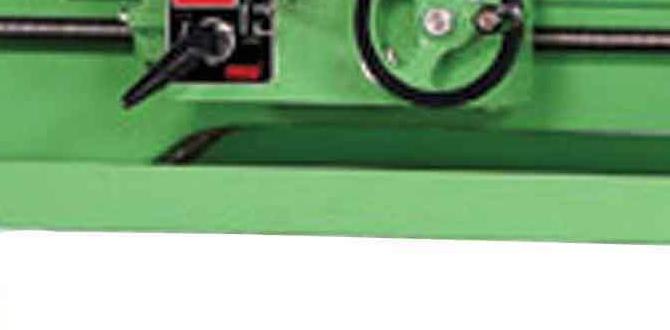

Lathe Metal Shaping: Understanding Metal Lathe Chuck Mechanisms Lathe Metal Shaping Is An Essential Process In Manufacturing That Involves The Use Of A Metal Lathe Chuck To Hold And Manipulate Metal Workpieces. A Metal Lathe Chuck Is A Critical Component Of The Lathe Machine, Responsible For Securely Gripping The Metal While Shaping, Cutting, Or Machining It Into The Desired Form. What Is A Metal Lathe Chuck? A Metal Lathe Chuck Is A Device That Attaches To The Spindle Of A Lathe. Its Primary Function Is To Hold The Workpiece Firmly In Place, Allowing The Rotating Lathe To Cut Or Shape The Material. There Are Various Types Of Chucks Available, Each Designed For Specific Applications And Levels Of Precision. Types Of Metal Lathe Chucks 1. **Three-Jaw Chucks**: The Most Common Type Found In Metalworking Shops, Three-Jaw Chucks Can Accommodate A Range Of Workpiece Sizes. They Are Self-Centering, Meaning That When The Chuck Is Tightened, All Three Jaws Move Simultaneously To Grip The Material Evenly. 2. **Four-Jaw Chucks**: These Chucks Are More Versatile And Allow For Better Gripping Of Irregularly Shaped Pieces. Each Jaw Operates Independently, Giving The Operator The Ability To Adjust The Grip Precisely. 3. **Collet Chucks**: Collet Chucks Provide A High Level Of Accuracy And Are Ideal For Holding Cylindrical Workpieces. They Work By Using A Sleeve That Tightens Around A Specific Diameter, Ensuring A Secure Hold. Advantages Of Using A Metal Lathe Chuck – **Precision**: A Well-Designed Metal Lathe Chuck Ensures That Workpieces Are Centered Accurately, Leading To Precise Cuts And Consistent Results. – **Versatility**: Different Types Of Chucks Allow For Flexibility In Terms Of The Shapes And Sizes Of Materials That Can Be Worked On. – **Ease Of Use**: Modern Metal Lathe Chucks Often Feature Quick-Release Mechanisms, Making It Easy To Change Workpieces Without Much Downtime. Conclusion Understanding The Function And Types Of Metal Lathe Chucks Is Crucial For Anyone Involved In Lathe Metal Shaping. A Quality Chuck Can Significantly Enhance The Efficiency And Accuracy Of Machining Operations. Whether You Are A Professional Machinist Or A Hobbyist, Selecting The Right Chuck For Your Metal Lathe Is An Important Step In Achieving High-Quality Work.

Lathe Metal Shaping: Understanding Metal Lathe Chuck

A metal lathe chuck holds the metal piece you work on. It’s like a strong hand that keeps materials in place. Did you know that choosing the right chuck can make your work much easier? There are different types, such as three-jaw or four-jaw chucks. Each serves a unique purpose. Proper usage can improve your shaping accuracy and save time. Remember, a good chuck is vital for successful metal shaping. What kind of projects will you try?Components of a Metal Lathe

Detailed explanation of essential parts: bed, spindle, tailstock. Importance of each component in the shaping process.A metal lathe has a few key parts that are essential for shaping metal. The bed is like the lathe’s backbone, keeping everything stable. The spindle spins the metal piece, helping to shape it into a perfect form. Lastly, the tailstock supports the other end of the metal, ensuring it doesn’t wobble like a jelly on a plate. Each part plays a vital role in creating precise shapes, making your project look neat and awesome!

| Component | Function |

|---|---|

| Bed | Stability and support |

| Spindle | Rotates metal for shaping |

| Tailstock | Holds the end of the metal |

The Function of a Lathe Chuck

Explanation of what a lathe chuck is and its types. How a lathe chuck secures the workpiece during operation.A lathe chuck is like a big metal hug for your workpiece. It grips the material securely while the lathe spins it around. There are various types of chucks, including three-jaw, four-jaw, and collet chucks. Each type serves a special purpose. The three-jaw chuck is popular for its quick grip on round objects, while the four-jaw chuck can hold odd-shaped pieces. Think of it as a life jacket for your projects—keeping them safe from flying away!

| Type of Chuck | Best For |

|---|---|

| Three-Jaw Chuck | Round Objects |

| Four-Jaw Chuck | Odd-Shaped Pieces |

| Collet Chuck | Small Parts |

In short, a lathe chuck is a vital tool that keeps everything in place. So, remember, without a chuck, you might as well be juggling your materials in a circus! Who wants that kind of chaos?

Selecting the Right Lathe Chuck

Factors to consider when choosing a lathe chuck. Comparison of different chuck styles: threejaw vs. fourjaw.Choosing the right lathe chuck can feel like picking a favorite ice cream flavor—so many choices! First, think about what you’ll be working on. Three-jaw chucks are great for quick, easy setups and hold round objects well. But, if you need more precision, a four-jaw chuck gives you the power to grip odd shapes tightly. Remember, the size of the chuck must match your lathe. Don’t use a mini chuck on a giant lathe; that could end up in a hilarious disaster!

| Chuck Style | Best For | Ease of Use |

|---|---|---|

| Three-Jaw | Round Objects | Easy |

| Four-Jaw | Odd Shapes | Trickier |

So, think carefully! The right chuck can make your metal shaping dreams come true. Or at least keep your project from flying off into space.

Benefits of Using Lathe Chucks for Metal Shaping

Advantages of better workpiece stability and precision. Impact on overall efficiency and smoothness of operations.Using lathe chucks for metal shaping has great benefits. They hold the workpiece tightly, which helps with stability. This means less shaking and better precision. A stable piece turns smoother, leading to faster work. With less chance of mistakes, your projects finish quickly and neatly. It’s like having a reliable friend helping you make the best shapes each time.

What are the advantages of lathe chuck stability and precision?

Better stability and precision give you higher quality results in metal shaping.

Key Advantages:

- Less vibration while working.

- More accurate cutting.

- Improves productivity.

Common Issues with Lathe Chucks and Solutions

Frequent problems encountered with lathe chucks. Troubleshooting tips and maintenance practices.Lathe chucks can sometimes act a bit quirky. One common issue is misalignment, which can result in uneven cuts. Keep an eye out for vibrations, they can make your work feel like it’s dancing! Regular maintenance is key. Clean the chuck well and check for any worn-out parts. Pressures can build up too, so ensure the material is held just right—not too tight, or it could throw a fit!

| Problem | Solution |

|---|---|

| Misalignment | Adjust the workpiece and ensure proper setup. |

| Vibrations | Check for balance and stability of the lathe. |

| Worn Parts | Inspect and replace any damaged components. |

Best Practices for Operating a Metal Lathe with a Chuck

Safety protocols when using metal lathes. Techniques for maximizing accuracy and efficiency in shaping processes.Using a metal lathe is no joke—safety is key! Always wear goggles to protect those peepers. Secure your workspace, and never wear loose clothing. Maximizing accuracy means setting the right speed and keeping your tools sharp. If the lathe was a dancer, it would want to spin smoothly. Remember to measure twice, cut once, or you might end up with a wobbly piece that looks like a potato! Here’s a quick table to keep your practices in check:

| Safety Tips | Techniques for Accuracy |

|---|---|

| Wear protective gear | Use proper speeds |

| No loose clothing | Keep tools sharp |

| Clean work area | Measure before shaping |

Applications of Metal Lathes and Chucks in Various Industries

Industries that heavily rely on metal shaping techniques. Specific applications and examples of lathe work in manufacturing.Many industries depend on metal shaping techniques. Metal lathes and chucks play a big role here. They help in crafting precise parts. For example, they are commonly used in:

- Automotive: Making engine components and gears.

- Aerospace: Creating parts for airplanes and jets.

- Manufacturing: Producing machine tools and equipment.

- Construction: Shaping metal for buildings and infrastructure.

Using a lathe, workers can turn metal into creative shapes. This makes tasks faster and more accurate, helping industries grow.

What are some common applications of metal lathes?

Lathe machines are used to make parts like axle shafts, bushings, and pulleys. These applications are important in various fields, ensuring machines work smoothly.

Resources for Further Learning about Metal Lathes

Suggested books, courses, and online materials. Communities and forums for metalworking enthusiasts.Want to learn more about metal lathes? There are plenty of exciting resources! Check out books like “The Metal Lathe” for solid techniques. Online courses such as those on Udemy can turn you into a lathe whiz in no time! Don’t forget about communities. Joining forums like Practical Machinist lets you chat with others who love metalworking. You might even find a friendly debate about which lathe is best!

| Type | Resource |

|---|---|

| Book | “The Metal Lathe” |

| Course | Udemy Online Courses |

| Forum | Practical Machinist |

Conclusion

In summary, a metal lathe is essential for shaping metal pieces. The chuck holds the metal securely while you work. Understanding how they function helps you create precise parts. If you’re interested in metalworking, practice using a lathe to improve your skills. Explore more resources or tutorials to enhance your knowledge and become a better metalworker!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Metal Lathe Chucks:Sure! Here are five questions about metal shaping using a lathe and lathe chucks: 1. What is a lathe? A lathe is a machine that helps shape metal. It spins the metal while tools cut it into shapes. 2. How do you use a lathe? You place metal in the lathe, turn it on, and use tools to carve it into the shape you want. 3. What are lathe chucks? Lathe chucks are parts that hold the metal in place. They help keep it steady while you work. 4. Why is metal shaping important? Metal shaping is important because it makes parts for machines, tools, and many other things we use every day. 5. Can anyone learn to use a lathe? Yes! With practice and guidance, anyone can learn to use a lathe and shape metal.

Sure! Go ahead and ask your question, and I’ll be happy to help.

What Are The Different Types Of Chucks Used In Metal Lathes, And How Do They Differ In Functionality?Metal lathes use different types of chucks to hold metal pieces tight. A three-jaw chuck has three parts that grip in a circle. This is great for round pieces. A four-jaw chuck has four parts and can hold odd shapes better. There are also self-centering chucks that adjust automatically to grip pieces well. Each type helps us work with different shapes and sizes.

How Do You Properly Set Up And Align A Workpiece In A Lathe Chuck For Accurate Machining?To set up a workpiece in a lathe chuck, first, grab your workpiece and clean it. Next, place it in the chuck’s jaws. Make sure the workpiece is centered and can spin freely. Tighten the jaws gently so the piece does not move. Lastly, double-check that everything is secure before starting to machine.

What Materials Are Commonly Used For Lathe Chucks, And What Factors Influence Their Selection?Lathe chucks are often made from metal, like steel or cast iron. These materials are strong and can last a long time. We choose them based on how much weight they need to hold and how fast they’ll spin. You want something tough for heavy work and lighter for easy jobs.

How Can You Ensure The Safety And Accuracy Of Operations When Using A Lathe Chuck In Metal Shaping?To keep safe and accurate when using a lathe chuck, you should always wear safety goggles and gloves. Make sure the chuck is tight before you start working. Keep your hands away from moving parts and never reach into the machine while it is running. Check the tools and parts for damage before using them. Lastly, always follow the instructions for the lathe to do a good job.

What Maintenance Practices Are Recommended For Extending The Lifespan And Maintaining The Performance Of A Metal Lathe Chuck?To keep your metal lathe chuck in good shape, clean it often. You should remove any dirt or metal shavings. Check for rust or damage and fix any problems right away. Make sure to use oil to keep moving parts working smoothly. Lastly, store it in a dry place to prevent rust.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Metal Lathe Chucks:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about metal shaping using a lathe and lathe chucks: 1. What is a lathe? A lathe is a machine that helps shape metal. It spins the metal while tools cut it into shapes. 2. How do you use a lathe? You place metal in the lathe, turn it on, and use tools to carve it into the shape you want. 3. What are lathe chucks? Lathe chucks are parts that hold the metal in place. They help keep it steady while you work. 4. Why is metal shaping important? Metal shaping is important because it makes parts for machines, tools, and many other things we use every day. 5. Can anyone learn to use a lathe? Yes! With practice and guidance, anyone can learn to use a lathe and shape metal.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Go ahead and ask your question, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Are The Different Types Of Chucks Used In Metal Lathes, And How Do They Differ In Functionality?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes use different types of chucks to hold metal pieces tight. A three-jaw chuck has three parts that grip in a circle. This is great for round pieces. A four-jaw chuck has four parts and can hold odd shapes better. There are also self-centering chucks that adjust automatically to grip pieces well. Each type helps us work with different shapes and sizes.”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up And Align A Workpiece In A Lathe Chuck For Accurate Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a workpiece in a lathe chuck, first, grab your workpiece and clean it. Next, place it in the chuck’s jaws. Make sure the workpiece is centered and can spin freely. Tighten the jaws gently so the piece does not move. Lastly, double-check that everything is secure before starting to machine.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used For Lathe Chucks, And What Factors Influence Their Selection?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe chucks are often made from metal, like steel or cast iron. These materials are strong and can last a long time. We choose them based on how much weight they need to hold and how fast they’ll spin. You want something tough for heavy work and lighter for easy jobs.”}},{“@type”: “Question”,”name”: “How Can You Ensure The Safety And Accuracy Of Operations When Using A Lathe Chuck In Metal Shaping?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep safe and accurate when using a lathe chuck, you should always wear safety goggles and gloves. Make sure the chuck is tight before you start working. Keep your hands away from moving parts and never reach into the machine while it is running. Check the tools and parts for damage before using them. Lastly, always follow the instructions for the lathe to do a good job.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Recommended For Extending The Lifespan And Maintaining The Performance Of A Metal Lathe Chuck?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your metal lathe chuck in good shape, clean it often. You should remove any dirt or metal shavings. Check for rust or damage and fix any problems right away. Make sure to use oil to keep moving parts working smoothly. Lastly, store it in a dry place to prevent rust.”}}]}