needs repairs. Keeping a regular schedule of checks can save you time and money.

- Clean the lathe regularly.

- Inspect for any loose components.

- Oil moving parts often.

What are common signs that your lathe needs repair?

Signs include strange noises, uneven cuts, or difficulty in turning. If you notice these issues, seek help quickly.

Safety Considerations in Lathe Machining

Essential safety protocols to follow when operating a lathe. Personal protective equipment (PPE) recommendations for lathe operators.Using a lathe can be exciting, but safety must come first! Always keep your hair tied back and wear goggles to protect your eyes from tiny flying metal bits. Don’t forget your gloves—they’re not just for fancy dinners! You will also need sturdy shoes to keep your toes safe from heavy equipment. Following these simple rules can help you avoid accidents while having fun with metal. After all, nobody wants to go home with a finger less than what they started with!

| Safety Gear | Purpose |

|---|---|

| Goggles | Protect eyes from shavings |

| Gloves | Guard hands from cuts |

| Sturdy Shoes | Protect feet from heavy items |

Remember, having the right gear makes you a cool lathe operator and keeps your fingers intact!

Conclusion

In summary, using a lathe for machining and threading is essential for creating precise metal parts. The threading dial helps you set accurate measurements. With practice, you can master these techniques. We encourage you to explore more about lathe operations and try your hand at simple projects. Learning through hands-on experience is the best way to improve!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Machining, Specifically Focusing On Metal Lathe Threading Dials:Sure! A lathe is a tool that spins metal to cut it into shapes. The threading dial helps us create grooves in the metal. You can adjust the dial to make sure the grooves are even. It makes our work more accurate and easier. We use it to make things like screws or bolts!

Sure! Please provide the question you’d like me to answer.

What Is The Primary Function Of A Threading Dial On A Metal Lathe, And How Does It Assist In The Threading Process?The threading dial on a metal lathe helps you make threads on a metal piece. It shows you the right spot to start cutting threads. You can easily line up the cuts so they are even and neat. Without the dial, you might make mistakes and the threads wouldn’t fit right. So, it makes threading simpler and more accurate!

How Do You Properly Set The Threading Dial On A Metal Lathe Before Starting A Threading Operation?To set the threading dial on a metal lathe, first, bring the tool close to the workpiece. Next, turn the threading dial until the marker points to zero. Then, you can move the carriage until the tool touches the material. Finally, make sure to start the lathe and engage the threading mechanism. Now you’re ready to begin threading!

What Are The Different Types Of Threading Dials Commonly Used In Metal Lathe Operations, And How Do They Differ In Functionality?There are a few types of threading dials used on metal lathes. One type is the “1:1 dial,” which matches the distance you move the carriage. Another type is the “2:1 dial,” which moves twice as far with each turn. Lastly, there’s the “4:1 dial,” which moves four times farther. Each type helps you make precise threads, but they work a bit differently based on how they measure.

What Are The Advantages Of Using A Threading Dial Compared To Other Methods Of Achieving Accurate Thread Pitch On A Lathe?Using a threading dial makes cutting threads on a lathe easier and more accurate. You can quickly line up the tool with the right spot. It helps you avoid mistakes, so your threads fit better. Other methods can take longer and be less precise. With a threading dial, you get great results faster!

How Can Improper Use Of The Threading Dial Affect The Outcome Of A Threading Operation On A Metal Lathe?If you don’t use the threading dial correctly, your threads can be uneven. This can make them weak or not fit together well. You might end up ruining your workpiece. It’s important to pay attention and follow the right steps so everything fits just right. Always check your settings before you start!