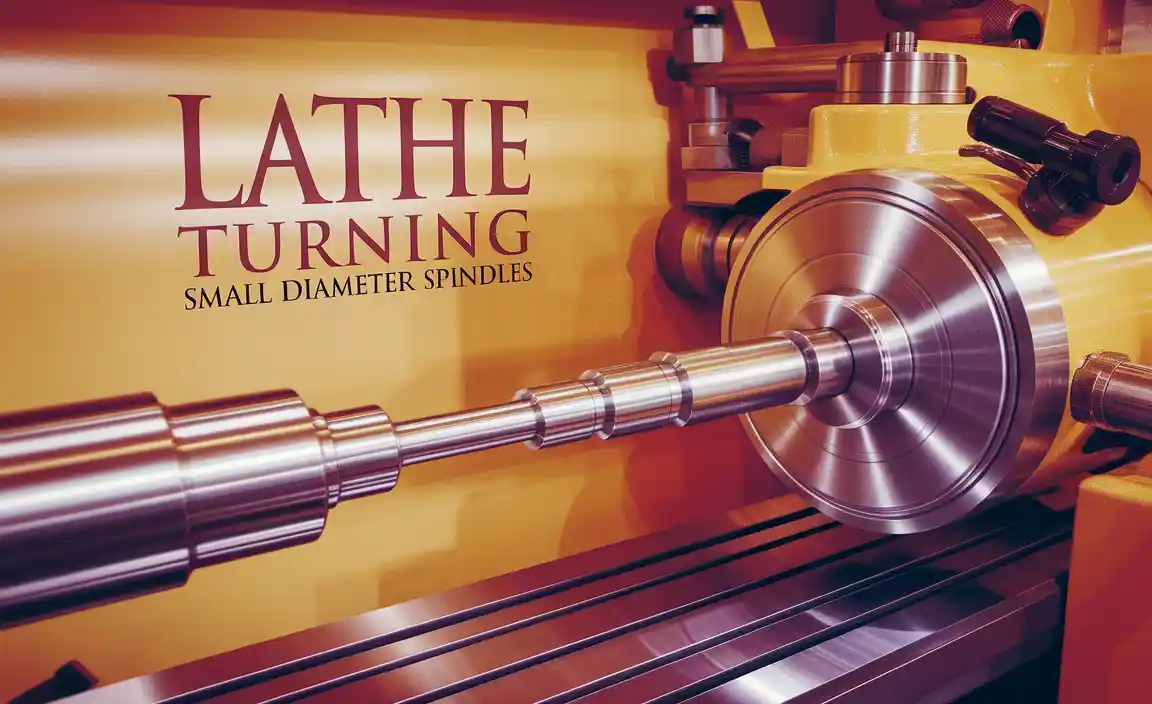

Have you ever seen a piece of metal change shape right before your eyes? That’s the magic of using a lathe. A metal lathe allows people to create precise shapes and designs in metal. It spins metal while sharp tools cut into it. This process transforms simple metal rods into beautiful and functional pieces.

Imagine a blacksmith or an artist shaping metal with their hands. What if they could achieve even more with a machine? That’s where the metal lathe comes in. It can make everything from tool handles to parts for machines.

Did you know this tool has been around for thousands of years? Ancient Egyptians used it to create furniture and ornaments! Today, it continues to be a go-to tool for hobbyists and professionals alike.

In this article, let’s explore how lathe metal shaping can ignite your creativity and enhance your projects. Get ready to dive into the world of metal lathes and discover their fascinating journey!

Lathe Metal Shaping: Unlocking The Power Of Metal Lathes

Lathe Metal Shaping: Mastery of the Metal Lathe

A metal lathe is a powerful tool for shaping various metal pieces. It works by spinning the material while sharp tools cut away excess metal. Did you know this method can create everything from car parts to intricate jewelry? With a metal lathe, precision matters. Users can design unique shapes and sizes by adjusting the speed and angle. This skill is essential for hobbyists and professionals alike. Imagine crafting custom pieces that fit perfectly every time!Understanding the Basics of Metal Lathes

Definition and function of a metal lathe. Key components and their roles in operation.A metal lathe is a machine that helps shape metal into various parts. Imagine a giant ice cream cone maker, but instead of ice cream, it’s spinning metal! The lathe holds the metal while it spins. Key parts include the spindle, which rotates the metal, and the tool rest, where the cutting tool sits. Together, they work like a team, turning a simple chunk of metal into something useful—like a new bike part!

| Component | Function |

|---|---|

| Spindle | Holds and rotates the metal. |

| Tool Rest | Supports the cutting tool. |

| Tailstock | Holds tools for drilling. |

Essential Metal Lathe Techniques

Explanation of turning, facing, and boring techniques. Tips for achieving precision in shaping metal.Metal shaping is like magic, but with machines! To shape metal correctly, learn three main techniques: turning, facing, and boring. Turning is when the metal spins and a tool cuts it, creating smooth pieces. Facing flattens the front of a piece like a pancake, making it neat. Meanwhile, Boring enlarges holes to fit your needs. For precision, always stay focused, measure twice, and cut once—like your mom’s advice but with a twist. And remember, a steady hand makes a happy metal lathe!

| Technique | Description | Tip for Precision |

|---|---|---|

| Turning | Material spins as the tool cuts. | Stay steady and check measurements! |

| Facing | Flattens the surface of the metal. | Use a light touch for a smooth finish. |

| Boring | Enlarges holes in the metal. | Go slowly to avoid mistakes! |

Selecting the Right Lathe for Your Project

Factors to consider based on project requirements. Recommended models for different skill levels.Choosing the perfect lathe for your project can feel like finding a needle in a haystack. First, think about your project requirements. If you’re working on tiny parts, a mini lathe is ideal. For larger work, consider a full-sized one. Next, your skill level matters. Beginners need simple models, while pros might want more features. Here’s a handy table to help you decide:

| Skill Level | Recommended Lathe |

|---|---|

| Beginner | Mini Lathe |

| Intermediate | Mid-Size Lathe |

| Advanced | Industrial Lathe |

Select wisely, and you’ll turn metal like a pro in no time. Just remember, a great lathe is like an umbrella in a storm—it makes all the difference!

Safety Practices When Using a Lathe

Key safety measures to prevent accidents. Recommended personal protective equipment (PPE).Using a lathe can be fun, but safety first! Key safety practices help keep everyone safe. Always wear personal protective equipment (PPE), like goggles and gloves. They make you look cool while keeping your hands and eyes safe. Before starting, check for loose clothing and hair that could get caught. Remember, your safety is number one; don’t let your creativity turn you into a human pretzel!

| Safety Measure | Description |

|---|---|

| Wear Goggles | Protects your eyes from flying debris. |

| Use Gloves | Keeps your hands safe from sharp edges. |

| Check Clothing | No loose clothing or long hair! |

Common Problems and Troubleshooting Tips

Identifying common issues faced while lathe machining. Solutions for maintaining optimal performance.Using a lathe can sometimes feel like a wild ride. Common hiccups like uneven cuts or strange noises can happen, and they can be a real head-scratcher. Don’t be alarmed! It’s often a sign that something needs a little TLC. Checking the tool sharpness and ensuring everything is tightly secured can work wonders. If you’re finding your metal shaping is more ‘wobble’ than ‘wonder,’ try adjusting your speed or your feed rate. Remember, *happy lathe, happy shape*! Below is a table to help you spot issues and solutions.

| Common Issues | Possible Solutions |

|---|---|

| Uneven cuts | Check tool sharpness and alignment. |

| Vibrations | Tighten all parts and check the balance. |

| Noisy operation | Lubricate moving parts and inspect components. |

| Overheating | Reduce speed and apply coolant if needed. |

Future Trends in Metal Lathe Technology

Innovations in lathe design and functionality. The impact of automation and smart technology on metal shaping.Exciting changes are happening in metal lathe technology! New designs are making lathes more powerful and efficient. They are like superheroes of the workshop, shaping metal with ease. Automation is taking over too. Imagine a lathe that can think for itself! With smart technology, lathes can work faster and better. This means less time working and more time to enjoy snacks! Here’s a quick laugh: Why did the lathe bring a pencil? To draw its own conclusions!

| Innovation | Benefit |

|---|---|

| Improved Design | More efficiency |

| Automation | Faster production |

| Smart Technology | Less human error |

These features will reshape how we think about metalworking. With these innovations, the future looks shiny and bright!

Conclusion

In summary, a lathe is a powerful tool for shaping metal. It spins material while cutting tools create precise shapes. You can use a metal lathe for various projects, from small parts to larger designs. To get started, consider finding a local workshop or online tutorials. With practice, you’ll master this skill and create amazing metalwork!FAQs

What Are The Key Components And Functions Of A Metal Lathe Used For Shaping Metal?A metal lathe has some key parts. The main part is the bed, which holds everything in place. There’s a motor that spins the metal. We use cutting tools to shape the metal as it turns. The tailstock helps support long pieces of metal while we work on them.

How Do You Set Up A Metal Lathe For Machining Different Types Of Metal Materials?To set up a metal lathe, start by choosing the right tool for the metal you are using. Next, secure the metal piece firmly in the machine. Then, adjust the speed based on how hard the metal is. Finally, check the cutting tool to make sure it’s sharp and suited for that metal type. Once everything is ready, you can start machining!

What Are The Common Techniques And Tools Used For Shaping Metal On A Lathe?To shape metal on a lathe, you can use different tools and techniques. One common tool is the cutting tool, which helps remove metal to create shapes. We also use a technique called turning, where the metal spins, and the tool cuts it. Another technique is drilling, which makes holes in the metal. Finally, sanding helps smooth out the metal’s surface.

How Do You Ensure Precision And Accuracy When Using A Metal Lathe For Metal Shaping Projects?To ensure precision and accuracy on a metal lathe, you should first measure your pieces carefully with a ruler or caliper. Always set the machine properly before starting. Keep your tools sharp and clean to make smooth cuts. Finally, double-check your work frequently as you go along. This way, you can catch any mistakes early.

What Safety Precautions Should Be Taken When Operating A Metal Lathe To Prevent Accidents And Injuries?When using a metal lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and remove loose clothing so nothing gets caught. Make sure the machine is turned off before you measure or change tools. Never reach over moving parts, and keep your hands away from the spinning workpiece. Following these rules helps keep you safe while working.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Components And Functions Of A Metal Lathe Used For Shaping Metal? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe has some key parts. The main part is the bed, which holds everything in place. There’s a motor that spins the metal. We use cutting tools to shape the metal as it turns. The tailstock helps support long pieces of metal while we work on them.”}},{“@type”: “Question”,”name”: “How Do You Set Up A Metal Lathe For Machining Different Types Of Metal Materials? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe, start by choosing the right tool for the metal you are using. Next, secure the metal piece firmly in the machine. Then, adjust the speed based on how hard the metal is. Finally, check the cutting tool to make sure it’s sharp and suited for that metal type. Once everything is ready, you can start machining!”}},{“@type”: “Question”,”name”: “What Are The Common Techniques And Tools Used For Shaping Metal On A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To shape metal on a lathe, you can use different tools and techniques. One common tool is the cutting tool, which helps remove metal to create shapes. We also use a technique called turning, where the metal spins, and the tool cuts it. Another technique is drilling, which makes holes in the metal. Finally, sanding helps smooth out the metal’s surface.”}},{“@type”: “Question”,”name”: “How Do You Ensure Precision And Accuracy When Using A Metal Lathe For Metal Shaping Projects? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To ensure precision and accuracy on a metal lathe, you should first measure your pieces carefully with a ruler or caliper. Always set the machine properly before starting. Keep your tools sharp and clean to make smooth cuts. Finally, double-check your work frequently as you go along. This way, you can catch any mistakes early.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Metal Lathe To Prevent Accidents And Injuries? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and remove loose clothing so nothing gets caught. Make sure the machine is turned off before you measure or change tools. Never reach over moving parts, and keep your hands away from the spinning workpiece. Following these rules helps keep you safe while working.”}}]}