Have you ever wondered how metal parts are made? One essential tool in shaping metal is a lathe. A lathe can carve and create different shapes from metal blocks. But what is a lathe exactly, and how does it work?

The lathe metal shaping process is fascinating. It’s like magic! You start with a solid piece of metal, place it on the lathe bed, and watch as it transforms into something new. Imagine a rough block slowly becoming a smooth cylinder.

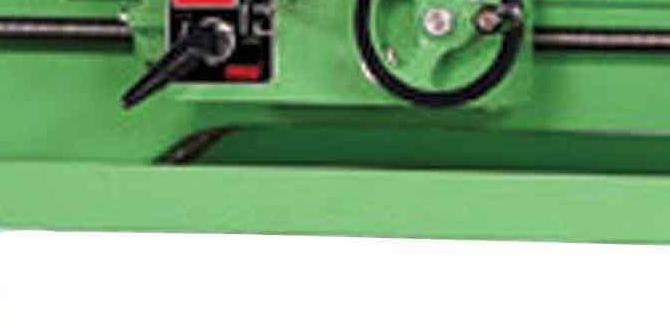

Did you know that the bed of a lathe is crucial for its performance? It supports the parts and helps keep them steady. This is important for making precise cuts. Without a sturdy lathe bed, the metal shaping process would be much harder.

Many people enjoy working with lathes. Hobbyists and professionals alike find joy in creating metal pieces. Whether it’s a small knob or a complex gear, lathes are the heart of metal shaping.

Join us as we dive deeper into how lathe metal shaping works and discover the secrets behind the lathe bed. You might just find a new hobby waiting for you!

Lathe Metal Shaping: Understanding The Metal Lathe Bed

Understanding the Metal Lathe Bed

The metal lathe bed is a crucial part of any metal shaping machine. It supports the entire lathe and keeps everything steady while working. Did you know that a strong lathe bed can enhance precision and reduce vibrations? This stability helps create smooth, accurate shapes. Choosing the right lathe bed material, like cast iron, makes a big difference in performance. It’s like building a strong foundation for a house; a good bed supports everything else!Types of Metal Lathe Beds

Description of different lathe bed designs: flat, V, and hybrid beds.. Advantages and disadvantages of each type..There are three main types of lathe beds: flat, V, and hybrid. Each design has its own benefits and drawbacks.

- Flat Bed: Great for simple tasks. It’s easy to build and very stable. But it may not support heavier parts well.

- V Bed: The V shape gives better support and accuracy. It handles heavy work better. However, it can cost more to make and repair.

- Hybrid Bed: This design combines features of both. It offers flexibility and strength. But it might be more complex to use.

Choosing the right lathe bed design depends on the work you need to do. Consider what is best for your projects!

What is a flat bed lathe?

A flat bed lathe has a flat surface designed for basic machining tasks. It is straightforward to use, making it popular for beginners.

Why would I choose a V bed lathe?

A V bed lathe provides superior stability and precision. It is ideal for heavy-duty work requiring high accuracy.

What are the benefits of a hybrid bed lathe?

Hybrid bed lathes offer versatility and performance. They can handle various types of projects, combining the best features of flat and V beds.

Key Features of a Quality Lathe Bed

Importance of rigidity and stability for precision.. Materials commonly used in lathe bed construction and their impact on performance..Strong and stable lathe beds are vital for precise metal shaping. A solid build keeps tools steady and reduces vibrations. This ensures every cut is accurate and clean. Common materials used for lathe beds include:

- Cast Iron: Known for its durability and excellent vibration absorption.

- Steel: Offers strength and resilience, ideal for heavy machining.

- Granite: Provides high stability, but is less common due to cost.

Using the right material enhances performance. It means fewer mistakes and better results.

Why is rigidity and stability important?

Rigidity and stability ensure that tools do not move unexpectedly, leading to accurate work and cleaner finishes.

What materials affect lathe bed performance?

The material choice impacts the lathe bed’s strength, vibration levels, and overall durability.

Maintenance Tips for Metal Lathe Beds

Regular inspection practices to ensure longevity and accuracy.. Recommended cleaning and lubrication methods..Keeping your metal lathe bed happy is key to its performance. Regular checks are vital. Look for any signs of wear or damage, and make sure all parts fit snugly. Next, cleaning is like giving your lathe a refreshing bath. Use a soft cloth to wipe away dust and chips. Don’t forget to lubricate it! A little oil can go a long way, making everything run smoother. Remember, a happy lathe makes for happy projects!

| Maintenance Task | Frequency |

|---|---|

| Inspect for wear and damage | Weekly |

| Clean surface and parts | After every use |

| Lubricate moving parts | Monthly |

Best Practices for Operating a Metal Lathe

Guidelines for setup and alignment of the lathe bed.. Techniques to ensure optimal shaping and cut quality..To operate a metal lathe effectively, start by setting up the lathe bed properly. Align the bed with precision. Ensure it is level and stable. This prevents vibrations that can ruin your work. Next, adjust the cutting tools to improve shaping quality. Here are some best practices:

- Check tool sharpness regularly.

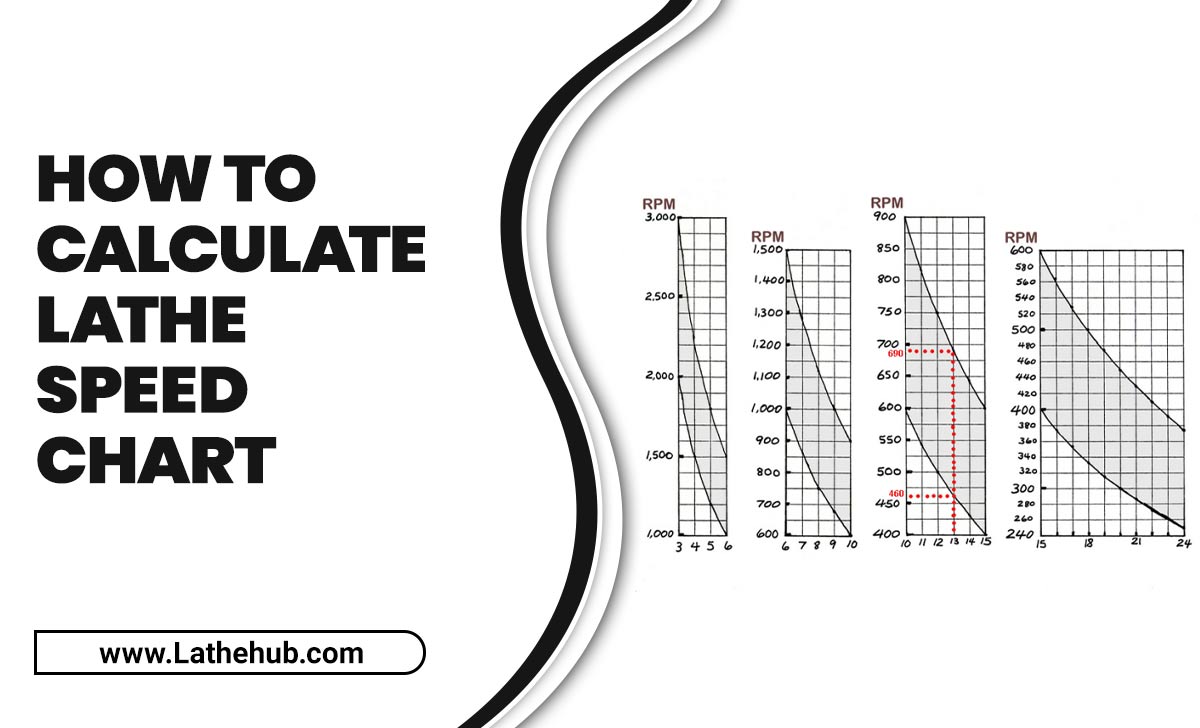

- Use the right speed for your material.

- Apply light pressure for smoother cuts.

This helps achieve a great finish on all projects!

What should I check before using a metal lathe?

Before using a metal lathe, check the tool alignment, ensure the lathe bed is level, and inspect cutting tools for sharpness.

Choosing the Right Metal Lathe for Your Needs

Factors to consider when selecting a metal lathe based on work requirements.. Recommendations for brands and models with superior lathe beds..Picking the perfect metal lathe can feel like choosing a new pet. You want one that fits your needs, has a sturdy lathe bed, and won’t run away when you need it most! First, think about what you’ll be working on. Do you need it for small crafts or big projects? Check the size and weight capacity. Popular brands like Grizzly and Jet offer models with great features. Also, consider if you want a variable speed control. And remember, a stable bed makes for smooth shaping!

| Brand | Model | Best Feature |

|---|---|---|

| Grizzly | G0768 | Heavy-duty bed |

| Jet | JWL-1442 | Variable speed control |

| Rockler | Precision Mini | Compact size |

Upgrades and Modifications for Metal Lathe Beds

Popular enhancements that can improve performance and durability.. Considerations when modifying existing lathe beds..Upgrading your metal lathe bed can make a world of difference. Popular tweaks include adding a sturdy cross slide or using better materials for improvement. These changes can boost both performance and lifespan. But caution! You must consider your lathe’s size and type before jumping in—unsafe modifications could turn your trusty tool into a fancy paperweight. Remember, “Measure twice, cut once!” It’s not just a saying; it’s a way to avoid tears and extra trips to the hardware store.

| Enhancements | Benefits |

|---|---|

| Upgraded Bearings | Smoother operation |

| Better Material | Increased durability |

| Improved Drive System | More efficiency |

Conclusion

In summary, a metal lathe bed is essential for shaping metal. It supports the machine and ensures accuracy in work. Understanding how it functions helps you appreciate metalworking better. If you’re interested, consider trying simple projects at home. You can also explore videos and guides online for more information. Keep learning and enjoy your metalworking journey!FAQs

What Are The Key Components Of A Metal Lathe Bed And How Do They Contribute To The Overall Accuracy Of Metal Shaping?A metal lathe bed is the big, strong part that holds everything in place. It keeps the machine steady while you work. If it’s well-made and flat, it helps you shape metal accurately. Other parts like the carriage and tailstock slide smoothly along the bed, making sure your work stays on track. This way, you get neat and precise shapes every time!

How Does The Material And Construction Of A Lathe Bed Affect The Performance And Durability Of A Metal Lathe?The lathe bed is the base of the machine where everything is attached. If it’s made of strong metal, it will last a long time. A well-built bed keeps the lathe steady, so you get better cuts. If it’s weak, the lathe can shake, and your work might not be smooth. Choosing a strong material helps the lathe work better and last longer.

What Maintenance Practices Can Extend The Lifespan Of A Metal Lathe Bed And Ensure It Remains Level And True?To keep your metal lathe bed in good shape, you should clean it often. Use a soft cloth to wipe away dust and oil. Check for any rust and remove it gently. Make sure to keep it level by using a level tool and adjusting the feet if needed. Finally, apply oil to the bed to protect it and keep it smooth.

What Are The Differences Between A Cast Iron Lathe Bed And A Welded Steel Lathe Bed In Terms Of Vibration Dampening And Stability?A cast iron lathe bed is heavier and can soak up vibrations better than a welded steel bed. This means it stays steadier while you work. The welded steel bed is lighter, so it may shake more. Overall, cast iron helps you make smoother and more accurate cuts.

How Do You Properly Align And Adjust The Lathe Bed To Achieve The Desired Precision In Metal Shaping Operations?To align and adjust the lathe bed, first, make sure the machine is turned off. Check if the bed is flat by using a ruler or a straight edge. You can adjust the bed if it’s not level by turning the screws on its base. After adjusting, check again to ensure it’s straight. This will help you shape metal better and more accurately!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Components Of A Metal Lathe Bed And How Do They Contribute To The Overall Accuracy Of Metal Shaping? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe bed is the big, strong part that holds everything in place. It keeps the machine steady while you work. If it’s well-made and flat, it helps you shape metal accurately. Other parts like the carriage and tailstock slide smoothly along the bed, making sure your work stays on track. This way, you get neat and precise shapes every time!”}},{“@type”: “Question”,”name”: “How Does The Material And Construction Of A Lathe Bed Affect The Performance And Durability Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The lathe bed is the base of the machine where everything is attached. If it’s made of strong metal, it will last a long time. A well-built bed keeps the lathe steady, so you get better cuts. If it’s weak, the lathe can shake, and your work might not be smooth. Choosing a strong material helps the lathe work better and last longer.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Can Extend The Lifespan Of A Metal Lathe Bed And Ensure It Remains Level And True? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your metal lathe bed in good shape, you should clean it often. Use a soft cloth to wipe away dust and oil. Check for any rust and remove it gently. Make sure to keep it level by using a level tool and adjusting the feet if needed. Finally, apply oil to the bed to protect it and keep it smooth.”}},{“@type”: “Question”,”name”: “What Are The Differences Between A Cast Iron Lathe Bed And A Welded Steel Lathe Bed In Terms Of Vibration Dampening And Stability? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A cast iron lathe bed is heavier and can soak up vibrations better than a welded steel bed. This means it stays steadier while you work. The welded steel bed is lighter, so it may shake more. Overall, cast iron helps you make smoother and more accurate cuts.”}},{“@type”: “Question”,”name”: “How Do You Properly Align And Adjust The Lathe Bed To Achieve The Desired Precision In Metal Shaping Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align and adjust the lathe bed, first, make sure the machine is turned off. Check if the bed is flat by using a ruler or a straight edge. You can adjust the bed if it’s not level by turning the screws on its base. After adjusting, check again to ensure it’s straight. This will help you shape metal better and more accurately!”}}]}