Have you ever wondered how metal objects are shaped? The secret often lies in a powerful tool called a lathe. This machine can turn solid metal into amazing shapes. Whether it’s a simple piece or a complicated design, a metal lathe works like magic.

But wait! With great power comes great responsibility. Using a lathe for metal shaping can be dangerous if safety is ignored. Imagine the sound of buzzing machinery while you focus on your project. It’s easy to lose track of safety when you’re excited about what you’re making.

Did you know that over 60,000 people get injured by lathes every year? Many of these accidents could be avoided. It’s crucial to know about metal lathe safety before you start your next project. By taking simple precautions, you can enjoy your lathe while keeping yourself safe.

So, are you ready to dive into the world of metal shaping? Let’s discover how you can make the most out of your lathe while staying safe!

Lathe Metal Shaping: Essential Metal Lathe Safety Tips

Lathe Metal Shaping Metal Lathe Safety

Metal lathes can shape materials into amazing creations. However, safety is key. Did you know that over half of workshop accidents involve machinery like lathes? Always wear safety glasses and keep your hair tied back. Use clamps to secure your workpiece and stay focused. Think about how a small mistake can lead to a big injury. With the right knowledge and precautions, you can work safely while creating impressive projects. Stay informed and stay safe!Understanding Metal Lathes

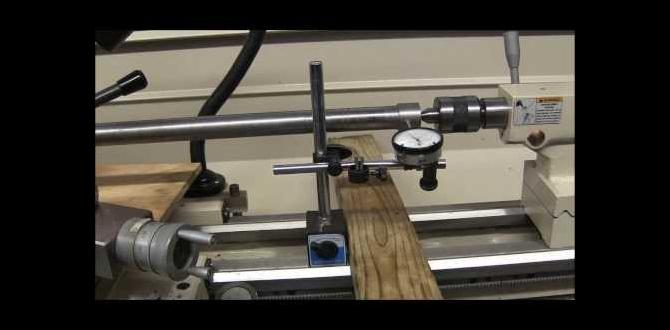

Definition and purpose of metal lathes. Types of metal lathes and their applications.A metal lathe is a machine that shapes metal. It spins metal and cuts it into different forms. This tool is essential for making parts for cars, machines, and tools. There are various types of metal lathes, each serving unique purposes. For example, a center lathe is common for shaping simple items, while a CNC lathe can create complex designs with high precision.

- **Center Lathe:** Ideal for beginners and simple projects.

- **CNC Lathe:** Uses computer programming for detailed work.

- **Turret Lathe:** Great for mass production with multiple tools.

Each type plays a crucial role in metalworking and helps create different metal items. Understanding these machines can make working with metal safer and more efficient.

What is the purpose of a metal lathe?

The purpose of a metal lathe is to shape and cut metal into precise forms. It allows workers to create various products for different industries.

What are the common types of metal lathes?

Different types include:

- Center Lathe

- CNC Lathe

- Turret Lathe

Each has its unique uses and benefits.

Pre-Operation Safety Checklist

Inspecting the lathe for defects and proper setup. Ensuring work area is clear and welllit.Before starting with the lathe, safety is key. Check the machine carefully for any defects. Look for loose parts or strange sounds. Next, set it up correctly. Make sure the work area is clean and well-lit. A tidy space helps you work safely. Consider these points:

- Examine the lathe for any damage.

- Ensure all tools and materials are easily reachable.

- Keep the area free of clutter.

- Adjust lights for clear visibility.

Taking these steps ensures a safe working environment.

Why is a safety checklist important?

A safety checklist helps prevent accidents while using a lathe. It reminds you to check crucial components and the workspace. This way, you stay safe and focused on your task.

Proper Techniques for Safe Metal Shaping

Guidelines for handling materials properly. Techniques to minimize accidents during operation.Handling materials safely is vital in metal shaping. Always wear protective gear like gloves and goggles. Keep your workspace clean to prevent trip hazards. Always know how to use the equipment before starting. Here are some tips to avoid accidents:

- Use clamps to secure materials.

- Keep hands away from moving parts.

- Turn off the lathe when making adjustments.

Following these rules helps ensure safety while you work. Remember, a safe workspace is a happy workspace!

What are the basic safety tips for metal shaping?

Always use gloves, goggles, and turn off machines when not in use. Secure materials firmly and focus on your task.

Common Hazards When Using a Metal Lathe

Identifying potential hazards such as entanglement and sharp tools. Understanding the risks of flying debris.Using a metal lathe can be dangerous if you don’t know what to watch for. One big risk is entanglement. Loose clothing or long hair can get caught in moving parts. Another hazard comes from sharp tools. They can easily cause cuts if you’re not careful. You also need to be alert for flying debris. Small bits of metal can fly out and hurt someone nearby. Stay safe by understanding these risks.

What should I be careful about when using a metal lathe?

It’s important to be aware of potential dangers. Always remember to protect yourself and others. Wearing safety glasses can help prevent injuries from flying objects. Tie back long hair and wear close-fitting clothes to avoid entanglement.

Emergency Procedures and First Aid

Steps to take in case of an accident. First aid responses for common injuries in lathe operations.Accidents can happen anytime while using a lathe. It’s vital to know what to do if one occurs. Here are the steps to follow:

- Stay calm and assess the situation.

- Shut down the machine immediately.

- Call for help if needed.

- Provide first aid for any injuries.

Common injuries like cuts or burns may need quick attention. Here’s what to do:

- For cuts, clean the area and apply a bandage.

- For burns, cool the burn with water and cover it.

- If bleeding is heavy, press firmly until help arrives.

Knowing these simple steps can help everyone stay safe while working.

What should I do if someone gets hurt?

Stay calm, assess the injury, and provide first aid quickly. Call for help if needed.

Routine Maintenance for Safety

Importance of regular maintenance and inspections. Checklist for keeping the lathe and tools in safe working condition.Regular maintenance keeps your lathe safe and working well. It helps catch issues before they become big problems. Keeping tools in good shape means fewer accidents. Follow these checks:

- Clean the lathe after each use.

- Check belts and gears for wear.

- Ensure all guards are in place.

- Test the power switch and emergency stop.

- Lubricate moving parts regularly.

This simple routine keeps everyone safe and helps machines last longer.

Why is routine maintenance important?

Routine maintenance is vital because it prevents accidents and keeps machines running smoothly. Regular checks help spot problems early and ensure everyone stays safe while using the lathe.

Checklist for Lathe Safety

- Inspect tools before each use.

- Tighten loose screws and bolts.

- Remove chips and debris from the workspace.

- Store tools properly after use.

Training and Skill Development for Users

Importance of proper training in metal lathe operation. Recommended resources and workshops for skill enhancement.Using a metal lathe is like riding a bike with a few more moving parts—training is key! Proper training ensures users stay safe and get the best results. Workshops or online courses can help develop skills. You learn the ropes (or wires) and avoid a “lathe-ocalypse” situation! Make sure to check out resources like community colleges or local maker spaces. They often offer hands-on workshops. Below is a table of some recommended resources:

| Resource | Type | Details |

|---|---|---|

| Local Community Colleges | In-person classes | Hands-on training with experienced instructors. |

| Online Courses | Virtual learning | Flexible learning at your own pace. |

| Maker Spaces | Hands-on workshops | Access to tools and expert help. |

Proper training not only enhances skills but also instills confidence. It keeps accidents at bay and helps you explore the creative side of metal lathe work. As they say, “Practice makes perfect, and a perfect lathe artist doesn’t need a cape!”

Conclusion

In summary, using a metal lathe safely is crucial. Always wear protective gear like goggles and gloves. Keep your workspace clean and organized to avoid accidents. Familiarize yourself with your machine’s controls before starting. Remember, safety first leads to better results. We encourage you to read more about lathe safety tips and practice regularly to improve your skills!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Safety In Metal Shaping:Sure! Here are some important things about lathe safety in metal shaping: 1. Always wear safety glasses. This protects your eyes from flying bits of metal. 2. Keep hands away from the spinning parts. It’s very easy to get hurt if you’re too close. 3. Tie back long hair and wear tight clothes. Loose items can get caught in the machine. 4. Make sure the lathe is turned off before you change pieces. This helps prevent accidents. 5. Always listen to your teacher or supervisor. They know how to use the lathe safely!

Sure! Please provide the question you want me to answer.

What Are The Essential Personal Protective Equipment (Ppe) Items That Should Be Worn While Operating A Metal Lathe?When using a metal lathe, you should wear safety goggles to protect your eyes. You also need to use ear protection to block out loud noises. Wearing gloves is important to keep your hands safe from sharp parts. A dust mask can help you breathe better by blocking tiny particles. Lastly, wear closed-toe shoes to protect your feet from heavy tools.

What Are The Common Hazards Associated With Using A Metal Lathe, And How Can They Be Mitigated?Using a metal lathe can be dangerous. You can get hurt by sharp tools or flying metal pieces. To stay safe, always wear safety goggles. Keep your hands away from moving parts. Make sure the lathe is turned off when you’re not using it. We should also keep the workspace clean to avoid slips and falls.

How Should The Workpiece Be Properly Secured In The Lathe To Prevent Accidents During Operation?To keep the workpiece safe in the lathe, you should use a strong clamp. Make sure it fits tightly around the piece. Always check that it is secure before you start. If it’s loose, it might move and cause accidents. Remember, safety first!

What Safety Procedures Should Be Followed Before Starting A Metal Lathe To Ensure A Safe Working Environment?Before using a metal lathe, you should wear safety goggles to protect your eyes. Make sure your hair is tied back and you’re wearing tight-fitting clothes. Check that all tools are in good condition and the lathe is clean. Never stand directly in front of the machine while starting it. Finally, ask for help if you’re not sure what to do.

How Can An Operator Recognize And Respond To Potential Issues, Such As Machine Vibrations Or Unusual Noises, While Using A Lathe?You can notice problems with the lathe by paying attention to how it feels and sounds. If you feel strong shakes or hear weird noises, stop right away. Check the machine for loose parts or damage. Ask for help if you’re not sure what to do. Always remember, it’s better to be safe!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Safety In Metal Shaping:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some important things about lathe safety in metal shaping: 1. Always wear safety glasses. This protects your eyes from flying bits of metal. 2. Keep hands away from the spinning parts. It’s very easy to get hurt if you’re too close. 3. Tie back long hair and wear tight clothes. Loose items can get caught in the machine. 4. Make sure the lathe is turned off before you change pieces. This helps prevent accidents. 5. Always listen to your teacher or supervisor. They know how to use the lathe safely!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Personal Protective Equipment (Ppe) Items That Should Be Worn While Operating A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, you should wear safety goggles to protect your eyes. You also need to use ear protection to block out loud noises. Wearing gloves is important to keep your hands safe from sharp parts. A dust mask can help you breathe better by blocking tiny particles. Lastly, wear closed-toe shoes to protect your feet from heavy tools.”}},{“@type”: “Question”,”name”: “What Are The Common Hazards Associated With Using A Metal Lathe, And How Can They Be Mitigated?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a metal lathe can be dangerous. You can get hurt by sharp tools or flying metal pieces. To stay safe, always wear safety goggles. Keep your hands away from moving parts. Make sure the lathe is turned off when you’re not using it. We should also keep the workspace clean to avoid slips and falls.”}},{“@type”: “Question”,”name”: “How Should The Workpiece Be Properly Secured In The Lathe To Prevent Accidents During Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the workpiece safe in the lathe, you should use a strong clamp. Make sure it fits tightly around the piece. Always check that it is secure before you start. If it’s loose, it might move and cause accidents. Remember, safety first!”}},{“@type”: “Question”,”name”: “What Safety Procedures Should Be Followed Before Starting A Metal Lathe To Ensure A Safe Working Environment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Before using a metal lathe, you should wear safety goggles to protect your eyes. Make sure your hair is tied back and you’re wearing tight-fitting clothes. Check that all tools are in good condition and the lathe is clean. Never stand directly in front of the machine while starting it. Finally, ask for help if you’re not sure what to do.”}},{“@type”: “Question”,”name”: “How Can An Operator Recognize And Respond To Potential Issues, Such As Machine Vibrations Or Unusual Noises, While Using A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can notice problems with the lathe by paying attention to how it feels and sounds. If you feel strong shakes or hear weird noises, stop right away. Check the machine for loose parts or damage. Ask for help if you’re not sure what to do. Always remember, it’s better to be safe!”}}]}