Have you ever wondered how a piece of metal turns into a beautiful, precise shape? Lathe machining is one popular way to do this. Many people enjoy working with machines, especially metal lathes. But how does one operate these machines safely and effectively? That’s where a lathe wiring diagram comes into play.

A lathe wiring diagram shows you how to connect the components of your machine. It might seem complicated at first, but it helps you understand everything better. Imagine working on your metal lathe, and suddenly, you need to replace a part. With a good wiring diagram, you can easily find the right connections.

Did you know that the first lathe dates back to ancient Egypt? This amazing tool has evolved over thousands of years. Yet, the core principles of lathe machining remain the same. Understanding wiring is crucial if you want to keep creating and perfecting your skills.

So, whether you are starting out or have experience, knowing about lathe machining and wiring diagrams is essential. Are you ready to dive into the fascinating world of metal lathes?

Lathe Machining Metal Lathe Wiring Diagram Explained

Lathe Machining Metal Lathe Wiring Diagram

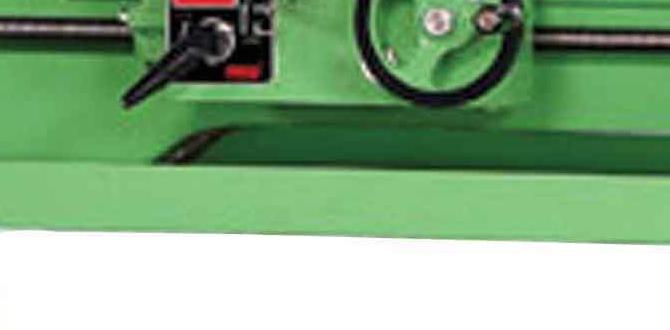

A lathe machining metal lathe wiring diagram shows how to connect different parts of a lathe. Understanding this diagram helps users set up their machines safely and efficiently. Did you know that improper wiring can lead to equipment damage or even accidents? This knowledge is crucial for anyone looking to start machining. Proper wiring ensures smooth operation, prolonging the lathe’s life. Whether you’re a hobbyist or a professional, learning about wiring diagrams enhances your skills and boosts confidence!Components of a Metal Lathe

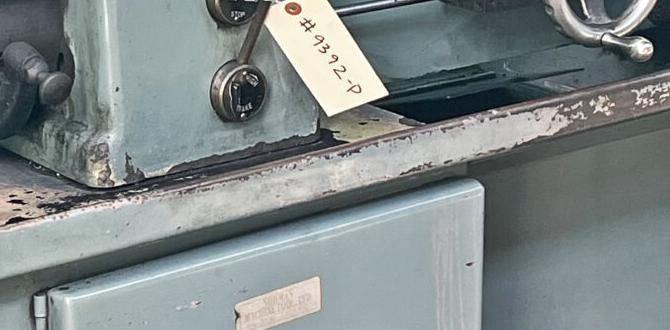

Detailed description of essential parts of a metal lathe.. Functionality of parts such as the headstock, tailstock, and carriage..A metal lathe has some important parts that help it work well. The headstock is like the brain. It holds the motor and spins the workpiece. Next comes the tailstock. This part supports the other end of the material you are shaping. Lastly, the carriage moves the cutting tool across the workpiece. Together, these parts make magic happen, turning blocks of metal into beautiful, useful items!

| Component | Function |

|---|---|

| Headstock | Holds the motor and spins the workpiece |

| Tailstock | Supports the opposite end of the material |

| Carriage | Moves the cutting tool for shaping |

Understanding the Wiring Diagram

Explanation of the purpose of a wiring diagram in lathe operation.. Key symbols and terminology used in wiring diagrams..A wiring diagram shows how different parts of a lathe are connected. This helps users understand the machine’s operation. Key symbols represent different electrical elements, making it easier to follow. Knowing these symbols is like learning a new language for machines.

- Lines: Represent wires connecting parts.

- Circles: Show points where connections happen.

- Squiggly lines: Indicate components like resistors.

Understanding the wiring diagram is essential for safe and effective lathe use. It simplifies troubleshooting and repairs, helping workers keep machines running smoothly.

What is the purpose of a wiring diagram?

A wiring diagram’s purpose is to illustrate connections and functions in machines. It ensures correct setup and helps troubleshoot problems quickly.

Key Symbols Found in Wiring Diagrams:

- Power Source: Shows where electricity comes from.

- Ground: Indicates a safe electrical path.

How to Read a Metal Lathe Wiring Diagram

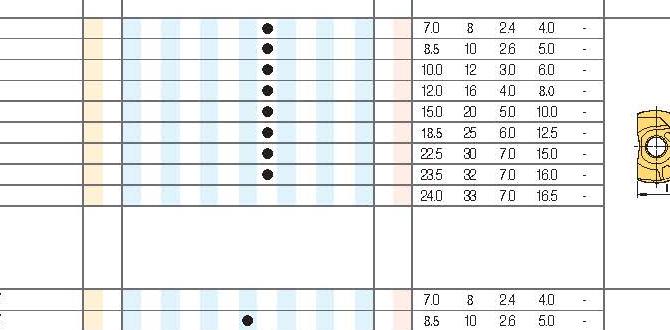

Stepbystep breakdown of reading wiring diagrams specific to metal lathes.. Common wiring setups and their configurations..Reading a metal lathe wiring diagram can feel like decoding a secret message. Start by familiarizing yourself with symbols. Each symbol stands for a different part of the machine. Next, check the layout—wires connect various components like the motor and controls. Don’t be surprised if it looks like a spider’s web; that’s normal! Here’s a simple visual aid to help you:

| Component | Symbol |

|---|---|

| Motor | 🔌 |

| Switch | 🔄 |

| Power Supply | ⚡ |

Common wiring setups often include thermal overloads and fuses. Remember, following safety rules is key; nobody wants a shocking surprise! If you encounter any confusion, don’t hesitate to refer back to your diagram. Like a map, it guides you through the land of metal lathes!

Wiring a Metal Lathe: Step-by-Step Guide

Detailed instructions for wiring a metal lathe from scratch.. Safety precautions and best practices during the wiring process..Wiring a metal lathe might seem tricky, but it’s really just like connecting the dots—only these dots can spin metal! First, gather all your tools and components; safety gloves are a must. Check the machine’s manual for the specific wiring diagram. Look out for loose wires, so nothing gets zapped. Here are some key steps:

| Step | Action |

|---|---|

| 1 | Turn off the power before you start. |

| 2 | Connect the power supply wires to the motor. |

| 3 | Secure all connections and check them twice. |

Always remember, it’s better to be safe than zapped! A little caution goes a long way. If you’re confused, ask a buddy or check online resources. Everyone needs a helping hand from time to time, just like a lathe needs a good motor!

Troubleshooting Common Wiring Issues

Identifying common problems in metal lathe wiring.. Solutions and fixes for various wiring complications..Wiring issues in a metal lathe can cause frustration. Look for signs like strange sounds, sparks, or lights not working. These can help you spot problems. Here are some common issues and easy fixes:

- Check for loose connections. Tighten any loose screws or wires.

- Inspect cables for damage. Replace any frayed wires.

- Look for blown fuses. Replacing them can solve power issues.

Always remember safety first. Unplug your lathe before checking wires. This keeps you safe from electric shocks.

What are common wiring issues with metal lathes?

Common wiring issues include loose connections, damaged cables, and blown fuses.How can I fix these wiring problems?

You can fix these by tightening loose screws, replacing damaged wires, and changing blown fuses.Maintenance Tips for Metal Lathe Wiring

Recommendations for regular maintenance of wiring systems.. Signs that indicate the need for wiring repairs or replacements..Keeping the wiring of your metal lathe in good shape is important. Regular maintenance can help avoid problems. Check for any loose connections or frayed wires. These could cause safety hazards. Look for signs like strange noises or sparks.

- Inspect wiring often for wear and tear.

- Replace damaged wires quickly.

- Keep your work area clean and dry.

By staying on top of these tasks, you can keep your machine running smoothly.

What are signs that wiring needs repair?

Watch for flickering lights, burning smells, or exposed wires. These might mean it’s time for repairs.

Resources for Further Learning

Recommended books, websites, and forums for metal lathe enthusiasts.. Online courses or tutorials on wiring and lathe machining techniques..If you’re eager to dive deeper into the world of metal lathe machining, you’re in luck! Check out some fantastic resources. Books like “The Machinist’s Bedside Manual” and “Metalworking for Beginners” offer great tips. You can also explore websites like “Machinists Network” for community support. Online courses, like those from Skillshare or Udemy, have classes on wiring and techniques. Just don’t mix up your lathe wires with your spaghetti! Here’s a quick table for easy access:

| Resource Type | Name | Link |

|---|---|---|

| Book | Machinist’s Bedside Manual | Link |

| Website | Machinists Network | Link |

| Online Course | Wiring and Lathe Techniques | Link |

So grab your tools and let’s get learning!

Conclusion

In conclusion, understanding a lathe machining metal lathe wiring diagram is essential for safe and effective operation. You learned about the key components and their connections. Remember to always follow safety guidelines when working with machinery. For more tips and visuals, consider reading additional resources or guides. Dive deeper and enhance your skills with practical projects!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Machining And Metal Lathe Wiring Diagrams:Sure! Here are some questions about lathe machining and metal lathe wiring diagrams that you might find interesting: 1. What is a lathe? A lathe is a machine that rotates metal to shape it into different forms. 2. Why do we use lathe machining? We use lathe machining to make precise and smooth parts from metal. 3. How does a metal lathe work? A metal lathe works by spinning a piece of metal while cutting it with a tool. 4. What is a wiring diagram? A wiring diagram shows how to connect wires in a machine, like a lathe. 5. Why are wiring diagrams important? Wiring diagrams are important because they help us understand how to safely connect parts and troubleshoot problems.

Sure! Please share the question you want me to answer, and I’ll help you out.

What Are The Essential Components Involved In A Metal Lathe Wiring Diagram?A metal lathe wiring diagram shows how to connect different parts. You need a power source, which gives electricity. Then, there are switches to turn the lathe on and off. Wires connect everything together, helping it work. Lastly, motors help move the lathe’s parts.

How Do You Interpret The Electrical Schematics In A Lathe Wiring Diagram For Troubleshooting Purposes?To read a lathe wiring diagram, you first look for the power source. This shows where electricity comes from. Next, follow the lines to see how they connect to different parts like the motor and switches. You should check for signs of breaks or problems along these lines. Finally, you confirm that everything is connected correctly for the machine to work.

What Safety Precautions Should Be Taken When Wiring A Metal Lathe?When wiring a metal lathe, you should always turn off the power first. Make sure your hands are dry and wear safety gloves. Check that there are no loose wires or broken parts. Keep your work area clean to avoid trips and falls. Finally, always follow the instructions carefully to stay safe!

How Can You Modify A Standard Wiring Diagram To Accommodate A Digital Control System For A Metal Lathe?To change a standard wiring diagram for a metal lathe, you need to add new parts. First, draw where the digital control box will go. Next, connect wires from the control box to the motor and other parts. You might also need to change some power sources, so everything works with the new system. Lastly, check your changes to make sure everything is safe and works well.

What Common Wiring Issues Can Occur In A Metal Lathe, And How Can They Be Diagnosed Using The Wiring Diagram?Common wiring issues in a metal lathe include loose connections and broken wires. You might see parts not working or strange noises. To find the problem, look at the wiring diagram. This diagram shows where each wire goes. You can check if any wires are loose or damaged.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Machining And Metal Lathe Wiring Diagrams:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some questions about lathe machining and metal lathe wiring diagrams that you might find interesting: 1. What is a lathe? A lathe is a machine that rotates metal to shape it into different forms. 2. Why do we use lathe machining? We use lathe machining to make precise and smooth parts from metal. 3. How does a metal lathe work? A metal lathe works by spinning a piece of metal while cutting it with a tool. 4. What is a wiring diagram? A wiring diagram shows how to connect wires in a machine, like a lathe. 5. Why are wiring diagrams important? Wiring diagrams are important because they help us understand how to safely connect parts and troubleshoot problems. “}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you want me to answer, and I’ll help you out.”}},{“@type”: “Question”,”name”: “What Are The Essential Components Involved In A Metal Lathe Wiring Diagram?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe wiring diagram shows how to connect different parts. You need a power source, which gives electricity. Then, there are switches to turn the lathe on and off. Wires connect everything together, helping it work. Lastly, motors help move the lathe’s parts.”}},{“@type”: “Question”,”name”: “How Do You Interpret The Electrical Schematics In A Lathe Wiring Diagram For Troubleshooting Purposes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To read a lathe wiring diagram, you first look for the power source. This shows where electricity comes from. Next, follow the lines to see how they connect to different parts like the motor and switches. You should check for signs of breaks or problems along these lines. Finally, you confirm that everything is connected correctly for the machine to work.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Wiring A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When wiring a metal lathe, you should always turn off the power first. Make sure your hands are dry and wear safety gloves. Check that there are no loose wires or broken parts. Keep your work area clean to avoid trips and falls. Finally, always follow the instructions carefully to stay safe!”}},{“@type”: “Question”,”name”: “How Can You Modify A Standard Wiring Diagram To Accommodate A Digital Control System For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To change a standard wiring diagram for a metal lathe, you need to add new parts. First, draw where the digital control box will go. Next, connect wires from the control box to the motor and other parts. You might also need to change some power sources, so everything works with the new system. Lastly, check your changes to make sure everything is safe and works well.”}},{“@type”: “Question”,”name”: “What Common Wiring Issues Can Occur In A Metal Lathe, And How Can They Be Diagnosed Using The Wiring Diagram?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common wiring issues in a metal lathe include loose connections and broken wires. You might see parts not working or strange noises. To find the problem, look at the wiring diagram. This diagram shows where each wire goes. You can check if any wires are loose or damaged.”}}]}