Have you ever wondered how machines shape metal? One of the coolest tools for this is the lathe. It spins metal pieces and uses sharp tools to carve them into unique shapes.

But how does a lathe know what to do? That’s where the metal lathe controller comes in. This device tells the lathe how to move and cut. It makes everything more precise and easy to control.

Imagine making a metal part for a robot or even a toy. The lathe can help create these parts accurately. Isn’t it fascinating that with simple controls, we can craft amazing things from metal?

Learning about lathes, especially the role of the lathe metal shaping metal lathe controller, opens up a world of possibilities. You may find that making something from metal is not only fun but also a bit like magic!

Lathe Metal Shaping: Exploring The Metal Lathe Controller

Lathe Metal Shaping: Understanding Metal Lathe Controllers

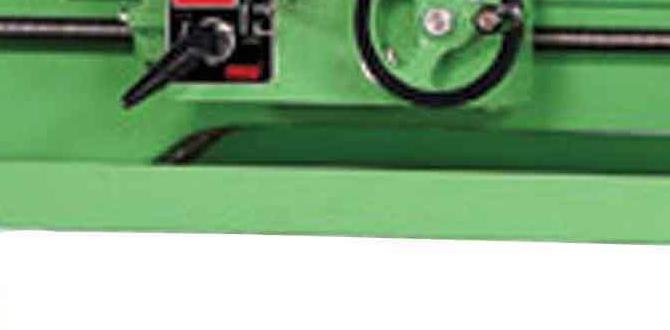

Metal lathes play a crucial role in shaping metal. They enable users to cut, carve, or refine metal pieces. A metal lathe controller allows precise control over the machine, making tasks easier and more accurate. Imagine creating a shiny metal part from a rough piece; a good controller lets you do this with confidence. Fun fact: with the right controller, even beginners can create professional-quality work! Understanding this technology can spark a new hobby or career path.Understanding Metal Lathes

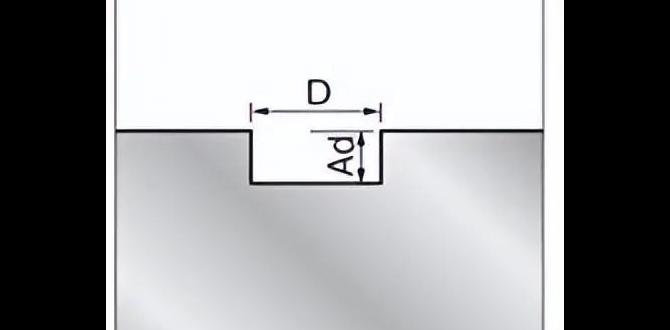

Definition and function of metal lathes. Different types of metal lathes and their applications.A metal lathe is a tool used to shape metal. It rotates a piece of metal while a cutting tool carves it. This process is neat and precise. Metal lathes come in various types, each for different tasks. Some common types include:

- Engine lathes: Great for general work.

- Turret lathes: Used for production of many parts.

- CNC lathes: Computer-controlled for high accuracy.

These machines help create parts like bolts, axles, and more. Understanding metal lathes makes it easier to see how they shape our world.

What are metal lathes used for?

Metal lathes are used to make precise items by cutting, shaping, and finishing metal.

The Importance of a Metal Lathe Controller

Role of a controller in metal shaping processes. How controllers enhance precision and efficiency.A metal lathe controller plays a big role in shaping metal. It’s like the brain of the machine! This controller helps the lathe cut with amazing precision. It makes sure each cut is just right, like getting the perfect slice of pizza. With better control, projects finish faster and smoother. Think of it this way: a skilled chef uses a good knife; a metal lathe controller is that knife for metalworkers. It makes work easier and more fun!

| Benefits of Metal Lathe Controllers | Description |

|---|---|

| Precision | Helps achieve exact measurements, reducing errors. |

| Efficiency | Speeds up the metal shaping process, saving time. |

| Ease of Use | Makes operating the lathe simpler for everyone. |

Choosing the Right Metal Lathe Controller

Factors to consider when selecting a controller. Comparing popular brands and models.Selecting a metal lathe controller can feel tricky. First, think about what you need. Here are some factors to consider:

- Control type: Manual or digital?

- Compatibility with your lathe

- Ease of use for beginners

- Budget and brand reliability

Popular brands include GSK and Taiwanese models. Each has various features. Some models offer touchscreen controls, while others have knobs. Compare them wisely to find your best fit!

What should I look for in a metal lathe controller?

Look for ease of use, features, and brand trust. A good controller should make your work easier and safer.

Key Features to Compare:

- Display type: LED or LCD

- Power requirements

- Support and warranty options

Setting Up Your Metal Lathe Controller

Stepbystep setup instructions. Common troubleshooting tips.Setting up your lathe controller is simple. Follow these easy steps:

- Find a flat surface for your lathe.

- Plug it into a power source.

- Connect the machine to your computer.

- Install the controller software.

- Calibrate the machine according to the manual.

If you run into problems, don’t worry! Here are some quick tips:

- Check all connections are secure.

- Ensure the software is up to date.

- Restart both the machine and computer.

Following these steps will help you set up your metal lathe controller smoothly. Happy shaping!

What to do if the lathe is not responding?

Try rebooting the controller and checking the connections. Ensure that the power supply is working, and all cables are properly connected.

Common Issues:

- Software not installed correctly

- Power issues

- Calibration errors

Advanced Techniques in Metal Shaping

Techniques for maximizing lathe performance. Integrating tooling accessories for enhanced results.To make the most of a lathe, you need to use smart techniques. Start by adjusting the speed and feed rates. This helps create smooth cuts. Using the right tools is also key. They can make shaping metal easier and faster. Add accessories like tool holders and coolant systems for better results. These tools can help you shape metal perfectly.

- Adjust speed for material type.

- Choose the proper cutting tool.

- Use tool holders for stability.

- Incorporate coolant for a smoother finish.

What are key techniques for lathe performance?

Some key techniques include adjusting speed and feed rates, choosing the right tools, and integrating accessories. These can improve both precision and efficiency.

Maintenance and Upkeep of Metal Lathe Controllers

Routine maintenance tasks for longevity. Signs that your controller requires servicing.Keeping your metal lathe controller in tip-top shape is crucial for smooth sailing in your workshop. Think of it like taking care of a pet. Regular check-ups help it live longer and work better! Routine tasks include cleaning dust, checking connections, and lubricating moving parts. You might need to call for help if you notice flickering lights or strange noises. These are signs your controller needs some TLC. Remember, a well-maintained lathe controller is a happy one!

| Routine Maintenance Tasks | Signs of Servicing Needed |

|---|---|

| Dust Cleaning | Flickering Lights |

| Check Connections | Strange Noises |

| Lubricate Moving Parts | Slow Response |

Future Trends in Metal Lathe Technology

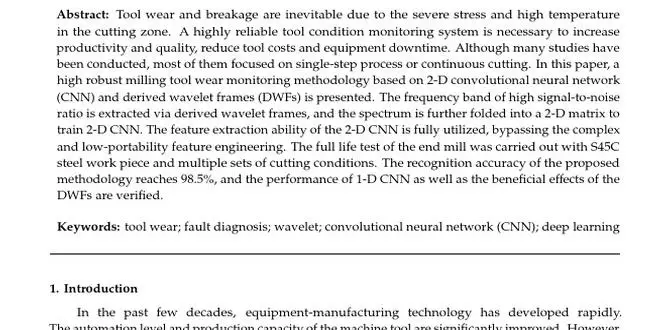

Innovations in metal lathe controller technology. Impact of automation and smart technology on metal shaping.Metal lathe technology keeps getting better. New metal lathe controllers make it easier to shape metal. They are becoming smarter and more automatic. This helps workers do their jobs faster and with fewer mistakes. Automation will change how we create items. Here are some cool trends:

- Advanced sensors for accuracy

- Remote operation for convenience

- AI to help with decisions

- Energy-efficient machines

These changes will make metal lathes more powerful. They’ll also help create better products with less effort.

How will smart technology change metal shaping?

Smart technology will make metal shaping quicker and more precise. Machines will learn and adapt to different tasks. This means less time fixing mistakes and more time creating. The future looks bright for metal workers!

Resources for Further Learning

Recommended books and online courses. Community forums and support groups for metal lathe enthusiasts.Ready to dive deeper? Grab a book or sign up for an online course! Start with a great book like “Metal Lathe Basics.” It’s a friendly guide, not a snooze-fest! You can also check out courses on platforms like Udemy that cover metal lathe skills from beginner to pro level. The best part? You can learn while wearing your pajamas! Don’t forget to join community forums. Places like Reddit and specialized metalworking groups are goldmines for tips and tricks. Plus, you can get advice when you mess up—trust me, it happens to the best of us!

| Resource Type | Name | Link |

|---|---|---|

| Book | Metal Lathe Basics | Link |

| Online Course | Metal Lathe Mastery on Udemy | Link |

| Community Forum | Reddit Metalworking | Link |

Conclusion

In conclusion, a metal lathe controller helps you shape metal accurately. It makes crafting parts easier and more precise. By understanding how it works, you can create better projects. We encourage you to explore different lathes and experiment with different techniques. With practice, you’ll master metal shaping in no time. Happy crafting!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Metal Lathe Controllers:Sure! Here are five questions we can explore about lathes. 1. **What is a lathe?** A lathe is a machine that helps shape metal. It spins metal while a tool cuts it into the right shape. 2. **How does a metal lathe work?** We put a metal piece on the lathe. Then, the lathe turns it around while a sharp tool shapes it. 3. **What can we make with a lathe?** We can make many things, like metal parts for machines or tools. 4. **What is a metal lathe controller?** A metal lathe controller is a computer that tells the lathe what to do. It helps control speed and cutting. 5. **Why is safety important when using a lathe?** Safety is important so we don’t get hurt. We should always wear safety gear and follow rules.

Sure! Please provide me with the question you’d like me to answer.

What Are The Key Features To Look For In A Modern Metal Lathe Controller To Enhance Precision And Efficiency In Metal Shaping?When you choose a metal lathe controller, look for easy controls. You want a display that clearly shows important numbers. A good controller should let you adjust speeds quickly for different tasks. Check if it offers automatic settings; this helps you work faster and better. Finally, see if it has safety features to keep you safe while working.

How Do Cnc (Computer Numerical Control) Lathe Systems Differ From Traditional Manual Lathes In Terms Of Metal Shaping Capabilities?CNC lathes use computers to control how they shape metal, while manual lathes need a person to turn the knobs. This means CNC lathes can make very complex shapes quickly and accurately. You can also program them to work on their own, which saves time. Manual lathes require more hands-on work, so they take longer for complicated designs. Overall, CNC lathes are better for making precise and tricky metal parts.

What Types Of Materials Can Be Effectively Shaped Using A Metal Lathe, And How Does The Controller Play A Role In Optimizing The Process?You can shape different metals like aluminum, steel, and brass using a metal lathe. You can also use some hard plastics. The controller helps you set the speed and shape so everything cuts smoothly. It makes sure you get the right size and finish, making your work easier and better!

What Are Some Common Troubleshooting Steps For Issues That May Arise With A Metal Lathe Controller During Operation?If your metal lathe controller has problems, try these steps. First, check the power supply to make sure it’s on. Next, look for loose wires or connections that might be unplugged. If it keeps stopping, resetting the controller might help. Finally, refer to the manual for more ideas on fixing it.

How Do Advancements In Technology, Such As Automation And Software Integration, Improve The Performance Of Metal Lathe Controllers?Advancements in technology make metal lathe controllers work better and faster. Automation helps machines do tasks by themselves. This means less time for people to spend on boring work. Software integration connects different tools to work together smoothly. Together, these changes make metal lathes more efficient and precise.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Metal Lathe Controllers:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions we can explore about lathes. 1. **What is a lathe?** A lathe is a machine that helps shape metal. It spins metal while a tool cuts it into the right shape. 2. **How does a metal lathe work?** We put a metal piece on the lathe. Then, the lathe turns it around while a sharp tool shapes it. 3. **What can we make with a lathe?** We can make many things, like metal parts for machines or tools. 4. **What is a metal lathe controller?** A metal lathe controller is a computer that tells the lathe what to do. It helps control speed and cutting. 5. **Why is safety important when using a lathe?** Safety is important so we don’t get hurt. We should always wear safety gear and follow rules.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Features To Look For In A Modern Metal Lathe Controller To Enhance Precision And Efficiency In Metal Shaping?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you choose a metal lathe controller, look for easy controls. You want a display that clearly shows important numbers. A good controller should let you adjust speeds quickly for different tasks. Check if it offers automatic settings; this helps you work faster and better. Finally, see if it has safety features to keep you safe while working.”}},{“@type”: “Question”,”name”: “How Do Cnc (Computer Numerical Control) Lathe Systems Differ From Traditional Manual Lathes In Terms Of Metal Shaping Capabilities?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CNC lathes use computers to control how they shape metal, while manual lathes need a person to turn the knobs. This means CNC lathes can make very complex shapes quickly and accurately. You can also program them to work on their own, which saves time. Manual lathes require more hands-on work, so they take longer for complicated designs. Overall, CNC lathes are better for making precise and tricky metal parts.”}},{“@type”: “Question”,”name”: “What Types Of Materials Can Be Effectively Shaped Using A Metal Lathe, And How Does The Controller Play A Role In Optimizing The Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can shape different metals like aluminum, steel, and brass using a metal lathe. You can also use some hard plastics. The controller helps you set the speed and shape so everything cuts smoothly. It makes sure you get the right size and finish, making your work easier and better!”}},{“@type”: “Question”,”name”: “What Are Some Common Troubleshooting Steps For Issues That May Arise With A Metal Lathe Controller During Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your metal lathe controller has problems, try these steps. First, check the power supply to make sure it’s on. Next, look for loose wires or connections that might be unplugged. If it keeps stopping, resetting the controller might help. Finally, refer to the manual for more ideas on fixing it.”}},{“@type”: “Question”,”name”: “How Do Advancements In Technology, Such As Automation And Software Integration, Improve The Performance Of Metal Lathe Controllers?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Advancements in technology make metal lathe controllers work better and faster. Automation helps machines do tasks by themselves. This means less time for people to spend on boring work. Software integration connects different tools to work together smoothly. Together, these changes make metal lathes more efficient and precise.”}}]}