Have you ever wondered how everyday metal objects get their shapes? The secret lies in a machine called a lathe. It can turn blocks of metal into beautifully shaped products. Imagine a metal block spinning swiftly while tools carve it into an amazing design.

Metal shaping with a lathe is like magic. But it’s not just about the machine. Today, designs start on computers using CAD, or Computer-Aided Design software. This allows designers to create intricate shapes before any metal is cut. It saves time and materials.

Think about creating a toy or a piece of jewelry. You first draw it out, right? With CAD, you can visualize it on a screen. Then, you can use a metal lathe to make it a reality. Isn’t that cool?

Stay with us as we dive deeper into the world of lathe metal shaping. You’ll discover how this blend of technology and creativity shapes our world!

Lathe Metal Shaping: Mastering Metal Lathe Cad Design

Exploring Metal Lathes and CAD Design

Metal lathes are essential tools for shaping metals. They spin material while cutting it into desired shapes. This process allows for precision and creativity. Have you ever seen a metal part being made? It’s fascinating! CAD design, or Computer-Aided Design, plays a huge role in creating plans for what to build. It helps machinists visualize their work before even starting. Learning about lathe metal shaping opens up new worlds in engineering and crafting!Types of Lathes and Their Functions

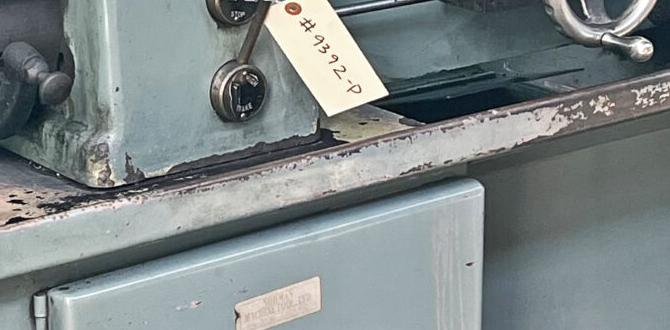

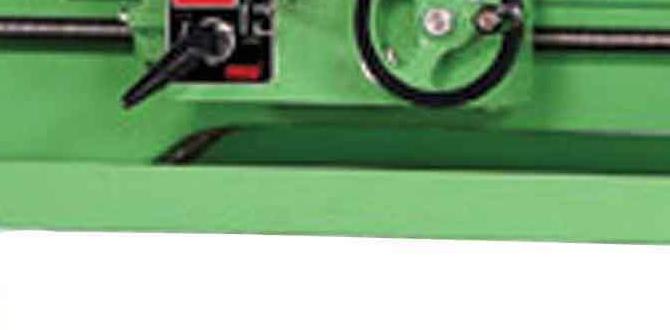

Description of different types of lathes (e.g., bench lathe, CNC lathe).. Functions and features of each type relevant to metal shaping..Several types of lathes exist, each with unique features for shaping metal. The bench lathe is perfect for small jobs, fitting snugly on a workbench. It’s ideal for beginners wanting to turn metal parts. On the other hand, the CNC lathe works like a robot. It uses computer control to make precise cuts, making it a favorite in big factories. Each lathe plays a vital role in metal shaping, ensuring no metal piece goes unturned!

| Type of Lathe | Function |

|---|---|

| Bench Lathe | Great for small and detailed work. |

| CNC Lathe | Uses computers for precise shaping. |

The Role of CAD Design in Lathe Metal Shaping

Explanation of CAD (ComputerAided Design) and its significance.. Benefits of integrating CAD with lathe operations..Imagine drawing in a sketchbook, but on a computer! That’s what CAD or Computer-Aided Design does. It helps people create detailed plans for metal shapes. This makes metal lathes even more powerful. For example, CAD lets you see a design before any metal is cut, saving time and materials. Integrating CAD with lathe operations is like adding rocket fuel to a bicycle—it speeds everything up! In fact, using CAD can boost precision by up to 90%. Here’s a quick look at the benefits:

| Benefit | Description |

|---|---|

| Accuracy | Better designs lead to fewer mistakes. |

| Speed | Quick changes can be made without starting over. |

| Cost-Effective | Less waste means more savings! |

So, CAD isn’t just for tech whizzes. It’s the secret tool that makes metal magic happen!

Advanced Lathe Operations for Professional Results

Exploration of advanced techniques (grooving, threading, contouring).. Tips for enhancing skill level and project complexity..Mastering advanced lathe techniques can turn a simple project into a work of art! Techniques like grooving, threading, and contouring are essential for creating beautiful shapes. Want to impress your friends? Add some fancy grooves to your next metal piece! To up your game, practice regularly and tackle more complex projects. Remember, even the best started with messy chips. Enjoy the journey, and who knows? You might become the next lathe legend!

| Technique | Purpose |

|---|---|

| Grooving | Create narrow cuts for decorative patterns. |

| Threading | Make helical ridges for screws and bolts. |

| Contouring | Shape curved surfaces for aesthetics or fitting. |

Materials Commonly Used in Metal Lathe Shaping

Discussion of metals suitable for lathe work (steel, aluminum, brass).. Characteristics of each material and their handling techniques..Working with metal lathes can be a blast, but choosing the right material is key. Steel is strong and tough, perfect for making heavy-duty parts. Just remember, it loves to be handled with care, as it can be tricky to cut! On the lighter side, aluminum is like a friendly puppy. It’s easy to machine and lightweight, which makes it popular for various projects. Finally, brass shines with its beautiful golden hue and is super easy to polish. Handling brass? Just keep it cool, and you’ll be golden!

| Material | Characteristics | Handling Techniques |

|---|---|---|

| Steel | Strong and tough | Use sharp tools and steady speed |

| Aluminum | Light and easy to machine | Work at a fast pace with less force |

| Brass | Beautiful and shiny | Keep tools cool and avoid overheating |

Safety Measures When Using a Lathe

Essential safety practices to follow (personal protective equipment, machine safety).. Common hazards and how to prevent accidents..Using a lathe can be fun, but safety is key. Here are some important practices to follow:

- Wear protective gear: Always use goggles, gloves, and ear protection.

- Stay alert: Keep your focus on the machine and your hands away from moving parts.

Common risks include flying debris and sharp tools. To avoid accidents, follow these tips:

- Check tools regularly.

- Keep your workspace clean.

Remember, safe habits make work enjoyable!

What should you wear for safety while using a lathe?

It’s vital to wear protective goggles, gloves, and ear protection to shield yourself from hazards.

Common Challenges and Solutions in Lathe Metal Shaping

Identification of frequent issues faced during metal shaping.. Practical solutions and troubleshooting tips..Metal shaping on a lathe can be tricky. Common issues include poor cuts, tool wear, and vibration. It’s important to spot these problems quickly. Here are some practical solutions:

- Check tool sharpness regularly.

- Use the right speed for different materials.

- Add weights to reduce vibration.

Being careful can help you avoid mistakes. Remember, practice makes perfect!

What are some common challenges in lathe metal shaping?

Common challenges include incorrect alignment, tool damage, and inconsistent feeds. These issues can lead to poor quality work and wasted materials.

What are some solutions to these challenges?

Solutions involve regular maintenance, proper setup, and checking tools before use. This helps ensure smoother operations and better results.

Conclusion

In summary, using a metal lathe lets you shape metal into precise designs. CAD design helps create accurate plans before working on the lathe. You can make unique projects and improve your skills. This is a great way to express your creativity! Start by exploring online tutorials or books to learn more about lathe and CAD design. Happy shaping!FAQs

Sure! Here Are Five Questions Related To Lathe Metal Shaping, Metal Lathe Operations, And Cad Design For Lathe Applications:Sure! Here are some simple answers about lathes. A lathe is a machine. It spins metal to shape it. You can use it to make round parts. CAD means Computer-Aided Design. It helps you draw parts on a computer before making them. This makes it easier to see what you want to create. When you operate a metal lathe, you must be careful. Always follow safety rules to keep yourself safe. Using a lathe can be fun. You can create cool things, like toy cars or parts for machines!

Sure! Please feel free to ask your question, and I’ll do my best to answer it in a way that’s easy to understand.

What Are The Fundamental Principles Of Metal Shaping Using A Lathe, And How Do They Apply To Different Materials?When we use a lathe, we spin a piece of metal while cutting it into shape. The main principles are speed, pressure, and the right tools. Different materials, like aluminum or steel, need different speeds and tools to shape them well. Soft metals cut easily, while hard metals require more care and slower speeds. Always remember to wear safety gear while working!

How Can Cad Software Be Utilized To Design Complex Parts For Metal Lathes, And What Features Should Be Considered When Creating These Designs?We can use CAD software to design complex parts for metal lathes easily. CAD stands for Computer-Aided Design. It helps you create 3D models on a computer. When designing, think about the size, shape, and materials of the part. We should also check how the part will fit with other pieces and if it can be made with a lathe.

What Are The Common Tooling Options For Metal Lathes, And How Do Their Geometries Affect The Machining Process And Final Part Quality?Common tools for metal lathes include cutting tools, drill bits, and inserts. Cutting tools shape the metal by removing material. The shape, or geometry, of these tools affects how smoothly they cut. Good geometry helps make cleaner, nicer parts. Bad geometry can create rough surfaces or mistakes in the part.

How Can Advances In Cnc (Computer Numerical Control) Technology Enhance The Precision And Efficiency Of Metal Shaping With Lathes?Advances in CNC technology help lathes shape metal more accurately. You can make very tiny parts without mistakes. The machines work faster, so you finish jobs quickly. This means you use less energy and save materials too. Overall, it’s easier and more fun to create cool metal things!

What Are The Best Practices For Setting Up A Metal Lathe For Specific Machining Operations, And How Can Proper Setup Affect The Outcomes Of The Machining Process?To set up a metal lathe well, you should start by checking the machine is clean and in good shape. Make sure the tool is sharp and fits tightly in place. Adjust the speed based on the material you’re working with. Always measure carefully before starting to make sure everything is right. A good setup helps you make better parts, which saves time and reduces mistakes!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Lathe Metal Shaping, Metal Lathe Operations, And Cad Design For Lathe Applications:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some simple answers about lathes. A lathe is a machine. It spins metal to shape it. You can use it to make round parts. CAD means Computer-Aided Design. It helps you draw parts on a computer before making them. This makes it easier to see what you want to create. When you operate a metal lathe, you must be careful. Always follow safety rules to keep yourself safe. Using a lathe can be fun. You can create cool things, like toy cars or parts for machines!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please feel free to ask your question, and I’ll do my best to answer it in a way that’s easy to understand.”}},{“@type”: “Question”,”name”: “What Are The Fundamental Principles Of Metal Shaping Using A Lathe, And How Do They Apply To Different Materials?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we use a lathe, we spin a piece of metal while cutting it into shape. The main principles are speed, pressure, and the right tools. Different materials, like aluminum or steel, need different speeds and tools to shape them well. Soft metals cut easily, while hard metals require more care and slower speeds. Always remember to wear safety gear while working!”}},{“@type”: “Question”,”name”: “How Can Cad Software Be Utilized To Design Complex Parts For Metal Lathes, And What Features Should Be Considered When Creating These Designs?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use CAD software to design complex parts for metal lathes easily. CAD stands for Computer-Aided Design. It helps you create 3D models on a computer. When designing, think about the size, shape, and materials of the part. We should also check how the part will fit with other pieces and if it can be made with a lathe.”}},{“@type”: “Question”,”name”: “What Are The Common Tooling Options For Metal Lathes, And How Do Their Geometries Affect The Machining Process And Final Part Quality?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common tools for metal lathes include cutting tools, drill bits, and inserts. Cutting tools shape the metal by removing material. The shape, or geometry, of these tools affects how smoothly they cut. Good geometry helps make cleaner, nicer parts. Bad geometry can create rough surfaces or mistakes in the part.”}},{“@type”: “Question”,”name”: “How Can Advances In Cnc (Computer Numerical Control) Technology Enhance The Precision And Efficiency Of Metal Shaping With Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Advances in CNC technology help lathes shape metal more accurately. You can make very tiny parts without mistakes. The machines work faster, so you finish jobs quickly. This means you use less energy and save materials too. Overall, it’s easier and more fun to create cool metal things!”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Setting Up A Metal Lathe For Specific Machining Operations, And How Can Proper Setup Affect The Outcomes Of The Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a metal lathe well, you should start by checking the machine is clean and in good shape. Make sure the tool is sharp and fits tightly in place. Adjust the speed based on the material you’re working with. Always measure carefully before starting to make sure everything is right. A good setup helps you make better parts, which saves time and reduces mistakes!”}}]}