Have you ever wondered how metal objects get their shape? Many of these shapes come from a machine called a lathe. A lathe spins metal pieces while cutting tools shape them. It’s a fascinating process that turns metal blocks into useful items.

But just like any machine, a metal lathe needs regular care. Metal lathe maintenance is key to keeping it in top condition. Without proper care, it can break or not work well. Imagine trying to make something cool, only for your machine to stop working. That would be frustrating!

Taking care of a metal lathe can also be fun. You can learn new skills and ways to fix things. Every time you maintain your lathe, you give it the chance to create magic. So, let’s dive into the world of lathe metal shaping and discover how to keep your lathe running smoothly.

Essential Lathe Metal Shaping: Metal Lathe Maintenance Guide

Lathe Metal Shaping and Maintenance

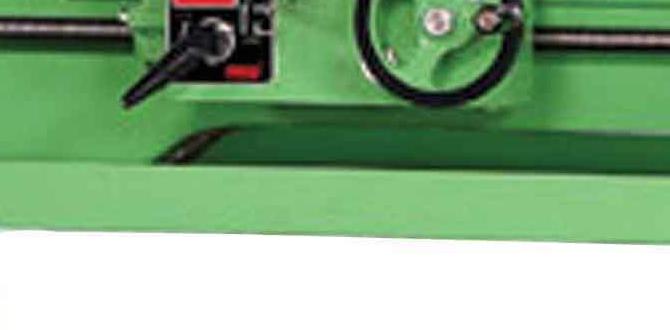

Using a metal lathe is essential for shaping metal parts accurately. Regular maintenance keeps the lathe running smoothly and extends its lifespan. Key tasks include cleaning, lubricating, and checking for wear. Imagine trying to create a perfect cylinder, but your lathe is worn out. Frustrating, right? A well-maintained lathe gives you precision and great results. You might be surprised how simple maintenance tasks can boost your machine’s performance! Engaging with lathe techniques opens up fun experiences in metalworking.

Understanding Metal Lathes

Definition and purpose of metal lathes. Types of metal lathes and their applications.

A metal lathe is a machine that shapes metal into different forms. It spins the metal while cutting tools shape it. Metal lathes are essential in many industries, from car parts to musical instruments. Here are some main types of metal lathes:

- Engine Lathes: These are common for general tasks.

- CNC Lathes: These use computers for precise designs.

- Turret Lathes: Great for mass production of small parts.

Each type serves its own purpose and makes work easier and faster. Understanding how these machines work can improve your skills.

What are the uses of metal lathes?

Metal lathes are used to create tools, parts, and other items in metalworking. They help make everything from screws to complex shapes.

Components of a Metal Lathe

Main parts and their functions. Importance of each component in metal shaping.

A metal lathe is like the superhero of the workshop! Its main parts each have cool jobs. You have the headstock, which holds the motor and spinning axle; without it, the lathe would be as useful as a chocolate teapot. The tailstock helps with adding tools and stability, while the tool rest ensures tools don’t fly off like popcorn in a microwave!

| Component | Function |

|---|---|

| Headstock | Holds the motor and supports the workpiece. |

| Tailstock | Provides tool support and stability. |

| Tool Rest | Keeps tools steady for cutting. |

Each part is crucial for shaping metal. Without these, it’s like baking without an oven—messy and impossible! So remember, happy lathe parts make for happy metal shaping!

Significance of Regular Maintenance

Benefits of maintaining a metal lathe. Potential risks of neglecting maintenance.

Regular care of a metal lathe is very important. It brings many benefits. First, longevity is a big one; a well-maintained machine lasts longer. Second, it helps keep your projects smooth and accurate. Third, it enhances safety by preventing accidents.

Neglecting this maintenance poses risks. You might face expensive repairs or even injuries. It is smarter to keep your lathe in good shape. A few simple habits can make a big difference.

Why is lathe maintenance essential?

Regular maintenance prevents costly repairs and ensures the lathe works safely and accurately.

Key Benefits of Metal Lathe Maintenance:

- Improved Accuracy: Makes your work precise.

- Increased Safety: Reduces chances of accidents.

- Cost-Effective: Saves money on repairs.

Routine Maintenance Tasks

Daily checks and cleaning procedures. Weekly and monthly maintenance activities.

Taking care of your metal lathe can be fun and easy! Start with daily checks: make sure everything is clean and running smoothly. A quick wipe here and there can save you from big issues later. Weekly, tighten those loose screws and lubricate the moving parts. Don’t worry, they won’t bite! For monthly tasks, give it a good inspection. Look for any wear and tear. After all, you want your lathe to last longer than your favorite pair of socks!

| Maintenance Task | Frequency |

|---|---|

| Daily checks and cleaning | Every day |

| Tighten screws and lubricate parts | Weekly |

| Full inspection | Monthly |

Common Issues and Troubleshooting

Identifying signs of wear and damage. Solutions for frequent problems encountered.

Keep an eye on your lathe for signs of wear and tear. Look for things like odd noises, slow movements, or vibrations that make it feel like it’s dancing! These hints signal that something is wrong. The common issue of dull cutting tools can be solved by sharpening or replacing them. Use oil to keep parts moving smoothly. Check the table below for more common lathe problems and their fixes:

| Issue | Solution |

|---|---|

| Unusual Noises | Check for loose bolts and tighten them. |

| Vibrations | Ensure all parts are balanced. |

| Slow Speed | Inspect belts for wear and replace if needed. |

Regular checks help keep your lathe in top shape. Remember, a happy lathe makes for happy projects!

Tools and Supplies for Maintenance

Essential tools for lathe maintenance. Recommended lubricants and cleaning supplies.

Keeping your lathe happy requires some trusty tools. First up, you’ll need a good set of wrenches. These help tighten and adjust parts. Next, grab a screwdriver. It’s perfect for removing covers and adjusting settings. Don’t forget a soft bristle brush for cleaning out dust and chips—no one likes a dusty lathe! For lubricants, synthetic oil works wonders. And some cleaning solutions keep the surface shiny. Here’s a quick look at handy supplies:

| Tool/Supply | Purpose |

|---|---|

| Wrenches | Adjusting parts |

| Screwdriver | Removing covers |

| Soft Bristle Brush | Cleaning dust |

| Synthetic Oil | Lubrication |

| Cleaning Solution | Surface shine |

With these tools, your lathe will run smoother than a freshly oiled greased weasel!

Best Practices for Longevity

Tips for improving the lifespan of your lathe. Importance of proper usage and operator training.

Keeping your lathe happy is key to making it last. First, always read the manual before using it. It’s like a treasure map! Proper training helps operators know what to do and what not to do. Regular maintenance is like feeding your lathe a good meal. After all, a well-fed lathe works better! Here are some quick tips:

| Tip | Description |

|---|---|

| Keep it clean | Dust and grime can be sneaky troublemakers. |

| Lubricate | It’s like giving your lathe a nice massage. |

| Avoid overload | Don’t make it lift weights it can’t handle! |

By following these simple tips, you’ll ensure your lathe will shape metal for years, making it the best buddy in your workshop!

Upgrading and Retrofitting Your Lathe

When to consider upgrades. Benefits of modern attachments and tools for efficiency.

Upgrading your lathe can boost your workshop’s efficiency. Consider upgrades when your equipment feels outdated or struggles with tasks. Modern attachments offer several benefits:

- Improved accuracy: New tools help make precise cuts.

- Time-saver: Advanced attachments speed up production.

- Enhanced safety: Many new tools reduce risks while working.

Choosing to upgrade your lathe not only increases performance but also keeps your work fun and safe!

When should I upgrade my lathe?

You should upgrade your lathe if it has trouble performing tasks or if it feels outdated. With new attachments, you can work faster and safer.

Conclusion

In conclusion, maintaining your metal lathe is essential for safe and efficient machining. Regular checks on parts and cleanliness help prevent problems. You should oil moving parts and keep the lathe clean. By practicing good maintenance, you can extend the life of your tools and improve your work quality. For more tips, keep reading or explore lathe maintenance guides!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Metal Lathe Maintenance:

Lathe metal shaping is when we use a tool called a lathe to cut and shape metal. It’s like carving wood, but with metal. To keep the lathe working well, we need to clean it and check for any worn parts regularly. You should also add oil to keep it running smoothly. If something breaks, we should fix it right away to avoid bigger problems.

Sure! Please provide the question you’d like me to answer.

What Are The Key Maintenance Tasks Required To Keep A Metal Lathe In Optimal Working Condition?

To keep a metal lathe working well, we need to do a few important tasks. First, always clean the lathe after using it to remove dirt and metal shavings. Next, check the oil levels and add oil to keep everything moving smoothly. You should also tighten any loose parts to prevent problems. Lastly, inspect the lathe regularly for any signs of wear or damage. This way, our lathe will last longer and work better!

How Can You Identify Signs Of Excessive Wear Or Damage On A Metal Lathe, And What Steps Should Be Taken If Detected?

You can spot wear or damage on a metal lathe by looking for rust, cracks, or loose parts. If you see rough spots on the metal, that’s a sign, too. If you find any problems, stop using the lathe right away. Tell an adult to help fix it or check it out. Keeping it clean and checking it often will help it last longer!

What Lubricants And Fluids Are Recommended For Maintaining A Metal Lathe, And How Often Should They Be Applied?

To keep a metal lathe working well, use machine oil and way oil. Machine oil helps the moving parts, while way oil is good for the tracks. You should clean and oil your lathe every few days if you use it often. If you use it less, oil it at least once a week. Always check the oil levels to make sure everything runs smoothly!

How Can Regular Maintenance Of A Metal Lathe Improve The Accuracy And Quality Of Machined Parts?

Regular maintenance of a metal lathe helps keep it working well. When we clean and oil the machine, it runs smoothly. This smoothness means that the parts we make are more precise. If we check and fix parts, they won’t wear out quickly. This way, we create high-quality pieces every time we use the lathe.

What Safety Precautions Should Be Taken During Metal Lathe Maintenance To Ensure A Safe Working Environment?

When we do maintenance on a metal lathe, we need to follow some safety rules. First, always wear safety goggles to protect your eyes. Make sure to turn off the machine before checking or fixing anything. Keep your hands and loose clothes away from moving parts. Finally, use tools correctly and ask for help if you’re unsure.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Metal Lathe Maintenance:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe metal shaping is when we use a tool called a lathe to cut and shape metal. It’s like carving wood, but with metal. To keep the lathe working well, we need to clean it and check for any worn parts regularly. You should also add oil to keep it running smoothly. If something breaks, we should fix it right away to avoid bigger problems.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Maintenance Tasks Required To Keep A Metal Lathe In Optimal Working Condition?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe working well, we need to do a few important tasks. First, always clean the lathe after using it to remove dirt and metal shavings. Next, check the oil levels and add oil to keep everything moving smoothly. You should also tighten any loose parts to prevent problems. Lastly, inspect the lathe regularly for any signs of wear or damage. This way, our lathe will last longer and work better!”}},{“@type”: “Question”,”name”: “How Can You Identify Signs Of Excessive Wear Or Damage On A Metal Lathe, And What Steps Should Be Taken If Detected?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can spot wear or damage on a metal lathe by looking for rust, cracks, or loose parts. If you see rough spots on the metal, that’s a sign, too. If you find any problems, stop using the lathe right away. Tell an adult to help fix it or check it out. Keeping it clean and checking it often will help it last longer!”}},{“@type”: “Question”,”name”: “What Lubricants And Fluids Are Recommended For Maintaining A Metal Lathe, And How Often Should They Be Applied?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe working well, use machine oil and way oil. Machine oil helps the moving parts, while way oil is good for the tracks. You should clean and oil your lathe every few days if you use it often. If you use it less, oil it at least once a week. Always check the oil levels to make sure everything runs smoothly!”}},{“@type”: “Question”,”name”: “How Can Regular Maintenance Of A Metal Lathe Improve The Accuracy And Quality Of Machined Parts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Regular maintenance of a metal lathe helps keep it working well. When we clean and oil the machine, it runs smoothly. This smoothness means that the parts we make are more precise. If we check and fix parts, they won’t wear out quickly. This way, we create high-quality pieces every time we use the lathe.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken During Metal Lathe Maintenance To Ensure A Safe Working Environment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we do maintenance on a metal lathe, we need to follow some safety rules. First, always wear safety goggles to protect your eyes. Make sure to turn off the machine before checking or fixing anything. Keep your hands and loose clothes away from moving parts. Finally, use tools correctly and ask for help if you’re unsure.”}}]}